Here you will learn:

- When do you need a pump to pump out water?

- Pumping water from a source: the essence of the process

- Which pump is suitable for pumping water

- Types of household pumps

- How to choose

- Comparative review of the best manufacturers

- How to make a hand pump for pumping out water with your own hands

A pump for pumping out water is necessary in many cases - when you need to pump out water from a swimming pool, from a flooded garage, to water plants from a barrel, and in many others. Such pumps are manual and mechanized, submersible and surface. We understand the types and the correct choice of equipment.

When do you need a pump to pump out water?

Situations when we need a special pump to pump out dirty water are usually typical:

- Pumping fecal water from septic tanks.

- Elimination of consequences of utility accidents.

- Pumping out drainage water.

- Maintenance of swimming pools and garden ponds.

- Watering plants with groundwater from surface sources.

- Used in fire fighting for drawing water from fire reservoirs.

- Application in various production processes, etc.

At the same time, the meaning of the word “dirty” water should not be misleading. A special pump may be required even if drinking water is pumped from a well or spring, since the sand content in this water will be so high.

Trade offers a huge selection of pumps for pumping out dirty water from different brands and manufacturers. Therefore, its acquisition should begin by studying information about them. Time will not be wasted on this; this way you will be able to choose the right pump correctly and then use it correctly.

What is it used for?

In the spring, when there is abundant melting of snow or prolonged rains, the storm drain may not cope with its responsibilities. This threatens to flood the basement floors of houses. Therefore, these types are used for drainage work.

It can be easily installed in the basements of houses where constant flooding occurs. Thanks to this, you can constantly monitor the level of groundwater inflow and keep the room dry.

The device can easily be used to inspect artificial reservoirs, drain them or fill them to the required water level.

The pump is also used as an additional device for storm drains when they cannot directly cope with their task. And with the help of such a device you can dump settled water onto the fields.

It will be very useful for auto repair shops or car washes, since the sanitary and epidemiological station prohibits them from working without local cleaning systems.

In agriculture, it is an indispensable assistant for pumping water.

The pumps have universal properties; they can be used to pump not only dirty water, but also clean water.

Pumping water from a source: the essence of the process

A private home needs a reliable drainage pump. After all, only with the help of this unit can you lower the level of the drainage system and pump fecal wastewater. In addition, the drainage pump is useful in the process of draining water from construction pits and during the elimination of groundwater breakthrough into the basement or basement.

Drainage pump for pumping out dirty water

But drainage equipment does these “works” only from time to time, and the owner of a suburban area equipped with an autonomous water supply system will have to do pumping water from the well, before cleaning the source, constantly. After all, both harmful and neutral microflora settle on the walls and crushed stone bedding at the bottom of the well, which can only be removed with a scraper. And chlorination of a source - the most common way to improve water quality - requires mandatory pumping out of liquid contaminated with chlorine that kills bacteria and algae.

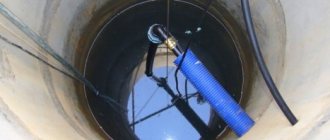

The pump is immersed to the very bottom, having previously been secured to a base stand. Moreover, regardless of the reason, the process of pumping water is implemented in approximately the same way, namely:

- The pressure hose from the pump is removed from the well or borehole, directed into a trench that drains water from a soil source adjacent to the mine.

- Next, the pump is turned on and left in the operating position until the entire shaft is empty.

As you can see, you can’t do this kind of work without a pump. And you can’t do it with the first unit you come across either. After all, a low-power pump can pump out the same volume of liquid that the well itself generates. Therefore, for such work you need a truly productive pump with the maximum possible immersion depth.

Review of popular models of inexpensive drainage pumps costing up to 5,000 rubles

ZUBR NPG – M1 – 550 (550 W)

High-quality, inexpensive, budget submersible drainage pump from a popular domestic manufacturer. It is perfect for use in gardens and personal plots. It is compact and has high impact resistance. Can be used for pumping clean water or contaminated wastewater containing various inclusions and particles up to 35 mm in size.

