All inspection well hatches are covered with round hatches, and this is done all over the world. The question involuntarily arises as to why the sewer manhole is made round.

This question has already become, one might say, a humorous puzzle; it reaches the point of funny things when people try to answer it. And the answer to it lies on the surface itself, you just need to know about its structure and where and what it is used for.

Why did they choose a round shape for the hatches?

There are quite a lot of answers to the question of why hatches are round, but the most reasonable assumptions are the following:

- In our country, well tunnels and sewer pipe sections are round, so there is no point in making covers of other shapes. At the same time, foreign experience knows many exceptions: for example, square manhole covers can be found in some cities of the Czech Republic and China, although they do not correspond to the shape of the wells they cover.

- Round sewer manholes will never fall into the well, which means they are best suited to fulfill their protective function. And all because the diameter of the covering circle is always greater than the diameter of the well itself, and square covers can fit into it, for example, at an angle.

- Hatches are made round in order to reduce the cost of their production. This is due to the specifics of the equipment: in order to produce a round lid, less material is needed. The standard norm for the width of a hatch is 600 mm, for a circle this will be the diameter, and for a square it will be the side, so the area of a square hatch will be 0.36 square meters, and a round one will be 30% less.

- The manhole cover is round because it is easy to carry. In most cases, manhole covers are made from scrap (gray cast iron), which is obtained by melting various scrap metals. The weight of one cover varies from 50 to 110 kg. It is quite difficult for one person to move the manhole cover from one place to another, but thanks to its round shape it can be rolled.

- Not square, but round hatches are convenient to install and dismantle, since load concentration points run along the entire circumference of the cover, while for square or rectangular hatches such points will only be at the corners. That is why the necks and, accordingly, the lids of the jars are made round.

In fact, discussions about the shape of sewer manholes may seem pointless to many

However, few people know that such a question of no particular importance can take anyone by surprise when... applying for a job! And don't be surprised by this

This kind of interview question is not uncommon. HR managers among themselves refer it to “cases,” that is, keys with the help of which they can give a more accurate assessment of certain qualities and abilities of applicants.

This practice is used mainly during interviews for applicants applying for high positions. In this way, we evaluate how a person behaves in the event of force majeure, what speed of thinking he has, whether he knows how to use non-standard approaches, etc.

Manhole cover

The cover is an integral part of the manhole hatch, which must be present. In addition, it should be comfortable and ergonomic, and should not rattle when a car wheel hits it. It also has a small hole through which you can check the gas contamination of the well.

With all this, the lid is most often made of cast iron and is very heavy. Its large weight is justified by the difficulty of theft, but it is precisely because of such a large weight that it is often stolen for subsequent scrap metal. And although the law prohibits the acceptance of sewer manholes at scrap metal collection points, this does not stop thieves. Some people use them in everyday life for different purposes.

However, this is not about that now. In most countries, the lids are indeed round, but there are exceptions. In some states of the USA and even in India they are made in the form of squares and triangles. Therefore, it cannot be said that all manhole covers are round. Why is the round shape most common? As mentioned above, there are different versions.

Riddles and secrets on the lids

Determine the manufacturer's data... It sounds so boring that it hurts your cheekbones! In fact, this work is extremely exciting and painstaking, sometimes comparable to an exciting detective investigation. There used to be simplicity and grace in the world! All the names of cities and manufacturers were written directly on the cast iron. That is why many have survived to this day in a more or less readable form.

However, somewhere in the early 60s of the last century, the lafa ended, and the foundries stopped providing such courtesy to their descendants-collectors. From this time on, obscure abbreviations and logos appear on the lids, and work begins on their recognition and attribution. I’m not talking about those mystery hatches that don’t have a single word or a single letter on them...

Do you know how long it took me to identify the campfire logo? But now I am proud to present to you - this is the sign of the Kusinsky Foundry and Machine-Building Plant, which is located in the Urals, in the Chelyabinsk region. But look: with a quality mark, a “sun” design and an emblem - a wonderful elephant! This is Moscow, logo.

But these are all simple problems. But the problem of designating the BSRP was solved by the bright minds of the entire community of Luke scholars, but the mystery was never resolved. The first suspicions fell on the Balakovo ship repair plant, then on the Berdichev machine tool repair plant. Experienced experts doubted: maybe it was the Baltic or Blagoveshchensk factories?

