The quality of water from a well or borehole often does not satisfy the owners of dachas, private houses and cottages. This water can be used for irrigation, but not for drinking. The question arises - how to purify water? For this purpose, modern water treatment and water purification systems are used. The aeration column is the first element of the system with a cylinder.

The aeration column is one of the important components of water purification systems. Thanks to it, the water is saturated with air, which leads to the removal of gases dissolved in the water (mainly hydrogen sulfide H2S) and the oxidation of iron before the water is supplied to the deferr filter.

Let's consider the types of aeration, as well as the composition, purpose and principle of operation of the aeration column. How to select and assemble equipment and when should it be serviced?

- Types of water aeration Pressure

- Non-stop

- Ejection

The principle of water purification

The process of removing iron and other unnecessary elements from water is that the ferrous iron contained in the water must be changed to ferric iron, which then accumulates in the form of rust and dirt at the bottom of the container.

As everyone knows from the school chemistry curriculum, divalent iron becomes trivalent in the process of oxidation with oxygen.

Also, an additional advantage to the oxidation of iron will be the purification of water from hydrogen sulfide and other undesirable chemical elements.

Types and characteristics of used superchargers

The work process of compressing and moving air is ensured by periodically changing the internal volume of the device chamber. The principle of oxygen injection is decisive when dividing compressors into types.

Screw

The working pair consists of two rotors with multidirectional profiles of their surfaces, reminiscent of a meat grinder screw.

The meshing rotors rotate in a sealed chamber and compress the incoming air by sealing the gaps between the housing and the screw pair. Then the exhaust valve opens, and air is briefly released to the compressor outlet. The valve setting, the frequency of the profile turns and the area of the teeth determine the frequency of air release and the magnitude of its pressure.

Advantages of screw structures:

- Durability of working screws made of high-strength steel.

- Economical energy consumption.

- Work with minimal vibration.

- Small dimensions.

- Good controllability of automatic systems.

Self-installation

Water aerator installation diagram. (Click to enlarge) In order to create conditions for maximum interaction of water with oxygen, you will need to assemble a simple aerator.

The basis of the aerator will be a simple tank (it is better to choose a container made of food-grade polyethylene), which is best placed in the attic of the house.

It is advisable to buy a tank of as large a volume as possible, so that in case of emergency there is a supply of water for several days. Keep in mind that you can use a maximum of 75% of the available water, because suspended matter and sediment collects at the bottom.

Water enters the container directly from a well or well, bypassing the solenoid valve. The valve should be chosen larger to obtain better pressure, and therefore faster filling of the tank.

Read an informative article about aerators for water mixers here.

Additional aeration

For faster oxidation of iron and high-quality aeration of water, it would not be superfluous to install a compressor in the tank (an aquarium one is quite suitable).

There are many ways to secure the compressor, and we will not dwell on this.

It is important to ensure that the compressor nozzle (air diffuser) does not touch the bottom, otherwise this may harm the subsequent operation of the aerator.

To prevent dust from entering the storage container, you must ensure that there is a lid. If a lid was not included with the tank, you should make it yourself from food-grade plastic or stainless metal.

Draining water from the storage tank

Since sediment accumulates at the bottom of the container, it would be more correct to place the tap for draining water into the water supply of the house at a distance of 15-20 cm from the bottom.

And you can always adjust the water supply parameters by bending the inner section of the pipe in the desired direction.

To drain sediment and rust, you should carefully make a hole with a diameter of about 10-15 cm in the bottom of the tank and install a tube with a drain valve into it.

Read the article about domestic pumping stations for a private home here.

And in this article you can read about the types of deep well pumps.

Additional water filtration

Flow-through filter for mechanical water purification When the water in the tank has stood for at least a day, all the rust should already have accumulated in the form of sediment at the bottom of the aerator.

If the concentration of iron in the water is excessively high, then it would be better to additionally install a mechanical water purification filter.

And remember that the larger the diameter of the filter mesh, the lower the resistance of the incoming water.

That's basically all you need to get water of acceptable quality from a well or borehole. Reviews about this aerator vary, but most people claim that using it at the dacha or in a village house is quite convenient and the quality of the filtered water is satisfactory. And the cost of components for the aerator more than pays off in one season.

By making an aerator for water filtration, you not only purify the water from iron, hydrogen sulfide and other impurities, but also get a container with a supply of water for several days, in case of unforeseen circumstances.

Watch the video in which an experienced user explains in detail how to make a water aerator from a well with your own hands:

Source: septik.guru

Briefly about water in general

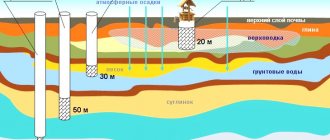

Resource extraction is carried out from different layers of soil

- Verkhovodka

- Water from sandy soil (the well is drilled to a shallow depth)

- Artesian water

Surface water

- Verkhodka contains organic iron.

- Lignins and tannins

- Compounds with humic salts

- Bacterial substance (bacteria transform divalent particles into trivalent ones)

The amount of iron impurities in perishable water does not exceed the norm too much, but is higher than the MPC (maximum permissible concentration). Remove humic iron compounds from such a liquid.

Well on sandy soil

The soil layers of this type of source contain oxygen, with the help of which bacteria change the valence of iron. The resource extracted from sandy soil layers is close in composition to perched water, which allows it to contain humates.