This popular drainage model is additionally equipped with a special float switch, which protects the device from so-called dry running. The weight of this product is 3.6 kg. The maximum possible height of water rise is 6.5 m. The maximum permissible immersion depth is 7 m. The level of productivity (throughput) is 160 l/min. The thread diameter of the outlet hole is 1 ¼. Can be used to pump water whose maximum temperature is 35 degrees Celsius.

ZUBR NPG – M1 – 550 (550 W)

Advantages:

- Reasonable price (average cost 3260 rubles);

- Availability of dry running protection;

- Warranty 1825 days;

- Does not create much noise during operation;

- Quickly pumps dirty water;

- Easy to use.

Flaws:

- Some users indicate that this model has low pressure;

- Flimsy body.

Makita PF0410 (400W)

One of the best, according to buyers, relatively inexpensive drainers for permanent household use. Suitable for pumping dirty water with particle sizes up to 35 mm. Equipped with a float switch that protects the unit from dry running. Lightweight, durable plastic was used to make the body of this product.

Thanks to the special handle located in the upper part of the body, this device is convenient to transport and move around the garden. The electric motor of this model is equipped with special, reliable overload protection.

The throughput of this unit is 8.4 cubic meters/hour. The maximum immersion depth and pressure is 5 m. Provides for vertical installation and is a submersible drainage type. Product weight – 3.3 kg. Equipped with a long power cord (10 m). Warranty period – 1 year.

Makita PF0410 (400W)

Advantages:

- Build quality and components;

- Simplicity and ease of use;

- Dry running protection;

- Convenient float regulator;

- Does not make noise during operation;

- Acceptable price/quality ratio.

Flaws:

- Some users complain about the poorly written, unclear instructions that come with the device;

- Small immersion depth.

NPC CALIBER – 400/35P (400 W)

Reliable submersible drainage system from a popular Russian manufacturer. This device is perfect for pumping wastewater and water from a variety of tanks, flooded cellars and other premises. In addition, it is an excellent, reasonable and inexpensive solution for organizing a temporary irrigation system in a personal plot.

It is equipped with a float mechanism, which, when the water level is high or low, activates or, on the contrary, turns off the device. The body of this product is made of high quality plastic, which protects all the internal mechanisms of this unit from all kinds of damage.

The maximum immersion depth is 8 m. The maximum pressure is 5 m. The throughput level (productivity) is 8 cubic meters per hour. It is equipped with a centrifugal pump and is capable of pumping wastewater containing fractions whose size does not exceed 35 mm. The maximum permissible temperature of pumped water is 40 degrees Celsius. Product weight – 4.5 kg.

NPC CALIBER – 400/35P (400 W)

Advantages:

- Low cost (average price - 2114 rubles);

- There is no strong noise or vibration during operation;

- Good level of performance;

- Equipped with a long cable (10 m);

- Overheat protection;

- Idling protection.

Flaws:

- Some users point to weak water pressure.

GARDENA 9300

A powerful model of a submersible drainage system, which is designed to perform heavy, complex work, as well as pumping out dirty wastewater. Can be used for draining or pumping water from ponds, wells, construction pits, and flooded basements. This model is designed specifically for pumping water that contains dirt and various particles, the size of which is no more than 25 mm.

The productivity of this unit is 9300 l/hour. The maximum immersion depth is 6 m. Power is 400 W. Weight – 3 kg. The material from which the body is made is plastic. Supplied with a 10 m long power cord. Warranty service period – 1 year.

GARDENA 9300

Advantages:

- Versatility of use;

- Build quality;

- Performance;

- No noise when pumping out waste;

- Compact dimensions;

- Possibility of fixing the float;

- Overheat protection;

- Reasonable price (3498 rubles).

Flaws:

Some users point out the low power of this model, although such negative reviews are isolated.

PATRIOT F 350 (300 W)

It is one of the cheapest models of submersible drainage pumps intended for domestic use. It perfectly pumps out water from flooded rooms and copes with pumping out groundwater. This drainage model can be installed in swimming pools or, if necessary, in gutters. Additionally, it is equipped with a special sealing system that prevents moisture from entering directly into the location of the electric motor.