Or here - construction and installation work. What is it and where to look for it? Who is the parent of the foundling, marked with the letters ChChZ - Chelyabinsk plant? Is PZA Penza? Who is hiding behind the abbreviation of this old man SKhK? The city does not skimp on throwing out riddles.

Repair of loggias on a turn-key basis

Start insulating your apartment by renovating the loggia or balcony. Our specialists will carry out minor or major repairs of your balconies and loggias. We carry out turnkey repairs and offer interesting design solutions.

In each country, the development of sewerage systems took place differently, but the only common feature has always been the need to install sewer manholes.

The first manholes appeared along with the emergence of public services back in the 30s of the 19th century: then manhole covers had different shapes, but preference was most often given to round-shaped covers. Currently produced, sewer manholes are round, and not of any other shape. This feature, despite everything, has remained unchanged. But why exactly round?

Manhole covers are divided depending on their purpose. They all have different patterns and embossing. On old hatches you can see outdated images of coats of arms, all kinds of drawings and inscriptions.

Modern manhole covers carry information about the manufacturer, serial number and date of manufacture. Some companies deliberately replace old hatches with new (“decorative”) ones near their offices and, as a rule, put images of their logos on the covers.

Logical version

The very first version explains the shape of the lids by economy. The fact is that it is the round shape that, at minimal cost, allows you to create a hole that a person can easily crawl through. For example, for a person to freely enter the well through a square hatch, the hole would have to be made a little larger in area. Consequently, when making a hatch for such a hole, more metal would be spent, and this is not economically viable. It is believed that the production of round hatches is 40% more profitable compared to the production of square ones, and on a large scale this is a fairly respectable figure.

Security Considerations

Despite their small dimensions, the lids weigh about 50 kilograms, because they are made of cast iron. And the weight of products located on the roadway exceeds 78 kilograms - after all, they must withstand the weight of passing cars. According to the rules, hatches located on sidewalks must carry loads of up to 12 tons, and those intended for installation on the road - up to 25 tons.

Given the significant weight of the covers, it is very important to follow safety rules when working in a sewer well. If the product falls through the hatch onto the heads of the workers, tragedy cannot be avoided

Fortunately, the round lids are designed to never fall down the well. Products shaped like a square or rectangle can easily fall off, because their diagonals are always larger than any of the sides.

Strength

Engineers have long known that round objects are much stronger than square ones. The sewer hatch is not only round, but also slightly convex in the middle: this shape provides the greatest resistance to mechanical load directed from above.

Internal stresses in a hatch of this shape are evenly distributed over the metal, while in square, rectangular and any other covers, under the influence of a load, the stresses are distributed unevenly, which leads to faster wear and, consequently, more frequent replacement of covers.

In addition, we should not forget that cast iron is a rather fragile material, and if you drop a rectangular lid, a corner may well break off. To crack a round manhole cover, you will have to put in a lot more effort.

Judging by the fact that almost all lids have been intact for decades (and some for more than a hundred years), under normal conditions it is almost impossible to damage a round lid.

Geometry of patterns

There are thousands of them. Vintage and new. Cast iron, steel and polymer. Flat, slightly convex and with a pronounced dome structure, well manhole covers lie on the streets of Saratov. And it just seems that they are all the same.

Look how different they are: this one, with pimples, looks like a mine - a formidable weapon of the Second World War - horned death, which often surfaced on the Kronstadt raids during the siege of Leningrad and on the seas of the USSR during the mine war.

But this is an old hatch. Old because it's domed. This is a tradition from the pre-automobile era.

And this one, very old in appearance, was found not far from the Glebuchevo ravine and surrounded by ancient buildings.

A rarity – that’s how I immediately and respectfully wanted to call it. And really, it looks something like the round shield of some invincible Olaf? Everything is like the warlike Vikings - a rosette and a umbo in the center...

My husband shakes his head in doubt; it seems to him that the handsome man is just a hatch-shifter. But I liked it - albeit on the wrong side, but wonderful.

Well, does this one really look like a shield?

Look, the real alpha male of the hatch kingdom. But why is this absolutely bald brutal man covered in cracks? What brought him to this state? Is the casting of disgraceful quality or has it been damaged by the heels of pedestrians in alliance with merciless time?

