Let's imagine the situation that we are about to do a renovation and decide to buy an acrylic bathtub, the most ordinary, no frills one, 160 x 70 cm, which will simply fit well into a modern interior. Arriving at a regular chain store, we will see a whole range of acrylic bathtubs, very similar in appearance, but completely different in price. Moreover, the range will start from 5 thousand rubles. and end with an amount of 25 thousand rubles. The question immediately arises: why such money, and where is the golden mean where you can stop. It all depends on what we are looking for and what our needs are. If we need an acrylic bathtub for 3 years, we can safely go to the nearest store and buy any model. If we are making high-quality repairs and hope that for at least 10-15 years we will not need to redo anything in this bathroom, then it is better to purchase a more expensive and solid option.

Photo by ReRooms Acrylic bathtub Ravak in the ReRooms design project

— What is acrylic?

Calculate the exact cost of repairs using an online calculator

and receive a free detailed estimate for repairs

Calculate

Let's start with the fact that acrylic, as such, does not exist in principle. This is not the material. What do you mean by acrylic? Today on the market there are 4 types of materials from which bathtubs are made, called acrylic.

Expert advice

First, it is better to study the recommendations of specialists who will help you make the right choice:

- Before purchasing a product with an acrylic bowl, you should determine the size of the structure so that it fits freely into the bathroom.

- In the store, you need to carefully examine the model you like and ask about the thickness of the material. A cut on the end of the side with two layers of acrylic and reinforcement indicates a design made of PMMA, the presence of three layers indicates that the product is made of ABS.

- It is necessary to take into account that the cut along the side shows the maximum thickness of the acrylic; accordingly, the walls are much thinner. Special attention is paid to the side cuts of the curved edges.

- It is necessary to check the bottom and walls of the bath for roughness and unevenness. The acrylic bathtub has an ideally smooth inner surface with a shine.

- There should be no odors coming from the surface, including from the outside. A pungent odor is an indicator of poor quality materials and non-compliance with production technologies. There may even be the presence of slightly toxic substances.

- Acrylic bathtubs are mounted on an auxiliary support frame. It is necessary that this metal frame be of high quality, and with a reserve it can withstand the weight of a person and the water necessary for taking a bath. The dismountable or welded structure includes supports at the corners of the tank, intermediate ribs and height-adjustable legs.

- When buying an acrylic bathtub, you should focus on the affordable price category. Plumbing with an excellent reputation has a price that fully corresponds to the quality.

- Ensure safe use - models are made of cast acrylic, which does not require an anti-slip coating or special mats.

- Even high-quality acrylic bathtubs have disadvantages. For example, products are sensitive to powders and alcohol-containing products. Therefore, in order to preserve the appearance of the plumbing fixtures for a long time and avoid scratches on the surface of the bathtub, cleaning products should be used without abrasives and aggressive chemicals.

Watch more video tips from popular experts.

Durability of structure and frame

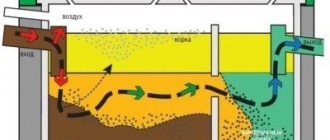

The strength of an acrylic bathtub largely depends on the method of its manufacture. That is, a bathtub that was made using solid PMMA acrylic casting technology, when completely filled with water, is able to retain its original shape. If the bathtub is made of extruded two-component acrylic ABS/PMMA, then when completely filled its walls may be slightly deformed. This is mainly due to the thin layer of PMMA and the thick layer of flexible ABS plastic.

Regardless of the acrylic used, all bathtubs are installed on a special welded or prefabricated metal frame, which serves as a base and holds the bathtub from excessive deformation when fully filled. At the same time, the design of the metal frame - frame, to some extent also affects the cost of the acrylic bathtub.

The simplest frame is a welded or bolted metal “sheathing” that will be located directly under the bottom of the bathtub. That is, such a frame will withstand vertical water pressure and the weight of a bathing person, but it will not strengthen the side walls.

A more complex frame for an acrylic bathtub has in its design elements that strengthen the side walls of the plumbing fixtures, which in total can extend the service life of the entire structure.

