The “Rucheek” pump was invented back in Soviet times for use in summer cottages and today is very widespread. Its operation is based on the vibrational mobility of an armature with a membrane, produced by the action of an electromagnetic coil. It can be used to clean wells clogged with silt, to deliver water from a well for consumption, to deliver water for irrigation, to fill a heating system, when pumping out a pool or reservoir. It is characterized by relatively low cost and good quality.

Connection and operating rules

Before installing the “Rucheek” pump in a well or borehole, a number of preparatory measures should be completed. First, determine exactly at what depth the pump will be suspended. You should stock up on a cord or rope of suitable length and provide a place for fixing the cable while the pump is operating.

Each Rucheek pump is equipped with a technical passport. Before installing the device, the manufacturer's recommendations should be carefully studied and applied.

The cord must be strong enough to support up to five times the weight of the suspended equipment. In the case of “Rucheyok” we are talking about twenty kilograms.

This point should not be neglected, because a pump falling into a well can become a real disaster. And getting broken equipment out of a well is not the greatest pleasure.

To partially dampen vibration, the pump is attached to a cord on a suspension made of durable and elastic rubber, a piece of which must also be stocked up in advance.

To suspend the “Rucheek” pump, you should use a strong nylon cord that can withstand five times the load. If the length of the supplied cord is not enough, you need to purchase a new one; extending the cord is unacceptable

Another necessary element is a hose through which water will flow upward. Its length must correspond to the immersion depth of the pump, and the diameter of the hose must match the pump nozzle.

However, there are adapters that allow you to attach a hose of a larger or smaller diameter to the pipe. The end of the hose on the pipe or adapter should be secured with a clamp, unless other methods of fastening are provided.

To do this you need to follow a number of simple steps:

- Unpack the “Rucheek” pump, straighten the electrical cable.

- Attach a nylon cord with a rubber adapter to the eye on its body.

- Attach a hose or water supply pipe to the pump outlet.

- Place a special protective filter on the water intake hole.

- Carefully and smoothly lower the pump into the well or well.

- Secure the nylon cord.

- Connect the pump to the power supply.

- Press the power button and check the operation of the device.

When purchasing a “Rucheek” pump, you should immediately check the length of the electrical cable that comes with the product. The standard model can be equipped with a cable length of 10, 15, 25 or 40 m, this is reflected in the cost of the device.

If the wire is not long enough, the problem can be solved in one of two ways.

The length of the “Rucheek” pump cable can be 10, 15, 25 or 40 meters. It is best to immediately purchase a device with a cable of sufficient length

The first is to completely replace the pump cable with a new wire of the appropriate length. To perform this operation, the pump will have to be disassembled and then reassembled. Sometimes it’s easier to extend the cable - attach a fairly long piece to an existing wire.

The junction of the cables should be carefully insulated and protected with a special heat-shrink sleeve. Complete cable replacement is more reliable because the part of the wire immersed in water remains intact.

But cable extension is a less labor-intensive procedure. After the pump is lowered into the water, you should inspect the resulting system and make sure that the load falls on the nylon cord and not on the cable or hose.

If you decide to extend the electrical cable of the “Rucheek” pump, you should use a special heat-shrink sleeve to protect the connection point

Both the cable and the hose should hang freely, remaining in a loose state. However, the cable should not be allowed to sag excessively, since during the process of lowering and raising the pump it may become tangled, and this will create additional problems.

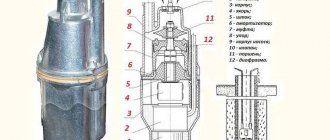

This diagram clearly shows the procedure for installing a “Rucheek” type pump, depending on the model, which can be with bottom or top water intake

After this, the device should be turned off to cool down. Manufacturers also recommend taking short breaks every two hours of operation of the device. Such a gentle operating mode will have a positive effect on the service life of the device.

When hanging the device, remember that it should be located approximately 0.5-1 meter from the sandy bottom, otherwise it may simply be pulled into the sand or layer of silt.

“Rucheek” for all occasions

It is best to equip a relatively shallow well with a low flow rate or a well with similar characteristics with a “Rucheek” pump or another budget model. More powerful and expensive equipment is simply not needed here. It will empty the well too quickly; the danger of a “dry run” in such a situation is very high.

The product data sheet says that the pump is intended only for digesting clean water. However, over the decades of the model’s existence, owners of private houses and summer cottages have found a wide variety of uses for this device. For example, this model is widely used when pumping wells.

This table shows the main characteristics of the “Rucheek” pump, thanks to which this unit is able to cope with many household tasks

After drilling of such structures is completed, the water remains heavily contaminated with particles of silt, sand, etc. To obtain potable clean water, this mixture must be completed.