The maximum permissible immersion depth is 7 m. The productivity of this model is 5 cubic meters per hour. Power – 300 W. Can be used for pumping dirty wastewater (solid particle fraction size no more than 35 mm). The body is made of plastic. Equipped with automatic float control over the water level. Product weight – 3.5 kg. Warranty period of service – 1 year.

PATRIOT F 350 (300 W)

Advantages:

- Low price (1994 rubles);

- Good build quality;

- Versatility;

- Idling protection;

- Low noise level;

- Not a bad level of performance.

Flaws:

- Low power;

- Some users claim that the automatic float control is difficult to configure to fully operate this unit;

- There are user reviews that claim that the real performance of this model is 18 l/min (the number of such reviews is minimal).

Which pump is suitable for pumping water

When choosing which equipment is best for you, you need to take into account its features. The water pump can be manual or mechanized (automatic):

Motorized pump

A mechanized pump can be surface or submersible

- the surface pump is located near the water;

- The submersible pump is installed directly into the water.

When using a surface pump, a rigid pipe is installed in the water, and a flexible garden hose is used for drainage. A surface pump is easier to monitor and easier to repair.

Its important advantage is its low cost associated with its simple design. However, it has many disadvantages. This type of pump is noisier because the sound cannot be muffled by water. If the housing is not sealed, it requires protection from moisture and precipitation to prevent a short circuit.

To remove heat, the pump must be equipped with a fan and fins. The surface unit is unable to remove liquid completely and stops working when a large volume of air enters the intake pipe. Another limitation is that the maximum intake depth is 9 m. Such a pump is best used for pumping water once.

UNIPUMP fecal pumps

A submersible pump can pump out almost all the water. Only a few millimeters will remain. And by installing a drainage hole, you can get a completely dry floor. It works quietly and can easily withstand exposure to air. Due to the fact that it is in water, it does not require refrigeration. These pumps are equipped with floats, which allows you to leave them in the pit and they can turn on and off automatically. They can take water from great depths. But submersible equipment is much more expensive, which is explained by the need to use a sealed housing, non-corrosion materials and a float mechanism.

Submersible pumps are classified according to their purpose:

- for wells;

- for wells;

- fecal;

- drainage

Drainage pumps pump out small solid waste along with liquid. To prevent damage to the mechanical parts of the pump, a filter made of mesh with small cells is placed on the lower section of the pipe. The filter is made of a material that is not subject to corrosion. The filter will prevent solid particles from entering the pump.

The fecal pump is not equipped with such a filter. Its main purpose is to pump out wastewater and soft waste like paper. To ensure high efficiency of its operation, it can be equipped with a cutting mechanism that crushes large particles.

Hand pump

A hand pump for dachas is indispensable, especially in the absence of electricity. Suitable for pumping small volumes of water, eliminating shallow flooding in the basement and for drawing water from 8-9 m.

Motorized pump

This is a piston device. The piston creates a vacuum and the water rises. Such a unit is usually used as backup equipment.

Classification of devices depending on the type of design and purpose

Drainage pumping equipment is divided into two categories based on the type of design. Such devices can be submersible or surface. According to their intended purpose, such devices, based on their power indicators, can conditionally belong to the household or industrial class.

Description of surface type units

Surface drainage pumps are installed directly above the liquid reservoir itself. To place these units, it is necessary to prepare a dry and level surface in advance. To pump out the liquid and the reservoir, a special hose is used, which can be made in the form of a rubber hose or PVC pipe. Surface pumps used for pumping out liquids are equipped with two hoses (pipes):

- Input (serves for entering and pumping liquid).

- Outlet (used for further disposal of wastewater entering the device from the tank).

It is worth noting that surface-type drainage pumps are able to carry out their work without operator participation, operating in automatic mode. To do this, they are additionally equipped with a special float sensor, which monitors the level of liquid pumped out of the tanks.