But there is also one point here that can help determine the quality of the bath. The frame frame has support points (posts and legs). The more such racks, the less durable the bath itself is. If the bathtub itself is of high quality, then the frame has supports only in the corners.

What material is of the highest quality?

Acrylic bathtubs are composite models with a highly layered or monolithic structure. The structures are made of polymer - extruded or cast acrylic.

There are two ways to make acrylic bathtubs. A budget option are models made of elastic plastic and homogeneous plexiglass, used to create an acrylic layer that wears out and wears out in about 4 years. More expensive and durable are bathtubs made of pure polymethyl methacrylate, which have a service life of 10 to 12 years.

Main selection criteria

So that the expenses do not turn out to be in vain, and the purchased product meets all requirements and serves for a long time, it is important to pay attention to some details when purchasing. When choosing an acrylic bathtub, it is useful to listen to the advice of experts. But you also need to have an understanding of the characteristics of the product.

Size

First of all, you should pay attention to the dimensions of the bathroom. Even the doorway matters. If the purchased product cannot be brought into the premises, it will be very disappointing. Also, plumbing fixtures should fit into the bathroom and not take up all the space.

The level of comfort is an equally important aspect. The ease of use is affected by the size of the bath.

- Height. Measured from the floor to the top edge of the product. The optimal figure is 65-70 cm. These sizes will be convenient for family members of any age and height.

- Depth. Distance from the bottom of the bowl to the overflow hole. The normal depth is 50-60 cm. If this value is less, the water will most likely not completely cover the body. Deeper bathtubs may make it difficult to hold your head up. They will also require more water to fill and may make it difficult for older people to get out.

- Width. Depends on body size. If located in the center, the walls should not be close. The standard is 75-80 cm. For large people this figure should be increased. If finances and space allow, you can choose a model with a width of a meter or more.

- Length. The average is 150-180 cm. The main guideline is growth and individual needs. If you want to stretch out completely in the bathroom, the product should be the same length as your body. If the model is equipped with a headrest or the need to slightly bend your knees is not scary, you can choose a smaller bathtub.

Always pay attention to the dimensions of the acrylic bathtub

Wall thickness and number of layers

It is logical that the thicker the walls and the more layers of reinforcement, the better and, accordingly, more expensive. But the characteristics stated by manufacturers do not always correspond to reality. Therefore, before purchasing, it is necessary to evaluate the quality of the product visually and by touch.

An acrylic thickness of 1 mm indicates the low strength of the product. It is better not to take such a bath. A layer of 2-3 mm will last 3-4 years, a layer of 4 mm - up to 7 years, more than 5 mm - 10-12 years. This parameter can be assessed by examining the edges of the sides. They look like a layer cake. The top layer is acrylic. The rest is reinforcement.

The thickness of the reinforcing coating also matters. Unscrupulous manufacturers know that it is the sides and walls that are visually assessed, so they make them normally and skimp on the rest of the surface. To avoid purchasing a low-quality product, there are other evaluation methods.

The walls and bottom are illuminated with a flashlight pressed tightly to the product. If light seeps through the layers, the bath is too thin. If you knock in several places, durable materials will respond with a dull sound. Pressing on the outer surface should not leave any dents.

Surface Requirements

The inner surface of the bowl should be smooth, without irregularities or scratches. Sometimes the seller attributes them to the characteristics of the coating. You shouldn't trust him. If the tubercles are made artificially, perhaps the manufacturer is trying to hide defects in this way or increase the price of the product with the help of useless decoration. In addition, it is easier to slip on such a surface, while feet seem to stick to smooth acrylic.

See also: How to repair a plasma TV

The acrylic bathtub should be smooth, without bumps or scratches

Color also matters. It should be uniform, without scuffs or streaks. The presence of such defects indicates low quality materials.

Smell

It’s a good idea to sniff the bathtub before purchasing. A strong chemical smell indicates toxicity of the materials. If you put such a product in an apartment, you will have to breathe toxic compounds for several years.