There are some without any pattern at all, and there are others decorated with concentric circles, stripes, waves, pimples, checks... A pleasant find, the “diamond” pattern is also a rarity for our streets. I would like to show you all of them, without exception, because even the most modest of them are interesting in their own way. It took a long time to choose. Look at the beauty I met!

At first, you look at every sewer hatch you come across with enthusiasm, lovingly take photos, and then you get fed up and begin to turn your nose up at some of the specimens. As if from russula growing next to the royal family of porcini mushrooms. There comes a time when you walk down one or two streets and there is not a single sample with a new design.

And although it’s sad to think that the number of their varieties is not infinite, I still have a lot ahead - I have not yet come across cast iron manhole covers with such unusual and beautiful geometric patterns as scales and trapezoids. But is the pattern of a chrysanthemum, a compass, a steering wheel worse?

By the way, now many people have become interested in searching for interesting manhole covers, and there are many pages on the Internet dedicated to them with photo collections.

Possible problems

During the work of deepening the well, some problems may arise. For example, you may encounter some difficulties when lowering new rings into the shaft. There are several ways to combat this problem.

The easiest way is to drill holes with a diameter of 150-200 mm along the outer perimeter of the upper ring. The depth of the hole should be as wide as possible. Therefore, it is necessary to prepare not only the drill, but also several attachments for it. A thick-walled pipe is ideal for making nozzles. During work it will not twist or deform. The length of the finished drill should be about 4 m.

The drilled holes should be generously moistened with water. If possible, equipment is used to shrink the rings, for example, a construction truck crane. If this is not possible, then several strong men can easily cope with this task by jumping on the end of the upper ring.

There is another way to lower the ring. It will require aspen boards and bars. The use of aspen is the main condition, since it does not rot in water. The boards must have a length corresponding to the distance from the bottom ring to the bottom. A circle is constructed around the perimeter of the lower ring of boards.

To prevent them from being squeezed out by the soil, a double belt of thick aspen timber is installed. The structure must be securely fastened and form a single whole. If all the work is done correctly, a new aspen ring will be installed in the well.

Diggers working to deepen a well are faced with another nuisance - quicksand. This is a serious danger along the excavation route. To quickly pass through a dangerous area, you will have to speed up the work and remove more soil. An additional ring must be used as a load. If the quicksand is small, it is possible to quickly install rings and strengthen the structure.

During work, extra care must be taken and additional protective equipment must be used to ensure that the lives of people working at the bottom are safe.

➤

Why did they choose a round shape for the hatches?

There are quite a lot of answers to the question of why hatches are round, but the most reasonable assumptions are the following:

- In our country, well tunnels and sewer pipe sections are round, so there is no point in making covers of other shapes. At the same time, foreign experience knows many exceptions: for example, square manhole covers can be found in some cities of the Czech Republic and China, although they do not correspond to the shape of the wells they cover.

- Round sewer manholes will never fall into the well, which means they are best suited to fulfill their protective function. And all because the diameter of the covering circle is always greater than the diameter of the well itself, and square covers can fit into it, for example, at an angle.

- Hatches are made round in order to reduce the cost of their production. This is due to the specifics of the equipment: in order to produce a round lid, less material is needed. The standard standard for the width of a hatch is 600 mm; for a circle this will be the diameter, and for a square it will be the side, so the area of a square hatch will be 0.36 square meters, and a round one will be 30% less.

- The manhole cover is round because it is easy to carry. In most cases, manhole covers are made from scrap (gray cast iron), which is obtained by melting various scrap metals. The weight of one cover varies from 50 to 110 kg. It is quite difficult for one person to move the manhole cover from one place to another, but thanks to its round shape it can be rolled.

- Not square, but round hatches are convenient to install and dismantle, since load concentration points run along the entire circumference of the cover, while for square or rectangular hatches such points will only be at the corners. That is why the necks and, accordingly, the lids of the jars are made round.

In fact, discussions about the shape of sewer manholes may seem pointless to many

However, few people know that such a question of no particular importance can take anyone by surprise when... applying for a job! And don't be surprised by this

This kind of interview question is not uncommon. HR managers among themselves refer it to “cases,” that is, keys with the help of which they can give a more accurate assessment of certain qualities and abilities of applicants.

