Original ideas for building and decorating a well house can be made with your own hands using standard construction tools. The creation of a private well traditionally ends with the arrangement of a house, which is both a protective and decorative element. There are quite a lot of options for the finishing design of the mentioned structure, but the order of arranging the houses as a whole remains almost the same. Only the dimensions, configuration and design features change. Traditionally, wood is used to create houses. Read the provisions of the presented guidelines and choose the house design option that suits your case.

DIY well house

Why do you need a well house?

A large selection of ready-made well houses is available for sale. However, the cost of this type of product leaves much to be desired. Therefore, many owners decide to build well houses on their own - there is nothing complicated about it.

Well house

The main purpose of the well house is to protect water from various types of pollution and direct sunlight. Insects, garbage, animals, excess heat - all this negatively affects the quality of water.

The house will also provide reliable protection of the well from various types of precipitation and chemicals used to spray vegetation. In winter, a properly equipped house will not allow the water in the well to freeze.

Well house

Gate

The well gate can be made in a variety of options:

- from a log;

- from a metal pipe;

- from a car wheel disc;

- from reinforcement welded into a cylindrical frame.

A pipe bent in the shape of a letter - G is used as a handle. There may also be other options:

- Steering Wheel;

- handle made of polypropylene pipe.

On the Internet you will find many unusual and original ideas on what to make your own pen from.

Set for work

- Woodworking Machine. This device will allow you to process wooden blanks as quickly and efficiently as possible. If you don't have access to a woodworking machine, at least have an electric plane ready.

- Circular Saw.

- Electric jigsaw.

- Hacksaw.

- Nail puller.

- Phillips screwdriver.

- Hammer.

- Pencil.

- Building level.

- Roulette.

- Edged board.

- Beam.

- Fastening elements.

- Roofing material. Choose at your own discretion. The main thing is that the support can properly withstand the weight of the finish, and that the roof itself is in harmony with the surrounding space. For example, slate, roofing felt, and metal tiles are suitable.

- Door.

- Door latch.

- Pen.

- Loops.

Prices for popular models of jigsaws

Jigsaw

Video description

After watching this video, the essence of making a brick shelter will become clear:

From a concrete ring

A well made of concrete rings or a caisson made of them, rising above the surface of the earth, already has walls on which it is necessary to install a roof. You can make a simple canopy over the well and a cover if you use it only in the summer and live in the country all the time during the season. In other situations, a house would be a better solution.

It is advisable to insulate its concrete walls so that in cold weather the shaft inside does not become overgrown with frost from rising and freezing water vapor. This can be done using polystyrene foam cut into strips and glued in a circle or roll insulation.

House with a gable roof

House for a well with a gable roof

The simplest and most popular design option. Such a well house can be easily built from available equipment, because... almost everything necessary (timber, boards, fasteners) remains after the completion of larger construction activities.

House for a well with a gable roof

Frame

To create the base of such a house, boards and wooden beams are used.

Well houses

Expert opinion: Masalsky A.V.

Editor of the “construction” category on the Stroyday.ru portal. Specialist in engineering systems and drainage.

First of all, it is necessary to select the optimal dimensions of the main structural elements. If the parts are too thin, the well house may not withstand wind and other loads. Elements that are too voluminous will make the house bulky.

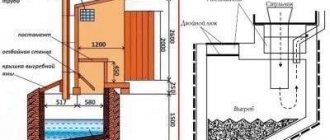

House diagram. 1 – base frame, 2 – gables, 3 – pillar, 4 – roof ridge, 5 – gate, 6 – gable cladding, 7, 8 – roof slopes

Well house with door

Well house with door

Therefore, stick to the recommended and time-tested parameters. Thus, the optimal thickness of the board is 4 cm, the cross-section of the timber is 8x10 or 10x10 cm. The design of such a house consists of four posts made of timber and the same number of boards, suitable for making the upper and lower trim. The recommended width of the boards is 120-150 mm.

