Owners of an autonomous well must prudently prepare a shelter for it from external influences and attacks from intruders. A do-it-yourself well house will hide the equipment from prying eyes and provide sufficient thermal insulation. This option is especially relevant in a situation where the pumping station is installed on the surface. The functions of the building can be expanded by using it to store tools.

But it should be understood that such an external building may not fully protect the components and assemblies of the water supply system from external influences. For this, a caisson is used - a sealed container made of metal, plastic or other materials. The container has a hole in the lower part for the entry of the casing pipe, and at the top there is an opening for access to the well, which is hermetically sealed. You can build a caisson for a well with your own hands. But in some cases, installing a caisson is impractical - for example, if water is collected only in summer. In this case, a simple house will suffice.

Beauty and benefits

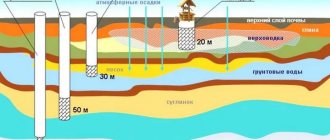

Even if you don’t care at all what your source looks like, you should care how well it works and what quality of water it produces. Any autonomous hydraulic structure, be it a well or a well, needs a house not only for beauty, but also for protection. And you need to protect it from:

- dirty surface, flood and melt waters;

- earth, leaves and other debris;

- insects, birds, small animals that may fall into the mine;

- winter frosts.

In addition, a protective and decorative structure over a well or borehole caisson, equipped with a reliable lock, will protect children from falling in it and will not allow attackers to damage or steal pumping equipment.

When leaving on business, you can close not only the house, but also the well Source na-dache.pro

You can provide such protection in different ways: put a cap or a cut plastic bottle on the casing pipe, or cover the well neck with a sheet of plywood. But these measures are insufficient and do not add aesthetics to the courtyard. Whereas a house for a well in a country house, in addition to absolutely fulfilling all practical functions, also decorates the site.

This is possible, but it’s not very pleasant to look at it every day. Source yaringstroy76.ru

Models from scrap materials

There are also no drawings for these well houses, since they are manufactured according to the “whatever comes to hand” principle.

One example is using a perforated metal barrel or washing machine drum. The product not only looks quite original in the garden, because to resemble a well house you only need to add a canopy on posts (metal) and a bucket on the collar. In such “wells” it is good to burn paper waste or use them for cooking over an open fire.

“Well houses” made from painted car tires also look interesting. Of course, they cannot be used in any way; these are purely decorative structures. But pots with outdoor plants look very good in them. This placement option is especially suitable for those plants that need protection from too bright sun.

Types of well houses

What type of house design to make will depend on many factors. For example, depending on the seasonality of the source’s use - if it is used only in the summer and preserved for the winter with the pump dismantled, you don’t have to do insulation.

It is also worthwhile to inspect the building materials remaining after the construction of a house or other capital facility. The house over the well has small dimensions, and any scraps will do for its construction. But when making it yourself, you need to take into account your experience in working with the available material and the availability of suitable tools.

Another point is the appearance of the water source itself, what it is made of.

- If it is just a pipe sticking out of the ground, it needs a full-fledged house with walls and a roof, pipe and tap outlets, and a door for easy access inside.

- If it is a caisson made of concrete rings or a similar well, then it is enough to decorate the existing walls with decorative materials and install a roof on them.

- A simple canopy for a well will be enough if it is made of a wooden frame and equipped with a lid.

Wooden well with a canopy Source avito.st

Finally, it is desirable to design a structure that will harmoniously fit into the surrounding space without disturbing its style.

There are many options, which one to choose is up to the owner. In any case, a sketch, drawing and calculation of material requirements are first required.

See also: Catalog of companies that specialize in finishing materials and related work

Frame

The easiest way is to build a frame house. If desired, it can be insulated, and a variety of materials are suitable for exterior decoration:

- edged and unedged boards;

- lining, including imitation timber and blockhouse;

- sawn along trimming logs;

- plastic and metal siding;

- flat slate;

- cement bonded particle boards;

- corrugated sheeting, etc.

The frame itself is assembled from wooden blocks or welded from profile pipes or angles.

The dimensions of the well house are selected individually depending on its location on the site and additional purpose. If you make it large enough, you will have additional space for storing garden tools and other needs, without having to build a separate utility unit.

An example of a multifunctional frame house Source shedsforhome.com

The insulated building is sheathed on both sides, placing insulation (most often polystyrene foam) into the cells of the frame under the sheathing. But insulation is only relevant for all-season wells and low, small houses - large ones will freeze.

A well house can be a smaller copy of a large house if it is faced with the same façade material and a similar roof is made. But you can give free rein to your imagination and turn the well into a rustic wooden well or a mill with a windmill. The simplest design will be in the form of a gable roof installed directly on the base.

Frame construction

For construction you will need the following materials:

- dry timber 5×10 cm;

- board 10×2 cm;

- lining, block house or siding;

- slats;

- flexible tiles

The work of building a well house with your own hands begins with preparing the site. The area near the casing is leveled and compacted.

