It is well known that the main purpose of wells is the extraction of minerals, which are oil, gas and water, from the bowels of the earth, but few people know that there are other types of them. Wells are used to perform auxiliary, injection, special and geological exploration work. Although the well design for each resource extracted or work performed is significantly different from its analogues, there is much in common between them.

A well is a working with a circular cross-section in the earth's crust, the diameter of which is significantly less than its length, obtained by drilling from the surface or in the ground at any angular direction to the horizon without direct human access to the channel. When considering the design of all types of wells, the terminology adopted to describe them in the mining industry is used.

Rice. 1 Water intake from a well with an electric pump

Well construction

The design of all water wells in a private house is approximately the same - it is a deep hole before the water occurs and a casing pipe that allows you to direct and control the flow of water from the bottom up. The differences lie in additional devices that increase the reliability and productivity of the well.

As a rule, wells are equipped with a device for forced lifting and distribution of water.

Any well has characteristics that allow you to choose the optimal device for collecting water. An important characteristic of such devices is the well flow rate.

Well flow rate

The flow rate of a well is the maximum volume of water received per unit of time.

The flow rate can be measured in liters per minute, m3/day or m3/hour. This is the main indicator of well productivity.

Caisson

A caisson is a reservoir for placing and waterproofing devices. The caisson for a well can be metal or plastic. For contrasting climates, metal ones are better suited, but they are more expensive and susceptible to corrosion, but they can be repaired. Plastic caissons do not rust and are much cheaper. However, plastic can tear, and it is not repairable.

Depending on the size, the price of a plastic caisson ranges from 17,000 to 40,000 rubles.

For a metal caisson, the price differs only in the upper limit and ranges from 17,000 to 60,000 rubles. The fact is that a metal caisson can be assembled in parts, each of which is sold separately.

Heading

A well cap is a device that is attached to the top of the casing. The head is sealed and serves to secure the outlet of the water pipe and the cable for the pump. The cap ensures the flow of water and increases the flow rate of the well by creating low air pressure inside the pipes. Made from plastic or cast iron.

The cost of heads designed for pipes with a diameter of 125-133 mm ranges from 2000 to 4000 rubles.

Adapter

A well adapter is a device that allows you to tightly connect a well to a ground water supply. Typically, the adapter is used in technical rooms with water supply equipment. One part of the adapter is attached to the casing, the other to the hose with the pump. It is necessary to use the adapter where equipment that needs to be protected from water is concentrated.

The adapter saves space. Its price ranges from 600 to 4000 rubles.

Packer

Well packers, also known as a seal, are a device that allows you to block and seal individual parts of a well or the inner wall of a pipe. In addition, with the help of a packer it is possible to separate the internal cavity of the well from the external, annular cavity. It can also be used to separate one part of the pipe from another.

The packer is used to carry out technological operations in a local area of the well.

Casing

The casing pipe is the main element of the well, designed to supply water from the source to the water supply system. These pipes got their name because of their function - to prevent the drilled hole in the ground from falling out. The casing pipes are lowered into the ground after the well is finally drilled. The space between the well wall and the pipe is filled with concrete. After this, the installation of the remaining equipment begins.

Bypass pipes vary in size and material. They are usually made from metal (cast iron or steel), wood, asbestos, and plastic.

The most popular is considered to be metal and HDPE casing pipe for wells with threads.

The price of casing pipes for wells is measured in linear meters and depends on the material and diameter. If we take the most common pipe diameter of 133 mm as a basis, then the price will be from 200 to 500 rubles per meter for plastic pipes and from 400 to 800 rubles per meter for metal ones.

Pump selection and installation

In order to properly equip a water well after drilling, select the type of electric pump with the necessary characteristics; the choice of a caisson well or adapter when arranging a water supply source depends on its parameters. All electric pumps, based on their location relative to the well, are divided into two large groups, differing from each other in their parameters.

Superficial

Surface centrifugal pumps with an efficiency of about 50% are used more often than other types to supply water; for most models, the suction depth does not exceed 8 m, so they are placed next to the well or at a short distance from it.