The advantages of surface aggregates include:

- Ease of installation;

- Carrying out quick, if necessary, dismantling;

- Does not require complex maintenance (it is enough to clean the dirt and lubricate the parts in time).

However, despite the high level of mobility and ease of operation, such drainers also have some disadvantages. It is worth noting that they are not capable of pumping wastewater that lies at great depths. This is due to the fact that the maximum liquid suction depth for these devices is no more than 12 m.

Description of submersible models

The operating principle of submersible drainage pumps for dirty water is almost the same as that of surface-type devices. However, these devices are usually used for pumping dirty, wastewater located in deep trenches or tanks. Often such equipment is used to clean wells.

Unlike surface-type models, submersible drainers pump out liquid without the use of a special pipe or hoses. Simply put, the process of pumping wastewater is carried out by the pump itself. To protect the working elements from all kinds of damage, the bottom of this device is equipped with a special mesh-type filter. This filter traps large, water-insoluble particles of dirt, soil or sand.

Such devices are capable of pumping wastewater at depths of up to 50 m. However, they are not recommended for emptying small tanks whose depth is less than 20 m. In order for such units to function in trenches or containers of shallow depth, their engine will have to be equipped with an additional cooling system. Otherwise, due to overheating, the engine may fail.

On a note! Submersible units are installed directly at the very bottom of a trench or tank. Liquid suction is carried out through a special grille (filter), which is installed at the bottom of the housing.

Household class devices

Domestic grade drainage pumps have a wide range of uses. Such units can be used for:

- Elimination of drains and water from the cellar or basements;

- Pumping liquid from different pools;

- Removing liquid from wells for technical purposes;

- Providing watering for a personal plot (a barrel or a natural reservoir is used as a reservoir for collecting liquid).

The average productivity of such single-phase equipment is about 800 liters per minute. In addition, the maximum liquid lifting height for such units is no more than 25 m.

Reference! For domestic use, as a rule, drainers are purchased whose body is made from stainless steel or reinforced, durable polymers.

Industrial models

Pumps belonging to the industrial class, as a rule, in the overwhelming majority, are used by a variety of construction companies, rescue services (EMERCOM), and public utilities. They are distinguished by a high level of power and great productivity. These devices are intended for:

- Elimination of various emergency floods;

- Drainage of waste from industrial enterprises;

- Drainage of various objects, such as collector pits;

- Removing drainage from clogged, clogged pipelines or sewer system tanks.

In industry, as a rule, they use drainers that are equipped with electric motors and a body made of cast iron. Such devices can be used for pumping wastewater, the particle size of which varies up to 20 mm. The performance level of such 3-phase units is up to 1500 liters per minute. In addition, they can lift liquids to heights of up to 150 m.

Types of household pumps

Pumps are classified depending on various characteristics.,

By purpose

According to this criterion, household pumps are divided into two main types.

- Drainage. The pump is designed to pump out liquids that do not contain solids. In this regard, the design of such a unit requires the presence of a special filter mesh at the point of water suction. The mechanism itself is not designed to allow any solid objects to get inside and will quickly fail when the filter is removed. The main purpose of this class is to pump water out of a certain cavity/container in domestic situations.

- Fecal. A powerful device with a stronger structure designed for pumping out liquids that contain small hard and soft objects. They are equipped with a special cutting device that shreds household waste entering the pump, for example, paper, cellophane, and the like. They are used both in domestic conditions and in commercial and industrial institutions.

By drive

Pumps, depending on what source of force drives the mechanism, are divided into two main groups.

- Manual. Such mechanisms require the effort of the hands, or less often the legs, to operate the pump; they are indispensable in the absence of electrical wiring or its damage due to flooding of the panel. They are used for pumping out small volumes of water and are designed as a piston type with the creation of a rarefied pressure zone.

- Mechanical. Pumps driven by a motor can be placed both in the liquid itself and outside it. The power of such units is variable; for domestic purposes, pumps from 0.3 to 1 kW or more are used.

Based on the type of fuel used, they are divided into two main subtypes:

- electrical;

- gasoline (diesel).

