To choose the best pump option for water intake, owners of summer cottages have to take into account many factors. Agree, you don’t want to find yourself in a situation where, after purchasing expensive equipment, it turns out that its performance is not enough.

We will help resolve this issue. We will tell you by what criteria we select surface pumps for a summer residence. Here you will learn how to connect a pumping unit, what equipment you will need if you decide to automate the pumping of water from a well or well.

The article presented for review describes in detail the design features of surface pumps and the specifics of operation. The material is accompanied by thematic photographs and videos that will help you do everything right.

Rules for installing the surface version

It is not practical to install surface pumps on deep hydraulic structures. When diving below 8 m, such devices fail. In small wells, their installation is justified due to their lower price than submersible options.

The installation procedure consists of the following sequential steps:

- A separate room is prepared to house the equipment. You can allocate space in the caisson for a surface pump.

- A rubber sleeve is placed on the suction pipe. Its length should be sufficient to connect to the aquifer.

- A check valve is fixed on the opposite side of the hose. It performs the function of stopping the drainage of liquid when the mechanism is turned off.

- A strainer is mounted on top of the valve device. It sifts out silt fragments and sand granules.

- The end of the elastic sleeve is lowered into the water.

The process ends with a trial run.

The nuances of installing a surface pump

The priority condition for placing a surface water pump is the correct choice of location for it. If the device will be used only during the “summer” season and stored in the utility room in winter, then there are no special problems with its installation location. It is enough to place the pump closer to the wellbore and higher so that the water does not flood it when pumping.

If a surface pump requires year-round use, then the choice of its location should be taken more carefully:

- Distance from the well. The power of external pumps is low, so they must be placed as close as possible to the water intake point;

- All-weather protection. It is necessary to protect the device from atmospheric phenomena by marking it in a room, bunker or inside the well head;

- Saving from frost. During frosts, the surface pump needs insulation; it should not freeze;

- Ventilation of the installation site. Placing the device in a room (shelter) with insufficient ventilation sharply accelerates the corrosive wear of the unit;

- Sufficient placement area. The water pump will require periodic maintenance. Therefore, its permanent location must be spacious, allowing for repair work;

- Sound insulation of the installation site. The operation of a surface pump is noisy, so the room for its installation will require complete sound insulation. Or you should choose the installation position of the device away from living rooms.

Note that the power of surface pumps is limited by the maximum suction depth of 8-9 meters. Moreover, the “vertical-horizontal” suction ratio corresponds to 1:4, which, with a maximum vertical suction power of 8 m, corresponds to 32 m of horizontal suction. Those. if water is drawn from an external pump from a depth of 6 m, then the maximum distance from the well to the location of the unit is calculated as follows: 32 – 6∙4 = 8 m.

However, you should also take into account the resistance in the adapter pipes and uneven voltage in the electrical network, which cause a drop in pressure. Therefore, the horizontal distance from the wellbore to the surface pump should be as short as possible, even less than the calculated one.

As for the permissible length of the pipeline at the outlet of the pump, the “vertical-horizontal” ratio will be 1:10, which corresponds to 10 m of horizontal water supply per 1 m of vertical.

Additional equipment for an external water pump required when organizing water supply from a well includes:

Fittings. Necessary for connecting a pipe or hose to the device;

Hoses (pipes). Needed for lifting water from a well and for supplying it to household consumers. The usual cross-section for an external pump is 32 mm;

Couplings (fittings) with external thread. Required for attaching functional elements (filters, check valves, etc.) to hoses;

Check valve. A valve attached to the end of the supply hose blocks water from flowing back into the well

An important addition to the water supply system, since the pump should run dry as little as possible;

Mesh filter. Mounted to the check valve (in front of it), it prevents mechanical particles (for example, sand) from entering the pump unit.

In addition to the above-mentioned components of the pumping system, it is possible to equip the surface pump at the outlet with a special five-pin adapter, which allows you to supplement the pump complex with a pressure gauge and a pressure switch that controls the pump operating cycles. Also, a five-pin adapter will allow you to connect a hydraulic accumulator tank to a water supply device, completing the construction of a full-fledged pumping station.