Practice has shown that “Rucheek” copes well with this task. The peculiarity of the Brooklet pump is that it has no rotating parts. Therefore, it does not clog too quickly when working in contaminated water.

Periodically, the pump is removed, disassembled, washed, the necessary repairs are made, and then reassembled and put into operation. Of course, with such treatment, the wear rate increases significantly. It is not surprising that during the process of pumping a well, the pump can completely fail.

To clean one well, depending on the situation, you may need two or even three or four such units. But in terms of money it comes out much cheaper than purchasing special equipment with increased wear resistance.

Inexperienced property owners sometimes believe that they can pump the well using the pump that will supply water to the water supply of the house. This is absolutely the wrong decision.

Owners of wells and wells periodically have to clean their structures. In these cases, a pump of this type is irreplaceable. It will effectively cope with pumping contaminated water from a well or borehole.

If the pump is at hand, all work will be completed much faster. If the well is silted or sandy, the vibrations that arise during the operation of the Brook turn from an enemy into a friend.

This is what the “Rucheek” pump looks like disassembled. The durable steel case reliably protects the device from external influences and frequent breakdowns

High-quality and expensive submersible pumps are usually designed for long-term operation with clean water. It is better to pump water heavily contaminated with sand using a “Rucheyok” or other budget equipment. If, after pumping the well, some “Stream” managed to “survive”, it will definitely find further use.

The vibrating effect allows you to quickly and effectively destroy the silt plug, clean the holes in the well filter and pump out dirt to the surface. As a result, the well's flow rate will increase significantly.

To clean silted wells, it is recommended to use a model with an upper water intake.

Image gallery

Photo from

Disassembling the Brook pump for repair

Replacement of worn seals and fasteners

Cleaning pump filters

Reassembly of the vibration unit Rucheek

“Stream” gathering dust in the barn will become a real find if the main pump in a well or well breaks down for some reason. It will be a completely acceptable temporary replacement, allowing you to restore water supply in the house in a matter of hours. While the main pump is being repaired, you will not have to purchase or rent new equipment.

Flooding of a basement, inspection hole in a garage, or other similar recess with drainage water is an unpleasant situation. And scooping out unnecessary liquid with a bucket will take a lot of time and effort.

Since drainage water usually does not contain much contaminants, the “Rucheek” pump is ideal for pumping it out.

Inexpensive, small-sized vibrators are used in cleaning water intake structures. They stir up silt deposits at the bottom of wells and wells, which are then pumped out by drainage pumps

It works slowly, of course, but steadily. Of course, one cannot expect ideal purity from drainage water. To improve the operation of the pump, it is recommended to use a special additional filter that will protect the structure from contamination.

The filter is made in the form of a cap and is intended for the upper part of the pump. To put it on, it is recommended to warm up this element first. Then installing the filter will be much faster and easier.

If your house has a swimming pool or other large reservoir of water, the “Rucheek” pump can be used to pump water out of such containers. In this case, it makes sense to use the “Rucheek-1M” . Unlike other models, it is equipped with a lower water intake, which allows you to completely remove water from the tank.

Pumps of the “Rucheek” type are also used when installing heating systems, namely for pressure testing, when filling the system with water is required. Water can be taken from a well or brought in a separate barrel.

Place a hose on the pump inlet and lower it into the water. The second hose, put on the pump supply pipe, is connected to the open drain valve of the heating system.

Using a pressure gauge, the pressure in the system is monitored. After crimping, the identified faults are eliminated. In general, we can say that “Rucheek” type pumps can be used to solve almost any problem of pumping out liquid or pumping it to its destination. The main requirement is that the water should not be too dirty.

The main advantage of the “Rucheek” pump and similar models is its budget price. It’s not a pity to “throw” them into doing “dirty work”. If the device fails, simply replace it with a new one.

Advantages and disadvantages

The most important indicator is the stable quality of pumping equipment of this brand, good performance characteristics, and efficiency. In addition, domestically developed products have the following advantages:

- Simple and reliable design.

- Relatively unpretentious in work.

- Reliability, low cost.

- High maintainability - it is possible to replace all rubber components and elements.

- Easy to use.

- Does not require expensive maintenance.

- Can be used for pumping water from any artificial or natural reservoir, container, well, well.

- The electrical part of vibration pumps cools well in cold water. Since the pump is located in the upper layers of the water, it cannot become clogged with debris or silt, which usually accumulate at the bottom.

- The pump set includes a thermal protection device, so if the unit heats up to critical levels, it automatically turns off. This usually happens if the water level in the source drops significantly.

There are also disadvantages in devices of this brand. This:

- Insufficient performance, therefore the “Rucheek” pump is designed for use in wells and boreholes with low water levels - it can supply water for a long time, and at the same time will not drain the hydraulic structure. Because of this, a disadvantage as such cannot be considered.

- The thermoregulation sensor may not always work. This leads to overheating of the unit, which shortens its service life.