By location relative to the working environment

This property determines, first of all, the specifics of operation and the location of the unit; the main distinguishing quality is the waterproofing of the power plant. There are two main types.

- Immersed. Such pumps can be completely or partially lowered into the liquid. Their body is completely waterproof.

- Surface. Units of this type are installed in close proximity to water, into which a hose is lowered to suck up water.

Features of the design of fecal pumps

The main purpose of the equipment is to pump out viscous and dirty liquid with a high concentration of fibrous and solid inclusions. The mechanisms can easily handle liquid processing, the linear size of inclusions of which can reach 50 mm.

Fecal category pumping equipment is designed for pumping and transporting liquids with an impressive amount of organic inclusions. To prevent the pump from clogging, the units are equipped with a chopper

Mud pumps are indispensable:

- when cleaning cesspools and sewer wells from silt deposits;

- when transporting wastewater with the possibility of its removal to distances regulated by sanitary standards;

- when draining storm ditches and basements of houses.

The need for such equipment may also arise when installing forced sewage pumping. They are installed when it is necessary to compensate for a small angle of inclination of the pipeline in order to prevent clogging of the system.

The main structural elements of the unit are:

- engine - a device that converts energy generated by sources into mechanical work, which drives the pump;

- pump - a moving part that pumps liquid into a special reservoir;

- inlet channel – ensures that liquid enters the pump;

- outlet valve - drains wastewater into a waste tank.

- grinder - a rotating element designed to grind large inclusions.

A characteristic difference between fecal devices and other types of pumps is their increased reliability and larger channel diameter.

The pump is responsible for creating forced circulation of liquid in the system; its malfunction can provoke a serious imbalance in the internal thermal regime of the unit

The chopper is a mandatory functional element of most models. It consists of rotating knives installed at the input of the unit. By grinding branches, debris and even small stones into small fractions, the rotating elements prevent clogging and failure of the unit.

The body and grinder of the fecal pump are made of materials resistant to mechanical and chemical influence, since they have to work in an aggressive environment and resist considerable load

Since mud pumps are designed to operate in aggressive environments, the product body is always made of heavy-duty materials. Most often, steel, stainless steel or cast iron are used to create it.

How to choose

Before you start choosing a drainage pump model, you need to determine the parameters of the underground tank for which you plan to use such a device:

- the depth of the well (it can be determined using a cord with a weight attached to its end);

- parameters of the cross-section of the well shaft - the diameter or size of the sides of the shaft if it has a square shape.

Knowing these parameters, you can calculate the maximum volume of water that needs to be pumped out. To make such calculations more accurate, it is necessary to take into account at what level in the well shaft the water surface is located.

Design features of pumps for clean and dirty water

The quality characteristics of the water in the well are another important parameter that should be taken into account when choosing a drainage pump. In this case, this parameter refers to both the number of insoluble inclusions in the water composition and their linear dimensions. The instructions for each model of drainage pump must contain information about the size of solid particles in the pumped water with which such a device can work. Naturally, in order for the pump you have chosen to work correctly and not fail after short-term use, the size of the inclusions contained in the pumped water should not exceed the standard values for a specific model.

The choice of drainage pump is also influenced by the mode in which such equipment will be used - year-round, seasonal or periodic.

Higher demands are placed on the selection and use of drainage pumps that are operated year-round. Installation of such pumps is carried out in a heated room to avoid freezing of the liquid in the pipeline system during the cold season.

To more accurately select a drainage pump, it is necessary to determine and take into account the following parameters:

- minimum and maximum water level in the well;

- average water level in the well being served;

- the intensity with which water flows into the well (source debit).

Area of application of the unit

If you plan to use the unit only for watering garden beds from a nearby reservoir or to drain a flooded cellar, you can get by with a device with a capacity of 120 l/min.

The size of solid elements that the unit can “digest” is indicated in the instructions for the specific model. On sale you can find models designed only for slightly polluted water, the structure of which may contain only a small amount of sand. There is also a wide range of units that can successfully handle even small stones.

