The vast majority of domestic summer cottages are not connected to a centralized sewerage system. In many villages and gardening associations it is simply not provided. But sewage and flood waters still need to be pumped somewhere.

Therefore, your own sewage pump for your dacha definitely won’t hurt. Let's find out which model is better to choose, because the range of sewer pumps is extensive.

In order not to make a mistake with the purchase, you need to compare the characteristic features of different pumps with the upcoming operating conditions, as well as evaluate the feasibility of purchasing an in-house sewage system. A short review of the best manufacturers will help you choose a reliable unit for your garden.

Types of sewer electric pumps

Sewage pumps are divided into indoor and outdoor installations. The first models are chosen for installation near toilets and sinks. They are designed for forced pumping of wastewater through sewer pipes to a septic tank.

Such units can be designed to connect one or several plumbing fixtures at once. The second category of sewer pumps is more familiar and they are the ones most often purchased for summer cottages.

Depending on the design features and installation method, all models of fecal hydraulic pumps are divided into three groups: surface, submersible and semi-submersible

Fecal, drinking water and drainage pumps should be clearly separated. The first ones are initially designed for grinding solid feces and small debris.

The second and third are intended for pumping water that is only clean or has fine suspended matter. If a rag or food debris gets into them, these electric pumps will simply break down.

Group #1: surface aggregates

Surface pumps for feces provide a dry installation method. To operate in automatic mode, they are mounted next to the storage manifold or in a manhole. In fact, it is a small pumping station made up of several separate parts.

At the dacha, a surface pump for dirty water is most often used in a portable version; it is assembled and turned on as needed, and then put back into the utility room

This type of hydraulic pumps for sewerage is the easiest to maintain and operate. At the dacha itself, it is installed next to a cesspool or drainage pit, and a hose connected to it is immersed in the fecal matter.

When choosing this pump, special attention should be paid to the maximum possible suction depth. The passport usually indicates 8–10 meters. If the hole is deeper, then this pump will not be able to lift wastewater from it.

But here it is necessary to take into account not only the size of the reservoir from which water is pumped, but also the distance from it to the pumping equipment. Each horizontal meter of hose reduces the depth capabilities of the unit by 10 cm.

Low-power models are a compact unit and for short-term operation are installed on the floor or ground next to the waste tank

More powerful installations require a stable platform. They are mainly installed indoors, where such a platform can be easily and securely fixed to the floor.

The main disadvantage of a surface sewage pump is that it cannot operate in a damp environment. Only the suction hose can be in the water; the unit body must be on the ground and in a dry place.

It is allowed to operate such a pump only in rainy weather, and it is better to erect a small canopy for it, otherwise moisture will get inside the housing, which will inevitably lead to a short circuit.

Surface models are cheap and easy to maintain, but are quite noisy. If the pump is selected for installation in a utility room or basement, then this is the best option. But for working outside and pumping feces from a septic tank located far from a country house and buildings, it is better to purchase a submersible analogue.

Group #2: Semi-submersible kits

Semi-submersible pumping equipment consists of an electric motor installed in a dry place and a working chamber immersed in drains. They are connected into a single whole by a torque shaft.

At dachas and in general in domestic conditions, semi-submersible pumps are rare; they are complex in design and operation - they are mainly chosen for industrial-level pumping stations

If a semi-submersible hydraulic pump is purchased for a summer residence, then it can be mounted by:

- fastenings on the wall of the drainage pit;

- installation on a platform floating on drains;

- installation in an extension next to the storage tank.

Another potential problem with the semi-submersible model is the lack of a grinder included as standard. And without it, the pump will quickly fail when pumping garbage and feces from the sewer system.

The chopper is installed additionally on such an installation, in the form of an attachment. And this increases the cost of equipment and complicates its maintenance.

Group #3: submersible hydraulic pumps

This modification of country sewage pumps involves directly immersing the entire unit in a pit with wastewater. And so that the installation does not break down in an aggressive and active sewage environment, its sealed body and all working parts are made of cast iron or stainless steel.

There are models on sale with a plastic casing, but it will not last long in the sewer. Submersible equipment for pumping feces can be used both for one-time work and in automatic mode.