Frame quality

The cast acrylic bathtub itself is durable and does not deform under the weight of the body and water. She doesn't need sustained support. In other cases, the type and strength of the frame play a direct role in the strength of the structure and in determining the price of the product.

The frame is made of square steel pipes with a coating that protects against corrosion. Consists of supports, stiffeners and adjustable legs. The simplest type of lathing is the one that is placed directly under the bottom of the product. It takes on the load, and the walls of the bowl can become deformed when filled. A more complex frame strengthens the sides and corners and distributes the load evenly.

There are prefabricated and all-welded models. By the number of support points in the frame included in the kit, you can judge the quality of the bathtub itself. Non-separable frames with a large number of legs and transverse ribs indicate the fragility of the product. Durable plumbing requires fixing only at the corners.

What should the thickness be?

The durability, wear resistance and service life of the model are affected by the thickness of the outer acrylic layer. Depending on the brand, it ranges from 2 to 6.5 mm.

The wall thickness of expensive and high-quality bathtubs is approximately 6 to 8 millimeters. Low-grade and budget products have acrylic walls with a thickness of 2 to 5 millimeters.

Often, in order to strengthen the thickness of the walls and base, the back of the bathtub is covered with a reinforcing layer such as extruded acrylic or reinforcing material.

Fiberglass is used in the manufacture of the lower reinforcing layer. If it is sufficiently thick, the product becomes rigid, strong, is not subject to deformation under the weight of a person and is not afraid of falling heavy objects.

Determining the thickness of the reinforcement is possible only visually from the end part of the acrylic bathtub. If you have doubts about the reliability of the design, you can lightly press the central part of the bowl with your hand. A good material should be elastic and not bend

PMMA baths

— What is the next material and what are its characteristics?

The next material is PMMA (polymethyl methacrylate), which is also called acrylic. It has a completely different chemical formula. There are two ways to produce bathtubs from this material - extruded and injection.

Extruded is a fairly inexpensive method of producing materials. It represents extrusion. This method is used to make many things from plastic film to polymer pipes. And the injection method is when the material is poured into special molds, and within 2 days it heats up and hardens. The result is two materials that are absolutely identical in appearance, but at the same time have different performance characteristics.

Extruded materials have one drawback: they can be easily damaged. For example, if we take a ruler and bend it lengthwise, it will bend easily, but if we try to bend it across, it will crack. A polymer pipe can be tied into a knot, but if you hit it across, it will also crack. The same thing happens with a bathtub that is made by extrusion. You can wash in this bath for 10, 15 and even 20 years. But if you drop some heavy object into it, a crack will appear in it. You will no longer be able to use this product.

Photo by ReRooms Acrylic bathtub Ravak BeHappy II 150x75 R in the ReRoms design project

— What is the difference between the material made by injection molding?

The disadvantage of cast PMMA is that it is a very expensive production method. If extrusion is extrusion, a continuous process when the product is manufactured in a short time, then the bath here takes more than two days. But precisely due to the fact that the process is slow, due to the gradual formation of huge field molecules, we get a product with a complete absence of pores, ideally smooth with ideal strength characteristics in all directions. As a result, a bathtub made from this material is of very high quality and can perform at its best even in the most extreme operating conditions. Molded PMMA is easy to clean, polishes and sands well, is absolutely non-slip, and retains temperature well. This is a material that practically does not change its volume. Therefore, if we want the bathtub to retain its appearance for many years, we should choose cast polymethyl methacrylate.

Photo by ReRooms Acrylic bathtub Ravak in the ReRooms design project

How to choose the optimal shape and size?

Thanks to the plasticity of acrylic material, in addition to the selected classic models, a large assortment of bathtubs of the most non-standard configurations and sizes began to appear. However, unlike standard designs, to make plumbing products with interesting shapes, thin rather than thick acrylic is mainly used. Therefore, we choose such acrylic bathtubs correctly and carefully.

Its comfort and performance completely depend on the size of the plumbing fixtures. Taking into account the requirements for maximum convenient use, there are optimal parameters.

An acrylic bathtub should have a height of 65 to 70 centimeters from the floor level. These values are suitable for both adults and children.

