To protect the well and equipment from external pollution, atmospheric phenomena and vandals, it must be properly equipped. Agree, comfort when using a water intake, servicing equipment and pipelines is as important as its safety. How to protect while ensuring ease of use?

For those who want to install a water well with their own hands, we will tell you how to do it correctly. We'll tell you which option is best to choose for your source. Here you will learn how to independently build a caisson for a well head, how to install an adapter, and also where to place the hydraulic accumulator.

A detailed description of methods and technologies for equipping a personal hydraulic structure is based on regulatory documentation and the experience of well owners. The information presented for review is supplemented by visual diagrams, photo selections, and video tutorials.

Why is it necessary to build a well?

The arrangement of a hydraulic structure on private territory is carried out in accordance with regulatory documentation. Experienced employees of specialized companies are well aware of all the rules and standards. Professionals begin to equip the source with the simultaneous installation of pre-selected water supply equipment after completion of drilling work and before connecting the internal water supply system. With their help, Abyssinian tube wells, simple up to 50 m and 100-meter artesian water sources are created.

Common types of wells Source hotel-a.ru

Proper improvement of a well, regardless of its type, allows you to ensure:

- necessary conditions for connecting and performing maintenance of additionally installed equipment;

- protection of personal hydraulic structures, pipes and devices from freezing;

- the purity of an independent water source by excluding dust, dirt, rain and melt water from entering it.

In addition to the submersible pump, all equipment of an autonomous water supply system is installed near the well or in the house. To install devices near the source, a technical room of estimated area is first constructed. A special small room in the house will also not be superfluous. The room is created at the entrance of the water supply to the building. It is convenient to install and maintain a water supply pump and other equipment. A special room is also used to supply electrical power to technical devices and enter pipes into the water source.

Technical room for downhole equipment Source specteh-vrn.speczakaz.info

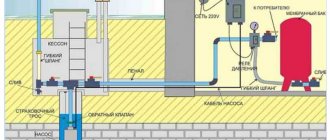

Hydraulic accumulator in the connection diagram of a well pump

The presence of a hydraulic accumulator in the water supply system of a private home prevents problems with water supply. The hydraulic tank prevents the pump from being overloaded. After filling the reservoir with water, the pump automatically turns off and resumes operation only when the liquid is consumed to a certain level. The volume of the hydraulic tank varies from 12 to 500 liters. When there is a power outage, there will always be a certain supply of water in the tank.

There are membrane and storage type hydraulic accumulators. In the first case, these are small-sized devices, with a check valve and a pressure gauge. They perform the task of ensuring pressure in the water supply system. Hydraulic storage accumulators have large-volume reservoirs; they are most often installed in the attics of houses, which requires reinforcement of structures and thermal insulation to protect against frost in winter.

The principle of operation of an expansion tank for water supply is to maintain pressure in the water supply system. The cylindrical container has two chambers, for air and for water. When filling the container with water, the air part decreases, and the pressure increases. An expansion tank of any type solves the following problems:

- maintains system pressure when the pump is turned off;

- protects equipment from water hammer;

- stores a reserve amount of water in case of problems with the electricity supply;

- protects system elements from rapid wear.

The expansion tank allows you not to turn on the pump every time when the need for water is insignificant and there is enough of it from the tank.

Now let's figure out how to choose an expansion tank for water supply. Everything will depend on other equipment included in the water supply scheme. You can always get comprehensive advice at special sales points.

Selection and installation of water supply equipment

When installing an individual water supply, the following technical means are required:

- Submersible or surface mounted pump.

- Automation that protects the pumping unit from overloads and controls its operation.

- Hydraulic accumulator in closed or open type. The first type of device is a tank with a membrane. Its use allows you to ensure stable pressure in the utility network.

The type and method of placement of technical devices affects the nature of the arrangement of the water source. Installation of a tank with an open design is carried out at the highest point of the water supply. It is installed in the attic or under the ceiling of the last level of the house. Modern well equipment, which includes a membrane accumulator, can be installed in any convenient location.

Closed hydraulic accumulator Source 3agorod.ru

Surface mounted pump for shallow water source

Surface-mounted pumping units are easier to install, easier to maintain and cost less than submersible devices. Manufacturers produce 3-in-1 units. The equipment includes a pump, automation and a tank with a membrane with a volume of 20 to 60 liters. Devices combined into one installation are a profitable and rational option. Such equipment is called a pumping station. Its installation requires less space than when installing individual devices.

