Septic tank Bars is a modern autonomous station for deep biological treatment of sewage, which easily adapts to any geological conditions of the site and the climate of the area. It is recommended to buy a Bars septic tank for the installation of a private sewer system, which does not require expensive sewer services, is unpretentious in maintenance and is as economical as possible in operation. By choosing a Bars septic tank, the price of which is affordable for domestic buyers, you, first of all, get the highest level of environmental safety and maximum comfort of living in a private home or country house.

A special advantage of the Bars septic tank is that it is offered in a wide range of modifications, which differ not only in performance, but also in the principle of operation. Therefore, it is worth buying a Bars septic tank, taking into account the individual characteristics of the site. Only in this case, the autonomous sewage system will not cause any problems and will work flawlessly for decades.

"Bars - Ultra"

"Bars - Ultra" is a reliable and durable installation that operates stably even at -30°C. The container is quite easy to install and maintain. Periodic power outages, detergents (in moderate quantities) and critical burst discharges do not affect the quality of the system (with a long-term power outage, productivity is reduced to 600 liters per day). Purified water is odorless and can be used for irrigating plants or washing rooms/cars, and the removed dry sediment is an excellent fertilizer for the garden.

You may be interested in information - Topaz sewerage

In total, there are 4 types of biological treatment stations “Bars-Ultra”:

- “5” – length 2000 mm and diameter 1200 mm;

- “9” – length 2400 mm and diameter 1200 mm;

- “12” – length 2800 mm and diameter 1200 mm;

- “17” – length 3500 mm and diameter 1500 mm.

The bodies of all septic tanks have a wall thickness of 25 mm. Energy consumption ranges from 70 to 100 W/h. Productivity – from 1000 to 3000 liters per day.

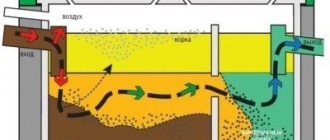

Principle of operation

How does SBO "Bars-Ultra" work?

Sewage, moving by gravity through the pipe, enters the receiver or denitrifier chamber. Here all the dirt is oxidized, the amount of nitrogen compounds is reduced under the influence of oxygen, i.e. primary cleaning takes place.

You might be interested in information about evo stok bio 5

Through a thin partition, the partially purified liquid is poured into the nitrification chamber. During the transfusion process, most of the insoluble inclusions are retained by the partition. In the second chamber, oxygen is supplied by a fine-bubble aerator, and a module with a special flat carrier is installed. This allows you to quickly decompose the waste entering the SBO.

Next, the liquid flows through the gap into the last chamber - the settling tank. A thin-layer block is installed here, where sediment accumulates.

If it is necessary to discharge purified liquid into a reservoir, an ultraviolet chamber is additionally installed in which the liquid is disinfected.

98% pure water can be discharged into a storage tank, drainage ditch, filtration field, or reservoir. You can find out how to install a “Topaz” septic tank in our article.

When the compressor, which is installed in the utility room or basement of the house, is turned off, the wastewater is treated with anaerobic bacteria in the airless environment of the SWB chambers.

"Bars - Ultra"

Design features

According to the manufacturer, Bars septic tanks are effective and reliable equipment for treating household wastewater due to the following factors:

- The thickness of the walls of the containers is 25 mm.

- The necks of the units are integral with the body, which ensures more reliable tightness of the structure and reduces the likelihood of groundwater getting inside the unit.

- Hatch covers have an anti-slip coating and special cushions for thermal insulation.

- The thickness of the walls of the internal partitions is 8 mm. They provide additional structural rigidity and minimize the likelihood of bending or breaking if the discharge is too strong.

- The internal communications of the unit are made of plastic pipes and fittings with an estimated service life of over 50 years.

- The building of biological treatment stations provides a separate container for the habitation and reproduction of aerobic bacteria. The developers claim that this helps biological material survive when aggressive chemicals enter wastewater.

- The inlet pipe in the tank can be located at any angle, which makes the installation process easier.

- The design includes a special basket for cleaning the installation from excess activated sludge. It is simply removed from the septic tank, and its contents are shaken out into the ground.

