Equipment for autonomous sewage systems must serve for a long time, operate without failure and not cause any problems with breakdowns. How to decide on the model and buy the most suitable fecal pump with grinder? After all, the list of responsibilities of this equipment includes not only pumping aggressive liquids, but also processing large organic particles.

For fans of country life, we will tell you in great detail everything about the design features and guidelines for choosing the right fecal pump. With our help, you can easily find and purchase the optimal model with the required performance and excellent technical characteristics.

The article presented to your attention describes in detail the types of fecal pumps and outlines their differences in design and operation. For potential buyers, a rating of models in demand on the market is given. The information is supported by photographs and video instructions.

Sewage pump grinders

Mechanical working elements - grinders - are an integral attribute of the fecal pump. The purpose of these elements is obvious: cutting, crumbling, dividing large and dense contents into small parts, which enters the pump along with the pumped liquid medium.

Different pump models are equipped with different shapes of grinders. Each manufacturer tries to achieve maximum effect. However, practice shows that changing the configuration of the chopper does not have a significant impact on the process. All grinders cope with the task quite successfully - they provide free passage of the pumped medium.

Typically, pumps contain grinders made like:

- impellers with blades-knives;

- cylindrical scissors-knives;

- cross-shaped cleaver;

- “meat grinder” type cutter;

- plate cutters.

Each type of cutter is practically no different from all the others in terms of efficiency. Another thing is the durability of the element. There is a direct dependence on the grade of steel.

This is what one of the design options for a fecal pump grinder looks like. The so-called “meat grinder” knife cuts large debris into small fractions up to 15 mm in size

Among the latest developments, the German design of the HOMA A-series submersible fecal pump, which uses an innovative grinder solution, attracts attention.

Installation

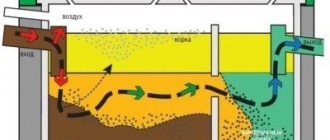

Let's consider installing a surface sewage pump to service a septic tank in the local area. For surface pumps, there is a fairly strict limitation on the height of liquid lift, so you must first determine the level of installation of the equipment. If the depth of the tank exceeds the permissible value according to the pump passport, then you will have to lower the platform with the installed pump below ground level and provide an additional sealed connection to the tank through the side wall.

Location of the pump in the sewer station

If you have to lower it, it is better to be below the freezing level of the soil, especially if you intend to use a fecal pump all year round. To arrange the installation site, it is best to use a caisson. It will provide tightness, protection from groundwater and external influences, precipitation and debris.

- Prepare the site for installation. This should be a massive metal slab on a gravel bed or a concrete base at least 10 cm thick with reinforcement and embedded elements for mounting the pump. The location should be chosen as close as possible to the tank from which the liquid will be pumped. In some cases, a remote location may be permitted to cover multiple injection fluid sources. But this must be taken into account in the pump power, given the large resistance added by each meter of horizontal pipe section to the suction.

- The pump is mounted in such a way that the pipe is directed towards the septic tank and minimizes pipe bends.

- To prevent water from leaking out of the system and to fill the pump faster, a check valve is installed on the pipe or inlet to the pump.

- To connect the pump, PVC pipes of the required diameter according to the device data sheet are used. Thinning or thickening the diameter of the suction pipe should be avoided. Each pipe element must be secured with clamps to the base of the tank or platform on which the pump is installed.

- A filter mesh or a grinder must be installed at the inlet.

- The length of the outlet pipeline is selected in accordance with the requirements for the pump and so that it is sufficient to deliver fecal matter and liquid to the discharge point. A minimum number of turns and bends should be used.

- The power cable should be selected in accordance with the requirements of the pump manufacturer and be sure to use a solid wire from the pump to the power point, the distribution panel. If necessary, you can install an outlet directly next to the pump, but be sure to comply with operating conditions and protect it from moisture and dirt.

At the installation site there must be enough space for servicing the equipment and all connection points for suction and outlet pipes. It is not worth installing close to the wall of the tank; it is very likely that even in a small area from the inlet with the mesh to the pump itself, a blockage will form that will have to be cleaned . If the pipe embedded in the tank goes directly into the pump, then the task will require dismantling the heavy equipment.

