A pump is a type of hydraulic machine that moves fluid by suction and discharge using kinetic or potential energy. The pump is necessary for use in fire-fighting equipment, for draining liquids in residential areas, for supplying fuel and many other purposes. There are different types and types of pumps depending on the area of application, design, and principle of operation. When using pumps for various purposes, you need to know what types there are and how they differ.

Separation of pumps by application

The scope of application of pumps is very wide. Today they are used in almost all areas: construction, industry, mining, and in the development of fire extinguishing systems. Various types of pumps are also used on a small scale, and their applications range from domestic use for irrigation, to installation in water supply and heat transfer systems. Depending on the scope of application, types and types of pumps are distinguished. Below are descriptions, their characteristics and varieties.

Pump types

By purpose:

- submersible pumps;

- surface pumps.

By energy supply method:

- electric pumps;

- liquid fuel pumps.

Depending on the type of water:

- for clean water;

- for water of medium degree of contamination;

- for highly contaminated water.

Types of household pumps and their scope

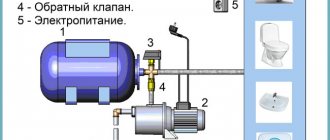

By area of application, pumps are divided into household and industrial. Household pumps come in surface and submersible types. For domestic use, the first type is most often used. Surface pumps are used for autonomous water supply to private houses, watering the surrounding area, pumping water from basements and ponds, increasing pressure during autonomous water supply to a private house.

There are four types of household pumps:

- garden;

- pumping stations;

- drainage;

- deep.

Description and characteristics of pumps

There are 2 types of pumps: surface and submersible. Surface pumps are installed at ground level; a hose is lowered into a well or hole. If the pump is equipped with an automatic on-off system when water is supplied, then it is called a station. Submersible pumps include: drainage pumps, sewage pumps, circulation pumps, pumps installed in wells and boreholes.

Types of pumps by design

All pumps differ in design. They can be vertical and horizontal. All pumps differ in their assembly; depending on the model, they may use vanes, blades, or screws.

What to look for when choosing?

Before choosing the type of pumping station, you should definitely take into account several conditions under which the installation will operate. Taking these nuances into account, equipment capable of ensuring uninterrupted water supply is selected.

The main parameters of the pumping station that affect its operation are:

- electric motor power;

- station performance;

- maximum storage capacity;

- the height to which the station can raise water.

It is worth remembering that the manufacturer indicates the maximum capabilities of the station, which in no case will coincide with the actually required parameters. For example, the passport indicates a value of 3 m3/h. This characteristic indicates the maximum possible volume of pumped water; at the moment this value is reached, there will be no pressure.

Or a maximum pressure parameter of 40 meters is indicated, this indicates that the source of water supply is located at the level of the pumping station, and no water consumption is provided for. Under these conditions, the pump will produce the specified pressure value, but will be absolutely useless.

In order to obtain accurate data on the relationship between flow and pressure at the head of the pumping station, it is recommended to use the data from the tables and graphs indicated in the equipment passport. As a rule, the manufacturer indicates the true characteristics of the pump, giving the consumer the opportunity to choose a water pump with selected parameters for specific purposes.

When choosing a model, it is recommended to pay attention to additional functions. A fairly useful option is overheating protection and idle operation (when there is no water). They increase the service life of equipment.

You can also select the pump housing. The materials for its manufacture are stainless steel, cast iron, and high-density polypropylene. The polypropylene body is quite cheap, but it is not susceptible to corrosion and does not transmit noise during operation. But even with increased density, do not forget that this is plastic, and if handled carelessly it can be easily damaged (for example, during transportation).

The second place in price is occupied by a housing made of steel, but in combination with a centrifugal pump, this housing transmits noise and even sometimes resonates. So the working process of this pump is characterized by an increased noise level.

A similar pump operating in a cast iron casing is noticeably quieter. But in acidic water, cast iron is subject to a high level of corrosion, which is not a positive quality: usually the iron content in water is already in excess. The best case can be considered to be one made of stainless steel, but its price is correspondingly the highest.