Well types and pump selection

For autonomous water supply, two types of wells are used: “for sand” and “for lime”. In the first case, drilling is carried out to an aquifer of coarse sand, in the second - to aquiferous porous limestone strata. Each area has its own characteristics regarding the occurrence of such layers, but the general thing is that the drilling depth for sand is much less and is usually in the range of 15–35 m.

1. Well for limestone. 2. Sand well. 3. Abyssinian well

Wells for sand are easier to drill, but they have low productivity, and with long breaks in work (for example, seasonal residence), there is a threat of silting of the galun filter.

The “heart” of any autonomous water supply system is the pump. Both the sand well and the lime well operate with submersible pumps. The pump is selected depending on the depth of the well and the required system performance, and this directly affects its price.

There are many different models of well pumps available, and among them you have to choose the best option in terms of technical characteristics and dimensions.

There is another type of well - the Abyssinian well. The difference is that the well is not drilled, but pierced. The “working” lower section of the pipe has a pointed tip, which literally pierces the soil to the aquifer. Just like for a sand well, this section of pipe has a perforation covered with a galloon mesh filter, and in order to keep the filter in place during puncture, the diameter of the tip is larger than that of the pipe. The pipe itself performs two functions simultaneously - casing and water transportation.

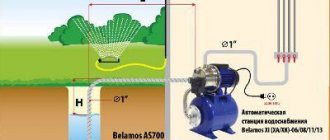

Initially, the Abyssinian well was designed to work with a hand pump. Nowadays, to supply water to private houses from an Abyssinian well, surface pumps are used, which, taking into account the depth of the caisson, can work with wells up to 10 meters (and only provided that the pipe diameter is not more than 1.5 inches). The advantages of this type of well include:

- ease of manufacture (provided that there is no rock outcrop on the site);

- the possibility of arranging the head not in the caisson, but in the basement (under the house, garage, outbuilding);

- low price of pumps.

Flaws:

- short service life;

- low productivity;

- unsatisfactory water quality in regions with poor ecology.

Types of pumps

If groundwater lies deeper than eight meters, it is better to purchase more efficient submersible pumps designed for drawing water from wells or boreholes.

Use of pumping systems

For comfortable water supply of a country house and garden plot, pumping stations are used. In addition to the pump, this equipment includes a storage tank and an automatic switching system when using water. The water filling tank is filled to the required level; when water is consumed for domestic needs, the automation turns on the pump and replenishes the water reserves in the tank. The cost of pumping stations starts from 5 thousand rubles.

Jemix W15GR-15 A

An excellent model that copes well with the problem of lack of pressure in the water supply circuit. A fan is used for cooling, which indicates the serious noise that this equipment generates. The device has manual and automatic control.

Characteristics:

- Maximum head – 15 m;

- Temperature limitation – from 0 to +110 degrees;

- Power – 0.12 kW;

- Productivity – 1.5 m3/hour;

- The diameter of the pipes is 15 mm.

How to properly install a pump in a well

The preparatory stage can be considered completely completed after all the component elements are connected into one whole structure. First of all, an elastic gasket and a cap are pulled onto the casing pipe. A pump is placed in the hole of the fixed head and then slowly immersed into the well. It is not recommended to make any sudden movements.

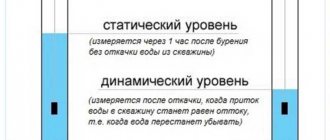

The immersion depth of the pump is determined according to the following principle:

- First of all, the distance from the surface of the water to the ground level is determined.

- The motor turns on, water must be pumped out of the well until the stream in the pipe stops. The dynamic level indicator is determined by the distance from the bottom to the surface of the water.

- When the dynamic level has been determined, the pump must be lowered by 2 meters. In such a situation, the pump should be located a meter from the very bottom of the well, so the quality of motor cooling will be optimal.