With a large distance between the pump and the source, each vertical meter of water column is converted into 7 m horizontally with a pipe diameter of 1 inch, taking into account hydraulic losses in fittings, bends, and tees. Thus, a surface pump can be placed not only in a caisson, but also in a house if the water level is close to the soil surface, for example, with a mirror (static level) of 5 m, the electric pump can be installed in the basement of a cottage 20 m from the well.

Free-standing external pumps are very rarely used in domestic water supply; they are usually operated as part of stations where an electric pump, a hydraulic accumulator, a pressure relay and a pressure gauge are placed on one frame, connecting them through fittings and flexible hoses.

Surface household pumping stations are capable of pumping water up to 5 m3/h with a maximum pressure of about 50 m, which makes them suitable for supplying water to a house with a family of five people.

Centrifugal surface pump - internal structure

Submersible

A large group of deep-well pumps operate using a centrifugal design; such units have the highest efficiency among all types, reaching up to 65% for high-tech expensive Grundfos models. In terms of parameters, submersible pumps are significantly superior to external ones; the volume of pumped liquid in household models reaches 20 m3/h, the maximum pressure reaches 300 m thanks to the use of a number of stages with impellers that successively increase the pressure.

On the pumping equipment market there are other types of submersible electric pumps with a different operating principle; their list consists of the following types:

Vibrating

Popular household models of the electromagnetic principle of operation, sucking up water due to the reverse and forward movement of the built-in piston connected to the armature of the electromagnetic coil. The maximum supply volume of vibration pumps does not exceed 1.5 m3/h, the pressure reaches 80 m with an efficiency of about 35%.

The average price of vibration pumps is around 1,400 rubles; in everyday life they are not used for constant water supply due to low technical characteristics, they are used mainly for irrigation, drainage work, pumping wells, filling pools and reservoirs with water, and other economic purposes. Vibrating pumps can pump out very turbid and dirty water without damaging the electrical part and housing (that’s why they are used for pumping wells), but the rubber piston and return valve are worn out by sand particles and may require replacement after a while.

Centrifugal and vibration submersible electric pumps - internal structure

Screw

Units of this operating principle are often called screw units; their operating principle is reminiscent of a household meat grinder, in which the liquid moves due to the rotation of a spiral screw. Screw models are not so popular on the market; their advantage is the ability to work with viscous and turbid media. The efficiency of screw units does not exceed 50%, the flow is up to 15 m3/h, the pressure reaches 100 m.

Vortex

In this type of electric pump, water is sucked in by the blades of the impeller through an opening on the side of the housing and pushed out by the impeller through the side pipe in the same plane. The distance between the blades and the walls of the working chamber is minimal to reduce hydraulic losses, so vortex models only work with clean water from artesian wells. The efficiency of such devices is also low (about 50%), household units have average technical parameters with the highest flow of 5 m3/h and pressure of 100 m.

Screw and vortex pumps - design

Well on sand

A sand well is the easiest option for extracting water after a well and an open reservoir. It is a thin pipe (d −100 mm), immersed in the ground to a depth of 15-30 m. At the end of the pipe there is a stainless steel mesh that acts as a filter.

The well got its name from the main requirement - the aquifer must be in sand or sand mixtures. This is a condition not so much of technology as of opportunity. Water will pass through the loose substrate easily, so you can get by with a simple pump.

Features of autonomous water supply systems

Installation and operation of an autonomous home water supply system requires knowledge of several nuances.

- When choosing a pump, it is important to take into account not only the flow rate of the well, but also its depth , the distance from the source to the house and the height of the building.

- The volume of the accumulator depends on the number of water consumers . It is usually calculated that there are 50 liters of water per person.

- Before commissioning a source, it is important to conduct a microbiological and chemical analysis of the water . If necessary, select water treatment equipment.