The average width of the structure can be from 75 to 80 centimeters. In this case, the individual complexion of the person is taken into account. For example, for people with a large build, it is possible to purchase a bathtub with a width of 100 centimeters.

The depth is measured from the bottom drain hole to the overflow level. This way it is determined how much water can be poured. Basically, the depth limit is from 50 to 60 centimeters. Too much depth is uncomfortable for those lying in the bathtub. Due to the shallow depth, the water will not cover the human body.

The average length is from 150 to 180 centimeters. The parameters of the font are selected to suit the height of the tallest member of the family. If the model is not equipped with a headrest, then its length can exactly match the height of the person bathing. If there is a headrest, for a person 1.8 meters tall it is appropriate to choose an acrylic bathtub from 165 to 170 centimeters.

Against the background of a steel and cast iron bathtub, acrylic bowls stand out due to their unique shapes. Using the unique properties of the polymer material, which responds to high temperature changes and remains flexible when cooled, manufacturers are able to achieve a wide variety of configurations.

For a small bathroom, typical of a city apartment, a compact rectangular model is perfect. Such a plumbing product is pressed against the far and side wall planes and covered with a protective decorative screen. Most often, such devices do not have additional options. Classic bathtubs sometimes include elements in the form of side handles or armrests.

A design with a corner modification will ideally fit into a medium-sized bathroom. These models are distinguished by one curved wall, a corner seat and a bowl rotated 45 or 90 degrees. The equipment is more advanced. In addition to the handrails, headrest and armrests, the set includes a hydromassage, a shower head, a faucet spout embedded in the side and glass inserts. An asymmetrical acrylic bathtub with a left- or right-hand design will allow you to create an individual and stylish bathroom design.

The spacious room allows for the installation of any model. An interesting solution is acrylic bathtubs of round or oval shape, located in the center.

Domestic manufacturers

The cost of plumbing fixtures from domestic manufacturers is significantly lower than the price of their European counterparts, but this does not affect their quality at all. Modern products from Russian companies are made from high-quality acrylic using innovative technologies and equipment, thanks to which they can become a good alternative to more expensive bathtubs.

Aquanet

Acrylic bathtub Aquanet Fregate 120×120

The Aquanet company is a leading manufacturer of sanitary ware, which manufactures products according to recognized standards using equipment from Italy. Among domestic companies, the products of this brand are considered the most expensive, since they have quality certificates and provide a guarantee for all models. Aquanet bathtubs are made from acrylic sheets 5 mm thick, but thanks to a special reinforcement technology, the products are wear-resistant and reliable. The brand's disadvantages include the use of a composite during the production process, which is why the bathtub can emit a strong chemical odor during the first time after installation.

Acrylic bathtub Aquanet Graciosa 150×90

Bas

To produce sanitary ware, the Bas brand also uses European equipment and materials, and during the process the material is treated with infrared rays, which allows it to be given any shape. Reinforcement is made using both glass fiber with the addition of polymers and safer and more environmentally friendly polyurethane. Bas's product range includes a large number of models of different designs, including bathtubs equipped with air and hydromassage systems. The manufacturer provides a ten-year warranty for all products.

Acrylic corner bathtub Bas Laguna 170×110 (right)

Acrylic bathtub Bas Nicole 170 cm

Aquatek

Aquatek bathtubs are made from five-millimeter sheets of acrylic without any impurities and are reinforced with fiberglass and polyester resin. In addition, they have a durable aluminum frame, which increases the reliability and durability of the products. The advantages of the brand’s products also include an attractive appearance and a pleasant-to-touch surface, which makes hygiene procedures as comfortable as possible. The surface of the bathtubs is easy to clean and is not subject to mechanical damage during operation. The weight of the products ranges from 15 to 25 kg, which greatly facilitates the transportation and installation of plumbing fixtures.