- Vibrating models can destroy the well.

- Submersible pumps must not be used to pump contaminated liquids or sewage.

Specifications

Different modifications of pumps of this brand differ only in power and performance. The table shows the technical characteristics of the Rucheek pump.

As you can see, the spread of some indicators is quite large, which requires explanation:

- The performance of the pump depends on the depth from which it pumps water. When diving to a depth of 40 m, it will be about 400 l/h, from a 20-meter depth the productivity will increase to 900 l/h, and if the intake is carried out superficially, from an open source with a dive of up to 1.5 meters, it will increase to one and a half cubic meters.

- Another important characteristic about the Brooklet pump is pressure. 40m is the nominal pressure at which the device provides the specified performance. As the pressure increases to the maximum value (60m), it drops.

- Low power consumption, not exceeding 300 watts and comparable to the power consumed by a conventional computer, makes the device very economical and most suitable for working in sources with low flow rates. More powerful units will quickly empty it and turn off, stopping the water supply. And the Brook will work evenly, providing, albeit small (5-7 liters per minute), but continuous supply.

- Such pumps are intended only for pumping clean water with temperatures up to +35 degrees Celsius and a content of undissolved mechanical impurities of no more than 100 grams per cubic meter.

Which is better?

All vibration pumps are in the same price range from 30 USD. up to 40 – 50 USD Their cost is so insignificant compared to the costs of constructing a well or borehole that it is not worth saving and buying a frankly low-quality product.

The domestic market is flooded with good models of Russian, Ukrainian and Belarusian production. But there are practically no foreign units: Italian, German, or they are not in demand. Don't buy a vibration pump made in China, save a little and just throw away the money.

Brook

One of the most common and reliable domestic pumps. Models with this name are manufactured by different factories: the Russian JSC Livgidromash (Rucheek), the Belarusian JSC Technopribor (Rucheek 1). Has an upper water intake chamber and a pressure of up to 60 m

But pay attention, the Rucheek pump in tests produced 598 l/hour and raised it to a height of 50 m, and Rucheek 1 only 300 l/hour to a height of 30 m. The name is practically the same, but the characteristics are different. Although both are equipped with good thermal protection

Although both are equipped with good thermal protection.

Baby

He also gained good fame among the owners of summer cottages. The “Malysh” pump is produced by “AEK Dynamo” (Moscow), “Electrodvigatel” (Bavleny), as well as other manufacturers. All of them are of fairly high quality, but it is necessary to clarify the characteristics, since there are models with an upper water intake, and others with a lower one. But you don’t have to worry about thermal protection; all models have it. This largely determines the reliability of the Kid and his good reputation.

Aquarius

This pump is more expensive than its counterparts, about 50 USD. It is produced in Ukraine, where its model range is very wide. You can choose a pump with dimensions that fit into a 90 mm well. You can have a unit with a capacity of 1500 l/hour or a pressure of 100 m. And also equipped with two valves. All models have high-quality thermal protection

But pay attention, the Russian Aquarius 1 vibration pumps are an order of magnitude inferior to the Ukrainian ones, so don’t make a mistake when choosing

In the end, I would like to summarize what an ideal vibration pump for a summer house should be. A unit with a capacity of 800 to 1300 l/hour, a pressure of 60 m, an immersion depth of 7 m, thermal protection, a long cord, and long-term operation without rest. And don’t forget to correctly calculate the specific performance you require.

Share on your social network or leave your comment.

Specifications

Each modification has its own technical characteristics. But there are common characteristics that are common to all models. These include:

- Power consumption. Each device needs from 220 to 300 W to operate.

- In order for the “Rucheek” pump to operate uninterruptedly, it needs a voltage of 220 V. In other words, you need a regular household electrical network.

- The maximum pressure, depending on the model, is from 40 to 60 m.

- Performance depends on depth. For example, if the liquid needs to be raised to a height of 1 m, then the pump can supply 1.5 cubic meters of water in an hour. From a depth of 40 m during the same time, the device will pump about 430 liters of liquid.

Based on the technical characteristics listed above, the Rucheyok pump is an ideal unit to meet the needs of any country house.

Below are also the technical characteristics of vibration-type equipment:

- The pump housing houses two working chambers. One of them is motor, the other is a pump with an anchor and a pump.

- The chambers are separated by a round diaphragm, made of thick elastic rubber. An anchor is attached to the rod, which is equipped with a rubber shock absorber.

- A magnetic coil is located in the chamber with the motor. It causes oscillations of the armature, which drives the pump pumping liquid.

- To ensure water drainage, the pumps have a valve. When the unit is turned on, it closes the hole, and when the device is turned off, the valve moves back and the liquid leaves the working area of the pump compartment without obstacles.

