General information about filters

The mesh filter belongs to the group of coarse filters, which is a mesh made of stainless metal (steel) or plastic, allowing removal of heavy particles up to 1 mm in size.

A cartridge filter is another type of water pre-purification filter, which has the form of a transparent plastic capsule, inside of which a polypropylene or polyester replaceable cartridge is placed.

By design, the following types of water purification filters are distinguished:

Inlet filter with check valve. This is the same mesh filter, but its distinctive feature is that the hydraulic check valve prevents the return flow of water from the vertical section of the water intake system.

The central filter is often used to purify water intended for irrigation and is located in an open area. Such a filter is installed between sections of hoses.

A suction filter is a mesh in a housing on a hose and is used for collecting water from open reservoirs using motor pumps, tank trucks and hand pumps. The built-in check valve in this filter allows the system to remain filled when the pump is turned off, which facilitates instant start-up.

Installation of mechanical filters is carried out either directly on the pump system itself or next to it.

Advice! It is recommended to install a pre-filter in front of the equipment. This makes it possible to timely clean the filter without damaging the pumping station. Thus, the pressure switch to which the filter is connected transmits a signal to the pump to turn off.

In addition to coarse impurities, water may contain heavy metals, salt ions, microorganisms, bacteria, which makes it unsuitable for human consumption and, as a result, it is necessary to carry out a deeper purification.

Pumping stations

Distinctive features

Many consumers who want to provide their homes with water are interested in many questions. For example, what are the differences between a pumping station and a conventional pump? What is the operating principle of pumping equipment, what does it consist of? How convenient is the station?

Experts give the following explanations: a pumping station is a device that is designed to create and maintain constant pressure in the water supply system. Such a system is fully automated and does not require human presence or participation.

The main component of the equipment is the pump itself, but additional devices are required to ensure its operation. Water pressure sensors monitor its level in the pipeline. Hydraulic accumulators control the entire system automatically, regulating the water supply over a wide range of pressure levels. The design of the pump is not particularly important.

How to make the right choice?

The main reason for purchasing pumping equipment for a house or cottage is the lack of centralized water supply. Naturally, purchasing a suitable pumping station is a very responsible task. And specialists, in turn, draw the consumer’s attention to the technical characteristics and certain parameters of such devices.

The main factor determining the choice of design is performance . Since a certain amount of water should be raised to the required level, providing all household members. Also not least important are the properties of water: wells have characteristics of depth, water level conditions, pipe sizes and type of filtration system. Basically, pumping equipment is designed for a nine-meter water supply depth.

Pumping stations are conventionally divided into the following types of devices:

- Self-priming.

- Centrifugal.

- Vortex self-priming.

Equipment by type of design can be monoblock or console . The first type involves the location of hydraulics on the same shaft where the electric motor is located.

There is also a division of devices by type of lifting:

- In the first option, water is supplied from a source.

- The second type of lifting includes the creation of water pressure above the level of the earth's surface, that is, approximately 2-3 floors.

- This is followed by a rise that fills the water supply system above the 3rd floor. This process is carried out by several pumps connected in a chain.

In this case, the source of water can be not only a well or a well; the main water supply or reservoir . The most popular type that has earned the attention of users is the self-priming pump.

Main technical parameters

To know the capabilities of the equipment, you need to understand its characteristics and parameters. A station with average power, having a hydraulic accumulator volume of 20 liters, is suitable for a home where a family of 3 or 4 people lives. The unit of pump performance is cubic meters.

Performance indicator is 2-4 cubic meters. m. have pumping stations used for domestic needs, while the water pressure parameters become from 40 to 55 m .

To extend the life of the pumping station, the quality of assembly and materials used for the production of device parts, as well as auxiliary devices, are taken into account. It happens that manufacturers use plastic, but you need to take into account that it is short-lived. Metal elements made of cast iron and steel significantly extend the operating life of the pumping station; they also smooth out noise during operation.

Pumping equipment with automatic control is usually produced on the basis of self-priming centrifugal systems. Built-in ejectors allow the device to supply water with a pressure of 40 m, even at a depth of 9 meters. It should be noted that the equipment is not affected by the air in the pipeline.

Fine filters also come in several varieties:

The most common type, which uses a polymer as a filter material, which is a barrier to all impurities in the water flow.

Membrane filter - in which the water is divided into two parts, the first purified water goes further to the consumer, and the second part, as waste water containing all the impurities, is sent to the sewer.

A wire filter, which is a pipe with stainless metal wire wound around it. Water passing under pressure through the wire is directed into the water supply, and all the pollutants it contains remain inside the cylinder.

Thanks to such a filter, a high degree of purification of the collected water is ensured.

