Providing a private home or country house with water is one of the most important components of comfortable living outside the city. In the absence of a centralized water supply, drilling a well is not enough. For the uninterrupted operation of the water supply system, it is necessary to have a water pumping station in it, which will ensure the supply of water to each of the water intake points. Choosing a suitable unit for your home plumbing is not difficult. It is important to take into account all comments and reviews regarding each of the water stations for your home or garden.

Design and principle of operation of the pumping station

The main task of the pumping station is to provide residential buildings and adjacent land with water from artificial or natural sources. It is these units that help fill additional tanks intended for watering the garden or garden plants, as well as provide water to traditional water collection points:

- faucets;

- toilets;

- Dishwasher;

- washing machine;

- geyser;

- boiler, etc.

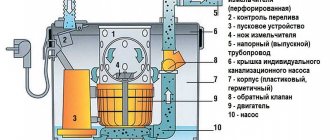

Design of a pumping station for a private home

As a rule, a pumping station is a combination of several individual mechanisms combined into one powerful device for pumping water. Each of the elements of the device has a very important task:

- Pump. The workhorse of the station. It pumps water directly from the source to the reservoir.

- Hydraulic accumulator. Presented in the form of a hydropneumatic tank with a volume of 18 to 100 liters.

- Pressure switch. It is used to control the station.

- Check valve. Prevents liquid from flowing back to the source.

- Pressure gauge. Allows you to monitor pressure readings in the system.

- Connecting hoses and pipes.

Advice. A filtration system installed in front of the pumping station will not only provide users with purified water, but will also extend the life of the water supply system by removing hardness salts, organic compounds and suspended substances from the liquid.

Advantages of HDPE pipes over steel analogues

The pipes that connect the submersible equipment to the surface centrifugal pump deserve special attention.

When choosing material for this area, you need to consider the following:

- Pipes must be easy to transport.

- Their installation should not be particularly difficult.

- You need to choose a material that is durable and abrasion-resistant.

- Products must be elastic and not lose functional characteristics when deformed.

- The absence of toxic substances in the material and safety when transporting clean water are the main conditions.

All of the above criteria can be found when studying the characteristics of low-density polyethylene pipes. In addition, they are not subject to corrosion like steel water pipes. On average, the operational period of HDPE pipes is about half a century.

When deciding to purchase pipes made of low-density polyethylene to supply water from a well, you should give preference to high-quality products with appropriate markings. The pipes must be marked with the type of product, outer diameter, wall thickness, nominal and maximum pressure.

Pipes that are planned to be used to lay a water supply from a water source must be labeled “drinking.” For use in a summer cottage, pipes with a diameter of 32 mm and a wall thickness of 2.4 mm are suitable. Pipes for pumping water have a blue stripe (for information, pipes for transporting gas have a yellow stripe).

What to consider when choosing a water pumping station

The first thing you need to pay attention to when purchasing a station is the power of the pump. The water pressure in the system and its flow rate depend on this indicator. The water supply parameter should be close to the maximum volume of consumption at all water points. As a rule, this indicator is averaged rather roughly and all models are adapted to a nominal flow rate of 1.5-9 m3/h.

Water pumping station

The pressure indicator is also entered into the station characteristics table separately. In the passport it is indicated as the distance over which the pump supplies water. But in fact, this parameter means the pressure that the station is capable of creating. So, the indicated pressure of 40 m shows that the pump will create a pressure of 4 atmospheres under ideal conditions. Since during operation there are some pressure losses on the pipeline layout, as well as water rising to a certain height, this figure will be significantly lower.

Important! A powerful device does not always justify the investment in it. As a rule, the productivity of such a system will exceed the filling of the well. In order to avoid this, it is necessary to take into account the parameters of the well. The shorter the distance to the source of water intake and the higher the level of occurrence of the water resource, the less power the purchased device should have.

Also, when choosing a water pumping station, it is necessary to take into account the autonomy of the unit. This will be needed by users living in areas with power supply problems. To ensure uninterrupted operation of the pump, you can additionally install a generator or solar battery on the site.

Connection procedure: step-by-step instructions

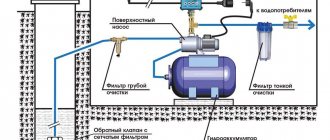

Not everyone knows how to properly connect a pumping station. When installing block equipment, assembly involves combining the pressure and suction pipelines. A filter with valves is connected to the pipe immersed in the well, and it is brought out through an adapter or head.

The suction line is carefully sealed. Otherwise, air will enter the water supply system, which will damage the pump. The pressure part is equipped with a valve.

12 steps to connect a pumping station:

It is worth considering how the pumping station is connected to the well when choosing modular equipment. Connecting a well to a pumping station includes the following steps:

- Hydraulic accumulator piping. First of all, install a fitting with 5 pipes. It is connected directly. After this, the protective relay, pressure gauge and water inlet are configured and installed. The remaining outlet is used to connect the pressure pipe. Submersible pumps are installed in wells more than 10 m deep. This avoids the problems caused by the need to install an ejector and a suction part.

- Pipeline outlet. Produced through the source head. Pressure pipes are laid in a trench leading to the house. The elements must be located below the soil freezing depth.

- Connection to the electrical network. During the installation process, the station's starting block is installed, and the output is connected to it with copper wires. The pump must be powered through a separate automatic switch.

After completing the assembly process, the tightness of the connections is assessed. For the first time, the accumulator is filled slowly so as not to damage the integrity of the membrane.

