It is well known that any plumbing work is one of the most highly paid, although many of them can be carried out independently, saving considerable money. Operations that are easy to do with your own hands without using a special tool include cutting into a 110 mm sewer pipe.

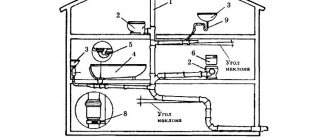

There are several ways to connect to the sewer; the methodology is different for metal and plastic pipelines. When deciding how to cut into a sewer pipe, it is also necessary to study the technology for connecting to vertical and horizontal lines.

Rice. 1 Types of fittings for connecting pipe parts

Reasons for tapping into the sewer system

Entry into the sewer is necessary in the following cases:

- If you need to connect a new plumbing fixture. This could be a washing machine or dishwasher, sink, toilet or bidet, the outlet pipes of which are connected to a line of a larger diameter.

- Transferring previously installed plumbing equipment to another location. The situation often arises during redevelopment, installation of a new vent riser, or separation of combined sanitary facilities.

- Connecting a private house to the central sewer system, which may require coordination of installation time with utility services.

Preparatory stage - recommendations

They cut into a plastic sewer pipe after determining the methodology and purchasing the necessary plumbing components and parts.

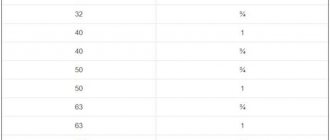

You should purchase components taking into account the basic rule - the pipeline running from the plumbing fixtures to a horizontal line must have the most obtuse bend angle possible - this greatly simplifies its cleaning from blockages and normalizes operation when different water flows collide. The pipes that connect to the riser enter it at a right angle (in plumbing this is 87 degrees).

Also, when choosing components, you should take into account the placement of the toilet outlet - it can be located in a horizontal plane or obliquely, at an approximate angle of 45 degrees to the horizontal. Selecting components for connecting a toilet with an inclined outlet pipe is not difficult; in the case of a straight channel, you may need an outlet with an offset center (eccentric).

When working during the daytime, related to cutting the riser, it is better to first ask the neighbors above not to use the sewer for some time.

Rice. 2 Insertion into a sewer riser - tool

Related article:

How to install sewerage inside a private house . As a rule, inserting into a 110 mm sewer pipe is accompanied by the installation of sewer pipes, and you can read more about installation in a separate article. What are the requirements for modern sewer systems, modern materials and methods of their installation.

What's the right way to start?

First of all, you need to decide on the type of sewerage system running near your home. Depending on this, there are two possible connection types:

- Separate. Used in case of connection of storm and domestic sewerage of a private house. It is carried out separately in two systems.

- Mixed. Can be used when there is a mixed type pipeline. In this case, one common pipe is supplied, which cuts into the system.

You need to understand that the sewer inlet, which will connect the intra-house system with the centralized one, is financed by the developer. This can result in a decent amount. Those who want to save money can try to implement the planned event during the planned modernization of the centralized branch. To do this, before starting work, you should contact the water utility and offer your financial participation in carrying out such modernization. If the decision is positive, the organization will take on part of the work, including design and connection, which will provide significant savings. Another way to pay less is to share with your neighbors. In this case, costs can also be reduced.

Independently tapping into the central sewer is a troublesome undertaking. Those who do not like to run through authorities can be recommended to contact a company that provides such services. In this case, the developer will be spared the need to collect a package of permits and resolve a number of organizational issues. In addition, the procedure for commissioning a new branch is significantly simplified. However, such services are not cheap and those who want to save money will most likely refuse them.

Those who decide to resolve the issue themselves will need to collect the following documents:

- A plan of the site and the house on which the sewer pipeline laying diagram should be applied. Performed by a company specializing in geodetic examinations.

- Technical conditions for a new connection. Developed by an organization that maintains sewer communications.

- Project for connecting the branch to the centralized sewerage system. The document is prepared by a design specialist. The basis for it is the previously obtained situational plan and technical conditions.