Well house frame

Saw off the boards in advance in accordance with the dimensions of your well, and then nail all the elements one by one to the support posts. As a result, you will get a reliable and even frame. To fasten elements of the mentioned dimensions, use nails approximately 100 mm long.

Gate device

At this stage, it is best to adhere to the following algorithm:

- fasten the first pair of support posts, bottom and top, with boards;

- connect the remaining pair of support posts in the same way;

- install prepared structures around the well;

- finally connect the frame elements with straps.

Installing a house on the top ring of a well

House installation

Well house

Roof and upholstery

Start arranging the roof of the well house. Start by installing trusses - this is a rigid structure designed to attach the sheathing. Make trusses from durable boards with a thickness of at least 30 mm. Select the length individually - the final height of the well house directly depends on this indicator.

Well house

House frame

Prepare boards for jibs and crossbars. Material 2.5-3 cm thick will be enough. In general, you need to prepare 6 rafter legs, 3 crossbars and 8 jibs. Cut the rafters at an angle, and then connect the upper ends of the products to each other. Fasten with self-tapping screws.

To prevent debris from getting into the well or any animals or insects from getting into the well, you need to cover the house with plastic wrap

To prevent debris from getting into the well or any animals or insects from getting into the well, you need to cover the house with plastic wrap

For additional fixation of the rafters, use crossbars. They should be placed 30 cm below the point of the upper rafter fastening. Create cutouts at the junctions of the rafter elements with the top trim boards. Use 12 cm nails to connect the rafters and frame.

Roof of the house

Strengthen the fixation of the rafter elements with jibs. To connect the trusses, use a kind of ridge - a structure made of two boards. Attach the sheathing boards in increments of about 15 cm. Provide 10 cm protrusions above the walls of the building. Cover the finished roof frame with roofing felt, and on top of it, if desired, attach the finishing roofing material at your discretion. Finally, all you have to do is cover the corner joints with wind boards.

Well house

Well house

It is most convenient to assemble the roof structure frame on the ground.

House roof cladding

Door

The door of such a well house looks like a kind of plank shield. The door is made according to an extremely simple principle. Cut boards about 150-200 mm wide. The length will be enough 85 mm.

House door

Place the boards one next to the other and fasten them with 30x25 mm bars. Two bars will be quite enough - you fix one on top, and nail the second from below. To fasten the elements of the product, use self-tapping screws. Four screws for each board will be enough.

Nail an additional diagonal block. It will help increase the rigidity of the product. Frame the gables, attach the latch and handle, and then hang the finished door on its hinges.

What should a high-quality antiseptic be like?

Don’t forget to treat the outside of the product with an antiseptic and varnish it. Before applying varnish, you can paint the door with waterproof paint.

Parts for manual gate

Gate

Gate

Gate

Option for covering a house with corrugated sheets

Prices for various types of lumber

Lumber

Preparation

The area needs to be cleared. Remove debris and grass, level it, pour crushed stone in a layer of 15-20 cm. First a layer of coarse gravel, then a layer of small crushed stone. The area is larger than the house is ready.

Wood is well suited for such construction. It is easy to handle, looks great and lasts a long time. Before construction, the parts are prepared according to the drawing with dimensions. Then quickly assembly will not be difficult.

Log house

Such a well house will have an original and very interesting design. To build such a structure you will need the following:

Log house

- rounded logs;

- boards for roofing and supports;

- finishing coating for roofing;

- material for arranging a gate with a comfortable handle.

Similar well houses are often found in villages. The pillars of the structure, gates and the log house itself are made from rounded timber.

Log house

Manufacturing technology

Fold the rounded timber into the log house according to the dimensions of the well. Connect the timber using any suitable and convenient method. Install two massive wooden beam supports. For additional rigidity, equip the house posts with supports. Place a wide roof structure on top of the support posts. The instructions for constructing the roof were given in the previous section of the instructions - do everything in the same order.