Types of pumps

Water stations differ from each other in the types of pumping units. This is the main part of the system that does all the main work. That is why the emphasis must be placed on choosing a pump for the water supply station of a private house.

- Self-priming pumps. They have great power and are capable of lifting water from a depth of 8-11 m. They do not “choke” in conditions of gas contamination of the liquid. The main disadvantage is the noise of the device. To create comfort in a residential building, such a pump must be isolated in a separate room.

Self-priming pump - Multistage pumping units. Such a pump will ensure the lifting of water from a depth of up to 9 m. When compared with self-priming pumps, a lower noise level during operation of the device was revealed, and there is also a noticeable difference in the liquid supply. Multistage pumps have significantly higher water consumption. The downside is the complicated design of the device, which also affects the increased price of the device.

Multistage pump unit - Vortex pumps. Such a device can be installed at a sufficiently high water surface. The groundwater level should not exceed 6 m. A pump of this type is capable of creating a high liquid pressure in the water supply system.

Vortex pump

Also, surface pumps differ in the type of ejector device. Designs are available with built-in and remote devices.

- Models with a built-in ejector are used when the water depth is no more than 7 meters. Such pumps can lift water with a high concentration of mineral salts, gases and particles up to 2 mm in size. Capable of creating high pressure. Water is collected using a reinforced hose, the end of which is immersed in the source. As a rule, this type of pump is equipped with a coarse filter, which prevents sand and other large contaminants from entering the housing.

Centrifugal surface pump with built-in ejector

- Pumps with a remote ejector are capable of pumping water from a depth of up to 40 m. In this case, the diameter of the well should not be less than 100 mm. A prerequisite for installing such a device is the additional installation of a filtration system. Such models are installed when the water source is located at a distance from the pumping station.

Self-priming pump with a remote ejector

Durability, noiselessness and stability of the water supply system depend on the material from which the product body is made:

- stainless steel - increases the cost of the product, improves the aesthetic appearance of the station, does not affect the quality of the pumped liquid, but does not have sound insulation;

- cast iron – a prerequisite is the application of an anti-corrosion layer, it pleases with a good level of sound insulation;

- plastic is practically silent, the possibility of corrosion and the presence of rust in water is excluded.

Hydropneumatic tank

Equipping water pumping stations with an accumulation tank will make the system autonomous in the event of a sharp drop in the water level at the source. This is achieved by accumulating the nominal amount of water resource specified in the documents accompanying the product. In addition, it acts as a pressure regulator in the water supply system.

Hydraulic accumulators

The volume of the expansion tank directly depends on resource consumption. Consequently, the greater the number of simultaneously active water points, the larger the required tank volume. The most common station models are equipped with hydropneumatic tanks up to 50 liters. Maximum volume – 100 l.

Advice. If only 1 person lives in a house or country house, then a tank with a volume of 18-21 liters will be sufficient.

Electronic control – additional protection of the pumping station

To increase the service life of the water station, it is equipped with an electronic control unit. The main functions that lie on it are protective.

- Dry run. The pump motor is cooled by the pumped liquid. An electronic relay will help to avoid overheating of the device, which turns off the device if there is no liquid in it. Very useful in cases of sudden changes in water level in the well.

Electronic pump control unit - Automatic on/off. A necessary device for rare use of water points. The pump starts automatically, thanks to an activity sensor at a particular point. The device turns off in the same way.

- Change in speed. A gradual increase in engine speed will help avoid water hammer in the water supply system. This also makes it possible to save energy.

The disadvantage of pumping stations equipped with electronic control is their increased cost. This is what turns off many buyers.

Useful video on the topic

Installing a pumping station is quite within the capabilities of an ordinary home craftsman. To do this, you only need the ability to hold the simplest plumbing tools in your hands - a wrench, a screwdriver, and pliers. Naturally, some plumbing experience and ingenuity will not be superfluous. You can clearly see the installation procedure of the pumping station in the video below.

The most important benefit of civilization that owners strive to equip their country house with is a water supply system. Moreover, the arrangement of such a system can now be afforded not only by those who live where the water supply networks run, but also by the owners of houses, dachas and cottages that are located far from civilization. To do this, it is necessary to dig a well or drill a well on the territory of a suburban area, and then, using a pumping station, organize an autonomous uninterrupted water supply for the entire house. If you decide to connect such a system yourself, you may find our step-by-step guide and video instructions useful.

Rules for installing a water pumping station for a private house

The main thing when installing a pumping station on a site is choosing a location for its placement. Here you need to take into account all the basic requirements:

- the distance to the source of water intake must correspond to the characteristics specified in the passport;

- the device must be installed in a heated room if operation is planned in winter;

- to avoid the appearance of condensation caused by the difference in ambient temperatures and the pumped liquid, it is imperative to select a well-ventilated room;

- Providing soundproofing of the walls of the room will help maintain the level of comfort in the house.

Water pump installation diagram

To dampen vibration of the pump, the station is installed on shock-absorbing rubberized pads or a mat. It is also important to take care of the grounding of the installation operating from the mains. This will ensure the safety of the system’s interaction with household members.

If the station pipes are not sealed, the pressure is lost. Therefore, in case of any deviations in the operation of the system, it is imperative to inspect all connections in the device.

Timely maintenance of the system will help prolong the operation of the water pumping station. Regular inspection for damage or blockages will save you from additional costs for repairs and the purchase of new equipment.

Pumping station for a private house: video

https://youtu.be/A0szy7b8hjY