Operating principle and advantages of the “Rucheek” submersible pump. Do-it-yourself repair instructions

The Rucheek pump was developed back in Soviet times more than forty years ago. It was manufactured at the Mogilev OJSC "Olsa" in Belarus. This device competed with any models in this class. This was explained by simple reasons:

- Its dimensions and cylinder shape are convenient for use in places inappropriate for other devices, such as a well, the bottom of a deep well, flooded garages and basements, the shore of a reservoir;

- Easy to use: does not require filling with water before use, no need to lubricate the mechanism;

- Long service life associated with high quality indicators and many years of process technology development;

- Good water pressure;

- The minimum power consumption is about 225 W per hour.

Breakdowns are rare, repair work is not complicated, spare parts are easily accessible and inexpensive. On average, a pump can last from five to eight years.

The “Ruchek” pump involves drawing water from above, this of course is a plus in terms of the entry of various contaminants into the device.

Technical characteristics of the “Rucheek” pump

The pump has a low power consumption of two hundred twenty to three hundred watts. This is comparable to an aquarium pump filter for three hundred to five hundred liters. If necessary, it can be easily powered by a battery or a generator. The pump is powered from a household network. For wells up to forty meters deep, the capacity will be up to 40 liters per hour. If the fence is superficial and the depth of the fence is no more than one and a half meters, the capacity of the fence will be up to one and a half cubic meters per hour. An operating time of up to twelve hours is provided and often used.

Brook pump design

It is not always necessary to attach a pump. In a vertical position it hangs on a cable.

The pump has a practical metal body and is very durable. To prevent collisions with the walls of the well shaft, a rubberized shock-absorbing ring is put on it.

Submersible vibration pump - operating principle

Applicable:

- for delivering water from a well for consumption;

- for delivery of water for irrigation;

- for filling the heating system;

- when pumping out a pool or tank.

The “stream” is used to clean wells clogged with silt. The pump can also be used to pump out drainage water. It is mainly used, of course, for pumping drinking water, but due to various situations that arise in summer cottages, it can be used as a drainage device. There is even a special device on sale that protects the pump when working with contaminated water.

This is interesting: Do-it-yourself balcony on the roof of a house: let’s look into it in detail

Scope of application

With its low power, averaging 225-300 W, and minimal price (1300-2100 rubles depending on the model), the Rucheyok water pump is quite capable of providing water to a small family of 2-3 people, as well as watering a summer cottage area of 6 -12 acres.

The vibration pump can also be used for purposes such as:

Pumping water from swimming pools, basements and various containers. Most often, the problem of flooding of premises located on the lower tiers of residential buildings and utility structures arises during the spring flood, when underground groundwater rises especially high. Since they contain practically no solid impurities, they can be pumped out using a submersible vibration pump Rucheek.

Important: To pump out contaminated water, you must use a filter together with the Rucheek pump, which will prevent it from possible large mechanical contamination. The filter for the pump “Rucheek” is a special device in the shape of a cap that fits onto the receiving part of the pump. It is better to perform this procedure after the pump has warmed up.

Filling the heating system before starting it up. This manipulation is carried out in the absence of the possibility of connecting to a centralized heating system at this stage of construction. The process itself looks like this:

— Water is delivered to the house in a barrel into which a hose from the pump is inserted.

— The second hose connects to the radiator drain valve.

— The tap opens simultaneously with the pump starting.

— The system is filled using a pressure gauge until the pressure in it reaches the desired level.

Providing autonomous water consumption for one point. This could be a washing machine, shower or washbasin. That is, the device that consumes water must be used locally, and the pressure will depend on the depth of the water source.

Temporary replacement of the main pump.

Drawing water from slow-filling sources. By using the Rucheek submersible pump, you can protect yourself from the need to restart the water supply system at home when the water level in the operating well decreases.

Restoring the functionality of a silted well. In this case, the device is lowered to the water intake level, at a distance as close as possible to the filter, after which it is started. Thanks to the vibration that occurs during its operation, solid deposits are removed from the filter, after which it begins to work efficiently and correctly again.

Important information: To restore water flow by 30-40%, a few hours of operation of the vibration pump is sufficient. If the well is heavily contaminated, this procedure can be repeated several times.

Installation

In order for any vibration pump to operate effectively throughout its service life, it must be installed correctly. You can do this with your own hands and without the involvement of specialists, the main thing is to take into account a number of features.

- The submersible pump must be completely covered with water, but located at a height of 50-70 cm from the bottom of the well or container. If you lower it to the very bottom, the device will raise debris and silt, the water will become dirty, and the mechanism will quickly clog.

- The device should not touch the walls of the well with its body and should be secured to a nylon or galvanized cable. Due to vibrations, the pump will either destroy the walls of the well, or, if the walls of the container or well are quite strong, it may damage its housing.