In the second case, the sewage pump for the dacha should be selected with a float and automation. When the specified level of liquid in the waste tank is reached, the pumping equipment is first turned on, and then, as sewage is pumped out, it is turned off by a float device.

The submersible sewage pump is installed directly on the bottom of the drainage pit or suspended at a height of 10–20 cm above it (+)

The presence of a float prevents the pumping equipment from running dry, which significantly prolongs its life. Submersible pumps are chosen by those who require productive and reliable equipment.

Many similar models are equipped with a built-in chopper. It stands at the input and grinds all incoming waste to a state in which it simply cannot lead to breakdown of internal mechanisms.

Compared to a surface-mounted competitor, the submersible pump is less noisy and consumes less electricity. All its power is spent on maintaining pressure in the pressure outlet pipe. It also does not have to waste energy on sucking wastewater from the bottom into the working chamber through a hose.

When a submersible unit operates, water absorbs most of the noise generated by the electric motor. But the unit is more difficult to operate and costs more than a surface model of similar power. Equipment immersed in sewage drains is initially more technologically advanced and complex than equipment left in the air.

Connection recommendations

The sewage pump in an apartment for the kitchen can be installed anywhere in the kitchen, including a cabinet under the sink, an area near the wall, a niche, etc. In this case, the supply pipes should be located with a slope of approximately 3 cm per 1 m of area and should not be too long, otherwise it will be necessary to install several pumps at the same time.

Please note: When using a dishwasher or washing machine in the kitchen, you must use devices that can operate at high temperatures (up to 90 degrees).

Pump installation features:

- When installing several pumps included in a pressure sewer, each of them must be connected to a common main line through a separate inlet. Connecting pipes to each other is strictly prohibited.

- If an extended section of the outlet pipe, laid horizontally, turns out to be below the level of the pumping unit, a special valve (0.7 bar) should be installed at its highest point to ensure air flow after the pump stops operating.

- When installing a device equipped with an air cooling system, you must additionally install a plastic pipe included with the pump. It is inserted into a hole located on its body and discharged at a distance of approximately 50-80 cm above the pump. This device will allow air to flow freely into the electrical system of the unit and cool it.

Important: The drainage pipe from the kitchen pump must be made of durable, hard plastic such as polypropylene or polyethylene. Flexible corrugation is not suitable for use in pressure sewers.

Sewage pumps in the kitchen apartment are connected via a 30 mA RCD. If they are supplied with a cord with a plug, they can be connected to a separate outlet by running the cable directly from the panel and the RCD.

In-house sewerage installations

Sewage pumps are also called small-sized pumping stations, which are designed to be built directly into the sewerage system inside a country house. Structurally and in terms of operating principle, such pumps resemble analogues from washing machines.

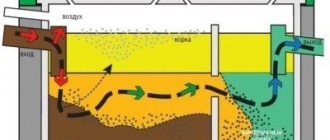

First, wastewater in such a domestic installation accumulates in a small tank, and as it fills, it is pumped out by an internal submersible pump into the sewer pipe (+)

Such models of fecal pumps belong to the premium segment of plumbing and cost a lot. However, thanks to them, toilets, showers and washbasins can be installed almost anywhere in a residential building. They calmly pump wastewater even through pipelines inclined upward.

The design of this pumping station was originally based on the principle of self-cleaning. It is undemanding in terms of maintenance; it is enough to only occasionally rinse the tank from silt deposits.

It also has a carbon filter and a check valve. The first eliminates the appearance of sewer stench in the room, and the second prevents the return of waste from the sewer back to the storage tank. Fecal pumps for toilets prevent blockages and provide forced drainage of wastewater.

Why do you need a sewer pump?

We often have to answer the question: “What are sewerage installations used for?”

In short, the need for such equipment arises when the wastewater does not flow away by gravity. As an example, let's look at three cases.

Moving your kitchen or laundry room to another location

Such redevelopment is carried out in order to convert the kitchen into additional living or working space. Let us say right away that such redevelopment in the apartment requires obtaining a special permit from the BTI, without which work cannot begin.