Limestone wells (artesian)

The resource from the artesian basin is environmentally superior to water extracted from sandy soil and high water. The impact of the environment on it is minimal. Depth of occurrence is from 50m to 200m. However, the water contains iron salts and minerals in excess quantities. This happens due to the interaction of water with certain types of soil. Considering the depth, and it is not small, the access of oxygen is limited, and accordingly the source is filled with divalent iron.

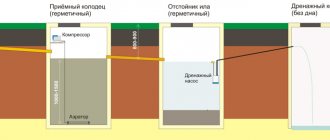

Non-pressure cleaning method

When using this cleaning method, water is supplied to the aeration column through nozzles, therefore it enters in the form of small drops, and thus oxygen saturation occurs.

In addition, with the help of a special compressor, the water is additionally saturated with oxygen, while air is supplied into its thickness. When using this method, due to the spraying of the water flow at the outlet, its pressure decreases. To eliminate this drawback, you can additionally purchase a pumping station, and in the case of a well, you already have one.

Oxidation products settle at the bottom of the tank, so it needs to be cleaned periodically, this should be done at least once every 3 months, but it all depends on the degree of water contamination.

A non-pressure aeration system consists of the following components:

- sealed tank with a capacity of 400-700 l;

- nozzles through which the incoming liquid is sprayed;

- compressor with aerators and air supply device;

- pumping station;

- hydraulic accumulator;

- filters;

- system control unit.

How to purify water

You can reduce the concentration of iron compounds yourself in several ways. The cleaning method depends on the volume of liquid consumed and how many impurities it contains.

Advocacy

The easiest way to clean a resource extracted from a well. An additional water reservoir is built, designed for the volume of expected liquid consumption per day, and sedimentation occurs in it.

pros

- A simple method that does not require large expenses

- There is always a supply of clean water.

- Installing the tank in the attic will create a gravity flow. And it will rid the water of hydrogen sulfide.

Minuses

- Cleaning is not complete

- The container must be cleaned periodically, which is not very convenient, since it requires disconnection from the system.

- Carefully monitor the amount of liquid consumed.

Aeration

Self-purification of liquid from metal impurities using aeration will give a good result. How does the work process proceed? The resource, enriched with oxygen, interacts with the metal, as a result of which an oxidation reaction is formed and organic iron settles as a sediment.

The deposited sediment at the outlet after cleaning is captured by mechanical filters.

- Gravity - Water comes into contact with oxygen to the maximum, this happens due to atomization. Sprayers move liquid into a reservoir. For more productive cleaning, if necessary, a compressor is installed in the container.

- Pressure type of cleaning - involves the entry of liquid into the system under high pressure. Working in parallel, the pressure and the compressor create bubbling and foaming, which allows the liquid to come into contact with air as much as possible.

In addition to removing iron, the aeration method gets rid of hydrogen sulfide.

- The main advantage of this cleaning is environmental friendliness. The process eliminates the use of reagents.

- Flaws. There is still a certain amount of iron left in the water. The operation of the system depends on the availability of electricity. The container and filters must be cleaned periodically.

Ozonation

The process is effective but labor-intensive.

It is almost impossible to purify water yourself using this method.

The use of chlorine is becoming a thing of the past. After cleaning using this reagent, it partially remains in the liquid and is harmful to humans and the environment.

Ozonation is considered to be the most reliable method, the effectiveness of which is created by the action of ozone and its derivatives on the impurities contained in water.

Organic iron is removed from a liquid by cumulative action. The process of purifying fluid extracted from a well by ozonation is quite complex. Requires installation of expensive equipment. An accurate calculation is required for productive work; it is very difficult to do it yourself (you need to calculate how much ozone is needed and the time of its exposure to water in accordance with the amount and type of impurities it contains).

Ion exchange

This cleaning is carried out using filters containing resin and free ions. As the water passes through the filter, the sodium ions exchange places with the iron ions. Therefore, the method is called ion exchange.

When the filter has used up all its resources, they must be restored.

Reverse osmosis

Purification of water from iron and impurities is done with a filter containing a membrane; it is this membrane that carries out filtration at the molecular level. The reverse osmosis method of iron removal is considered the most productive. Dissolved particles are removed. To improve the quality of filtration and stop the failure of the membrane, it is necessary to pre-clean the water with mechanical filters.

Attention. Membrane cleaning removes all salts completely, which is why mineralizer blocks are installed.

Reverse osmosis completely purifies water from all types of contaminants. The method is the most effective, but very expensive.

Microfiltration, nano- and ultra-membranes work similarly to reverse osmosis.

Introduction of Reactants and Catalysts

The use of chemical reagents for deferrization of liquids is mainly used in industry. Additional purification of the liquid is necessary. Chemical compounds must be removed. The principle is similar for all purification systems - a chemical reaction occurs between the iron and the reagent, resulting in the formation of a precipitate.

Catalysts are used together with aerated water or with the use of reagents for the oxidation of iron.

The catalytic method of iron removal from water occurs using filters containing material with catalytic properties. Water passes through porous fillers, which provide high-quality cleaning.

Source: iseptick.ru

Application for removal of dissolved gases

Everyone knows that carbon dioxide contributes to the destruction of pipes, and hydrogen sulfide saturates the liquid with the smell of rotten meat. In order for water to acquire high quality indicators, it is necessary to get rid of unwanted gases in its composition. This process is called degassing. This eliminates ammonia and its residue, as well as nitrogen oxide and hydrogen sulfide.