This practice is used mainly during interviews for applicants applying for high positions. In this way, we evaluate how a person behaves in the event of force majeure, what speed of thinking he has, whether he knows how to use non-standard approaches, etc.

Logical explanation

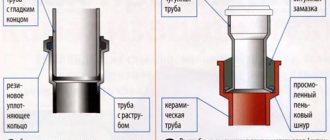

So why is a manhole round? The described technical object consists of several parts - a round shaft, an inspection room and a lid.

The viewing room can have different shapes. It all depends on what communications are laid in the well. Dimensions are chosen taking into account the ease of their maintenance. But the mines are invariably made round. The diameter of the oval is 0.7 meters. They are assembled from brick and additionally equipped with a ladder that helps the service worker to go down without hindrance.

The top of such a hatch must be closed with a lid. It prevents various types of foreign objects from entering sewer systems that could cause accidents. Almost everywhere the lid has a round shape. Why not square? Because in any position, such a lid will never fall inside and hit the person located there.

A square lid can easily fall inside under the influence of vehicles, slipping through at an angle. After all, the diagonal of a square is always greater than any of its sides. A circle has the same radius, no matter how you look at it.

Typically, manufacturers produce lids that weigh more than 50 kg. This is done so that no heavy traffic of cars could move them.

Other explanations for the shape of the hatches

It is very rare to find such a form

There are several more explanations to help understand why manhole covers are round:

- Firstly, a circle has a higher ratio of cross-sectional area to circumference than a square or rectangle. This allows the lid production process to reduce material costs and save on product production.

- Secondly, the round shape reduces the internal forces that invariably occur when installing any cover on an object. And this also provides savings on the production of the product, since in this case it is possible to produce lids of smaller thickness.

- Thirdly, the round shape helps reduce the production of defective products. By reducing the number of reference lengths, the likelihood of errors leading to the appearance of uneven protrusions and other characteristic defects is reduced.

And further. The round lid is much easier to transport for one person. He can just roll her to the place. A square or rectangular one will have to be carried in several hands.

The above arguments show that the choice of form is explained by elementary practicality.

The first victim of an insidious trap

Alexandra Kapitonova, a young bourgeois woman from the Tver province, on that day suddenly felt an urgent need for “an elegant and good women’s dress of the latest cut from foreign and the best Russian fabrics.” Full of the most serious intentions, she hastily went to the mother throne.

But her trip to the Moscow “boutiques” of the early 20th century ended for her before it even began. Immediately upon arrival, the poor thing, according to the reporter, “slightly suffered”, falling into a round trap near the famous Moscow store Muir and Meriliz, thus becoming the first victim of the treachery of the hatches.

However, we will deal with the horror stories associated with cast iron rounds later, but for now here’s a question for filling: why is the sewer cover covering the manhole shaft round, and not oval or, for example, square?

Geography of cast iron hatches in Saratov

There were many sacred places in which new cast-iron hatches appeared in the world in the 20th century. After all, by and large, any enterprise with a foundry could make them. They did not hesitate to make hatches for inspection wells even at the factory, renowned for its centuries-old traditions, which produced highly artistic Kasli castings. Newborns moved from their homes to a new place of residence, sometimes hundreds of kilometers away, where they regularly performed their unnoticed service.

A short raid around the rear of my parents’ house in Saratov immediately discovered many of these nomadic hatches. Their logistics defy explanation. Cast iron lids came to our city from Rzhev, Voronezh, Kerch, Sverdlovsk, Yaroslavl, Lipetsk, Rostov-on-Don, Novocherkassk, Kharkov and a bunch of other cities, some of which I didn’t even know existed.

For example, take Andreapol. I don’t know how it will be for you, but just by the name alone, I immediately heard the music of the waves of the Black Sea and saw the white antique columns left over from the ancient Greek polis. But no, this is a city from the Tver region.

Tearing up a pile of manure, the rooster found a grain of pearl... That’s how I found this miracle from Tambov with a big star.

One day I came across an old, very large and convex hatch. There was something written on it, but it was impossible to read what exactly. I guarded the lid, trying to guess the right direction of the light. And kept watch! After the summer rain, the rays illuminated the letters and I read - Peskovsky Plant.