It is imperative to check the insulation of the electricity supply cable, since water easily conducts current, and this can lead to irreparable consequences. All fasteners must be adjusted and rechecked

Separately, it is worth paying attention to the channels through which water will flow from the discharge chamber - check them for blockages and leaks. If you follow the operating rules recommended by the manufacturer, the vibration pump rarely breaks down

And even if they are not observed, the first malfunctions may occur only after 3-4 years of operation without proper care. If the vibration pump is still under warranty, under no circumstances should you attempt to open the housing and carry out repairs yourself. You need to contact the seller or service center with which the contract has been concluded

If you follow the operating rules recommended by the manufacturer, the vibration pump rarely breaks down. And even if they are not observed, the first malfunctions may occur only after 3-4 years of operation without proper care. If the vibration pump is still under warranty, under no circumstances should you attempt to open the housing and carry out repairs yourself. You need to contact the seller or service center with which the contract has been concluded.

The problem can be diagnosed based on certain symptoms.

The vibration pump hums, but no water flows. There may be several reasons for this problem. For example, the piston fasteners have become loose, the valve has been damaged, or the rod has broken. It is necessary to disconnect the faulty device from the network as quickly as possible and lift it to the surface, after which you can disassemble the pump and look for the cause of the breakdown.

- The vibration pump hums and gets very hot. Most often, the cause of such a malfunction is the operation of the pump above the surface of the water, which is contrary to the rules for using the device. The design of the vibration pump does not include a cooling element, which replaces the constant presence of the mechanism in cool water, so the pump suspended in the air quickly overheats and damages the electromagnet. Replacing it yourself is quite difficult, but it is possible with certain skills in working with a soldering machine.

- The vibration pump works, but is completely silent. Vibrating devices cannot operate in absolute silence, so the absence of a steady hum should also be alarming, as should excess noise. The cause of this malfunction is a dropped voltage in the network. In this case, you need to disconnect the device from the power supply as quickly as possible and troubleshoot the network itself. The pump can be reconnected only after the mains voltage has normalized.

Brief overview of popular models ↑

There are more than a dozen popular models on the market, but the owner must finally decide which vibration pump is best for a particular well. To do this, you should take into account the design features and technical characteristics of each product. Let's look at five well-known models.

The compact device has several modifications with the following characteristics:

- voltage – 220 V;

- power – 225-300 W;

- productivity – 400-1500 l/h;

- pressure – 40-60 m;

- weight – 5 kg;

- cost – 2250-2500 rub.

About the pump "Rucheek-1"

This is a universal-purpose equipment, but is not suitable for pumping dirty water (for example, sewage). It does not have special fastenings to the walls of the well; it is suspended on a cable or strong rope. It has a long service life and replacement of rubber parts is easy. Operating time is up to 12 hours a day, constant monitoring is not required.

The household pump "Malysh-M" is intended for use in summer cottages:

- voltage – 220 V;

- power – 240-245 W;

- productivity – 1.3-1.5 m³/h (up to 1.8 m³/h without pressure);

- immersion depth – 3 m;

- weight – 4 kg;

- cost – 1400-1800 rubles.

This model is designed for pumping clean drinking water, but there are also drainage modifications that can deliver liquid with a high degree of contamination. Most often used to provide 1-2 water points or for watering a garden. There are options with upper and lower water intake. The main element of thermal protection is an enlarged copper winding that protects against overheating.

Simpler models are suitable for watering a vegetable garden, while powerful modifications are suitable for providing water to a home, farm, or small business.

- voltage – 220 V;

- power – 225-240 W;

- productivity – 24 l/min;

- maximum head – 60 m;

- weight – 3.8-5.5 kg;

- cost – 1400-1800 rubles.

The advantage of the brand’s products is the duration of continuous operation up to 200 hours (the maximum value of analogues from other manufacturers is up to 100 hours). An easy-to-use vibrating well pump has an upper water intake fitting, which prevents the intake of dirt and debris, but allows particles up to 2 mm to pass through, so it can also be used for cleaning purposes.

The minimum diameter and compact dimensions of the equipment allow it to be used in both wells and boreholes.

- voltage – 220 V;

- power – 180-280 W;

- productivity – 960-1100 l/h;

- height of water rise – 60-80 m;

- weight – 4-5 kg;

- cost – 1700-3000 rubles.

When purchasing, pay attention to the length of the power cable - from 10 to 40 m. More powerful models are equipped with a more powerful motor and a built-in thermostat that protects against overheating. Inexpensive products are used for pumping only clean drinking liquid

Inexpensive products are used for pumping only clean drinking liquid.

Small, lightweight pumps are designed for gardening and household work in suburban areas.

- voltage – 220 V;

- power – 200 W;

- productivity – 660-1050 l/h;

- height of water rise – 40-75 m;

- weight – 4-5 kg;

- cost – 1200-2500 rub.

