You can make a drill for a well with your own hands, but in terms of strength it may be inferior to special equipment. For this reason, before starting work, it is necessary to study the properties of the soil on the site. A tool will last longer if it is made according to the load placed on it.

Drilling a well is the optimal way to provide water to a suburban area in the absence of a central water supply line due to the low cost of the work compared to well water supply and technological accessibility.

Types of drills

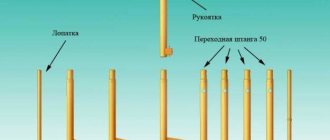

There are two types of tools:

- disk. The product is equipped with two semicircular blades, which are placed one above the other. To drill a hole with such a drill, the operator moves it back and forth;

Disc drill - screw It uses a solid blade that is wound around a base. To drill with this drill, you need to move clockwise.

Auger drills

Features of drilling with homemade devices

Drilling with homemade projectiles is possible under the following conditions:

- the aquifer lies at a depth not exceeding 20 m;

- the soil is sandy or clayey, but not rocky.

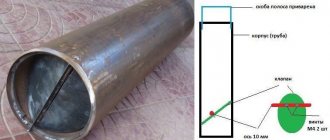

They make attachments for percussion-rope or rotary drilling - only these methods are suitable for constructing a well yourself. The first method does not require the creation of complex equipment. They build a simple drilling rig from materials that are available on the farm. The method is also attractive because you can work without assistants.

When rotary drilling, a tool is used that, going deep into the soil, lifts it up. 2 people stand on the sides of the bar and rotate it, applying force to the transverse handle. Spiral or spoon type drill bits are used.

Selection rules

When choosing a drill for your dacha, consider the following points:

- type of instrument. It is better to use an auger drill because it is more efficient. The operator takes it out of the ground less often, and it captures more soil during excavation;

- diameter. The larger it is, the wider the hole becomes. This allows the product to be used for making holes for planting plants with a large root system;

- removable knives. This allows you to install attachments depending on the size of the hole. It should be taken into account that due to the removable knives, there is a play in the structure;

- drilling depth. The larger it is, the deeper the hole is, which is especially important for arranging a pile foundation;

- weight. The lighter the weight of the tool, the easier it is to use;

- lever. The larger it is, the easier the drilling process will be;

- type of construction. If the tool will have to be transported frequently, it is better to use a collapsible model. At the same time, it is taken into account that after assembly and disassembly, backlashes appear. A solid drill is stronger.

Video - Tips and tricks when choosing a hand drill

When choosing a drill for your dacha, you should also take into account the size of your budget. If you need an inexpensive model, pay attention to the Tornadica pro product. If you need a reliable tool in the mid-price category, we recommend the Fiskars QuikDrill Fiskars (large). If the budget is not limited, and you have to use the drill often, you can use the tool with a walk-behind tractor. The best option is ELITECH BM 52E 2.5 hp. In our rating you can choose any tool that satisfies the needs of even the most demanding users.

Tips and tricks

It is necessary to take into account some subtleties, which will allow you to make a better drill with your own hands:

- to create small holes in the ground, use a spiral tool;

- the coil spiral should be bent as strongly as possible, which will increase the speed of work;

- it is recommended to provide a working edge with the possibility of self-sharpening during the drilling process;

- it is necessary to control the speed of insertion of the tool into the soil: it must correspond to the speed of drilling.

Before starting work, the equipment is checked at idle speed.

Voting for the best drilling tool for the dacha

Which drilling tool would you choose or recommend?

ELITECH BM 52E 2.5 HP

8.14 % ( 7 )

MAXCUT MC 55 3 HP

12.79 % ( 11 )

Fiskars QuikDrill Fiskars

19.77 % ( 17 )

Bison 39491-250

4.65 % ( 4 )

PATRIOT 742104425

9.30 % ( 8 )

Tornadica pro

24.42 % ( 21 )

Sibrtech 64503

1.16 % ( 1 )

Bison 39491-200

2.33 % ( 2 )

CALIBER NSHU-200/ZEM

5.81 % ( 5 )

What types of wells are there?

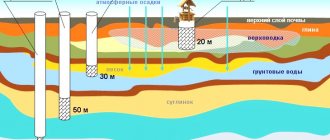

Before considering the issue of equipment intended for drilling wells, it is advisable to become familiar with the technologies for extracting water from a summer cottage. To do this, you can use one of the main types of wells:

- Construction of a well with quick filling from a good spring. It can be an excellent storage tank for water, containing approximately two cubic meters of liquid.

- A sand well, which is a pipe with a diameter of one hundred millimeters, which is immersed to a depth of up to 30 meters using an auger. At its recessed end of the pipe, a stainless mesh is attached, which acts as a filter when immersed in sand with a coarse fraction. The depth of such a device is from 10 to 50 meters, the operating period is at least five years.

- An artesian filterless well is used to extract water located between layers consisting of porous limestone. The depth of such wells is from 20 to 100 meters, they can be operated for up to 50 years.

A water well is a kind of narrow well, as can be seen in the photo.

Water well design

The duration of well operation depends on the frequency of its use. With increasing intensity, its service life increases. You can determine the depth of drilling a well by first focusing on similar devices in neighboring areas, and purchase the number of casing pipes with some reserve for adjusting the depth of groundwater.