It is Peskovsky because it stood on the Peskovka River in the Kirov region. Cast iron has been produced since 1771. But now the plant no longer exists - it went bankrupt, but it was one of the most successful and, in its own way, unique among other iron foundries in Russia.

Look at the unusual shape of this hatch from Leningrad. I came across another similar one, also consisting of four segments, but this one was without any identification marks. However, it is known that very, very old hatches, manufactured at the end of the 19th - beginning of the 20th centuries, had such a specific form of lids - it is called a menagerie. Nowadays these are very rare.

I somehow came across a nice hatch from the Kamensky foundry. I began to puzzle over where this Kamenka was. Ural? Ukraine? Then I found the same lid in the blog of the famous Saratov local historian Denis Zhabkin, according to which it turned out that these were made in the village of Kamenka, Krasnoarmeisky district, Saratov region.

It may very well be, because according to data from the Internet, an iron foundry was created there in 1897, which was later transformed into a factory. And, besides, somewhere near the territory of the village there was a camp point at Kamenlag, and foundry was a very difficult job, which often involved prisoners.

By the way, what about locally produced sewer manholes? Haven't I come across any of these? Of course there were some! We’ll talk about those that were done directly in Saratov next time, but we also came across manhole covers from Volsk (there are many of them!), Balashov, Kalininsk, Petrovsk.

And, perhaps, here is another hatch that arrived from Tbilisi. He’s not particularly good-looking, but I’m afraid no one will see him now: the road was being patched and the workers mercilessly covered him with asphalt chips. Now you can't scratch it out. Only a piece sticks out, and if I didn’t know where to look, I would never have found it.

Sometimes life gives us funny surprises. I started my story with a beautiful hatch from Spain. How could I have known that one day on a Saratov street a distant country would send me its greetings with a hatch made in Barcelona.

Well, now the amount of incomprehensible things in our world has decreased somewhat! And now, friends, you have homework.

Don't pass by indifferently, take a closer look at the sewer hatches. To the variety of patterns on them, to how their constituent elements are repeated and alternated, how they are arranged according to the laws of symmetry into very simple and more complex variants of patterns. How many lid design options have you seen on the streets of your city? Try to read their biography from the inscriptions on the cast iron mugs. And we will meet soon and continue...

Category: Russia

Fun facts

There are known cases around the world of using lids of other shapes. For example, in the American city of Nashua you can still see sewer wells covered with triangular covers. Their sharp corners indicate the direction of wastewater flow, and until recently this helped repair crews to navigate well. But today their use is considered unsafe, so the prefecture is dismantling them and replacing the triangles with circles.

Other forms are also found

Now you know why sewer manholes are made round. But why they are made so massive and heavy is also an interesting question. Although the explanation lies on the surface. The weight ensures relative safety from theft and delivery of the described products to metal collection points. About 10 years ago, a wave of characteristic crimes swept across the country. Lids began to disappear en masse, so the designers came up with an interesting solution.

Most modern sewer wells are not simply covered on top with a massive object that one person cannot carry away. The lids were placed on strong hinges, and they turned into real doors, which were additionally locked.

There is no way to leave wells open, especially those that contain storm drainage and water supply. Their depth sometimes reaches 6 meters, and at the bottom of the technical room there are many protruding pipes and pieces of fittings. If a person falls there in the dark, it will end in death. Therefore, those who are responsible for sewer hatches - and this is the district administration - have a great responsibility for the safe use of this technical structure.

Who else could be responsible for the hatches?

But the Russian people are still accustomed to seeing such a hatch

There are wells that are not municipally owned, but belong to the property of an apartment building or to the property of a certain legal entity.

All ownerless objects are first registered by the body that registers the right to property. This happens at the request of the local government. Then, through the court, everyone can challenge their own right. If there are no volunteers within a year, all ownerless objects are transferred to the departments of specialized companies.

Metal saving

Why is the round shape of hatches more optimal in terms of saving metal? Given the same length of the perimeter of a round and rectangular hatch, the area of the circle is always greater than the area of the rectangle or any other geometric figure.

If we translate this into economic indicators, it turns out that a circle is the most profitable hatch shape, since it requires much less cast iron for the cover (saving up to forty percent) than for a rectangular cover.

If you calculate how many sewer manholes are needed even for one small city, then the scale of metal savings will not seem insignificant at all.