- Coordination of the prepared project in the water utility and the Architectural Department. At the same time, a company is being approved that will subsequently be involved in connecting the new branch.

Another important point. It is worth obtaining the consent of the residents of neighboring houses to carry out construction work in the immediate vicinity of their plots. You should prepare a document and collect signatures from neighbors. If the pipeline will pass through areas where the networks of other organizations are located, for example, electrical or thermal, and it is also planned to be laid under the roadway, additional permits will be required. If all these procedures seem too troublesome and you want to carry out an unauthorized connection without collecting documents, you need to know that for such actions there is a significant fine and forced dismantling of the pipeline at the expense of the developer.

To arrange an external sewer branch that will be extended to the central main, you should use a special pipe

Required tools and supplies

The advantage of sewerage installation is its relative simplicity - the entire system is assembled from ready-made standard units of the same size, sealing is ensured by built-in gaskets, and no special equipment is required for installation. When cutting, the following household tools and consumables are usually used:

- Hacksaw or grinder. During the assembly process, the main operation using a tool is cutting elements made of plastic or metal. In the first case, a simple hacksaw with a fine tooth is enough to cut any materials; you can use a grinder with a disk for stone or metal; cast iron parts can also be cut using the latter method.

- Crowns. For cutting into a 110 mm pipe. make a 50 mm hole. This operation can be performed in plastic using inexpensive crowns of the specified size; for cutting holes in metal, there are also bimetallic crowns, the cost of which is quite high. Holes in cast iron can be made with a regular metal drill or a gas cutter.

- Adjustable wrench or wrench. The tool will be needed when using the adapter as a pipeline penetration system.

- File or sandpaper. When cutting water pipes, it is necessary to get rid of the burrs that remain inside - this can lead to a blockage. To clean protruding surfaces outside and inside the end, use a file, sandpaper, or a painting knife.

- Sealant. To facilitate the operations of connecting pipeline components and sealing joints, laundry soap and sealants are used.

Drilling cast iron pipe

It is not always possible to drill a hole of the required diameter in a cast iron sewer pipe. This is due to the diameter of the drills available. The size of the drill chuck rarely exceeds 10-12 mm. To make a hole with a diameter of more than 10 mm, it is perforated in a circle and cut out using a hacksaw blade.

This work requires care and patience. To make drilling easier, it is necessary to remove the top hardened layer of metal. The work is performed with a low-speed drill. The holes are made in several stages, using drills from smaller to larger diameters. The sharpening angle of the cutting edge should be within 110-115°. Periodically, the drill must be cooled, preferably in machine oil. When drilling a hole, you need to apply minimal force to the drill.

Pipes and fittings are made from gray cast iron. If you come across white products, they cannot be processed at home, but their service life is disproportionately longer.

Methods of cutting into sewers

The sewer pipe to which the plumbing equipment is connected can be located vertically or horizontally. Methods of cutting in with different line locations at 110 mm. are no different; they are divided into main types: correct and incorrect.

The right way

To carry out work in a plastic pipeline, standard plumbing parts are used: tees, regular and expansion couplings. The method consists of the following operations:

- Measure the length of the riser, which must be cut taking into account the dimensions of the mounted parts. It should be equal to the size of the tee and expansion coupling, taking into account the depth of the mounting sockets.

- The pipe is cut in the right places, its outer and inner edges are protected.

- Coat all parts with silicone grease and insert them into the cut in a certain order. There are several installation options:

- The tee, which is used to insert into the system, is fixed in the following way: the lower part of the tee is connected to the riser with an adapter coupling with rubber sealing rings, the upper part is secured with a compensation coupling. This technology is used for installation in vertical risers.

- With the second method, the outlet is located in the compensator itself, and there is no need to use an extra part in the form of a tee. Typically, the lead is located at an angle of 45 degrees to the center line of the compensator - this allows this method to be effectively used for cutting into horizontal sections.