There are two hoses coming from the surface pump. One of them is the suction tube. She descends into the water source. The use of a surface-mounted pump simplifies the maintenance of the device and the installation of a water well in a private house. Moreover, a small diameter hose is connected to the equipment. This makes it possible to equip Abyssinian well structures with surface pumps, which do not include submersible devices.

Surface pumping unit Source ozone.ru

A station or a separate pump on the surface has one drawback - the equipment is not designed to lift water from deep wells. The overwhelming majority of manufactured models have a limit of 10 m. Therefore, water supply pumping stations and individual surface-mounted units are usually installed near the mouth of an underground water source. For installation in a residential building, more powerful equipment is needed that can overcome the resistance of the pipeline from the source to the building.

Submersible pump for deep water source

If the well is more than 10 m deep, then the water is raised using a submersible pumping unit. When selecting this type of equipment, its height in the casing is taken into account. Only specialists can correctly determine the value. If you make a mistake, the water pressure in the building will be weak or completely absent.

Submersible pumping devices Source variant-a.ru

See also: Catalog of companies that specialize in engineering systems and related work

Installation of a deep-well pumping unit begins with connecting a hose for supplying aqueous media. With modern models this process is simplified as much as possible. The device itself is held in the borehole by a cable.

When selecting equipment for a well at a dacha after drilling, it is better to mount a closed-structure hydraulic accumulator together with a deep unit. If necessary, it can be placed together with the automation at a significant distance from the water source. The ideal option for installing a membrane tank is a special room in a residential building. It may be on the first floor. It is also often installed in the basement.

Expert advice

To properly equip a well with your own hands, you will need to make many decisions, in which any additional information will only be useful, especially if it comes from professionals in their field. The tips below will help prevent some common mistakes many homeowners make due to lack of knowledge:

- When choosing a borehole caisson, it is better to give preference to modern technologies - models made of polymers with high tightness and low thermal conductivity - this will prevent the well from freezing in the cold season. Too high a cost should not discourage you from purchasing: the production of plastic caissons is well developed, manufacturing companies often organize promotions with significant discounts, and in winter and late autumn the product can be purchased at a price 2 times lower.

- It is also not necessary to carry out drilling work only in the summer in dry weather; drilling is a year-round process, and carrying it out in winter will cost much less, and all other work can be postponed to the warm spring-summer season.

- When choosing an electric pump, they look at its technical characteristics, and you should know that the given maximum values are one and a half times higher than the nominal values at which the pump effectively sucks water.

Pumping equipment in a plastic caisson - examples of placement - If you use an Abyssinian or a well on sand, before supplying water to the hydraulic accumulator or automation elements, be sure to install a coarse sand filter; it would be useful to install another additional mechanical filter with a polypropylene cartridge.

- To avoid draining water from the system, a check valve must be installed at the outlet of the submersible electric pump and at the inlet of the surface pump.

- With limited financial resources, an Abyssinian well is drilled manually; private owners carry out this work within one day (unless they come across a large cobblestone or stone slab during excavation, after which the drilling ends). The cost of the work is approximately 100 USD; manually it is possible to reach depths of up to 35 m; for example, the depth of wells in the Moscow region starts from 5 m.

- The idea of using a well adapter should be approached with caution - the dovetail connection on two adjacent rubber rings can leak under high pressure. The purchased parts must fit very tightly into each other.

Connection diagram of the pumping station to the water supply system

Methods for protecting an underground water source from precipitation and atmospheric influences

The well and water supply equipment must be protected from the negative effects of rain, snow, sunlight, wind, hail and even fallen branches. To do this, a ground or underground structure is built around the mouth of the water source.

Construction of a protective structure for a water source Source forum.guns.ru

Ground pavilion

Installing a structure in the form of a compact pavilion over an underground water source is the most simplified way to protect the water intake structure. To reduce heat loss, the building is covered with a little earth. A pavilion in this design will resemble a free-standing cellar.

This protection option is rarely implemented in dacha and cottage areas. More often it can be seen above wells that are used on an industrial scale. A pavilion is rarely installed, because the structure clutters the site and has to be additionally insulated.

Ground protective pavilion over a water source Source skvazhiny.ru

Well-caisson underground

When deciding how to design a water well in a dacha beautifully, most site owners choose a well in the form of a caisson. The protective structure does not clutter the area. Underground placement allows you to hide the structure. An exceptionally small hatch remains on the surface. It is located in the same plane with the ground.