Aquatek Betta 170x95 (right) with hydromassage

Bathtub Aquatek Altair 158x120 (right)

Radomir

Radomir is one of the first companies to begin producing acrylic bathtubs in Russia. The company's product range includes bathtubs of various shapes and sizes, including products designed for people with disabilities. In the production of sanitary ware, the main attention is paid to its safety and environmental friendliness, which is why Radomir products can be found in hospitals and sanatoriums. The baths have a special coating that prevents the growth of bacteria, as well as the formation of fungus and mold on the surface of the material. Additionally, brand products can be equipped with hydromassage, lighting, touch screen and other options.

Acrylic bathtub "Estelona" with panel

Hot tub "Sorrento"

1Marka

Bathtub 1marka

The 1Marka company has been operating in the domestic market for 15 years, the main production line is located in Kazan. The manufacturer specializes not only in acrylic bathtubs, but also in other plumbing fixtures. A special feature of the company is the presence of its own design bureau, which allows it to constantly improve products and create new models. 1Marka products are aimed exclusively at domestic consumers, so the company’s assortment includes many small-sized products that are well suited for small bathrooms. If desired, any consumer can order plumbing fixtures according to their own original sketches.

Distinctive features

Triton

Bathtubs of the domestic brand Triton are made from Dutch and Austrian materials using advanced technologies and reinforced with high-strength fiberglass. To give the products additional strength, specially shaped inserts are used, and the top of the plumbing fixtures is coated with a compound that protects it from bacteria and mechanical damage during operation. The Triton product range includes rectangular and corner bathtubs, models with hydromassage, lighting and chromotherapy lamps.

Acrylic bathtub Triton Troy

Bath Triton Troy. Scheme

What strength is suitable?

Acrylic bowls have low strength because they are made of flexible and pliable plastic. To strengthen, a reinforcing layer with epoxy is applied to the outside. The more layers of reinforcement, the stronger the acrylic bathtub becomes.

Polyester resins strengthen the acrylic sheet. In order to make the structure even more durable, it is appropriate to use a reinforcing metal frame and bottom or reinforced chipboard. Due to its light weight, this plumbing fixture allows for simplified transportation, installation and dismantling during repairs. The weight of the bath is thirty kilograms, and the cast iron product weighs 80-150 kg.

What are the advantages of acrylic bathtubs?

Note:

- light weight, facilitating transportation and installation;

- maintaining the selected water temperature due to the low degree of thermal conductivity;

- ease of maintenance (the absence of depressions and protrusions allows you to clean the device by wiping it with a damp cloth);

- variety of shapes, designs, colors;

- restoration without significant costs.

The disadvantages include the fragility of the material, the service life is no more than 10-12 years.

What additional options should I take?

Due to the auxiliary parameters, acrylic bathtubs make taking water procedures pleasant and comfortable. To increase comfort while swimming, almost all plumbing fixtures are equipped with headrests, stands or armrests.

The most popular and healthy addition is the Jacuzzi model. In addition to the usual properties characteristic of an acrylic bathtub, the jacuzzi is equipped with hydromassage, which is a relaxing and healing procedure for the human body. A similar hydromassage effect occurs when air is mixed with water jets supplied through the nozzles. By turning the nozzles the direction of the jets changes. These sprayers can be located on the sides or built into the bottom of the bowl.

Another option that children will especially enjoy is air massage. Water jets mix with directed air currents, resulting in the formation of bubbles on the surface.

There is also chromotherapy. Using this function, directional lighting colors the water jets in certain shades, which, in combination with hydromassage, helps to enhance the beneficial effect on the human body.

Modern acrylic models are equipped with elements such as game consoles or radios. The system is controlled by a hydraulic switch or control panel. Plumbing fixtures with a special shelf for a laptop or a product with an integrated panel with a plasma TV are common. The jacuzzi has Wi-Fi or a direct connection to the central smart home system. These acrylic bathtubs meet any preferences and requirements.

Differences from steel and cast iron products

When buying a bathtub, you need to consider all the options.

I introduced you to the features of acrylic bathtubs in the previous section. To understand how a cast iron bathtub differs from a polymer bathtub, I will list the most important advantages of the first option:

- A bathtub made of cast iron has the highest strength. Unless you specifically set such a goal, it is almost impossible to break the cup. However, this does not apply to the external decorative enamel coating. Firstly, it wears out during use, and secondly, it can be easily damaged as a result of an impact.