Rice. 4 The main parts for correct tapping are an oblique bend, a tee, an expansion joint and a coupling

The correct method can be connected to a 110mm line. pipes that match in size or 50 mm bends.

In the case of steel or cast iron sewer pipes, they are shortened to fit the tee for insertion, which is then welded to the break point with a welding machine.

Wrong way

This technique is designed for cutting into an existing sewer line without completely cutting the pipeline, but using cutting, when a hole of the required diameter is made in the pipe.

Then the outlet pipe is placed over the cut hole and its body is secured. When carrying out work, special adapters or saddles are used, through which the sewer line is connected to the outlets of plumbing fixtures.

The nuances of working on a water pipeline under pressure

For insertion into the pressure pipeline, electric-welded saddles and clamps with a built-in cutter are used. It is located in a special sealed nozzle housing. To drill into plastic, it is often enough to turn it with a hex key. But there are also models for a drill.

The presence of a sealed branch with a cutter inside ensures that there is no splashing of water when drilling a pipe under pressure

Some similar designs have a built-in valve. Then, after drilling is completed, the cutter is raised, the valve is closed, and the attachment with the drill is removed. Instead, a drain pipe is installed.

However, there are also products on sale with a discharge pipe, which is directed sideways from the drill (parallel or at an angle to the connected water supply).

The use of linings with an internal cutter allows you to cut into any water pipes. It doesn't matter whether they are under pressure or not. But such attachments are much more expensive than conventional clamps and saddles.

They greatly simplify the insertion process, but you will have to spend money on them. At the same time, in terms of the tightness of the resulting connection, they are neither superior nor inferior to standard solutions.

Insertion into a sewer pipe 110 mm. with your own hands

Although cast iron pipes are practically never used anywhere, in many houses they have been standing in risers without replacement for many decades. To work with modern pipelines, adapters made of cast iron are put on or a plunge is made. Working with plastic is much easier; all connections can be easily made with your own hands without a special tool; the most difficult thing is not to make mistakes in the measurements.

Rice. 5 Insertion into a plastic sewer riser

Inserting a plastic pipe into a vertical riser using the correct method

Before making an insert into a PVC pipe, if the procedure is carried out during the day in an apartment building, it is advisable to ask the residents above not to use the sewer system at this time. You can rely on luck and not waste time on warnings - the whole process will take no more than 10 minutes, and take a bucket as a safety net. The procedure for installing a tee and compensator consists of the following steps:

- When the riser is released from its fastening in the walls, it will move to the side.

- A part of the riser is cut out with a grinder or a hacksaw to the size of the compensator, the edges outside and inside are processed with a file, sandpaper or an angle grinder disc. To avoid trouble, the upper end is placed in a bucket.

- The upper and lower sockets of the riser are coated with lubricant, and a transition coupling is placed on the lower part to connect the tee. If the tee is changed, the old mounting socket is used for it, and the lower adapter coupling is not needed.

- Place the compensator on the upper end and move it up until it stops.

- The tee is installed in the adapter coupling or the old socket; before this, its surface is lubricated with silicone.

- Lower the compensator down until it is firmly fixed in the upper socket of the tee.

- The riser is secured by screwing it through clamps to the walls, and the pipeline is connected to the line.

Safety features when performing work

Installation work is closely related to the implementation of safety precautions. Following the rules will help avoid injury and equipment damage. Since a lot of unpleasant odors appear when working with sewerage, it is necessary to ensure the installation site has good ventilation. Working with power tools on wet equipment requires special attention and the use of protective equipment against electric shock.

To prevent the tool or dismantled parts from falling into the shaft, they must be secured and removed from the installation area after cutting. When working with electric cutting tools, be sure to wear a protective mask or goggles. Work should only be carried out with gloves. This will protect your hands from damage and infection.

Following the simplest rules will reduce the risk of injury and improve the quality of work.