The installation process of lightweight compact household sewage pumps with a storage tank is carried out strictly in accordance with the requirements of the manufacturers. The location of the fastener is taken into account. The strength of the base and the load capacity of each fastener. Usually the mounts that account for the main vibration from the engine are indicated, and damping pads are included to reduce noise.

Equipment operating parameters

The power source for pumping equipment is usually a stationary electrical network. At the household level, the voltage is traditionally 220 V, but in industry and agriculture equipment with a voltage of 380 V can be used.

The following parameters are also important for the future owner:

- power (for domestic use 0.5 - 1.5 kW);

- productivity (150 – 600 l/min);

- height of the liquid column – pressure (10-20 m);

- operating fluid temperature (+1… +40 ºС);

- working environment temperature (+1…+40 ºС);

- degree of density of the pumped medium (up to 1200 kg/m3);

- acidity level of the working environment (Ph – not higher than 10).

Work with pumping equipment must take into account the specified parameters; moreover, for each individual model, the noted indicators can be expressed in specific values that cannot be exceeded.

Review of the best brands

The modern market opens up wide horizons for the selection of fecal pumps equipped with grinders. Italian, German, Spanish and other equipment are offered to buyers, and each manufacturer offers an impressive range of models for sale.

Imported products, present in large quantities on the modern market. The main suppliers of fecal pumps are German, Italian, Spanish companies

Grundfos. Among the best manufacturers, the company takes first place in the ranking. The Germans have succeeded in the development and production of pumps for various purposes. There were also German ideas in the production of fecal equipment with a grinder.

Their Grundfos Seg model, made for professional use, is well suited for ordinary private households. Despite the cast iron body of the device, it is easy to transport from one place to another.

The electric motor of the device is equipped with a sensitive protection system against overheating and short circuits. There is a rotor speed regulator for the electric motor. With a maximum operating power of 0.9 kW it gives a head of at least 15 meters. Immerses to a depth of 10 meters.

The Grundfos brand is famous for producing a wide range of garden pumps. The line of submersible pumps presented to the buyer is dominated by models for pumping clean and dirty water

Gilex . German equipment attracts buyers with its technology, but alienates it with its high price. It was the affordable price combined with good quality that brought “Dzhileks Fekalnik” to second place.

The development of Russian engineers also falls into the category of professional equipment. The efficiency of operation and quality indicators in the work were appreciated by many users of this equipment.

"Dzhileks Fekalnik" is made of stainless steel. It can be submerged to a depth of up to 8 meters. The power of the device is 0.4 kW, and the productivity is 160 l/min. The reliable hermetically sealed housing, equipped with a thermal protection system, also makes it easy to maintain.

Herz. The next best representative of liquid pumping devices is another German invention, this time from the Herz company. The WRS25/11 model is in high demand due to its reliability, durability, and wear resistance. A special feature of the model is its design for use in extreme conditions.

Sewage pumps from the German manufacturer Herz attract with excellent performance, practicality and a wide range, allowing you to choose equipment for pumping any volume.

The development from Herz provides a capacity of up to 260 l/min, creates a pressure of up to 14 meters and can dive to a depth of 8 meters. The weight of the pump is 31 kg due to the cast iron body and steel working parts. The electric motor winding has insulation class “B”.

Vortex . The well-deserved fourth position in the ranking of the best is occupied by the “Vikhr” fecal pump. The FN-1500L model showed good results in operation. Efficient pumping and efficient shredding of large debris. Fully automatic control of the water level in the working chamber - switching on and off when the specified parameters are reached.

Device for pumping feces of the “Vikhr” brand. The pump equipped with a chopper is produced by a Russian company. The technique has received clear recognition from users. Demand for “Whirlwinds” exceeds supply

The pump is capable of lifting a column of liquid up to 18 meters. The productivity of the device reaches 24 cubic meters per hour. The throughput capacity for crushed particles is 15 mm. Maximum power – 1.5 kW. The material is the steel blade of the chopper knife and the cast iron body of the pump itself.