Some models have a lower water intake, which is convenient for operation in deep reservoirs. Sheet steel and copper motor windings ensure a long service life. In addition to a set of cables, the kit includes spare membranes.

Repair features

Many consumers do not repair pumping equipment, but prefer to purchase new products because they believe that restoring the device is expensive and difficult.

But in fact, just the opposite: pumping units have a very simple design.

But, if you don’t know some of the features, the repair may not be successful at all. Problems may arise when:

- Removing the mounting bolts. During operation of the pump, the fasteners become covered with rust and cannot be unscrewed. The best solution is to cut off the bolt heads with a grinder. If you take a large disc to an angle grinder, you can damage the internal mechanisms, so you need a small disc element.

- If the electromagnet filling is damaged, you need to fix this problem with auto sealant. It's easy to do. Use a grinder to make shallow grooves on the electromagnet - they will help to securely strengthen it. Then all that remains is to apply the adhesive composition to the magnet itself.

- If the membrane is worn out or damaged by foreign objects, it must be replaced with a new one.

Important! If the winding breaks down, if you do not have the proper knowledge, it is best to contact a specialist

Prevention of pump unit breakdowns

By following the operating rules recommended by the manufacturers, you will reduce the risk of pumping equipment breakdown to a minimum, and it will serve you for many years.

Basic operating rules:

- Do not allow the pump to operate without water.

- Do not use the pump if there is unstable voltage in the electrical network.

- Do not operate the pump with a damaged power cord or housing.

- Do not move the unit by the power cord.

- Do not pinch the hose to increase pressure.

- Do not pump water containing dirt, impurities, or debris.

When installing the pump in a well, it is necessary to put a protective rubber ring on it, which will protect the equipment from hitting the walls.

The unit can only be turned on/off using a plug or a two-pole switch embedded in the fixed wiring system.

Before use, carefully read the operating instructions and follow the manufacturer's recommendations, this will help avoid damage.

During the operation of the “Rucheyek” vibration pump, it is necessary to carry out timely preventive inspections and monitor the quality of the pumped water. If the water coming in is dirty, then the pump must be turned off and its position relative to the bottom checked.

Main types of malfunctions and their causes

All faults can be reduced to two types:

- electrical part;

- mechanical part.

In turn, each of them can be divided into two subgroups. This is a complete inoperability and partial disruption of work.

Partial loss of pump functionality does not necessarily mean a violation of regulation. Sometimes the reason lies in the failure of its individual parts. But let's start in order.

Type #1 - electrical faults

The most common malfunction is coil failure. Complete burnout or breakdown of insulation on the housing. Detachment from the compound body occurs less frequently. There is only one reason for the malfunctions - dry operation, without water, which causes the coil to overheat.

Then the insulation burns, the compound burns out and, due to the difference in thermal expansion of different materials, the filling delaminates and the yoke falls out of the body.

Sometimes the pump stops pumping altogether, but the housing may break. This is the most unpleasant breakdown, which can only be avoided by following the operating rules.

Type #2 - mechanical failure

There is a complete variety of causes and consequences:

- Liming of parts. Occurs from pumping hard water. This is a white limescale deposit similar to limescale in a kettle. This is not particularly noticeable during operation, but after long-term storage, for example in winter, the lime may jam the piston. The malfunction is rare; as a rule, it only makes disassembly more difficult and slightly reduces the pump’s performance.

- Violation of the integrity of the body. The impression is that it was precisely cut with a file or router. Usually the top edge of the body. The reason is simple - contact with the concrete surface of the well during operation.

- Pump working cavity clogged. For example, sand. Sand and pebbles, branches, algae - all this disrupts the tightness of the valve to the bed. Not critical, but unpleasant - the pump does not develop the required power.

- Loosening of threaded connections. Occurs from vibration, occurs infrequently. For example, the nuts securing the piston are loosened. The consequences can be the most dire - up to the destruction of the hull.

- Violation of rubber properties. Leads to a decrease in pump power. In rare cases, complete cessation of performance occurs.

The most capricious part and sensitive to the weakening of rubber properties is, oddly enough, a massive shock absorber. Too elastic rubber contributes to the core breaking, too hard - a decrease in vibration amplitude and loss of power.

In addition, when the core is rotated in the shock absorber, the projection of the base of the rod (a part called an anchor is pressed onto the rod) does not completely coincide with the yoke and is less attracted to it. A hard piston moves water worse. A broken piston does not pump at all.

When the valve loses elasticity, it works worse, but the pump does not fail completely. We also observe when the valve adjustment is violated.

Sometimes there is simply a loss of power. Often the reason is to turn on the pump again without immersing it in water. Most often this happens due to neglect of operating rules.