The optimal ratio of perimeter length to area makes it necessary to make round hatches not only for sewer wells, but also in much more serious structures - for example, between compartments of submarines or spaceships. Round hatches are more economical and can withstand greater loads than any other shape.

What materials is the drain well made of?

There are several popular options for drainage wells for dachas. Firstly, it is brick; this particular material is considered a kind of classic, since it allows you to build a fairly strong, reliable and durable structure. In this case, the brick is selected in approximately the same way as for construction. That is, it must withstand both high humidity (that is, have a low water absorption coefficient) and low temperatures.

It is necessary to note the features of brickwork in this case. It resembles a chessboard, that is, the bricks are laid in a checkerboard pattern with a gap of approximately 50 mm between them. Thus, some of the cells in this “board” will be holes for draining water. To save on such material, you can use bricks that have already been used and are left over from the dismantling of some structures.

Secondly, a popular option is a well made of concrete rings. It allows you to solve the problem of draining water at your dacha relatively inexpensively. Concrete rings are sold ready-made, but they are intended for ordinary wells, and to drain them they will still have to be modified by making holes using a grinder.

Thus, any country well must have holes so that water can easily seep into them

It is generally believed that this is not so important for seasonal living. However, experts recommend not to lose sight of this point, since this way you can achieve better results.

Another interesting option is a tire well. In this case, suction of wastewater can only occur at the bottom. Theoretically, you can cut holes in the walls of tires, but this is rarely done. Despite the fact that such a structure is quite inexpensive, it is not used so often due to numerous disadvantages, including the settling of solid waste on tire cavities and relatively low performance characteristics.

And finally, another option is a barrel well. For it to work well, you need to make holes in the walls of the barrel. Only they must be small, otherwise the barrel will begin to rot. Usually drill holes of approximately 10 mm. The distance between two holes can be 50 mm. The disadvantage of this option is the short service life. For it, they usually take a metal barrel, and it will inevitably collapse under the influence of corrosion. The process can be slowed down a little by using bitumen. A layer of it is applied to the surface of the barrel, in the walls of which holes have already been made.

Features of the installation of underground communications

We rarely think about how the city sewerage system, drainage systems, how communication lines and powerful power cables are laid. This is a rather complex engineering system that has its own laws and unshakable rules. When designing a sewerage system, they take into account not only geodetic data, but also the communications system, which was laid perhaps several centuries ago.

The city sewer system project contains a lot of information that is compiled into one document. A lot of factors are taken into account:

It often turns out that one hatch can work both for servicing communication channels and for water supply, heating and sewerage systems, which greatly complicates the process of repair and operation.

Other forms

Note that hatches are not always round. Different countries may have different forms. In India, triangular shapes are common, and in some countries they can be a generally vague geometric figure. Square shapes are not uncommon in the USA and other American countries. There are even hatches with eight corners, and very rarely there are models in the shape of a diamond or semicircles.

But it is worth recognizing that most often they are round. This form is the most popular, comfortable and ergonomic.

Generalization on the topic

The round shape of sewer manholes is more practical than all other types. Over many years of operation of sewerage structures, it has been proven that round holes are more technologically advanced and have a longer service life. And all because such a hatch is more resistant to temperature changes.

Have you ever wondered why the sewer manholes are round

, and not square? Manhole covers are made of cast iron, sometimes concrete. This is so that the lid is heavy and cannot open spontaneously. If we talk about cable ducts, then most often there are two of them: shut-off and protective. The first one weighs much lighter, it is usually made of steel and is needed to protect the cable from theft. They place it just under the protective cover, and on the cover itself they simply write the purpose of the hatch.

Some details about sewer manholes

The described items are made of cast iron or concrete. They are specially made heavy and unbearable, so that no one would have the desire to take a “useful” thing with them. Opening a technical hole on your own is not so easy, and this is specially provided for in the design for the safety of passers-by.

Sewer hatches have a conditional classification. They are divided according to the material of manufacture and the type of communications passing under the launch shafts. Therefore, experts highlight:

- Drainage systems.

- Storm drains.

- Electrical networks.

Hatches are made from high-strength cast iron and plastic, a special polymer-sand mixture, composite materials and reinforced concrete. But they are all invariably round in shape. Why, let's find out.