The advantage of a caisson is also that it is easier to insulate compared to a ground-based building. Moreover, the structure is dug in below the soil freezing level. Therefore, the underground part of the protective structure is located in the zone of positive temperatures, which allows the heat from the soil to slightly warm the caisson. In this case, the structure must be well waterproofed in order to eliminate the negative impact of ground and flood water on the technical devices of the underground source.

A caisson well can be erected directly on private property when the well is being installed. The structure is also available in finished form. It is manufactured in factories of different shapes and sizes.

Ready-made underground caisson made of plastic Source userapi.com

Choosing a drilling site

When I was planning where on the site to make a well, I thought that the optimal place would be away from the septic tank, somewhere in the garden.

With experience, I came to understand that a well needs to be drilled where there will be a clean and improved area. I believe that the best place to drill is at the entrance to the yard, and here's why:

The best place to drill a well is the entrance to the yard

If the pump breaks down, it will be easier to get it if there is a lot of free space around. Usually the pump hangs on a HDPE water supply pipe with a diameter of 32-40 mm and is secured with a cable.

The pump can hang at a depth of 20-30 or even 50 meters, and all this pipe needs to be laid somewhere when pulling the pump out.

It's best when the yard is landscaped. A pipe laid on concrete or paving slabs will remain clean and will be lowered into the well without problems after replacing or repairing the pump.

Now imagine that you have a well in your garden and the well pump has stopped working. It's raining outside. By the time you pull the pump out of the well, you will get dirty in the mud and smear the pipe. And it will need to be lowered into a well with clean water again.

Imagine that you need to pull a pump out of a well through such mud, and then lower it back without smearing the pipe

Many people do not understand that a well is a technical structure that sometimes needs maintenance. Sooner or later you will have to pull out the well pump with the water supply pipe.

And it will be good if there is a place for this. In my practice, there are many cases when a person bought a plot. I drilled a well because water is needed to build a house. He made a well, and built a house or garage above it.

Then the well pump broke, and dancing with a tambourine began. It’s inconvenient to pull out the pump; the garage or basement is small, you can’t really turn around. The water supply pipe is wet and does not bend well.

How far from home can you drill?

Much depends on the design of the well, but I would not drill it closer than 2 meters from the house. A normally drilled well does not in any way affect the shrinkage of soils or their movement.

At what distance from the septic tank can you drill a well?

The smartest thing to do would be to place the well as far as possible from the septic tank. Just take into account where your neighbors' septic tanks are located. I have seen several times how a person removes the well as far as possible from his septic tank, but does not take into account the fact that the neighbor’s septic tank is only two meters from his well.

You can place the well next to the septic tank, and the water will be free of contamination. The problem is that you need to isolate the annulus of the well, and 98% of drillers cannot do this.

I drew how wastewater from a septic tank flows into a well

They just don't have the right technology and equipment. Therefore, drill as far away from the septic tank as possible.

How to find out where to drill

On the plain you can drill anywhere and there will be water. Therefore, customers themselves determine where the well will be built on their site.

In difficult areas, usually foothills or mountains, dozens of different methods are used to find the optimal drilling location. I have seen specialists who search for water with frames or electrodes. I saw how they were trying to find underground water flows using an echo sounder.

If we drill in such areas, we use the RAP (Resonance Acoustic Profiling) method.

But unfortunately, no method of finding water gives a 100% success rate. At least I haven't come across anything like this. Therefore, if you have a difficult area, negotiate payment terms in advance in case of unsuccessful drilling.

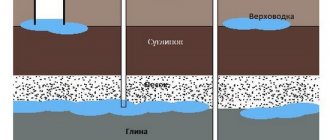

Find out the aquifers

During my time working for a drilling company, I realized that it is better for the client not to understand anything at all about aquifers. Naturally, if he does not make the well with his own hands.

You can read the theories that are written on websites, but in reality on the site, everything will be completely different than what is written on the Internet. It is not always possible to get a good well to the same depth as your neighbors.

We often have cases when a customer demands to drill a well like a neighbor’s at 60 meters, but we drill him at 34 meters and there is good water there.

Unscrupulous drillers can drill 60 meters and say: you wanted it, we did it. The fact that there is no water at such a depth is not our problem. We agreed on the footage.

Remember: the result of drilling is good water, not footage.

Well caisson dimensions

The protective structure over the underground water source must allow the installation of all necessary auxiliary water supply equipment. The installation location of technical devices affects the dimensions of the caisson well. It is recommended to choose a protective structure where a person can “turn around” when performing work.