For example, hanging a pump on a steel cable and without a shock absorber - the pump mount must be shock absorbent! Therefore, the kit includes a fishing line or nylon cord and a shock-absorbing ring for fastening.

Placement nuances

Installation is possible provided the well diameter is at least 120-125 mm, the electric submersible pump can withstand a standardized depth of up to 10 m (and, if necessary, even more, the strength of the housing allows this). There is a relationship: the deeper the pump is placed, the lower its performance; as it goes down, the pressure decreases to 70%. The pump is immersed in the well in the following sequence:

- A protective ring and filters are placed on the body.

- The pump is lowered into the water at least 1 m using a fastening cord (string or cable). To prevent winding of the electrical wire and subsequent jamming of the housing, it is advisable to secure the wiring and pressure hose with clamps.

- The location of the device is checked: the pump should not lie on the silt, the recommended distance from the bottom is 1 m.

- The insulation of the supply wire and control system is checked. It is recommended to operate the pump with the expansion tank connected.

It is not advisable to use the Rodnichok to connect to more than one water intake point (especially if they are located in different buildings), this leads to its overload. This is a deep unit, but the lower it goes, the weaker the pressure will be. When used for cleaning wells, the pump is located at a minimum distance from the bottom filter and breaks up solid deposits by vibration. In this case, additional insulation of the housing is required; ideally, it is completely protected from silty suspensions and solid lumps.

Operating nuance: the pump should never be raised or lowered using the power cord or pressure hose! Insulation failure leads to a short circuit in the network and tripping of the protection. To avoid emergency shutdowns, the location of the connections is checked. It is unacceptable to lower them into water; if the depth of the well exceeds the length of the cord, then it is worth extending it or purchasing the necessary modification in advance.

- Mechanical impact on the housing with subsequent depressurization.

- Pump operation without water.

- Overheating if the recommended mode is violated (more than 12 hours of continuous operation).

- Stones and silt particles get inside the housing.

WATCH THE VIDEO

Preventive measures include the creation of correct operating conditions: the housing is protected by additional filters such as a cap or glass (they are purchased separately) and a rubberized ring. The last point is very important; the mechanism vibrates at a high frequency; without protection from direct contact with the walls of a well or borehole, it cannot withstand the load. Long-term operation is allowed, but no more than 12 hours a day and subject to shutdowns for 10-20 minutes at least once every 2 hours. Heating leads not only to damage to the insulation, but also to peeling of the fill. The pump cannot pump hot water; the permissible liquid temperature is ≤ 40 °C.

If the fill peels off (most often due to overheating), you can try to repair the Fontana yourself. The electric drive is separated from the top of the housing, the core is removed and shallow grooves are cut. Then the magnet is lubricated with glass sealant, placed back and fixed until completely dry, after which the pump is assembled. The pump assembly diagram is indicated in the attached instructions. The valve is changed according to the same scheme, but without disassembling the electrical chamber; such repairs will require a thick rubber ring.

If the pump is running but the water is not pumping

There are three steps to solve this problem.

Step 1. Slightly loosen the lock nut that is located where the water enters. This action should slightly reduce the efficiency of the device.

Step 2. The rubber cuff may be damaged. This can only be checked after disassembling the pump. They look quite small (4 cm in diameter), and they don’t cost much.

Step 3. The pumping rod is damaged. Repairing a device with a faulty pumping rod is a very complex procedure. You will need the old pump as a parts donor. In addition, getting to this part is very difficult, and you cannot do it without special equipment.

Device capabilities

Of course, this pump will not radically solve your global problems in the water supply of a large suburban area, since on average it has a power of one hundred and fifty to two hundred and twenty-five watts. But the owner of a country house will be able to effectively understand many processes.

Hydraulic feed

In the house, this unit copes with the necessary supply of natural water. True, at the same time you will not be able to calmly bathe in the bathtub, wash the accumulated dishes and do laundry, since the pump only produces up to seven liters per minute.

But if you use it skillfully and sparingly enough, it will be enough to take a warm summer shower and wash the accumulated clothes. Water pressure directly depends on the depth of a particular water resource. The higher the number, the correspondingly less feed.

It is not advisable to connect the pump simultaneously to your country house, bathhouse and other important outbuildings, as this may cause an unwanted automatic reboot of the system.

Pump replacement

Some private owners of country houses who use more powerful and expensive equipment in their home water supply buy this budget pump as insurance. After all, absolutely anyone can break down, even the best imported device, and it will take a lot of time before you get it repaired by specialists and get it back.

And in any case, the pump will be useful to you on the farm. And then “Rucheek” will be useful to you to meet your life needs. It is a kind of lifesaver for the owners of country houses and will not leave you alone in difficult troubles, of which there are so many in the daily life of every person who owns a country house.

Application in a slow-filling source

When carefully digging a well or well, it is difficult to guess in advance how quickly the proper water level will be restored after repeated use. One source will do this instantly, while the second will take many days for the long-awaited update.