In order to maintain the purity of water in ponds, bottom aerators are used, which significantly improve the physical and chemical parameters of the reservoir Source Sveklon.ru

A chemical method of removing gases is resorted to when it is impossible to process compounds in a gaseous state or when their content in water is low. However, such degassing is characterized by the complexity of the process, the high cost of reagents and the risk of damage to the liquid due to an incorrectly calculated dose of the substance. These reasons have led to low demand for the procedure.

Aeration is considered a physical method of degassing. It aims to minimize the partial pressure of gas upon contact with liquid.

Types of degassers

The following types of degassers are distinguished:

- film They have a columnar structure with nozzles. Water flowing through the nozzles comes into contact with air over a large area. The material used to make devices in the form of rings is ceramic, wood or plastic;

- vacuum The principle of operation is to use a vacuum pump to bring water to boiling water without changing the air temperature;

- bubbling Air under pressure greater than atmospheric pressure is passed through the liquid;

- thermal. As the water temperature rises, the unwanted gas evaporates.

Before aeration, it is recommended to settle the water from the well, for which the simplest tanks with a float system are made Source Remont-book.com

Film devices are considered cost-effective, are small in size and highly reliable. The operation of such degassers is based on the supply of air through a fan to slowly flowing water. After contact with gas bubbles, the liquid ends up in a special container, from where it is removed through a water seal.

Degassers using compressed air consume a large amount of energy and, as a result, are rarely used.

How to deferrize water

The quality of drinking water leaves no one indifferent. Residents of cities and holiday villages have long been accustomed to the fact that tap water is not suitable for drinking.

It contains a huge number of various impurities that can harm human health. People are forced to resort to a filter to purify water and buy water, the quality of which may also have some doubts.

Aeration of wells - features of aeration, types of cleaning methods, why aeration of wells is needed

Compressor-aerators for wells and boreholes effectively purify water from various harmful impurities that it may contain.

Aeration of wells is especially popular in places where the water has a high iron content. Such impurities can negatively affect not only human health, but also the performance of mechanisms. The essence of the well aeration method is to actively saturate the water with oxygen. Due to the influence of oxygen, most of the harmful impurities precipitate, after which the chemical composition of the water is brought back to normal.

Why do you need to deferrize water?

Water deferrization plant.

Almost throughout the entire territory of Russia, there is an excess of iron content in water. Such water from wells, wells and water supply networks has an adverse effect on the condition of the skin and blood composition, and can often cause various types of allergies. It comes out of the tap with increased turbidity (image 1), and is colored yellowish-brown. It cannot be used for drinking. In technical devices and in heating and water supply systems, it causes flaky precipitation that harms pipes and tanks.

Iron impurities cause rusty stains on the surface of sinks and bathtubs that are difficult to remove. In medical institutions, this significantly impairs the performance of some devices. All this is the reason for taking measures to remove iron from tap water. In some cases, it is enough to use a special filter to remove iron from water; in other cases, more complex installations will be needed.

How to deferrize water?

Iron in water from wells and other sources can be contained in different forms and quantities. There is no single method for removing it today. There are several ways to deferrize water from a well or other source:

Water purification using airlift.

- Common to all methods is preliminary preparation for the process of deferrization of water. To do this, it can be mixed to saturate it with oxygen, add alkali, or carry out chlorination or ozonation. As a result of a chemical reaction, divalent iron is oxidized and passes into the trivalent state. In this form, iron-containing products can be removed by settling and filtration.

- Very often, water from wells is purified from iron using the catalytic method. Its use accelerates the process of iron oxidation and its transformation into the trivalent state. Oxidation occurs in a special tank with bulk filters, which are constructed from highly porous materials. In them, the transformation of iron from one state to another occurs. Oxidized ferric iron settles and remains inside the porous filter. This method can remove iron particles up to 10-25 microns in size from water. Smaller fractions need to be removed additionally.

- The aeration method is used in different versions. It can be carried out by gushing with special spray installations, spraying water into containers (showering), introducing air into the water using atmospheric pressure changes, using a compressor. Often the aeration method is enough to make water from wells drinkable.

- Addition of strong oxidizing agents. This method accelerates oxidative processes and works more efficiently than aeration. Oxidizing agents destroy iron compounds and convert them into trivalent form. The most common oxidizing reagent used in our country for disinfection and iron removal of water from wells and wells for more than 100 years is chlorine.

- The method of chlorinating water with chlorine gas is quite effective. But it also has disadvantages. Liquid chlorine is highly toxic. Delivering it to the chlorination site presents certain problems. But this is to some extent compensated by the fact that chlorine is capable of destroying hydrogen sulfide, divalent manganese, and many other substances of organic origin.

- Water treatment with sodium hypochlorite is used using special dispensers. This procedure does not affect water hardness. Sodium hypochlorite can be obtained directly at the site of water treatment from table salt.

- Water purification using ozonation does not pollute it with by-products formed as a result of chemical reactions. The entire ozonation process can occur automatically. Ozone is obtained at the site of water treatment from technical oxygen and ordinary air from the atmosphere. During the process of ozonation, a huge number of gas bubbles are released, some of which float to the surface, the other part dissolves in water and oxidizes it.