- The enamel with which cast iron is coated has virtually no pores in which dirt can accumulate. Therefore, caring for cast iron plumbing products is very simple.

- A cast iron bathtub retains heat well. Hot water inside the bowl will cool more slowly than in an iron or acrylic structure.

- Once purchased, a cast iron bathtub, subject to the conditions of its operation, will faithfully serve not only you, but also your children. And even grandchildren. You will only have to change it to something else if you decide to somehow “refresh” the design of the plumbing room.

Cast iron bath (pictured). – an excellent choice, if not for several disadvantages.

As you can see, a cast iron bathtub has excellent performance characteristics. And I would gladly give the palm to her, if not for a few nuances:

- the product weighs more than 120 kg, so transportation and installation may cause problems (especially if you live in a high-rise building without a freight elevator);

- a considerable part of the thermal energy of the water is spent on heating the cast iron, so for a comfortable bath you will have to adjust the temperature of the liquid accordingly;

- The shape and appearance of cast iron bathtubs are not original due to the difficulties in processing this material.

A steel bathtub is another alternative to acrylic.

However, in addition to cast iron, there is also steel. After all, it was steel bathtubs that were used for installation in most plumbing rooms in houses built in the second half of the last century. Therefore, it’s time to figure out what is better – a steel or acrylic bathtub. In my opinion, here the latter option is more attractive. I'll explain why:

- Inexpensive steel bathtubs have thin metal walls that become deformed during use. Cracks, chips and other defects appear on the enamel, which cause inconvenience when performing hygiene procedures. And the cost of more expensive products with thick walls is close to the price of high-quality acrylic and cast iron models, which negates the low cost advantage.

- Steel has high thermal conductivity, so hot water poured into a bathtub cools quickly. You won’t be able to fully enjoy a pleasant pastime in the foam by candlelight.

- When filling the bowl, the stream of water makes a loud noise that is heard not only by you, but also by all your neighbors. This problem can be partially solved by insulating and soundproofing the product with polyurethane foam.

- A metal bath requires mandatory grounding during use, which is not always possible due to the lack of an appropriate cable in the electrical wiring.

- Due to its design, it is difficult to install a steel product securely in the bathroom. Typically, specialists resort to various kinds of tricks, described in detail in the articles on this site.

The only advantage in protecting steel bathtubs is the low cost. However, it does not pay for the problems that you can get by installing such a structure at home.

But the winner is obvious. At least for me.

I hope we have come to the same conclusion on the question of whether a cast iron, acrylic or iron bathtub is better. But in order to fully enjoy the benefits of your purchase, you need to purchase a quality product. That is why the next section is devoted to how to choose the right bath.

What about brands?

According to experts, it is recommended not to save money when purchasing an acrylic bathtub and to give preference to proven brands that can last for many years.

The market presents a large number of models of different quality levels and price categories. Manufacturers offer plumbing fixtures made of acrylic in any color of the rainbow. A win-win and universal solution is a glossy snow-white bathtub. When choosing a non-standard colored bowl, a harmonious combination with other plumbing fixtures and the interior is important.

German and Italian designs are considered expensive and high quality. These foreign manufacturers prioritize quality. There are plumbing products from the company GNT (Germany), Sunranz (Germany), Artcheram (Italy) or Novellini Elysium (Italy). Acrylic bathtubs are very durable with an average price from 55,000 to 200,000 thousand rubles.

Simplified and cheap acrylic products are produced by Turkish or Chinese companies. Of course, there is also functional plumbing from the company EAGO (Eago) from Hong Kong, but if we are talking about ordinary market models, then it is possible to purchase an acrylic bathtub at a price of 6,000 to 30,000 thousand rubles.

The problem of choosing a bathtub for your home: cast iron, steel or maybe acrylic

Considering that a bathtub is a durable item, installation of which is possible only during renovation work in the room, comparison of products made from different materials is quite reasonable.