Well house made of logs

The edges of the roof should extend beyond the base of the well house. This will prevent precipitation from entering the well shaft.

Fasten the gate securely. You can decorate the protruding ends of the beam with a variety of curly cutouts.

How they did it in the old days

You cannot simply secure the constructed gable roof to the side posts with a collar. It is necessary to thoroughly strengthen and strengthen the supports, install struts, and only after that attach the protective canopy. Otherwise, at the first strong wind, due to the large windage, the roof can simply destroy the pillars and even throw off the gate. An illustration of how seriously in the old days they approached the problem of installing a roof for a well with their own hands can be seen in the diagram of a log house below.

An ordinary wooden chopped well was always equipped with a fairly high and wide roof with a roof span of more than 2.5 m. The height of the ridge above the ground was also about 2.5 m. The result was a rather bulky structure, capable of accommodating at least five people under a canopy. The height of the overhangs was about 2 m, this is enough to use the well even in winter, with a lot of snow.

In order to reliably fix and hold a fairly heavy hinged structure, the craftsmen had to use the following solution:

- Install two vertical log posts with a diameter of 200 mm. They also served as supports for installing the lift gate;

- The supports, about four meters long, were dug 1/3 into the soil backfill without concreting or installing external struts;

- The roof support posts were not connected to the frame, so any lateral or vertical load on the roof did not in any way affect the stability and strength of the well head.

Almost the entire well structure, from the roof to the lower crowns of the frame, was made of oak. The lower parts of the supports driven into the ground were first burned to charcoal, covered with birch tar and coated with clay. As a result, the roof and the well itself served for many decades, delighting the owners with clean water and a convenient device.

Hexagonal well house

Hexagonal well house

Modification of the previous design. The only difference is the shape - it is hexagonal and allows you to save additional space, which is important for owners of compact wells and small plots of land.

Hexagonal well house

In general, the sequence of construction of this house remains the same as in the case of the construction of an ordinary quadrangular building made of timber. The house is well suited for framing a shaft with pumping equipment.

Types of well pumps

For construction, it is recommended to use a 10-centimeter beam. You can trim the roof with edged boards - it looks very beautiful and original. Be sure to treat all wooden structural elements with antiseptic impregnation.

Prices for popular types of antiseptics

Antiseptics

Appearance

The house is built depending on how the owner wants it to be. Whether it is a simple shield that covers the top of the hole or a real small house topped with a roof with one slope or two, in the shape of an “umbrella” - this will be an original solution. Doors are installed single- and double-sided. The panel is often sliding.

Decorating the house

Carved well house - decoration of the site

Several methods can be used to decorate the house. A popular decoration option is carving. A neat carved house will fit into any landscape, the design of which is made using wood.

Decorating the house

Another simple and popular option for decorating such structures is painting. Varnishes and impregnations allow you to radically change the texture and color of the material.

In some situations, it will be appropriate to decorate a house using a ceramic or wooden figurine of an animal.

Well houses

Otherwise, each owner must independently think through the finishing design of the well house so that the finished structure fits well into the environment and fully demonstrates the individuality and taste of the owner.

Good luck!

Video - DIY well house

Materials

In the classic design, the well house is made of wood. Timber is used for strength elements, board or block house is used for cladding.

Even the roof for closed houses is sometimes made in the form of shields from tightly fitted boards. The main disadvantage of wood is its tendency to rot. Especially in high humidity conditions.

Therefore, the house is often made of a combination: the strength part is made of a metal profile, the finishing of the lower part (around the well) is made of stone or moisture-resistant facade panels, the “rafter system” is made of wood, and the roof is covered with modern roofing materials.

You can find many ready-made projects on the Internet, choose the appropriate one and adapt it to a specific landscape design. And the most common way of selecting materials is compatibility with the decoration of the house and outbuildings. This is especially attractive when there are unused building materials left after construction.