Not only furniture and appliances are moved to the new location, but also engineering systems - water supply, electricity and sewerage. For installation of the latter, it is important to maintain slopes towards the riser. And in the case of redevelopment, it can be extremely difficult to comply with this condition. This is where special sewer pumps come to your aid, which forcefully remove waste from the sink, washing machine and/or dishwasher.

Installation of an additional bathroom in the basement of the house

Owners of private houses can equip saunas, gyms, repair shops and other premises in their basements where a bathroom is needed. Usually in this case the bathroom is located below the sewer level. This cannot be done without forced removal of wastewater.

Condensate pumping

During the operation of condensing gas boilers, ventilation systems and air conditioners, a large amount of condensate is formed.

For example, a 24 kW condensing boiler produces about 30 liters of liquid per day, which needs to be disposed of somewhere. In Russia, most often, it is simply poured directly into the sewer, but in Europe, the condensate first ends up in the neutralizer. Most often, the boiler is located far from the toilet or bathroom and in order for the condensate to get into the sewer, a pump is needed.

How should you choose a fecal pump?

The passport of a sewage pump for a summer residence contains a lot of technical characteristics. And all of them must be taken into account when choosing this technique. The first indicator is the operating temperature of the pump, i.e. drain temperature.

Pumping equipment for sewerage can be:

- Designed to work only with cold and warm water up to +45°C.

- Designed for pumping wastewater with temperatures up to +90°C.

To pump water from the cellar and fecal sewage from the street septic tank, a first category pump is sufficient. But for uninterrupted operation as part of a forced sewer system with a lot of plumbing in a country house, you will have to select a model from the second group.

Automation, chopper and housing material

Constantly monitoring the condition of the fecal pump and controlling its operation manually means wasting your time. The dacha is always full of activities. Therefore, equipment should be immediately selected with a float and thermal relay.

The first will control the level of waste in the pumped out pit, turning the pump on/off as necessary, and the second will prevent overheating of the electric motor.

Some fecal pumps are able to cope with solid waste and stones without a grinder, but only the presence of a cutting mechanism guarantees such equipment a long service life

Structurally, the chopper is designed as:

- two-bladed knife;

- impellers with cutting edge;

- combined mechanism with several blades.

An impeller is the cheapest option for a chopper, but pumps with it have the lowest performance. A knife with a pair of blades located perpendicular to each other is more reliable and productive.

However, the most advanced is the combination of three cutting blades and a perforated disc. Passing through such a grinder, solid fecal fractions are transformed into a homogeneous ground mass.

Additional selection tips and best options for fecal pumps with a grinder are presented in this article.

Based on the body material, it is best to choose a metal pump for pumping out sewage in a dacha. Stainless steel and cast iron will last many times longer than plastic. This nuance is especially important for submersible equipment, which is constantly located in aggressive, dirty water.

Lifting height, power and power supply

The higher the performance indicated in the passport, the faster the pump will pump the wastewater. However, the more electricity it will consume. A cesspool at a dacha is rarely made large, so a low-power unit is often enough to work on a dacha plot. It will pump out the sewage not in 5 minutes, but in 20, but there is no need to rush outside the city.

The optimal pump power option for a dacha is 400–500 W. This is a productivity in the region of 140–160 l/min. Such performance characteristics will make it easy to cope with pumping sewage from a drain or cesspool, and with getting rid of excess water in a country cellar.

The pressure numbers show the maximum height to which the pumping equipment through the pressure pipe is capable of lifting liquid with feces. But when calculating this indicator, it is necessary to take into account not only the vertical section of the highway, but also the horizontal one.

In addition, atmospheric pressure, material of manufacture and cross-section of pipes, as well as the temperature of the wastewater and the size of impurities in it should be taken into account.

In a simplified calculation of the required pressure, the footage of the horizontal section is divided by ten and added to the length of the vertical section of the pipe, and then all this is increased by 20–25% - the resulting figure should be less than that indicated in the data sheet (+)

Some models of sewer pumps are designed to be powered from a single-phase network, while others are designed to be powered from a three-phase network. The first group is cheaper. As a rule, it is recommended to choose just such a fecal pump for a summer residence. It will cause fewer problems with connecting to the power grid. And if necessary, it can be powered from a portable generator.