There are the following types of filters based on the method of water purification:

- — Mechanical filters, which are a mesh or cartridge that cleans solid impurities. Such filters are classified as coarse filters.

- — Ion exchange : purify water from salts of heavy metals and other chemical elements.

— Biological : The essence of cleaning this filter is the use of a community of microorganisms capable of purifying water as a result of processing organic substances as food.- - Electric . Ozone in the filter element, under the action of electric current, purifies water from hydrogen sulfide, chlorides, iron and manganese ions.

- - Sorption . Watercourse purification is carried out as a result of the process of absorption of pollutants by an absorber (activated carbon).

Criterias of choice

Complex cleaning system

To install suitable filters, you need to know the power of the pumping station and the degree of water contamination: the size of impurities, the concentration of polluting chemical elements, microorganisms and bacteria. This can be found out after laboratory tests.

The first indicator is especially important if you decide to install a reverse osmosis filter. To operate the device, a working pressure of 2.8 bar is required. If the pumping unit is low-power, you will have to purchase booster pressure equipment.

It is better if the coarse cleaning device is made of stainless steel. Galvanized parts have a much shorter service life, and plastic products have an even shorter service life.

When selecting a mesh filtration device, the method of cleaning it is taken into account. A product with flow-through flushing requires a ball valve with a handle. When it is opened, part of the water flow will pass through the flask and wash it of all impurities.

A device with backwashing cleans itself after a certain period of time - from four minutes to three months. It is also possible to start the drive not by a timer, but remotely, or from a relay that responds to pressure drops. For such filters, it is necessary to install a stationary container under them or connect to the sewer main.

If you do not want to buy separate filtration elements, you can purchase a modular unit, which includes: a pump, several filters for pre-cleaning and additional cleaning using post-filtering and mineralizing cartridges.

Installation of a cleaning system

It looks like this:

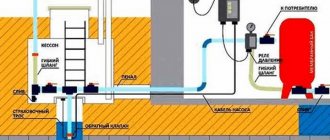

- First, there are hoses lowered into the well or borehole, then a coarse pre-filter is installed in front of the pump.

- It is recommended to connect the intake filter in a horizontal place in the pipeline, where there is access for the purpose of performing preventive maintenance on the filter, inspecting it and carrying out timely cleaning of the filter material.

- Then comes the pumping unit itself, after which a fine filter is connected directly in front of the tap.

How to install a filter for a water station

In Moscow and other large populated areas, you can contact specialists to install a main filter in front of the pumping station. If you have experience and the ability to work with such mechanisms, you can, however, cope with the work yourself.

It is important to first read the instructions that came with the filter device and make sure that you have all the components necessary for the tools to operate.

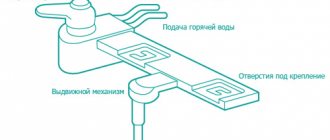

It is possible to install the device both before and after the pumping unit. It is better to choose a horizontal section of the highway for installation work. The cleaning device is secured using the threaded method.

To increase the strength of joining elements, you should use clamps; in some cases, additional adapters may be required. The filter must be placed so that access to it is not difficult, since consumables will need to be periodically replaced or cleaned.

Installation features depend on whether a surface pump is used or a submersible one.

The order of arrangement of water filters before and after the station

Filtering devices must be placed correctly to achieve the desired effect and protect expensive equipment from damage.

The order of installing cartridges can be found here.

First, systems for coarse cleaning are installed and only after that – fine cleaning. This way, large particles, debris and dirt will first be removed from the liquid, and then dissolved salts, bacteria and protozoa. Filters for coarse cleaning are placed in front of the pump, fine filters - after it.

Features of installation of the filter structure

Many engineers ask the question: “Is it possible to install a filter unit in front of the pumping structure?” As practice shows, this is quite possible.

It is recommended to place the filter on a horizontal section of the pipeline in front of the pumping structure and secure it firmly with a threaded connection. For better docking, the filter device is equipped with adapters of various diameters and clamps. At the same time, unhindered access to the filter must be ensured for inspection, inspection cleaning and repair work.

Top 3 best filter manufacturers + useful video

| Filter brand | Photo | Specifications and Features |

| Marina Speroni | The products are suitable for installation in front of watering equipment and for simultaneous operation with water supply machines. The filter cartridges will have to be replaced periodically. It is better to use replacement parts from the same manufacturer. | |

| Basic | Suitable for both household and garden pumps. Thanks to the check valve, the efficiency of pumping equipment increases and its start-up becomes easier. The advantage of this option is its low cost. A hose adapter and clamp are included in the kit. | |

| Elitech | Their coarse cleaners work best with pumps from the same manufacturer. Water gets rid of impurities of different sizes. It has high productivity: the filter unit can pass through up to 3500 liters of water in an hour. The advantage is that the cost is not too high. |