But when buying a device, few people think about this, and it happens that the unit pumps out water very quickly rather than replenishing it. In such a situation, the system may shut down automatically and require an early restart. By drawing quickly, the chances of getting cloudy water increase.

It is best to take “Rucheek”, as it works more stably and has a low intake intensity.

How to successfully restore a clogged well?

You can develop a system using the Brook. The quality of the water, of course, will not change, but the volume will increase significantly, you will immediately notice this for yourself.

Turn on the pump and lower it as close as possible to the required filter. Thanks to the vibrating mechanism, numerous layers will be knocked out and then raised to a flat surface. Several such successful attempts, and the well will begin to come into complete order.

It is not necessary to stand directly next to your well while working. In any case, the water pump will not pump out all the water. Therefore, you can take care of your accumulated household chores. For example, you can water your garden. You will immediately notice a change in water quality and volume.

Pumping water out of a flooded room

In the spring, very often, summer residents' basements and cellars are heavily flooded. Carrying water out using small buckets is very problematic and takes up a lot of precious time. A good quality pump from a Belarusian domestic manufacturer will help you here.

New heating system

When building a new house, the heating system is done first of all, rather than connecting to the water supply. We need to somehow fill all the pipes.

The scheme is this: you bring water in a huge barrel, insert this pump into it, and connect the second hose to the drain valve of the battery. Next, the tap is carefully opened and this unit is started. While the system is carefully filling, look carefully at the special pressure gauge to determine when the pressure is at the level you need.

Recommendations for selection

The following manufacturers are considered the best-selling vibration models:

Each manufacturer has models for different purposes. These can be pumps with a lower water intake or with an upper one, more powerful or weaker, with or without additional protection. The principle of operation is the same, the main differences are the depth of immersion, the method of water intake, and productivity.

You can also find other well-known companies on the market such as Grundfos or Karcher. They were not included in the list, since they are more focused on the production of pumps of a different operating principle: screw, centrifugal, vortex and others.

The Aquarius vibration pump is distinguished by increased power and lifting heightSource 999.md

Design

Vibration pumps are in demand due to their reliability, affordable cost and ease of operation. The device is connected to a hose and placed in the well, with this all the homeowner’s tasks are over, you just need to supply electricity to start pumping water.

The metal housing is completely sealed and additionally protects the pump from mechanical damage. Source pinterest.com

A submersible vibration pump consists of many elements. If you look at their location on the diagram, you can identify 11 main components. In complex designs, additional elements may be present, but this does not change the principle of operation.

The vibration pump consists of 11 main elementsSource obrawa.ru 0 0 0 Electromagnet. Electric coil with a steel plate core.

- Electromagnet. Electric coil with a steel plate core.

- Vibrator. An electromagnet is attracted to a magnet when current is applied.

- Discharge chamber.

- Suction chamber.

- Shock absorber. Responsible for returning the vibrator to its initial position. The better the material used, the more efficiently the work is carried out.

- Washers. Limit the piston stroke

- Stock. The piston bends.

- Valves. Elastic elements are responsible for absorbing water.

- Screw. Fixes the piston.

- Piston. The moving element creates increased pressure. Most often it fails due to contamination with small grains of sand and dirt.

- Outlet channel. Discharges water into the connected hose.

Sectional design of a vibration pumpSource vodatyt.ru

The design may vary depending on the manufacturer. For example, they may change the location of the valves or the outlet channel.

Points that deserve consumer attention

The numerous advantages of the “Rucheyka” model are accompanied by several negative aspects.

- Intolerance to idling. “Rucheek”, which is not equipped with thermal protection, can fail when operating without water supply even for a few seconds. Cause? Damage to the winding due to overheating.

- The threaded connections of the “Rucheyka” pump very often come loose. This is provoked by a continuous vibration process. But there is always a way out, you just have to replace the regular nuts with self-locking ones.

- Over time, rust appears on the housing bolts. The aluminum casing of the Rucheek pump is equipped with steel bolts, which are susceptible to corrosion during prolonged contact with water. It is easy to solve the problem - replace the existing parts with new ones made of non-ferrous metals.

- An additional filter in the form of a metal mesh, placed on the suction opening of the unit, can slow down the process of wear of the rubber elements of the Rucheyok pump.

- Over- or under-locking of the check valve is also easily resolved. Before you start using the Brook, you just need to tighten the nuts or adjust the fastening.

The “Rucheek” pump, like all vibration-type units, is sensitive to voltage changes. Reducing voltage levels by 10% halves performance. There is no point in rejoicing when a voltage higher than required by technical specifications ensures accelerated operation. This process leads to rapid wear of the mechanisms. Adding a voltage stabilizer to the Rucheyka pump will help eliminate problem situations.