Advice. It is better to start arranging the house a few months after drilling the well. During this time, natural shrinkage of the soil will occur.

Frame assembly

The foundation for the building is prepared from various materials: paving stones, tiles used to pave the yard or a concrete foundation. The simplest and most affordable option is concreting corner supports.

- Places for placing timber are marked around the pipe. Pegs are driven into the support areas, then cords are pulled to determine the perimeter.

- Holes are dug 30 cm deep, the bottom is covered with sand 10-15 cm deep.

- The support pillars are inserted into the holes and secured with auxiliary material (stones) at the level. Filled with concrete.

- After hardening (3-4 days), the lower framing of the frame is performed. The beam is connected along the perimeter using metal corners and self-tapping screws.

- The next step is the top trim. It is performed similarly to the bottom one. For structural strength, you can install an additional vertical stand in the middle of each wall.

Sheathing

The choice of material for cladding depends on the owners. It can be lining, imitation timber or a block house, in the form of a rounded log. Sheathing slats are placed on the frame, and if necessary, waterproofing and insulation are laid on them. The casing is attached to the top with self-tapping screws.

Roof of the house

The standard option is a gable roof. To install it, it is necessary to create a rafter system. It consists of trusses - two boards are fastened at the ends at an angle of 30°. Their strength can be strengthened with a crossbar - a plank nailed 20 cm from the top of the truss. You will need two roof trusses. They are connected to each other by a ridge beam. On one of the slopes, two additional beams are nailed to the ridge, which form an opening for the door.

The sheathing is mounted on the rafters. The waterproofing is spread over it tightly. Roofing material is laid on top, for example, flexible tiles or ondulin.

Roof for construction

Advice. For ease of well maintenance, some craftsmen make the roof removable.

Door

The design of the door is very simple, it is a panel made of boards. To make it, several boards 10-15 cm wide are laid, then in the upper and lower parts they are fastened with a block. There are 4 screws for each part. Reinforce the door with a diagonal strip. Metal loops are used for hanging.

Door for the house

Video description

After watching this video, the essence of making a brick shelter will become clear:

From a concrete ring

A well made of concrete rings or a caisson made of them, rising above the surface of the earth, already has walls on which it is necessary to install a roof. You can make a simple canopy over the well and a cover if you use it only in the summer and live in the country all the time during the season. In other situations, a house would be a better solution.

It is advisable to insulate its concrete walls so that in cold weather the shaft inside does not become overgrown with frost from rising and freezing water vapor. This can be done using polystyrene foam cut into strips and glued in a circle or roll insulation.

Well heads

To protect against

dust, dirt, sand, foreign objects, amphibians and dirty water from getting into the well when flooded by spring waters, the upper end of the casing pipe is equipped with a cap - a plug that hermetically closes its neck.

The head mounted on the pipe provides reliable hanging of the electric pump, wires and water hose.

In winter, sealing saves the well from freezing, and if there is a locking device, it will protect against unauthorized entry.

The most popular on the market are domestically produced heads “Dzhileks” and “Aquarius”

, combining low price and desired quality.

The downhole head "Dzhileks" is intended for equipping wells with casing pipes with a diameter of 90 to 160 millimeters and pumps with polyvinyl chloride pipes with a diameter of 25, 32 and 40 mm. They are made of cast iron or plastic.

The Aquarius head is made of plastic and is intended for shallow wells with a casing pipe diameter of 113-127 mm and a pressure pipe diameter of 32 mm.

Another one releases headlines

made of plastic and cast iron for wells with an outer pipe diameter of 107-159 mm and a pump pipe diameter of 32 and 40 mm.

Useful tips

When designing a house for a well, the dimensions of the future structure need to be correlated with your own dimensions, so that it is convenient for you to get water with a bucket or get inside for cleaning, repairing or inspecting equipment. In the case of a well, it is more convenient to make the door not in the roof, but in the wall of the house, if it is not a concrete ring.

For the installation of any structure it is necessary to make a foundation. For wooden houses, it is enough to place posts in the corners. When making frame buildings, vertical corner posts are lowered into holes and filled with concrete or secured with corners and anchors to the concrete base. And if the house above the well is made of stone or brick, a strip foundation or slab is poured under it.

After cutting and fitting, all wooden elements must be treated with protective impregnations, and the finished structure is coated with varnish or paint.

Original house made of wood and stone Source na-dache.pro

In order not to constantly climb inside the house to open the tap or turn on the pump, it is better to immediately take the water supply controls outside.

How to choose the right well head

To make the right choice, you need to know what the digital and letter markings on the products for sale mean; their decoding in order looks like this:

It should be noted that not all manufacturers support this marking and its sequence; there are designations AOC, OGS, OD, which do not play a special role in determining the purpose of the product.