Well needle

This version of the well was also called the Abyssinian well. The needle well is simpler than the sand well, but in many ways it is similar to it. In addition to its simplicity and cheapness, the Abyssinian well has the advantage of being able to pump very clean water. The needle takes water passed through the sand, while the “sand well” pumps water from the loam horizon.

This well is called a well because its water intake depth is the same as that of a regular well. It turns out that this is a well one pipe wide.

The well is called a needle because it is actually a pipe driven into the ground. It was as if a needle had been inserted into the ground. The undoubted advantage of such a needle is its low cost, quick installation and long service life - up to 30 years. It takes up little space on the surface of the earth, so it can be placed in the basement of the house. Water is obtained from such a well using a pump or pump.

Flaws

- low productivity;

- the likelihood of a decrease in water supplies in winter or during dry periods;

- Possibility of installation only on loose soils;

- the impossibility of using several water intake points without compromising the pressure;

- the likelihood of siltation during breaks in use;

- inability to connect several water points without reducing pressure.

There are two methods for constructing a needle: driving and drilling. Drilling is simple and cheap, but there is a chance that you will miss aquifers or hit a stone, after which you will have to start all over again. As the pipe is pushed down, water is constantly added to it. When the water begins to go into the ground, you can begin installing the pump.

The water flow in an Abyssinian well is approximately the same as in a regular well (from 0.5 to 3 m3/hour).

Need to take into account

- You should use metal or plastic pipes of 1 or 1.5 inches, which are cut into 1-2 meter sections. After immersing one section, the pipe is extended using threaded connections with another section.

- Silicone, paint, and couplings are better used as a sealant.

- The diameter of the pipe tip must exceed the diameter of the pipe itself. There should be a special filter at the end of the pipe. In this case, the tip and pipe must be made of the same material.

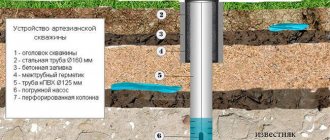

Artesian well

An artesian well is the most labor-intensive, expensive and at the same time reliable way to raise water to the surface. In this case, water is drawn from the layers where limestone lies. Pollutants usually do not penetrate to such depths. Such a well often has several casing pipes and distribution and locking devices such as a head, caisson and adapter.

Flaws

The disadvantage of an artesian well is not only the cost of drilling to great depths and the need to obtain a permit, but also the unpredictability of the mineral composition of the water. Most often, water has a low level of mineralization.

But there is always a chance of drilling to deposits with “mineral water” that has an acidic or alkaline reaction.

The complexity of a well depends on the depth to which it is drilled. At a depth of 50-100 meters it is necessary to install a casing pipe with a diameter of 133 mm. Below, from the lime layer upward, there should be a second pipe with a smaller diameter (125 mm), in which the pumping equipment is located. At a depth of 100 meters, it is necessary to install telescopic columns. They are made up of pipes with constantly decreasing diameters ranging from 133 to 125 mm.

In an artesian well, water rises under its own pressure to the middle or 2/3 of the structure, so pumps need to be installed at this depth.

Wells are divided into single-pipe and those with additional pipes. In the latter case, a thinner plastic pipe is placed inside a metal pipe, clogged to the limestone layer. It is this pipe that enters the groundwater. If the soil is unstable, the well must be equipped with a conductor. This is an additional pipe that is significantly wider than the casing pipe. It is installed on top to protect the casing from excessive pressure. When the artesian well is completely ready for use, it is necessary to install the caisson and the head.

Final Settings

The third stage consists of final settings that allow you to adjust the operation of the entire system, the optimal pressure is checked and set, the pump itself is connected directly to the electrical network, the system is started for the first time, tested and corrected if problems are found, pipes and insulation are checked again for leaks .

If you plan to construct a well yourself, it is better not to neglect the preparatory work and seek advice from experienced and trusted specialists who have already received good reviews.

They will help you choose the best place to organize a water source, and also recommend the best pump to cope with a specific volume of liquid, and an adapter, and will also put an end to the question of the need to install a caisson and help solve many other problems, explaining the principle of operation in as much detail as possible.