- A filter based on synthetic ion exchange resins works very efficiently. It copes with a fairly high iron content. Its disadvantage is that it quickly becomes clogged, requiring replacement of filter elements.

Rating of quality compressors for septic tanks and ponds 2020-2021

Our list is compiled based on real reviews, it takes into account the opinions of customers familiar with the product and its functions. Here you will find photos and comparison tables.

Inexpensive

Secoh Air Pump SLL-30

The Secoh membrane installation is designed specifically for continuous operation inside the Tank, Topas, Topol and other treatment plants. "Secoh Air Pump SLL-30" has low power and is used for filling ponds and aquariums with oxygen. The unit has an electric motor consisting of a core located in the field of two magnets. The main design element is rubber membranes that generate air in the system.

Significant advantages of the device include its mobility, light weight and waterproof, soundproof casing. When purchasing a Secoh device, you will not need to take additional care of lubrication, since the machine’s chamber, the muffler (located at the bottom of the body), is designed in such a way that the air stream at the outlet will not pulsate.

Equipment:

- manual;

- 12 month manufacturer's warranty;

- integrated thermal relay;

- connecting pipe.

Areas of application:

- aeration of septic tanks, mobile sewers, ponds, aquariums;

- medical or laboratory use

Technical indicators:

| Options | Characteristics |

| Manufacturer | Secoh |

| Weight | 4.50 kg |

| Dimensions (L x W x H) | 254.00 x 177.00 x 176.00 mm |

| Guarantee | 1 year |

| Voltage, V | 230 |

| Operating pressure | 12.7 kPa |

| Country of Origin | Japan/China |

| Noise, dB | 32 |

| Productivity, l/m | 34 at 150 mbar |

| Power consumption, W | 27 |

Secoh Air Pump SLL-30

Advantages:

- built-in overload protection;

- energy saving;

- noiselessness (30 dB), will not attract attention in the garden area (no louder than the ticking of a wall clock);

- The warranty period is 12 months.

Flaws:

- not detected.

Pondtech A-30

"Pondtech A-30" is an aerator that can provide oxygen to a pond, increasing the chances of preserving the vital activity of flora and fauna inside the reservoir. The unit is able to slow down siltation and water pollution. "Pondtech A-30" has a low noise level and meets all requirements and regulations. The device can work outdoors, it is easy to use, and has a long service life. “Pondtech” is a multifunctional device, used inside aquariums, ponds, septic tanks, and suitable for smokehouses.

Technical indicators:

| Options | Characteristics |

| Voltage, V/Hz | 220/50 |

| Dimensions (H x D x W), mm | 180 x 150 x 135 |

| Power, W | 15 |

| Number of outputs, pcs | 1 |

| Capacity, l/min | 25 |

| Pressure, MPa | 0.03 |

| Suitable for pond, m3 | 20 |

| Material | ABS plastic |

| Pumping depth, m | 2.5. |

| Noise level, dB | 38 |

Pondtech A-30

Advantages:

- noiselessness, membrane design;

- the casing of the unit is resistant to ultraviolet radiation, made of strong ABS plastic with 2nd sound insulation;

- "Pondtech" has anti-vibration mounts;

- Energy consumption;

- attractive design;

- The air flow is adjusted using an external tap;

- continuous operation 24/7;

- the design can work outdoors if protected from rain;

- comfortable use, long service life;

- official warranty - 1 year.

Flaws:

- not detected.

Jecod PA-60

The PA Jebao series multi-functional air units have been designed for water-related applications. All devices of the “PA” line operate from a standard electric current of 220 V and are equipped with a power cord 1.8 meters long. The oil-free engine is specially designed for efficient operation, saving energy. If you are using it outside, it is recommended to cover the unit to protect it from the elements.

Technical indicators:

| Options | Characteristics |

| Performance | 60 l/min |

| Power consumption | 38 Watt |

| Noise level, dB | 35 |

| Weight | 3.8 kg |

| Included | Passport, compressor, adapter |

| Country of Origin | China |

Jecod PA-60

Advantages:

- low noise level (35 dBA), double damping absorption system;

- the engine saves 30% energy thanks to the new “eco energy” technology;

- aluminum alloy body;

- pressure is 40% higher than that of competitors’ devices;

- mobility;

- Comes with 8-output 1/4" divider;

- Ideal for a variety of water related needs.

Flaws:

- not detected.

Boyu ACQ-007

The Boyu ACQ professional line of machines is modern, powerful and efficient compared to its competitors. Its 4 models cover power from 70 to 150 W, consume from 60 to 150 l/m, generate a nominal pressure of up to 0.035 MPa. These parameters allow aeration of densely populated aquatic systems for ornamental or consumer aquaculture, ponds or professional aquarium systems with a capacity of up to 20,000 liters.

The device has a brass fitting and a manifold for 10 4/6 mm outlets. “Boyu ACQ” has a metal outer casing, which ensures increased strength of the equipment, a practical handle made of high-quality ABS plastic. When purchasing this unit, you will not have the question: “how to install the product?” Due to the supports, it can be secured with screws.

This device is designed using "CAD" computer program and is manufactured under strict quality control offered by . In all professional systems, power, reliability and cost-effectiveness are the determining factors. This is achieved by an oil-free AC motor that uses permanent magnetic induction technology and a single piston system. This design provides high efficiency at the appropriate pressure. The motor runs smoothly and is very reliable.