Rice. 7 Installation diagram of the Gilex OSPB head in the well

When choosing a head, here are some tips to keep in mind:

The most convenient, practical and inexpensive are plastic devices; they are best used for shallow immersion depths of low- and medium-power electric pumps. If the immersion depth is large (large mass of water in the pressure pipe) or the electric pump is large and heavy for pumping significant volumes, it is better to use more durable steel or cast iron heads

Although the terminal box makes it much easier to connect and disconnect the electric pump from the power source, its use must be approached with caution when operating high-power equipment. The fact is that the design proposed by the manufacturer and the terminal strips themselves are too unreliable methods of connecting wires, and with the high current that powerful electric pumps consume, overheating of the contacts, melting of the plastic head or cable insulation is possible

Also, high humidity in the tip area, even with reliable insulation of the terminal box (from the point of view of the domestic manufacturer), can lead to corrosion of the contacts, overheating or short circuit.

Briefly about the main thing

Every owner must first of all ensure that fresh, clean and safe water flows uninterruptedly into the house from the well. And for this, the source must be protected from dirt getting into it and from freezing of water in the pipes. Both problems can be solved by installing a protective shelter in the form of a house over it, and you will receive an additional bonus - an interesting landscape design object. You can buy a house ready-made or make it yourself from wood, brick and other materials left over from construction.

Ratings 0

Design features

If you wish, you can easily make a house for a well with your own hands. It might look like this:

A simple shield with a visor. This design will protect the water shaft from possible contamination, but the bucket and top of the lid will collect dust. In winter, water may freeze here.

A house that protects the entire outer part of the well. It is the most effective design, completely protects the well shaft and water-lifting mechanism from possible contamination.

Each person decides independently which option he needs.

What else needs to be considered

- The cable for attaching the pump can be made of high strength polymer or stainless steel. A regular cable cannot be used. Sooner or later it will rust and may break.

- Borehole pipe inclination . You need to check the pipe for verticality before purchasing a pump. If the device is equipped with a centering sliding bearing (and most manufacturers in the CIS and Chinese countries install it), it is not suitable for a pipe with an angle - it will simply break. There are usually no such problems with European models.

- Pump fork . To thread the electrical cable into the head, you need to remove and then reassemble the plug. If it is collapsible, no problem. But if the plug is solid, cutting the wire will void the warranty on the pump!

So. Factory-made heads look solid, securely fix all elements and cost from 2 to 4 thousand rubles. When starting to create a homemade version, you need to take into account that it is not so easy to make connections, especially electrical cables, airtight. A skilled craftsman can do everything, but the costs may not be justified.

Drilling a well is an expensive undertaking, but if you need a shallow well, you can handle drilling it yourself. For this you need a special tool. How to make a hand drill for a well yourself and how to use it? Read on.

We will consider the main characteristics of centrifugal pumps and the principle of their operation in this article.

Preparatory work

Basic carpentry tools are enough.

The simplest and best option is a frame quadrangular house covered with clapboard. It is crowned with a gable roof, on the slope of which a door for servicing the hydraulic structure is mounted. To create such a shelter for a well, you will need:

- plane;

- jigsaw;

- screwdriver;

- hacksaw;

- level;

- roulette.

It is better to choose lining “for logs”. It will give the structure the appearance of a log house. You can use decorative trims for decoration. Regular 50x50 mm timber is used as frame racks. It and the lining are pre-treated with an antiseptic. To build a house faster, you should create a mini-scale diagram indicating the dimensions of the structure.

The procedure for making a headband yourself

The well cover is made of fasteners and thick metal. The sheet thickness must be more than 10 mm.

For better sealing of the structure, a caisson is used, which is a waterproof container. This device is effective in cold weather. It protects the mine from icing and promotes regular operation of pumping equipment.

The caisson houses filtration structures and automatic control and monitoring elements.

The casing pipe is pre-prepared. It is trimmed and irregularities are removed from its surface. The edges are primed and paint with an anti-corrosion effect is applied to them.

Self-construction work consists of the following stages:

High-quality sealing increases the efficiency of the well. When the pressure in the pipe decreases during operation of the pumping equipment, the flow rate of the source increases.

During operation, the cable, water pipe and cable are fastened with plastic clamps. This prevents sagging.

Operating principle of the protective cap

The design of the protective head is quite simple. Various materials are also used for manufacturing. Steel heads are considered the most reliable, but for plastic casing, a plastic head can be used. The disadvantages of plastic are obvious. This is poor resistance to temperature fluctuations, insufficient strength in the cold; cracks will quickly appear on the plastic head and it will cease to perform its function.

The composition of the cover is as follows. This is the cover itself, a brass or plastic clamp, eye bolts, plastic or steel inputs, a rubber ring, a carabiner, a fastening device, a flange.

The structure is installed using bolts.

The pump hose is inserted through the cover using eye bolts.

To install the head, it is necessary to make an accurate and even cut of the casing pipe. Connect the pump on the cable with the cable and the outlet pipe using clamps. Once you lower the pump into the well, you can put the seal cap on.

It should be noted that most large companies that install wells include capping in their services. Perhaps, when ordering well drilling, you should clarify whether this necessary service is provided.

It is best to use factory-made heads.