When planning to use the unit for pumping dirty water, including fibrous structures and various-sized debris, it is worth considering the option of purchasing a fecal pump.

In addition, units of this type are created from materials with increased strength and are not afraid of exposure to aggressive environments. Therefore, they have a longer service life than conventional garden pumps for dirty water.

Main characteristics and rules for their calculation

In addition to the parameters of the well, before choosing a drainage pump, it is necessary to determine the characteristics of the device itself. This includes the performance of the pump and the pressure force of the liquid that such equipment pumps.

The performance of the pump, which characterizes the volume of liquid pumped by it per unit of time, is determined based on the total volume of water in the well and the length of time during which all the liquid contained in the underground reservoir must be pumped out.

To determine the amount of liquid pressure, the depth of water intake and the distance over which the pumped water must be transported along the horizontal section of the system are summed up.

Calculation of pressure for a drainage pump

Design features

The suction hole of a submersible drainage pump is located at the bottom of the device, which ensures the most complete pumping of water from the well shaft. For the manufacture of the hydraulic machine body, cast iron, polymer material or steel alloy can be used. More preferable are devices with a steel body, which is not too heavy and is highly durable. Cast iron cases, although reliable, have a significant weight, and plastic ones are not strong enough.

The size of inclusions in the pumped water that a pump can handle without compromising its technical condition is mainly influenced by the size of its working chamber.

Auto shut off float

Although automation increases the cost of equipment, it helps prevent engine overheating.

The float is a device in the form of a plastic floating box. An electrical cable and a steel ball are placed inside it. It reacts to changes in water level and closes/opens the switch contacts.

The main advantage of the device is that it simultaneously performs two functions: it acts as a water level sensor and serves as an actuator for controlling the pump.

By spending a little more money on a device equipped with an automation system, you don’t have to worry that after pumping out the water it will run dry. The only thing is that once every few months it is recommended to wash the float switch with a stream of water under pressure to remove dirt. Preventative cleaning will prevent the float from sticking to the outlet pipe.

Rules for safe operation

Installation, connection and use of the equipment must be carried out in strict accordance with the operating rules specified in the technical passport.

It is important to observe the following:

- Connection to the electrical network is made through a differential circuit breaker.

- A running pump must not be moved or moved to another location.

- The size of suspended solid particles in water should not exceed the permissible size.

- Pumping flammable and explosive substances is strictly prohibited.

Manufacturers have foreseen unexpected moments that can happen to the pump during operation. For example, large stones are retained by a mesh fixed to the inlet channel. But you need to follow the instructions in order not to lose the warranty for equipment repair in the event of a breakdown.

Comparative review of the best manufacturers

It is rightfully considered the market leader. The Danish company is the oldest manufacturer of pumping equipment. The developments introduced by the leading company's technologists were subsequently adopted by other manufacturers.

The equipment of this manufacturer is famous for its ability to easily cope with water of any degree of contamination without harm, as well as its high reliability

The range of manufactured products is represented by pumps of all varieties and types. And they all have one thing in common - the highest quality, confirmed by an effective manufacturer’s guarantee.

Another imported brand that has earned a positive reputation among buyers from different parts of the world is the Pedpollo brand.

“Pedrollo pumps work everywhere” is the main slogan of the world famous brand. And if you study the characteristics of the equipment he produces, it is worth highlighting the versatility of its application. The pumps are capable of operating in contaminated water, aggressive environments and at high temperatures.

Among domestically produced pumping equipment, the most well-proven products are those manufactured under the following brands:

- "Dzhileks" - pumping equipment of a domestic manufacturer is focused on the conditions of the Russian outback with its abundance of "difficult" soils and wetlands, as well as possible fluctuations in power supply networks.

- “Whirlwind” - pumps from this manufacturer are famous for their high power and low noise. The certified equipment produced by the company undergoes numerous tests for performance and endurance.

- “Foreman” - powerful and easy-to-maintain pumps of this brand are manufactured using advanced technologies. This allows the company to keep the quality level at a high level.