"Bars - Bio"

"Bars-Bio" is a horizontal, energy-independent bioseptic tank, suitable for installation even in the northernmost regions of the country. The cylindrical container is made of durable plastic with a thickness of 25 mm. Inside there are brush filters (2 pcs.) and compartments (3 pcs.) where the cleaning process takes place.

You may be interested in information - storage septic tank

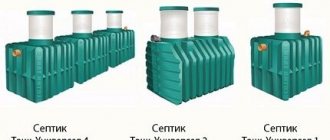

A total of 10 “Bio” variants are produced, differing in size and performance.

"Bars - Bio"

Table 1. Types and characteristics of Bars-Bio treatment plants

| Model | Weight, kg | Productivity (consumption), l/day. | Volume, l | Diameter, mm |

| 5 | 180 | Up to 800 | 2500 | 1250 |

| 7 | 200 | Up to 1000 | 2850 | 1250 |

| 8 | 225 | Up to 1100 | 3400 | 1250 |

| 9 | 245 | Up to 1300 | 3950 | 1250 |

| 10 | 265 | Up to 1500 | 4550 | 1250 |

| 10 | 300 | Up to 1400 | 4420 | 1550 |

| 11 | 280 | Until 1700 | 5150 | 1250 |

| 11 | 310 | Until 1700 | 6000 | 1550 |

| 13 | 330 | Up to 2200 | 6350 | 1250 |

| 13 | 350 | Up to 2200 | 6000 | 1550 |

Operating principle

The design of the septic tank is quite simple, but somewhat different from models from other manufacturers. Accordingly, there are certain nuances in the operation of the installation.

The drainage from the room moves into a settling tank located in the center of the structure. Here, under the influence of gravity, separation occurs into heavy insoluble sediment and fats. A primarily purified layer is formed in the central part of the settled wastewater. It is this layer that flows into the next (2nd) chamber through a mechanical brush filter, which retains large particles of toilet paper, etc. In compartment number 2, waste processing by bacteria continues.

You may be interested in information - septic tank topas device

From the second chamber the liquid flows into the next one. For overflow at a certain angle of inclination, a pipe is installed that passes through the first chamber and leads to the second brush biofilter. The slope of the pipe helps to calm the liquid in the tank and allow better sedimentation of contaminants. From the third chamber, the liquid is discharged to infiltrators or other disposal points.

Sewerage "Bars-Bio"

"Bars - Bio Plus"

Scheme "BARS-Bio Plus"

A variation of the previous septic tank model. The only difference is that in the third chamber of the septic tank there is a compartment for installing drainage pumping equipment (float type). Treated wastewater is discharged forcibly. The cost of this model has been increased by only two thousand rubles (plus the cost of the pump).

"Bars - Bio Light"

"Bars - Bio Light"

This is a horizontal septic tank with only two chambers and one brush biofilter. The model is ideal for installation in summer cottages or small private baths. The ends of the product are convex - this design allows you to evenly distribute the load on the walls.

"Bars - Bio Light"

Two-chamber (termite septic tanks) are produced in four versions with different volumes (2-4 thousand liters), productivity (650-1400 liters per day) and weight (135-215 kg). The diameter of all septic tanks is 1250 mm, the thickness of the body wall is 25 mm. The length of septic tanks ranges from 2100 to 3900 mm.

Attention! All models of Bars-Bio septic tanks require the installation of infiltrators, a filter well or drainage fields. Discharging liquid from a septic tank directly into a ditch; the reservoir is prohibited without preliminary purification.

Principle of operation

The wastewater is discharged through sewer pipes into the first chamber, where it settles, after which it is poured through a biofilter into the second chamber for post-treatment. Cleaning is carried out by anaerobic bacteria. Purified water is discharged through the outlet pipe into a filtration well, drainage pipes or infiltrator.

Service

All models of Bars-Bio septic tanks require periodic annual pumping of accumulated sludge from the bottom of the chambers. Maintenance can be carried out much less frequently, provided that bioactivators are used. Pumping is carried out through the necks after removing the covers. The walls inside septic tanks and SBOs have a thickness of at least 8 mm, which guarantees the reliability of the structures.

Reviews

Users leave reviews about Bars septic tanks that are mostly positive.