Hole sizes for different conditions

For different types of soil and operating conditions, there are certain standards for excavating holes:

- If there is a possibility of too low temperatures, which will last for several weeks, this means that the ground will freeze to a greater depth. For such conditions, it is recommended to make a recess of at least 1.5 m.

- If the structure consists of solid parts and has a high windage, then the hole should be made to the maximum depth that the drill allows. For mesh or lattice structures, you can dig a well 20-30 cm less than the maximum drill depth.

- If in the place where you plan to make a deepening the soil is too soft or the groundwater is too high, then you should dig a hole to the maximum accessible depth. For clay soil, you can make smaller holes.

You should carefully drill under fence posts or other structures, since if you dig a hole that is not large enough, the entire structure may tilt or collapse within a year.

Depth of the post hole Source toolbuild.ru

Pile field calculation

After geological surveys, you can begin to calculate the pile field. Taking into account the type of soil, as well as the location of the groundwater level, you can get an idea of the expected depth of the wells. The table below shows approximate recommendations for the depths of wells in weakly subsiding soils that are safe under the specified conditions:

Laying depth recommendation

Wet, subsidence, highly heaving and other unreliable types of soil foundations are not recommended for the installation of bored piles.

Layout of groundwater

Soils with a groundwater level higher than 1000 mm are considered water-saturated and the construction of pile foundations on such foundations is strictly contraindicated by technology. High groundwater levels can be lowered by carrying out drainage measures, laying drains, etc. Reliable weakly heaving soils are considered to be those in which the groundwater level is at least 1 meter below the freezing depth.

The data given in the table will help to get a general idea of the dependence of the depth of the pile column on the characteristics of the soil. To obtain more accurate and reliable indicators, you should carry out a simple mathematical calculation. The principle of calculation is to take one of the indicators (for example, diameter) as a standard and calculate the rest based on these data. Using the comparison method, the most suitable configuration of piles is selected, from which a pile field is subsequently formed.

Calculation of the length of suspended piles

Pile pillars that are not supported by a load-bearing layer of soil are considered hanging. This means that the main load is taken by the side walls of the well, and not by the supporting soil layer. It is preferable to install such foundations in areas with a deep rocky layer. The load-bearing capacity of such piles does not differ from racks of the same diameter.

If you have access to the geology of the area, and the type of soil is suitable for installing bored suspended pile columns, you can begin to calculate the length. The proposed calculation scheme is as follows:

- We accept a certain average cross-sectional width of the pile n=60 mm.

- We calculate the load of the house per linear meter of the foundation slab:

Friction piles of various lengths

To calculate the load per linear meter of the foundation, you need to divide the total load by the perimeter. You can calculate the total load of the house in accordance with the instructions of SNiP 2.02.01-83* or SP 22.13330.2011 - in the relevant sections you can find the calculation algorithm, the necessary values of the wind and snow load coefficients and other necessary information.

The resulting value in kg/m will be the desired value. The average weight of a one-story brick house is 50 tons. Therefore, for a house with a perimeter of 20 meters (10×10), the load per linear meter will be 2500 kg/m.

- We accept a column spacing of at least three diameters and no more than two meters - for the selected diameter a pitch of 1.5 meters is suitable. The total number of piles will be 13.

- We calculate the load on one pile: to do this, we divide the load perceived by a linear meter of the foundation by the pitch of the piles. We get a value approximately equal to 1700 kg/m. This required tensile strength must be placed in one pile.

- For a pile with a cross-sectional area of 0.28 m2, this strength value will be equal to:

F=R∙A+u∙Eycf∙fi∙hi;

Where F is the bearing capacity; R – soil resistance, the calculation formula for which can be found in SNiP 2.02.01-83*; A – cross-sectional area of the pile; Eycf,fi and hi – coefficients from the same SNiP; u is the perimeter of the pile section divided by the length.

Foundation on bored piles

For the two-meter-long pile considered in the example, the maximum load in clay soil will be 32.3 tons, which makes it possible to reduce the number of piles by increasing the pitch of pile columns, or to reduce the cross-sectional area of each individual pile, which will save money spent on concreting wells.

The depth of such piles will depend solely on the characteristics of the top layer of soil, the relative level of groundwater and the depth of freezing. Data on soil freezing and the position of the groundwater level should also be taken into account. Detailed examples of calculating the depth of laying of hanging piles are given in SNiP 2.02.01-83* in section 2, paragraph 5 or in SP 50.102-2003.

Calculation of the length of the racks

Bored piles of increased depth can act as racks. And although drilling types are usually suspended, there are structures supported on a solid layer of soil. The length of such piles should be calculated taking into account the depth of the strong bearing layer.

We recommend making calculations manually or contacting specialists.

Calculation of the length of bored piles

There are many services on the Internet for automatically calculating the size and number of bored piles. The use of such services imposes a certain risk on the user, since the algorithm does not always take into account all the necessary parameters, and the owners of the software are not responsible for the result obtained.

All accompanying calculations of the load-bearing capacity and geometry of the pile are made in accordance with the technology for calculating rack piles and are similar to the example given earlier. Additional information on the calculation can be obtained from the above documents.