Classification by operating principle - by type of working chamber

There are different types of pumps based on their operating principle and design. They are divided into positive displacement and dynamic pumps.

- Positive displacement pumps are those in which liquid is moved by changing the volume of a chamber containing liquid under the influence of potential energy.

- Dynamic pumps are mechanisms in which fluid moves along with a chamber under the influence of kinetic energy.

Dynamic pumps, in turn, are divided into vane and jet pumps.

Separately, there are types of volumetric pumps based on the principle of operation, depending on the design:

- Rotary pumps are a solid body, with a certain number of blades/blades driven by the rotor.

- Gear pumps are the simplest type of mechanism, consisting of interlocking gears that move under a forced change in the cavity between the gears.

- Impeller - blades are enclosed in an eccentric body, which squeeze out liquid when rotating.

- Cam pumps are pumps, the housing of which contains 2 rotors, which, when rotating, pump liquids of varying degrees of viscosity.

- Peristaltic - the body includes an elastic sleeve in which the liquid is located. When additional rollers rotate, the liquid moves along the sleeve.

- Screw pumps are pumps consisting of a rotor and a stator. When the rotor rotates, the liquid begins to move along the axis of the pump.

There is also a division of dynamic pumps according to the operating principle:

- Centrifugal - includes an impeller with liquid inside; when the wheel rotates, the particles acquire kinetic energy, and centrifugal force begins to act, under the influence of which the liquid passes into the motor housing.

- Vortex pumps are similar in principle to centrifugal pumps, but are smaller in size and have lower efficiency.

- Jet - based on the transition of potential energy into kinetic energy.

The vortex pump type is the most commonly used due to its ease of installation. For domestic needs, such a unit is installed in country houses to ensure water supply. Water circulation is ensured by liquid supplied to the blades located in the pump housing. The key element here is the wheel, to which water is supplied through the inlet. This type of pump is also used for wells, as it creates high pressure. They have the ability of self-priming and can process not only liquid, but a gas-water mixture.

Centrifugal pumps are often used for domestic and industrial purposes:

- for organizing water supply systems at industrial enterprises;

- for organizing water supply systems for residential areas;

- for irrigation systems.

These pumps are easy to use, as the operating principle is quite simple. The main load is taken by the wheel with blades, to which the liquid is supplied, but if there is no liquid inside, the pump will fail. Most often such pumps are surface pumps. Due to this, their productivity decreases. Centrifugal-type submersible pumps require high-quality casing tightness.

Design specifics

The “wet” pump operates absolutely silently, is reliable in operation, and economical. Due to its low efficiency (up to 50%), it is recommended for installation in a cottage or country house.

A “dry” pump has a high efficiency (about 80%), but is noisy in operation. It is necessary to move units of this type to a separate room with increased sound insulation. These pumps have high power. As a rule, they are used in high-rise buildings, or for water supply to large areas for various purposes.

Classification by purpose

Depending on their intended purpose, various types of pumps are used for industrial purposes (in the food, chemical, paper industries). For domestic purposes, pumps are used in construction, pumping water from wells and wells, for drilling wells, and for heat supply. Drilling a well requires the use of a pumping station or submersible pump. The pump supplies water from the well under low pressure.

In cars and industrial machines, pumps are auxiliary devices.

When extracting minerals, various types of pumps are used to drill a well, develop the area adjacent to the well, pump out liquids, and process liquids. In industry, pumps are installed at enterprises for hydraulic removal of production waste.

Pumps used in the food industry often have devices to crush materials (other than stone and metals) to prevent pipeline clogging.

Separately, there are pumps for fire extinguishing. The design of such pumps provides for the supply of water under high pressure.

Drainage pumps are submersible; they are characterized by the presence of a grinding and filtration system.

Pressure pumps are used in systems that require increased pressure during operation (heat supply, water supply).

There are types of water pumps according to their purpose:

- Water lifting.

- Circulating.

- Drainage

Depending on the scope of use, there is a classification of water pumps according to their operating principle.

- Water lift pumps are used to extract liquid from wells or wells.