Companies involved in the installation of autonomous sewers also do not note any particular complaints from clients regarding the operation of Bars installations.

However, sometimes you can encounter the opposite situation in reviews.

In the video, Bars tests the strength of the base of the septic tank body.

"Bars - Mini"

"Bars - Mini"

This is the smallest non-volatile model. Compact two-chamber septic tanks are available in several standard sizes with a volume from 1000 to 1600 cubic meters, a length from 1400 to 3200 mm and a capacity of 330 to 530 liters per day. You can choose a model with a diameter of 860 or 955 mm and a wall thickness of 8 or 25 mm. The smallest weight of the septic tank is only 85 kg. The largest Mini model weighs 115 kg. Installation is easy to do yourself in just one day.

Septic tank "Bars-Mini"

Principle of operation

The principle of operation of the product is similar to the “Bars-Bio Light” model. The only design feature is an inclined pipe through which wastewater moves from the first compartment to the second, bypassing the filter. Another difference is that the ends of the Mini model are not convex.

About production

Aqua Hold LLC has been producing polymer structures since 2008. Factory facilities are located in the Moscow region. Products are manufactured by extrusion welding.

Bars septic tanks are the company’s own development, created in collaboration with specialists from the Department of Water Supply and Sanitation of Moscow State University of Civil Engineering. As a measure of protection against counterfeit products, the company prints a 12-digit serial number on its products.

The cleaning system is patented and each product has a serial number

Storage septic tank "Bars - N"

The sealed storage tank “Bars-N” is the best alternative to cesspools. Ideal for summer cottages with seasonal residence. The drives are available with a diameter of 1500 or 1200 mm and a length from 2100 to 5700 mm. The weight of the containers ranges from 120 to 440 kg. Small drives can be installed with your own hands, with the help of 2-3 people.

On a note! Septic tanks are made of HDPE, the service life of which is 50 years or more. The ends of the septic tanks have stiffening ribs that increase the strength of the structure and prevent any deformation.

Service

The storage tank does not have a discharge pipe. The drains must be pumped out by calling a sewer truck. If the groundwater level is extremely high, pumping is carried out only up to half the volume.

Advantages of spiral pipe

Advantage No. 1. The shape of a circle implies the annular rigidity necessary for operation.

Advantage No. 2. High resistance to deformation. Pipes retain high strength even with frequent changes and negative temperatures; they are used even in earthquake-prone areas, where earthquakes are frequent and, as a result, additional ground movements. Only these characteristics are already sufficient to achieve the goal.

Advantage No. 3. By analogy with plastic profiles in house windows, the pipe design has air layers that ideally retain heat inside the septic tank without dissipating it outside.

Advantage #4. The operating temperature range of polyethylene (HDPE) is from -40 to +60 degrees. This temperature range is as close as possible to the actual operating values of the septic tank. For example: the operating temperature range of polypropylene is from -10 to +80 degrees. It is for this reason that polypropylene is less suitable for the manufacture of septic tanks.

Installation of horizontal septic tanks "Bars". Step-by-step instruction

Installation of horizontal septic tanks "Bars". Step-by-step instruction

Horizontal Bars models are installed using similar technology.

Septic tank

Step 1. Select a location for the storage system, storage tank or septic tank.

Step 2. Using an excavator or shovels, a pit and a trench for inlet/outlet sewer pipes are dug. The width and depth of the pit should be 40 cm larger than the dimensions of the housing.

Digging a pit

Step 3. A reinforced concrete slab with metal eyelets is placed at the bottom of the pit, or a cushion of cement-sand dry mixture (1:3) with the addition of crushed stone (3 parts) is poured. The backfill is compacted and leveled horizontally. The pipe ditches are filled with a 10 cm layer of sand. It is important to maintain a slope of 2 cm per 1 linear meter, which is necessary for the movement of sewage waste by gravity.

Step 4. The septic tank is carefully lowered into the pit, aligned vertically, and “anchored,” that is, the eyes of the tank and the reinforced concrete slab are connected by cables / nylon cords / chains. Meter-long reinforcing bars with a thickness of 10 mm are inserted into the cement-sand fill.