The Boyu ACQ compressor line guarantees equipment durability at virtually zero cost. In addition, like any other product, the product has excellent warranty service and a reliable supply of spare parts.

Technical indicators:

| Options | Characteristics |

| Frequency | 50/60 Hz |

| Consumption | 75 W |

| Length of cable | 189 cm |

| Maximum pressure | 0.035 MPa |

| Consumption | 100 liters per minute |

| Number of outputs | 10 |

| Dimensions (Length x Width x Height) | 225 * 140 * 195 mm |

| Accession | 9/12 |

| Operating temperature °C | 0-40 |

| For aquariums | Up to 12000 liters |

Boyu ACQ-007

Advantages:

- the product is made of modern materials;

- replaceability of all parts;

- oil-free engine.

Flaws:

- not detected.

Average

Hailea VB-1200G

The device "Hailea VB-1200G" was released by a popular Chinese company founded at the end of the twentieth century. This is an effective, economical vortex air flow generator, which differs from the membrane, piston design in greater productivity. The device is used for aeration of large wastewater treatment plants and ponds. In addition to the above functionality, the mechanism can work as a vacuum pump, packaging padding polyester.

By generating a powerful flow of clean air, Hailea VB-1200G forms the necessary concentration of oxygen inside the reservoir. This is necessary for the survival of bacteria in wastewater treatment plants; they provide the necessary biogenesis inside the pond. The three-dimensional impeller design together with sectional stabilizers generate a silent air flow.

A powerful, stable motor with low torque consumes a small amount of energy compared to analogues from competitors. “Non Oil” technology eliminates the use of oil during engine operation, which guarantees maximum purity of the generated stream. "Hailea VB-1200G" has an attractive design, mobility, durability, and ease of maintenance.

Technical indicators:

| Options | Characteristics |

| Official guarantee | 1 year |

| Manufacturer country | China |

| Type | Vortex |

| Aquarium, l | 79 000 — 160 000 |

| Pond, l | 79 000 — 160 000 |

| Septic tank, m³ | 65 |

| Productivity, liters per hour | 79000 |

| Power, W | 600 |

| Mains voltage, V | 220V, 50Hz |

| Noise level, dB | 65 |

| Number of channels | 1 |

| Pressure | 0.019 MPa |

| Flow adjustment | — |

| Portability | — |

| Outdoor cord | + |

| Dimensions, cm | 31*31*32 |

Hailea VB-1200G

Advantages:

- versatility, used inside large aquariums, ponds, septic tanks, fish farms, ventilation systems, refrigerators;

- used as a vacuum pump;

- efficiency, economy;

- “Non-Oil” technology allows not to use lubricants;

- three-dimensional impeller design;

- motor with low torque;

- adjustment of the air flow is carried out using external taps;

- the device can operate 24/7.

Flaws:

- not detected.

Airmac DB-80

Airmac equipment is imported to Russia from Taiwan. It is attached inside the septic systems “Topac” and “TopAero” produced by them. The machine has proven itself to be an advanced equipment; it has superior rated power than competing brands, has high-quality assembly, and low levels of vibration and noise. Airmac has a sealed casing designed specifically for the Russian climate.

The Airmac engine operates using electromagnetic oscillations, which helps reduce wear of parts to a minimum. The design of the mechanism provides for the complete absence of rubbing elements, which, coupled with excellent quality spare parts, makes the equipment of this brand one of the most reliable on the market.

Airmac devices can be installed in any brand of septic systems (Topol, Tver, Deca, Bioksi, Ubas). The product has high performance indicators and is interchangeable with most well-known brands. The machine is ideal for upgrading your autonomous sewer system; it will significantly improve the level of wastewater treatment. Airmac is one of the most reliable devices sold on the Russian market.

It is important to note that inspection and repair of mechanism parts is necessary every 2 years. If you skip maintenance, performance may decrease, vibration and noise will increase, which will subsequently cause breakdowns and failure of the entire structure. In addition to septic tanks, Airmac DB-80 is used for aeration of reservoirs, in medical institutions, and during physiotherapeutic procedures. The design has been tested by time, most consumers give laudatory reviews. The unit is used to supply air inside:

- biological treatment systems, septic tanks;

- local treatment structures;

- autonomous sewers;

- for aeration of ponds at fishing enterprises.

Technical indicators:

| Options | Characteristics |

| Voltage | 220 V |

| Operating pressure | 150 Mbar |

| Performance | 84 l/min |

| Noise level | 37 decibels |

| Weight | 7 kg |

| Manufacturer country | Taiwan |

| Dimensions | 207 × 178 × 206 cm |

Airmac DB-80

Advantages:

- multifunctionality;

- powerful electric motor;

- acceptable price.

Flaws:

- not detected.

Hiblow AIR XP 80

We bring to your attention a professional, top-class Hiblow device with high performance and high-quality membrane construction. “Hiblow AIR Pump XP 80” can be used by commercial enterprises with strict ventilation requirements; the main advantage of the product during its operation is the absence of odors and the tightness of the housing.

The unit is mobile, lightweight, and has a reliable membrane. "Hiblow AIR Pump XP 80" with a volume of 80 liters is suitable for wastewater treatment. The product comes standard with built-in thermal protection against overheating. The product has rubber feet to prevent vibration.