Calpeda . Fifth place in the ranking was taken by the Italian product Calpeda GMG, which surpassed even the Germans in price. However, the high cost of this equipment is compensated by its high reliability and durability. This model has one important detail - the presence of self-sharpening chopper knives.

A fecal pump with a self-sharpening grinder from Italian manufacturers is designed for operation in extreme conditions. The design allows immersion to a depth of up to 20 meters. During operation, a pressure of up to 40 meters is created. Productivity indicator – 16 cubic meters/hour.

A powerful device from an Italian manufacturer is the Calpeda GMG fecal pump with a grinder, which is equipped with a self-sharpening mechanism. Equipment whose service life depends only on the natural wear of parts

This is what the rating of the best pumping equipment from the group of fecal systems looks like. Of course, this list should be taken purely conditionally. The range of pumping equipment is very large, and only five models are not able to show the situation completely. But when choosing a pump for everyday use, it is quite logical to focus on the designated list.

Main varieties

With all the variety of models of such equipment, they are divided into several categories:

Submersible units are made from high-strength materials and are equipped with a float on/off device. The housing is sealed and equipped with durable gaskets, reliably protecting the internal structure from the penetration of aggressive liquids. The main area of application of submersible devices is for pumping out the contents of cesspools, but they can be just as successfully used for pumping out storm sewer collector wells. And absolutely nothing prevents them from being used for watering vegetable gardens. Thus, by purchasing a submersible unit, you can solve many problems.

Installation of such a pump is carried out by attaching a suction pipe to the bottom of the tank, to which the unit itself is attached. The float switch ensures timely shutdown of the unit, preventing it from operating outdoors. The pumped substance plays the role of a cooling agent. A submersible sewer pump in a private home is one of the most reliable units in its class.

Semi-submersible fecal models are characterized by a reduced size of the outlet pipe. The maximum particle size is 15 millimeters. But such devices are equipped with a solid inclusion destroyer, so they are successfully used for pumping sewage waste in a private home. Semi-submersible units are most often installed on a floating platform, and their position always corresponds to the level of the pumped liquid.

When installing such a unit, the lower part is located in the liquid, the upper part is above its level.

Surface pumps are usually installed outside the tank and therefore require the use of a protective casing. Such units are not characterized by high productivity, and the maximum permissible size of solid inclusions is no more than 5 millimeters. However, the long service life and very affordable price of such a unit make it very popular among residents of country houses.- Domestic sewage pumping stations are designed to solve a number of specific problems related to the organization of wastewater disposal. In this case, the following points are resolved:

- the possibility of including plumbing equipment located below the level of the main sewer line into the general drainage system. The equipment allows you to lift liquid to a height of 5 to 15 meters, which allows you to place household plumbing in the basement and basement floors;

With the use of such equipment, it becomes possible to transport wastewater over a distance of up to 100 meters, without worrying about compliance with slope rules for gravity systems. The problem of possible seasonal soil movements that deform an extended pipeline is also being solved.- The use of a grinder in a sewerage pumping station makes it possible to obtain a pumped-out substance of a homogeneous mass, which makes it possible to use pipes with a diameter of 40-50 millimeters.

- Such installations make it possible to introduce a carbon filter into the design, which eliminates the smell of sewage from the room.

The criteria for choosing a station installation are the following circumstances:

- The depth of the location of the main sewer system and the presence of a height difference between them and the connected plumbing equipment.

- Type of wastewater - temperature and characteristics of contaminants.

- The estimated volume of sewage waste expected to be pumped by the pumping station when used in normal mode.

- The need for a device to operate in automatic mode and the choice of method for controlling the installation.

Pumping units for domestic use are available in compact designs and can be installed directly under the sink, bathtub or behind the toilet without taking up much space.

Conclusions and useful video on the topic

Overview of the technical characteristics of the pump from the Polish manufacturer:

Fecal pumps containing a grinder in their designs should be considered technical equipment designed to serve not only for the benefit of industrial production farms. This equipment is necessary for any private household, as it has wide functionality for pumping out contaminated liquids.

You can talk about how you selected and used a fecal pump in the block below. Please write comments, ask questions about controversial and unclear points, photo dividers and useful information on the topic of the article.