The septic tank is lowered into the pit

Step 5. Sewer pipes are insulated and connected to the tank pipes. If the design includes aerators, then an additional air duct tube with a diameter of 20 mm is laid inside the plastic sewer pipe. Only the supply pipe is connected to the Bars-N storage tank.

Step 6. Water is drawn into the container. At the same time, backfilling is carried out layer by layer (layers - 20 cm, backfilling with sand + cement in a ratio of 5: 1) with compaction of each layer. The necks are filled with soil so that the lid rises 10-15 cm above the soil, otherwise melt and rain water will be poured into the treatment equipment. The pipes are covered with sand and soil.

The septic tank is covered with sand and covered with lids

Step 7. For “Bio” and “Mini” septic tanks, additional filtration equipment is installed, which is connected to the outlet pipe of the tank.

Water disposal

Why do you need a biofilter and how is it maintained?

The biofilter is a vertical chamber with a brush loading. The biofilter serves to accumulate anaerobic bacteria (biofilm) on its surface, which during their life cycle absorb organic pollutants from the drain. Therefore, the presence of biofilters in septic tanks makes it possible to absorb and process about 25% of organic contaminants from wastewater. Maintaining the biofilter is extremely simple and just involves washing it annually with a stream of water under pressure. When washing, the spent biofilm is washed away. There is no need to remove the biofilter from the septic tank. The formation of a new layer of biofilm occurs within 2-3 days. During this time, no significant deterioration in the quality of the filtered effluent was observed.

"Bars - Aero"

"Bars - Aero"

"Bars-Aero" is a vertical biological treatment station. It is reliable, economical, environmentally friendly and very easy to maintain. The stations are produced in three versions (5, 7 and 9), each of which differs in productivity (from 1000 to 1500 liters per day), diameter (1200 - 1500 mm), weight (175 220 kg). All three models have a total height of 2700 mm and a wall thickness of 25 mm. The stations are supplied complete with a Japanese compressor, which is installed indoors. When there is a power outage, the sewage treatment process does not stop.

The cover and top of the units are already insulated, which reduces the cost of purchasing insulating materials.

"Bars - Aero"

Operating principle

In the first chamber (denitrifier or settling tank), where wastewater flows through pipes, there is an artificial microflora carrier (grid) and aerators. These elements contribute to the rapid oxidation of dirt and a decrease in the level of nitrogen compounds.

The liquid, initially cleared of large particles, enters the second chamber – the nitrifier – through the partition. The design of the nitrifier is such that the remaining dirt particles are deposited on special plates of the module. After final cleaning, the water exits through the pipe to the discharge point or storage tank.

The sludge from the first chamber, as it accumulates, flows through the airlift into a settling container, from where it is periodically removed in an already dehydrated form and disposed of or used as fertilizer.

Video — Bars Aero

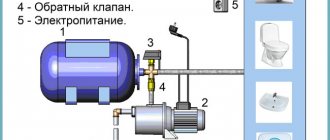

Installation of vertical SBO

Installation of vertical SBO

Installation of the Bars-Aero SBO has a number of nuances:

- Before installation, you should clarify the dimensions of the tank and prepare a pit, the dimensions of which will be 400 mm larger in depth and radius. If the walls of a vertical pit are severely crumbling, it is worth installing temporary formwork from welded metal mesh or wooden panels;

- a minimum twenty-centimeter layer of a dry mixture of sand, crushed stone (3 parts each) and cement (1 part) must be poured into the pit. The backfill is compacted and leveled horizontally. Instead of dry backfill, it is permissible to use a ready-made reinforced concrete slab with metal embedded parts. Cables will be attached to these mortgages and eyes of the upper part of the body - clamps necessary to prevent the system from floating up or being pushed out by the ground;

- the station is lowered into the center of the pit on cables. The sewer pipes are connected to the protruding pipes. An aerator tube with a diameter of 20 mm is laid inside a plastic sewer pipe to avoid crushing. Pipes must be insulated with three layers of insulation, which is fixed with construction tape;

- backfilling is done in layers (200 mm each) with tamping with a mixture of five parts sand and one part cement. At the same time, the tank is filled with water;

- sewer pipes are filled with sand and soil;

- The neck of the septic tank is filled with soil. The septic tank lid should protrude 10-15 cm above the soil surface;

- The compressor is installed indoors and connected to a 220 V power source.