- Circulating types of pumps are used to move fluid in heating, air conditioning and water supply systems.

- Drainage pumps are used to pump out liquid from basements and sewers.

Rating

In suburban areas, far from the benefits of civilization in the form of water supply and sewerage networks, the pump is a source of familiar comfort, and its choice is approached especially carefully. Help in choosing is provided by ratings of drainage pumps for dirty water, which are compiled by both specialists and ordinary users.

Watering the garden is one of the functions of pumping equipment Source grounde.ru

Classification by type of pumped medium

Depending on what type of fluid will pass through the pump, design and other features will vary.

Pumps are used to pump:

- clean liquid and slightly contaminated liquid;

- moderately contaminated liquids with light suspended impurities;

- not highly gassed liquids;

- mixtures of gas and liquid;

- aggressive liquids;

- liquid metals.

To work with different types of liquid, positive displacement pumps are used. This type of pump works on the principle of changing the volume of the chamber, which leads to the conversion of engine energy into the energy of the substance. Such pumps can handle any media, but high levels of vibration must be taken into account.

Dynamic pumps can also handle any type of liquid, but they are not self-priming. Depending on the design features of the pumps, there are various ways to process the fluid being moved. For example, dynamic vortex pumps are not designed to handle contaminated fluids that include abrasives. For such units, liquid with impurities is destructive, leading to thinning of the pump walls.

Video description

About the Grundfos Unilift Kp 250 m1 pump in the following video:

- AL-KO Dive 6300/4. A high-pressure pump with a capacity of up to 6300 l/h and a maximum flow of 40 m, suitable for use both in irrigation systems and for installation in a well. The device is designed for long-term operation, as evidenced by the stainless steel motor shaft. One of the disadvantages is the problematic check valve.

- VORTEX DN-900. The unit is used for pumping clean, rain, drainage, and groundwater. The advantage is its power of 900 W, a throughput of 15.5 cubic meters per hour, as well as protection against dry running and overheating. The disadvantage of the model is the leaky housing, the reason for frequent repairs and relatively quick failure.

- PATRIOT F 850. The vertical immersion model is designed for pumping dirty water (with impurities up to 35 mm). The advantages include automatic silent operation, a stepped diameter of the outlet pipe, and excellent engine tightness. Cons: the float can become clogged with silt, the body is made of plastic, the impeller is also plastic and therefore fragile.

High pressure pump AL-KO Dive 6300/4 Source vencon.ua

Types of industrial pumps

There are different types of pumps used in industry. The main types of pumps used in various enterprises:

- multi-stage;

- gear oil pumps;

- chemical submersible pumps;

Industrial pumps are used in various fields

- in light industry;

- in the chemical industry;

- in construction;

- in mechanical engineering;

- in mining.

The type and type of pump is selected depending on the needs of the enterprise, the properties and quality of the pumped liquid.

The most popular are deep-well pumps, as they are widely used for domestic and industrial purposes. They are easy to install when installing water supply and heating systems; they are used for drawing water from wells and in heating systems.

Main types of pumps by type of energy input:

- pumps powered by mechanical energy;

- water jet pumps;

- pumps powered by compressed steam or gas.

Pumps powered by mechanical energy include piston pumps, propeller pumps, screw pumps, centrifugal pumps and rotary pumps. Despite the same principle of operation, these pumps are very different in design. Water jet pumps - elevators, ejectors, operate by supplying liquid to the wheel blades.

Options for supplying water to a country house

Not every summer resident can boast of having a centralized water supply; some have to solve this problem on their own. In some regions, obtaining high-quality water is not so easy and the only way is a well. You will be interested to know how to find water on the site for a well. In addition, a river or a well can serve as a source for supplying water to the building.

Water can be used interlayer, artesian, from an open reservoir, or groundwater.

The choice of source will depend not only on the depth of groundwater, but also on the financial capabilities of residents. The most affordable option is a well, the main advantage of which is accessibility and the ability to use a simple bucket. It is worth digging it away from outbuildings so that the water is suitable for drinking.

If you install additional thermal insulation, you can use it even in the cold season.