And one of the main and exciting questions in this case is how to wash an acrylic bathtub at home , most often arises due to a lack of knowledge about the material.

Everyone is familiar with cast iron and steel bathtubs and their operation is not difficult, but despite the fact that acrylic products have been actively conquering bathrooms for more than twenty years, they have not yet managed to enter every apartment or house.

Repairing acrylic bathtubs at home

Secrets of the popularity of cast iron baths

They began to objectively compare baths with each other only after the advent of acrylic products. Previously, when considering the advantages of two types of cast iron and steel, the advantages always remained with the former, since they:

- durable;

- heat-intensive;

- the strength of the enamel coating can withstand mechanical and chemical influences;

- relative ease of care.

Comparing these performance characteristics in order to determine which is better, an acrylic bathtub or a cast iron one , it is not easy to make a choice, since they are quite similar, with the exception of service life.

But cast iron is a heavy material and this fact is both a “plus” and a “minus” of products made from it. On the one hand, this provides them with stability and reliability, but on the other, their installation requires the involvement of at least four strong workers.

The main disadvantages of cast iron bathtubs, in addition to their heavy weight, should be considered:

- lack of variety in product shapes and differences between models mainly come down to different sizes and the presence/absence of a certain number of accessories, most often handrails;

- Over time, enamel loses not only its original shine and luster, but also cracks and becomes contaminated with lime deposits and rust, which are very difficult to remove. The radical solution, restoration with enamel, only solves the problem for a while.

In addition, if you compare these two types in terms of price, there is no obvious advantage. The exception is exclusive models of one or another type, the pricing of which depends on functionality, exclusivity or design solutions.

Steel baths: inexpensive and tasteless

The main advantages of steel bathtubs have always been: low price and low weight, which made it easy to install. But just like cast iron, they are not distinguished by a variety of shapes, the differences are only in size.

If we consider the quality of enamel of modern products, especially imported ones, it is quite high, but in other characteristics this type of bathtub is inferior to both its eternal rival, cast iron, and the new favorite of buyers, acrylic.

Steel baths:

- have a low heat capacity, so the water cools down quickly, which does not allow taking a bath to be considered a comfortable procedure;

- have poor impact resistance, which is why falling even a light object can lead to cracks on the enamel surface;

- quite unstable;

- “noisy”, the process of drawing water is a loud sound, which often causes discomfort for people living in the apartment.

Therefore, when comparing whether an acrylic bathtub or a steel one is better, the choice is obvious - acrylic .

No. 4. Pay attention to the reinforcing layer

If acrylic bathtubs were made without a reinforcing layer, they would not withstand heavy loads. Many people are accustomed to evaluating different bathtub samples, so to speak, from above, looking at the snow-white acrylic and analyzing the dimensions. It also doesn’t hurt to look “under the body” and look at the reinforcing layer. There are few options for its implementation:

- a layer of polyurethane , which is dark in color, has sufficient strength, is environmentally friendly and odorless. This is ideal for a bath;

- layer of a mixture of ester resins and fiberglass inferior in strength and characterized by an unpleasant odor, which manifests itself when heated to high temperatures. This reinforcement has a rough surface and sharp edges, so during installation you must be especially careful not to get hurt.

The reinforcing layer should not be thin. This can again be assessed by the end of the side. However, some cunning sellers deliberately make the sides thicker, knowing that buyers who are knowledgeable and savvy in matters of choosing an acrylic bathtub will definitely look at the ends. The rest of the bath receives a thinner layer of reinforcing layer, so it doesn’t hurt to carry out additional experiments. You can lightly press the bottom of the bathtub and its walls with your hand: normally, the material should not sag.

For another check, you will need a flashlight or laser pointer. It is necessary to lean the switched-on flashlight against the bottom of the bowl and look from the back to see if the light penetrates. You can fold your palms and look into the hole formed between them to assess as accurately as possible whether some of the rays pass through the material. A sufficient layer of acrylic and reinforcement will not allow a drop of light to pass through. Remember that the thickness of the reinforcing layer must be uniform throughout the entire bathroom.