Water disposal

Table 2. Cost of septic tanks (including installation), storage tanks and biological treatment stations "Bars"

| Model | Cost with installation |

| BARS-Ultra 5 | 130 200 |

| BARS-Ultra 9 | 161 500 |

| BARS-Ultra 12 | 191 500 |

| BARS-Ultra 17 | 283 000 |

| BARS-Aero 5 | 107 900 |

| BARS-Aero 7 | 120 000 |

| BARS-Aero 9 | 150 500 |

| BARS-Bio 5 | 100 000 |

| BARS-Bio 7 | 110 000 |

| BARS-Bio 8 | 124 900 |

| BARS-Bio 8 | 143 000 |

| BARS-Bio 10 (volume 4550 l) | 164 000 |

| BARS-Bio 10 (volume 4420 l) | 146 000 |

| BARS-BioLight 4 | 81 400 |

| BARS-BioLight 5 | 93 000 |

| BARS-BioLight 6 | 106 000 |

| BARS-BioLight 7 | 121 500 |

| BARS-N 2 | 81 400 |

| BARS-N 3 | 104 000 |

| BARS-N 4 | 127 500 |

| BARS-N 5 | 138 500 |

| BARS-Mini 1 (2000 x 860 / 1400 x 955 mm) | 61 000 / 48 000 |

| BARS-Mini 2 (2600 x 860 / 1850 x 855 mm) | 72 000 / 55 400 |

| BARS-Mini 3 (3200 x 860 / 2300 x 955 mm) | 81 000 / 62 000 |

Septic tank for cottages and houses BARS

Installation cost

| volume, m3 | Diameter, mm | Length, mm | Quantity of sand, m3 | Up to 0.5 m Sand (Loam, clay) | Up to 0.7 m Sand (Loam, clay) | Up to 1.0 m Sand (Loam, clay) |

| 2,5 | 1200 | 2500 | 4,2 | 36000 (41500) | 38500 (44500) | 42000 (49000) |

| 2,85 | 1200 | 2800 | 4,6 | 39500 (45500) | 42000 (48500) | 46000 (53500) |

| 3,4 | 1200 | 3300 | 5,2 | 45000 (52000) | 48500 (56000) | 53000 (62000) |

| 3,95 | 1200 | 3800 | 5,9 | 51000 (59000) | 54500 (63000) | 60000 (70000) |

| 4,55 | 1200 | 4300 | 6,5 | 57000 (65500) | 61000 (71000) | 67000 (78000) |

| 4,42 | 1500 | 2500 | 5,2 | 45000 (52000) | 48000 (56000) | 52500 (61000) |

| 5,15-10,2 | — |

Additionally, sand and cement are purchased (approximately 7,000 rubles). Installation work guaranteed for 2 years.

For more detailed information about station installation, see the Installation Services page

Is it possible to direct the wastewater treated in the septic tank directly into the drain?

After treating wastewater with a septic tank, it is necessary to provide options for the construction of soil filtration (tertiary treatment), for example, a filtration field or a filter well. For maximum filtration, water purified in a septic tank must pass through about 1 m of soil layer. The runoff can then be discharged into a drain. To discharge runoff into a ditch, filter trenches are usually used, in which, after passing through the filter layer, the purified water is collected by drainage pipes and discharged into the drainage ditch.

Do you need to call a sewer truck? How often?

Calling a cesspool truck is necessary to pump out the sediment that accumulates at the bottom of the septic tank. Sludge is pumped out once every 1-2 years. If it is not possible for a sewer truck to arrive, pumping can also be done using a submersible drainage pump with a cutting edge; in this case, the sediment should be drained into a hole specially prepared for this and then covered with soil. The sediment will continue to rot and serve as a fertilizer for the soil. When living seasonally, bacteria can be used to remove sediment, which decompose the accumulated biomass by 70-95%. In this case, the discharge of wastewater into the septic tank must be excluded for 2-3 months, the time that is necessary for bacteria to process the sludge.