Additional elements for installation of pump station

Sewage stations, like industrial sewerage stations, are equipped with special float sensors placed in a storage tank. They transmit information about the level of sewage in the storage tank to the control unit. The pump turns on and off automatically, which facilitates its operation and extends its service life.

In industrial models, such sensors are installed at four different levels. They reflect the safe state when the storage tank is practically empty, the levels at which the pump should be turned on or off, and the overfill level.

If the last set of float sensors turns on, this indicates a serious breakdown in the system and requires immediate intervention from specialists.

Storage tanks for sewage pumping stations are usually made in a cylindrical or cubic configuration, but with rounded corners so that solid waste particles do not linger in them

In addition to such sensors, it is also recommended to provide the SNS with a backup power supply and a pressure gauge. Special pressure sensors may be needed. An additional set of shut-off valves would not hurt.

The ground part of the KNS is usually hidden under a metal pavilion, but another shelter can be arranged. It must protect the device from bad weather and unwanted outside interference in the operation of the complex mechanisms.

Periodically, both the pump itself and the sewer pipes connected to the pumping station should be cleaned to prevent breakdowns and blockages. It is best to purchase a set of special equipment in advance that will make this task easier. Another important point is the manual control mechanism of the sewage pumping station.

In normal operation it is not needed, since all devices turn on and off automatically. But manual control will be very useful if the pump station breaks down or becomes clogged. When putting a new sewer station into operation, manual control is also used.

Brief overview of manufacturers

When choosing a fecal pump, it is better to give preference to models from well-known manufacturers. They specialize in this type of equipment, so their technology is always on top. And even in case of breakdowns, parts for repairing such pumps are always much easier to find.

Among the variety of brands suitable for use in the country:

- Pedrollo Vortex – “VXm” series with low power (Italy).

- Gilex – “Fekalnik” series (Russia).

- SFA – compact grinder pumps for home use (France).

- Grundfos (Denmark).

- Marina-Speroni (Italy).

- Calpeda (Italy).

- Whirlwind (Russia).

- Belamos (Russia).

It is worth saying that Russian pumps are in no way inferior to their imported counterparts. They were initially developed for domestic realities with voltage drops, etc.

Procedure for servicing the pump station

The operation of any device depends on timely maintenance, and sewer stations are no exception. You should not wait until the breakdown becomes obvious; it is better to carry out preventive inspections in a timely manner.

Such forethought can subsequently result in significant savings, since minor and major repairs differ markedly in price.

During visual inspection and maintenance of sewage pumping stations, special personal protective equipment should be used. It is not recommended to use household chemicals when cleaning the drive.

Before starting preventive maintenance work, the sewerage station should be stopped and disconnected from the power supply. Then you need to completely relieve the pressure inside the system, and also wait until the device has completely cooled down. For work you will need work clothes, as well as other protective equipment: a respirator, goggles, gloves, etc.

When servicing domestic sewer pumping stations, it is first recommended to visually inspect the device and check the operation of the shut-off valves. Then the condition of the pumps is assessed.

Problems may be indicated by too high a noise level when operating pumping equipment. Another alarming phenomenon is excessive vibration of the pump during operation. If such dangerous signs exist, the pump can be removed, washed, cleaned, its operation checked and reinstalled in the pump station.

The indicators on the control panel are also assessed. Since solid waste particles can accumulate inside the container in the form of sediment, periodic flushing of not only the pump, but also the storage tank is performed.

The pump is an important part of the fecal and any other sewer line. If the pump becomes too noisy or vibrates excessively during operation, it should be inspected and flushed.

For this, use ordinary water. It can be supplied using a hose. To remove dirt from the inside of the drive, you can use regular household brushes.

But the use of household chemicals in such situations is not recommended. During flushing, care should be taken to ensure that no pressure water comes into contact with the pressure gauge or control panel.

Sewage pumps in such installations are usually mounted on a special pipe coupling. When carrying out preventive cleaning and flushing, it is important to correctly remove the pump from such a coupling, and then ensure that the device is reinstalled correctly.

Another important component is the large debris catcher. It should be inspected and cleaned. During the test, all connections are checked for leaks. All fasteners should be tightened using a wrench.