Pumps for fire extinguishing systems

The main requirement for fire extinguishing system pumps is the supply of water under high pressure. Centrifugal pumps are the most commonly used because they allow water to be pumped quickly using centrifugal force. Important points when choosing a fire extinguishing pump are:

- pressure;

- wheel speed;

- efficiency;

- suction lift;

- volume of water moved.

Depending on the number of wheels with blades, pumps are single-stage or multi-stage. Multistage units allow you to create higher pressure, which in turn affects the pressure and height of the supplied liquid. When installing fire extinguishing systems in buildings, it is worth considering that the equipment must be checked periodically, since stagnation can cause difficulties during startup. Fire trucks are equipped with centrifugal pumps and auxiliary units. Auxiliary pumps fill the centrifugal pump housing with liquid and turn off automatically.

Where can I buy?

To find a supplier of pumping equipment, you can safely look on the Internet. Knowing the desired indicators, it is not difficult to choose a brand and model, as well as get advice from professionals. For this purpose, it is better to consider large firms or companies that are official dealers. Moreover, they don’t take money for it. After you decide on the brand and model, you can look for a selling organization with the best price, location, delivery, installation capabilities, warranty and post-warranty service.

The choice of offers is huge: from spontaneous markets to official representative offices of famous brands. It is worth remembering that chasing the best price is not always justified, since the time will come when you will be faced with issues of warranty and post-warranty service.

Let you always have clean and tasty water, and in sufficient quantity. Clean water for you, comfortable living and coziness in your home.

Oil and fuel pumps

Industrial types of pumps include oil and fuel devices installed on automobile and machine engines and internal combustion engines.

Oil pumps reduce friction between interacting engine parts. They are adjustable and unregulated. Car engines are equipped with rotary or gear pumps for pumping oil.

Fuel pumps are installed in cars without fail. They ensure the delivery of fuel from the tank to the combustion chamber. Depending on the design, fuel pumps are either mechanical or electric.

Submersible pumps

Submersible pumps are used when working at a depth of more than eight meters. All types of submersible pumps have a cooling system and are also made of durable material that helps avoid deformation under pressure. Submersible pumps are either centrifugal or vibration pumps. In the second type of pumps, liquid is sucked in using a vibration or electromagnetic mechanism.

When choosing a pump, it is important to consider a large number of factors:

- purpose of use;

- place of use;

- the need to install auxiliary units;

- pump dimensions;

- pump operation method.

Which drainer is best for pumping?

Let's consider several important parameters that will help you make the right choice of drainage pump:

| Options | Description |

| Performance | First of all, the scope of future work is determined. Many household models are capable of pumping up to 180 liters per minute. For home use this may well be sufficient. |

| Pressure | The pressure or speed of pumping water determines the power of the engine, the depth of the source and the distance of water release. Every 10 m of hose loses 1 m of pressure |

| Pumped medium | The units are divided into several varieties according to their ability to pump liquid with inclusions of different diameters. Up to 5 mm for lightly polluted, up to 25 mm for moderately polluted, up to 38 mm - melted snow and rain. This must be taken into account when choosing a device |

| Power | The model, with a power from 200 to 400 W, is capable of pumping up to 100 liters per minute. The mid-level device has a power of up to 1000 W 300 l/min. This pump is manufactured for industrial use. |

| Suction connection | There are three positions: top, side, bottom. To drain a flooded room, the bottom location of the pipe is suitable, and the top direction for a silted reservoir |

| Additional functions | Availability of automation: remote or built-in float, thermal relay, etc. If you want not to interfere with the process, then the set of automation must be complete |

| Emptying level | If it is necessary to completely drain a container or shaft, this is taken into account when choosing. For example, a self-priming model is installed in water up to 40 mm deep |

| Water temperature | During operation, the engine and the entire device tend to heat up. Some are used for pumping exclusively cold water. Other models are allowed for pumping liquids with temperatures up to +70 °C |

| Materials | It is also important what material the blades and body of the unit are made of. It’s good if the electric pump has a metal casing, as well as blades |