Among the brands of pumps for dirty water, the brands “DAB”, “Karcher” and “Belamos” have also proven themselves well. The equipment produced under these brands is famous for its optimal price-quality ratio.

When purchasing a suitable model, you have to set priorities: pay more and choose an unquestionable European brand, or purchase an inexpensive domestic product, but risk receiving low-quality warranty support.

Scope of application and operating conditions

Drainage equipment for pumping out dirty liquids is practical and versatile, and therefore has been widely used to solve industrial and domestic problems.

It is used for certain purposes:

- Pumping out wastewater during breaks and accidents of central sewer main pipes.

- Drainage of basements and basements in case of flooding.

- Removing excess water that accumulates after intense and prolonged precipitation.

- Cleaning artificially created reservoirs.

- Irrigation of large areas by drip irrigation.

- Supplying water for decorative fountains.

In order for the drainage pump to operate correctly without interruption, a number of conditions must be met:

- the temperature at which the unit is operated should not be higher than +40 degrees;

- the density of the pumped liquid medium is 1000-1200 kg/cubic. m.;

- amount of solid impurities – no more than 10%;

- the voltage for industrial devices should be three-phase, 380 V, and for household devices - single-phase, 220 V;

- frequency -50 Hz.

Types and differences

Soil pumps, depending on the cross-sectional size of the flow path, are divided into three large categories:

- Enlarged.

- Normal.

- Reduced.

Flow path coating options:

- metal, rubberized;

- metal, corundum.

Metal used in the manufacture of high quality flow path. It has wear-resistant, anti-corrosion qualities.

Classification options regarding the body:

- Single casing pump.

- Double-casing pump - in cases where work is carried out on relatively large, dimensional materials. This type provides additional protection.

Classification by shaft location:

Soil pumps GRAT

- horizontal shaft arrangement (often used);

- vertical shaft arrangement (rarely used, in special cases).

Earth pump - belongs to the category of soil pumps, this is facilitated by the identical structure of the unit and operating principle.

Refuler pump – used at great depths. Low pressure and increased flow facilitate efficient use at great depths. Also classified as soil pumps. They have their own specific work and are manufactured to special order.

A pulp pump is a device designed to bring pulp to the surface. A liquid containing soil fragments is called pulp.

Slurry apparatus is a pump that pumps sludge out of the ground. Various particles of metals and chemical compounds are called sludge.

Submersible pump is a water type of pump. Designed to pump out water.

Under what conditions can this unit be used?

Most household and private plots now have an autonomous water supply system. It has a lot of advantages, and the most important of them is the ability to use water at minimal cost . The system itself is quite simple, but it necessarily includes a pump that will supply water to the site.

Submersible Dirty Water Pump

And the presence of a drainage pump plays an important role, which helps solve a number of problems:

- it will allow you to remove water from the site that could appear on it due to heavy rainfall or as a result of rising groundwater;

- it will ensure the pumping of melt and rain water from pits and trenches that are being constructed during a number of works;

- If necessary, drainage of a low-lying area is also carried out using such a pump. In this way you can get rid of waterlogged soil;

How to choose a drainage pump

- the pump will allow you to pump out water from the basement if it accumulates there due to heavy rainfall or melting snow;

- the pump will help pump out water from storm sewers, sewage pits, septic tanks, and a number of artificial or natural reservoirs;

- such a pump will also help clean wells from sediments that form in their bottom or on the walls of the shafts;

This type of pump should remain submerged in water as deeply as possible and the return hose should be as far away from the pump as possible

Important! Such pumps allow you to completely remove water from the well if there is a need to carry out work to increase its depth.

- a drainage pump, if necessary, can provide pumping of contaminated water from one reservoir of a treatment plant to another;

- Using a drainage pump, you can take water from a natural reservoir and use it to water the plants on your site.

Drainage pump for watering the garden

By the way, such a pump is also suitable for pumping clean water. That is, the scope of its application is very extensive, which ensures the popularity and necessity of purchasing this equipment. But to use it as efficiently as possible, it is important to understand how it works and what type of pump is best to buy.