If it is decided to install the equipment in a caisson well, the distance from the front and side of the pumping station or accumulator to the walls of the structure must be at least 50 cm. When creating a well for drinking water in a private house, it is necessary to provide in advance in the building design a technical room with a minimum size of 80* 80 cm. It would be better, of course, if it were more spacious.

Criteria for selecting components

The quality of water depends directly on the choice of equipment.

The equipment necessary for the well is selected according to various parameters corresponding to the specific device.

The caisson is selected according to dimensions, volume, wall thickness, and material.

The pump is selected according to the following criteria:

- manufacturer (the most popular are Gilex, Grundfos, Malysh, Rucheek);

- power;

- productivity: it should not exceed the flow rate of the source, otherwise the pump will quickly drain it;

- immersion depth;

- pressure;

- type (vibrating, centrifugal).

As for the hydraulic accumulator, the main criterion for its selection is volume.

Video description

The creation of an Abyssinian well in a residential building is shown in the following video.

If during the construction of a protective structure it is decided to use reinforced concrete rings, then their standard diameters are 90, 150 and 200 cm. Products with the smallest size are best used to create a caisson well in which a pump will not be mounted and a membrane tank. Reinforced concrete rings with a diameter of 150 cm are suitable for protective structures where it is planned to locate medium-sized equipment. Two-meter products are an ideal option for creating a caisson, in which you can easily mount a large pumping station and even install a 200-liter membrane tank.

Manufacturers produce caisson wells of various sizes. The product range allows you to select a factory product to accommodate equipment of any size.

Important! The bottom of the protective structure must be at least 15 cm below the soil freezing level. This is a prerequisite for climatic regions with harsh winters. The ideal option is to install 1/3 of the structure in a non-freezing area.

The third lower part of the ketone must be located below the freezing point of the soil Source ksportal.ru

The upper part of the caisson well must be insulated. The heat insulator is usually used on the outside. Extruded polystyrene foam or other similar products that are resistant to humid environments are used as an insulating material. If the well is connected in a house for all-season living, there is no need to use an additional heat insulator. After all, such a structure must have a heating system.

Operation of water supply

- After checking the functionality of all components, it is necessary to perform several test runs of your pumping station. Moreover, it should be turned on with minimal load.

- Do not forget that at first, when drawing water from a home well, it may be quite cloudy, and it must be given several hours to clear.

- It is necessary to adjust the pump capacity so that it matches the calculated capacity of the aquifer.

- When operating the pumping station, try to avoid short-term switching on in order to extend the life of the pump.

- Annual scheduled inspection and check of the technical part (filters, tanks, pump and the caisson itself).

Sealing the casing

Dust, rain, melt water and condensate formed in the caisson well should not enter the underground source. Otherwise, harmful microscopic organisms will penetrate the well. To fix this, you will have to spend a lot of time and money. Therefore, even during the development of the project, protection of the casing is provided. A borehole head is used for this purpose. It is a special steel cover. The product has holes for communications. The steel cover is also equipped with a hook, which is designed for hanging the pump unit.

What to do after drilling

So, they drilled a well with an auger and blew it out to clean water, what should I do next? The first step is to install a well pump and use well water for at least a few days. This is necessary to make sure that the well does not become sandy and does not run out of water.

We are waiting for the drilled water well to be pumped

I will write a separate article about how to independently measure the flow rate of a well and select a pump.

Only after you have made sure that everything is fine with the well, the water comes out clean, there are no grains of sand in it, you can equip it. There will be a separate article on how this is done. After flushing the well, be sure to do a water analysis .

Video description

For installation of one of the heads, see the video.

The selection of a special well cap is carried out taking into account the diameter of the casing pipe. The head package includes a rubber crimp collar. It is used to seal the casing. To enter the electrical cable and water pipe, the special cover also provides sealing elements.

Experts do not recommend cutting the casing to the level of the caisson well floor. Otherwise, it will be inconvenient to install a pumping unit with a head and the likelihood of contaminated water entering the well will increase if the protective structure is flooded. It is recommended to cut the casing at a distance of at least 25 cm from the caisson floor.

Arrangement options

At the moment, the following 3 methods of constructing wells are widely used - with a caisson, an adapter or a head. The choice in favor of one or another option is made after drilling a well and studying the wishes of the customer.

Using a caisson

A caisson is a waterproof chamber made of metal or durable plastic. The container looks like an ordinary barrel. The volume is usually equivalent to a standardized RC ring of 1 m. The product is buried in the ground and is used to solve the following problems:

- protection from water and dirt;

- ensuring that equipment is kept at above-zero temperatures all year round;

- frost prevention;

- ensuring tightness;

- year-round well operation.