Technical indicators:

| Options | Characteristics |

| Model | TAKATSUKI Hiblow XP 80 |

| Rated Voltage Volt/Hz | 230/50 |

| Normal pressure generated | 147 mbar |

| Air volume (air flow) | 80 l/min |

| Power consumption | 58 W |

| Noise level | 36 dBA |

| Dimensions | W 132 x D 208 x H 186 mm |

Hiblow AIR XP 80

Advantages:

- high performance with minimal power consumption, easy startup;

- No oil required, providing clean, stable airflow;

- absence of vibration and noise thanks to the muffler;

- simple design, ease of maintenance, ergonomics;

- durability, reliability, resistance to voltage surges;

- price quality.

Flaws:

- not detected

Expensive

Aquaviva BL 60-2

We bring to your attention the low pressure unit “Aquaviva BL”. This is a reliable device designed to generate air flow inside ponds, septic tanks, swimming pools or spas. The single-stage “Aquaviva BL” operates thanks to the rotation of the impeller.

The housing, together with the main structural elements and the impeller and blower, are made of strong aluminum alloy. The Aquaviva BL engine does not require lubrication, ensuring an environmentally friendly environment during air generation, does not pollute the pond, and you do not need to purchase a filter. The mechanism is characterized by easy operation, installation, and excellent build quality.

Technical indicators:

| Options | Characteristics |

| Productivity, m3/h | 318 |

| Produced pressure, bar | 0.02 |

| Voltage, V | 220 |

| Power, kW | 1.3 |

| Insulation class | F |

| Protection class | IP 55 |

| Weight, kg | 18 |

| Connection input/output, inch | 1″ ½ |

| Electric motor | With cooling |

| Thermal protection | + |

Aquaviva BL 60-2

Advantages:

Advantages:

- the casing is made of aluminum;

- The design of the electric motor provides cooling and thermal protection.

Flaws:

- not detected.

Secoh JDK-250

"Secoh JDK-250" has a number of advantages, including efficiency (significant reduction in electricity during operation), low noise level, and simple maintenance. The device's motor operates from the mains, providing a high level of efficiency.

Thanks to the simple but robust design of the device, you can successfully use it for a long time. Secoh machines of the SLL, EL series have thermal fuses that protect the device from overloads. If the device heats up above 130°C, the mechanism stops; after cooling to 120°C, it starts again in automatic mode. An important advantage of the Secoh JDK-250 machines of the SLL and EL line is the waterproof casing.

The mobile "Secoh JDK-250" can be used to treat fishery reservoirs, small ponds, treatment structures, septic tanks, where pneumatic aeration is possible. The productivity of this device is 250 l/minute. The noiselessness of the Secoh JDK-250 allows it to be placed inside a residential complex or garage. With proper care, the machine can last 4-6 years.

If a situation arises in which one of the device’s membranes breaks down, the protection system is activated, after which the device stops. This is important to preserve the magnetic core of the mechanism, which is subject to additional stress when one of the membranes ruptures. To fix the problem, you need to go to a service center to have the unit repaired.

Technical indicators:

| Options | Characteristics |

| Capacity, liter/min | 280 |

| Pressure, mbar | 150 |

| Noise level, dB | 48 |

| Air pipe, Ø mm | 26 |

| Power consumption, W | 225 |

| Dimensions, mm | 230x180x240 |

Secoh JDK-250

Advantages:

- energy saving;

- overload fuse;

- warranty up to 2 years;

- low noise level;

- there is no need to lubricate the engine;

- structural strength.

Flaws:

- not detected.

Substances for deferrization of water

Cartridge filter for mechanical water purification.

Various materials are used to purify, disinfect and deferrize water from a well or a well. The most common synthetic material used in catalytic cleaning is Birm. This porous substance is lighter than water. It easily removes contaminants, including iron. In combination with chlorine, this material loses its properties. Therefore, when using it, chlorination is not carried out.

Some natural substances are used as backfills during catalytic purification. These are dolomite, glauconite, zeolite and other minerals. Based on them, backfill materials MZhF, Damfer, and Magnofilt are produced. When using Magnofilt, the water should not contain hydrogen sulfide or oils. The pH level should not exceed 8.5. The presence of chlorine reduces the effectiveness of Magnofilt.

Dampher contains a certain amount of copper and silver, which enhance the effect of this composition. It additionally purifies water from heavy metals, sand and clay.

Greensand is not exposed to various microorganisms. The water does not need to be disinfected after treatment. Its disadvantage is the high content of potassium permanganate.

The material for water purification MFO-47 is in great demand. This is a relatively new catalytic sorbent. Expanded clay, quartz sand, and dolomite are used for its production.

Conditions for independent water deferrization

Technological scheme of water purification.

To perform the procedure for deferrizing water at home, you must:

- Provide water supply using a circulation pump.

- The filter must be installed in a warm room.

- For normal operation, the filter must clean at least 200 liters of water per week.

- Iron deferrization of water can be carried out by settling it in a glass container.

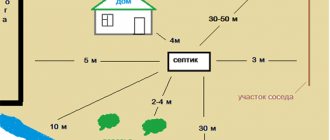

For an individual house, on the site of which there is a well or well, you can independently manufacture a system that ensures the accumulation of water, its deferrization and the destruction of bacteria (image 2). Such a filter for deferrizing water cannot be used if the water supply system contains metal pipes, pipes, couplings and other parts. The pipes must be metal-plastic, and all fittings must be made of stainless steel or brass.

The main part of the installation is a duralumin container with a capacity of 100 liters. Under the action of a pump, water is supplied to the A4 sprayer and sprayed into the container. Element A1 ensures the concentration of ozone in the tank. Water from O1 is supplied for filtration. The well is equipped with a pump that supplies water to O2. Oxygen or air is supplied to the tank through the O3 pipe. To control the water level in the tank, pipes O4 and O5 are used. They are connected by a transparent silicone hose. A2 – check valve. Water is pumped from the tank by pump A3.

The quality of life and health of a person is largely determined by the quality of the water he uses for drinking and cooking.

Purifying water with your own hands and removing iron from it is an important condition for maintaining health.

For this purpose, various types of treatment facilities are used to prepare water on an industrial scale. In private houses, cottages and apartments, it is recommended to install a filter of any design. It will provide residents with clean water for a long time.

Source: moyaskvazhina.ru

The water that we are accustomed to, observing it in nature - streams, rivers, seas - is in a bioregulation system. Bacteria and aquatic plants purify water from dissolved substances, making it suitable for life of insects, fish, birds, animals and humans, of course.

When we take water from a well, a well, or any other underground source, we habitually expect to receive clean water.

However, iron, manganese, organic matter, hydrogen sulfide (these are the main pollutants, there are many others) make our water unsuitable for drinking and domestic needs.

HOW IT WORKS?

A small amount or complete absence of oxygen dissolved in water is a common feature of all underground water supplies. But all these sources have one more characteristic feature - such water contains dissolved substances:

- metals, mainly iron and manganese,

- organics - fulvic acids, humic acids, anthropogenic substances (from human activity)

- bacteria and other microorganisms,

- dissolved gases - hydrogen sulfide, ammonia, chlorine

Water with dissolved metals and other substances comes out of the well absolutely transparent, has the taste of iron and/or the smell of iron and hydrogen sulfide. Being in an open container, over time, the water becomes cloudy, acquires color, and after some time (hours or days) the water becomes clear again, and a red or white sediment forms at the bottom. This is due to the fact that water is very quickly saturated with atmospheric oxygen and metals dissolved in water are oxidized (attach an OH ion) - they pass from a divalent (dissolved) to a trivalent (undissolved) state and form colloids - large clumps of molecules that however, they are still too small for us to see with our eyes. Therefore, water containing colloidal iron appears cloudy and colored to us.

Colloidal solutions are dispersed systems - sols. These are stable suspensions because their particles have the same charge and electrostatically repel each other. Therefore, the water can remain cloudy for days, and sometimes for months.

Typically, in warm, stagnant, oxygenated water, aerobic bacteria begin their work very quickly. They enter the water from the air, attack colloidal substances and absorb them, integrating them into their structure. We call this type of granulation iron bacteria. They work like a coagulant - they collect colloids into larger particles that are heavy enough to precipitate. We call the sediment formed at the bottom of the container iron hydroxide or iron hydroxide. The composition of hydroxide also includes decomposition products of organic substances, other metals, such as manganese, as well as decomposition products of hydrogen sulfide - sulfates and many other substances - chlorides, fluorides, salts, petroleum products... a lot of things.

What are the main benefits of aeration?

It is reagent-free

— iron dissolved in water and unnecessary gases are eliminated using ordinary air oxygen. No toxic reagents or formation of secondary by-products.

It is quite affordable

residents of private country houses, while having the opportunity to choose a system that is suitable in terms of power and performance. There are also large-scale options for industrial complexes of autonomous sewerage, as well as central water supply.

Aeration systems operate entirely autonomously

and do not require additional maintenance or highly qualified personnel.

Modules for water aeration have compact dimensions

, which allows them to be installed even in small spaces.

OPERATING PRINCIPLE OF AERATION

To purify water from dissolved metals, organics and hydrogen sulfide, the method of oxidation with atmospheric oxygen is used. You can simply pour water into an open container, spraying it for better mixing with air, and then feed it back into the water supply with a second lift pump. This method is convenient for summer cottages, as well as houses with a large boiler room, in which a large container can easily be placed. But it has a number of its shortcomings

A more modern solution to the problem is pressure aeration.

Types of compressors

These machines are classified according to the way they work, it is possible to find two categories, each with different functionality, let’s look at what they are:

1. Positive displacement devices: characterized by the presence of a chamber in which the volume of gas decreases, reaching the maximum compression value specified by the design. It is then pushed into the system:

- Piston devices are designed quite simply to understand. They have a gearbox, a crankshaft driven by an electric motor, which makes the structure work. As the piston moves down, the system absorbs gas, then compresses it during the return stroke. This process is repeated as many times as necessary, and when the operating pressure reaches the maximum level, the fuse sensor turns off the motor to reduce energy consumption and provide protection against overheating. This device will be an excellent additional improvement for a septic tank.

- Diaphragm compressors (membrane) are distinguished by the fact that the air does not come into contact with the mechanical parts of the structure. It has a diaphragm in which the gas is concentrated. The compression method is carried out thanks to a piston that pushes out concentrated air.

- The operation of a screw machine is based on the interaction of two spiral blades, which rotate together, entraining gas into gaps located along the body. These slots become smaller as the air moves, creating more force. This way it can be compressed.