First, a pit is dug out. Depth - up to 2 m. Then a hole is cut below for the casing pipe. The container is lowered into the hole and placed in the center of the well. The casing is cut and welded to the bottom. At the end, the product is covered with soil. Only a hatch is visible on the surface.

Operating the adapter

Construction of a water well involves leading the water supply directly through a cased column. The pipeline is laid below the freezing depth of the soil masses. The element itself is manufactured in the form of a threadless pipe connection. One end of the device is rigidly fastened to the casing, and the other is screwed into the pipe connected to the submersible pump.

If necessary, downhole equipment can be easily removed for replacement or repair.

Application of heads

Elements are created either from plastic or metal. The devices consist of covers, connecting flanges and rings made of rubber. Installation does not involve welding.

Installation begins with cutting the casing pipe. Then the pump is lowered and the cover is put on. The flange and rubber seal rise to its level. Fastening is done by tightening the bolts.

Video description

The following video describes the installation of the downhole adapter in detail.

The downhole adapter is located below ground level. Therefore, when maintenance is required, which is carried out very rarely, excavation work must be carried out to gain access to the device.

An adapter is a special fitting consisting of an internal and external part. The external part is designed to connect the pipeline through which water will flow into the house. The internal part of the adapter is located in the well. It is designed to connect a pipe from a submersible pumping unit. When connecting both parts, hermetic seals are used.

Important! The borehole adapter is installed below the freezing point of the ground. Only a small part of the casing remains on the surface. It is closed with a special lid through which the power supply cable for the submersible pump is inserted.

Installation of downhole adapter Source svayburvod.rf

Do-it-yourself plumbing according to the diagram

Let's look at the water supply system step by step using the collector connection method as an example:

- A shut-off valve is installed after the storage tank, followed by a tee.

- In the tee, the water flow is divided into two directions - for the filtration system and for other needs that do not need purified liquid (watering the garden, washing a car, washing machine).

- Water is supplied to a deep filter.

- Then a tee is installed, from which the cold and hot water line is supplied. It goes into the heater and is then distributed.

Briefly about the main thing

Modern arrangement of a well in a country house or area with a cottage is carried out to protect the water source, equipment, and pipeline system from dirt, precipitation, dust, the negative effects of low temperatures, melt and rain water. To do this, the installation or construction of a protective structure is carried out. It can be above ground level or in the ground. One of the options is also to arrange a special technical room in the house. Regardless of the option, it is used for installing a pump, accumulator and automation.

Ratings 0

Pipeline installation indoors

- The installation of the pipeline should begin after approval of a detailed plan for its passage through the building and the surrounding area. During its development, you can easily identify difficult areas and carefully work them out in advance, because it is easier to solve difficulties at the development stage than to lay a new trench. In addition, a detailed drawing will make it possible to draw up a more specific estimate, which also contributes to significant savings and reduction of unforeseen expenses.

- When laying a pipeline inside walls in grooves, remember that the cold water pipe must be below the hot water pipe. This prevents condensation from entering and prevents heating.

- Installation of a water supply system begins with laying a cold water line, starting with connecting the pipe to the inlet into the house. After this, it is connected to the hydraulic accumulator, then through a tee it goes to the water treatment system and then to consumers.

- The pipe from the coarse filter is led to the bathroom, where it is connected to the toilet cistern. There it is connected to the system through a tee and an additional shut-off valve, then the water is distributed sequentially among all users. Also with shut-off valves at each drainage point.

- The installation of a hot water supply system is carried out in exactly the same way; the only difference is the presence of a larger number of points for attaching the pipe to the walls to prevent sagging.

- After laying the lines and securely fastening them to the walls, you can begin to install plumbing equipment: sink, shower, washbasin.

- After installing all the equipment, it is highly advisable to perform a pressure test of the entire system and check the operation of the drain.

Filters for water

The incoming water from the well contains mechanical and mineral impurities. Pump filters handle large particles, but complete cleaning requires the installation of an additional filtration system. It is selected based on water analysis. Filters can reduce the concentration of iron, calcium, magnesium, and manganese salts. To do this, they use technology that works on the principles of reverse osmosis, ion exchange, and iron removal.

It is recommended to assemble the entire installation kit before starting work on the well construction. This will eliminate unnecessary downtime and ensure reliable installation of all sections of the water supply system.