- The spiral apparatus functions due to the orbital movement of two rotors, one stationary, the other rotating. They are 180° out of phase.

- The vane mechanism has an internal rotor located eccentrically with respect to the motor shaft (it is located on one side of the circle, not in the center). Blades are built inside it, which generate air pressure at the moment of rotation.

- The vane apparatus is characterized by having two rotors connected by a set of gears that rotate simultaneously but in opposite directions to control the pressure.

2. Dynamic (turbochargers) use molecular acceleration as the compression principle. This occurs thanks to the suction impeller, a diffuser ring that stops the air, creating pressure. Maintenance and operation of mechanisms in this category are expensive. There are two different types - axial and radial (centrifugal) compressors:

- The operation of axial units is almost identical to the operation of a conventional fan. It rotates the turbine to suck in air and create more pressure at the outlet. This flow is generated in the axial direction, perpendicular to the rotation.

- The principle of operation of a radial mechanism is almost the same as that of an axial compressor, except that it is constructed differently to create pressure in the same direction as the rotation of the shaft.

All models have different assembly, mounting supports, working surface length, functionality and efficiency, so you need to purchase the necessary equipment wisely.

PRESSURE AERATION

Air is pumped into the water supply using a compressor, allowed to mix with water in a special column, after which undissolved air bubbles are removed through an automatic air vent, and water saturated with oxygen is supplied to a column-type deferrization filter with catalytic loading - a loose material like sand that enhances the oxidation reaction of everything that can be oxidized and mechanically retains particles of substances we do not need.

Clean water goes to the consumer, and retained contaminants are periodically washed into the sewer by a reverse flow of water during periodic washing of the filter. A STEP BY STEP description of the operation of the aeration column in more detail is as follows:

1. Water is supplied to the aeration column on the left (looking at the diagram).

2. Air is supplied to the pipe in front of the aeration column using a compressor, which is turned on by a signal from a flow switch installed after the deferrizer when water flow occurs (water is opened in the house).

3. Water and air rush into the column in many jets through a divider located in the air bubble.

4. The height of the air bubble is adjusted by a long air outlet tube (20-35cm).

5. If the amount of air entering the column is greater than the flow rate of dissolved air, then the excess air will exit through an automatic air vent at the top of the column.

6. In the upper half of the column, air mixes with water, air bubbles float to the top without reaching the bottom.

7. Oxygen-saturated water is taken from the aeration column through the longest tube from the bottom of the tank.

8. Water saturated with dissolved oxygen, separated from bubbles, is sent further through the water purification system to a deferrization filter. See the following diagram.

In this video you can see clearly how a pressure aeration column works and what equipment we use to organize the process of water oxidation with air oxygen

The inlet pipe of the aeration head becomes overgrown with hydroxide.

Next we look at the wiring diagram.

- The aeration column compressor is turned on by a signal from the BRIO-2000-M flow switch, which is installed AFTER the deferrization filter. This is important, firstly, so that the relay operates in clean water and is not subject to contamination by hydroxide. Secondly, during backwashing of the iron remover, air should not enter, otherwise hydroxide will be retained in the thickness of the load and the filter will not work correctly.

- Water saturated with oxygen is supplied to the deferrization filter, where the catalytic loading enhances the oxidation reaction of dissolved substances.

- Large particles of hydroxide are mechanically retained on the loading surface and in its upper layer.

- Colloidal particles (suspensions) are filtered out in the lower layers of the load, being electrostatically attracted to the walls of the grains of the load.

Disassembly, cleaning, as well as more visual operation of the aeration column - watch the VIDEO above.

Now let's talk about what components the aeration system consists of and how to assemble an aeration column yourself.

AERATION KIT COMPOSITION:

- A compressor capable of pumping air in the required volume, overcoming the water pressure in the water supply system

- Column (cylinder) of suitable size

- The aeration head is a plastic blank with a system of channels for the movement of water and air

- Pipes of suitable diameter and length

- Divider

- Installation kit for compressor piping

- Flow sensor

- Ball valve

- Check valve 3/8″

- Fittings 3/8″ and 1/4″ (for compressor, head and air vent)

- Pressure hose of the required length to supply air from the compressor to the column

- Air vent valve

For self-assembly of the kit, watch the video instructions above.

Source: ochistkavodi.ru

Features of operation and maintenance

The air unit will delight you with uninterrupted and reliable operation, subject to the basic operating rules:

- The device must be grounded.

- The compressor is located in a moisture-proof box.

- The suction zone and cooling system of the device are fenced off from vapors and gases rising from the tanks.

- The electrical circuit must provide protection against sudden changes in network voltage.

- The unit's air inlet filter requires periodic cleaning.

- Careful handling without falls or mechanical damage to the device during operation and when removing it before storing the septic tank.

- Do not overfill or flood the treatment tank.

The membrane-type products used require periodic replacement of the working element due to loss of elasticity and physical wear. Replacement is carried out independently (after the warranty period has expired) or by a specialist. It is advisable to prepare the necessary repair kit in advance. If there is no practical experience, the sequence of work on replacing the membrane is studied by watching a thematic video.

Overheating and frequent activation of the thermal relay are signs of contamination of the device with organic deposits that enter inside with sewer gases and fumes. Complete disassembly, cleaning and flushing of the unit will be required.

Other recommendations are indicated by the manufacturer in the accompanying operating instructions.