To complete such work, the efforts of at least three people will be required. One carefully lowers the cable down, and two firmly hold the submersible pump in suspension. In this case, it is not recommended to pull the pump itself, the power cable, or the pipe. If any obstacles arise during the immersion of the device, they must be removed with special care. The process of lowering the pump down must be stopped, after which you need to carefully turn it first in one direction, then in the other. In this way, it is often possible to bypass the problem area of the well. If this method does not prove to be effective, the pump will have to be pulled out and the well condition checked again.

It is advisable to check the pipe before installing the submersible pump. During installation, it is necessary to prevent any foreign objects from entering the well; they may cause difficulties when immersing the pump. Many inconveniences can arise even due to an ordinary nut getting into the system.

Basic parameters for choosing a pump

So, we have already written about the height to which you need to raise water

What else should you pay attention to when choosing? We need to know exactly the distance of the well from the house, and the volume of pumped liquid, which will depend on the total volume of the water supply network and the maximum possible water consumption at any given time. A trivial example: we open the tap closest to the point of entry into the building - we get good pressure, open the second one - the pressure drops, and at a remote point the water flow will be the smallest

The calculations here are, in principle, not complicated; you can do them yourself by using an online calculator, or simply by studying the instructions from the manufacturer.

What does the pressure in the system depend on? It depends on the power of the pump and the volume of the hydraulic accumulator - the larger it is, the more stable the average pressure in the water supply. The fact is that when turned on, the pump does not work constantly, since it requires cooling, and when the operating pressure is reached, it should not continue to increase it. The system is designed in such a way that it pumps water into a hydraulic accumulator, in which a check valve is installed, which prevents water from flowing back when the pump is turned off. When the pressure in the tank reaches the set threshold, the pump stops. If water withdrawal continues, it will gradually drop, reaching a minimum level, which is a signal to turn on the pump again.

That is, the smaller the accumulator, the more often the pump is forced to turn on and off, the more often the pressure will rise and fall. This leads to accelerated wear of the engine starting equipment - in this mode the pumps do not last long. Therefore, if you plan to use water from a well constantly, buy a tank with a larger capacity for the pumping station.

When constructing a well, a casing pipe is installed into it, through which water rises. This pipe can be of different diameters, that is, it may have different throughput. Based on the cross-section of the casing pipe, you can also choose the right equipment for your home.

All the necessary information will be in the instructions for the purchased pump. You can also get recommendations from the specialists who are drilling your well. They will know exactly the optimal operating parameters. It will also not be superfluous to make some reserve in the power of the unit so that the pressure in the system rises faster to a comfortable threshold, otherwise water will constantly flow sluggishly from the tap.

Grundfos UPA 15-90

This pump for water supply in an apartment is installed on a pipeline and has minimal dimensions. There are no temperature restrictions. Wet rotor, i.e. Ordinary water is used as a cooling substance. The device is reliably protected from corrosion, operation in the absence of liquid and overheating.

There are three working modes:

- OFF – the pump is turned off, and the liquid passes through the pipes without pump intervention;

- MANUAL – mode of constant forced operation of the pump, in which the protection against operation without liquid does not work;

- AUTO – the equipment turns on when the sensor detects water consumption by consumers, and turns off after the consumption decreases.

Performance indicators:

- Maximum head – 8 m;

- Temperature limitation – from +2 to +60 degrees;

- Power – 0.12 kW;

- Productivity – 1.5 m3/h;

- Pipe diameter is 20 mm or ¾ inch.

Complete connection diagrams

There are several connection systems. We present some of them, the most typical.

Connection using a coffer chamber

If you decide to make a caisson chamber, then start this at the very last stage of well equipment.

In this case, the complete connection will look like this:

- A – caisson chamber;

- B – constant water level;

- C – safety rope;

- D – pump;

- E – dry running sensors – pay attention to these very useful auxiliary elements of the system; they are not installed often, but sometimes they are indispensable when analyzing the progress of work;

- F – well casing;

- G – control system electrical cable;

The first possible connection option is with a caisson (see description in the text)

H – control panel; I – pressure switch – another important element controlling the system; J – fitting for five inputs; K – pipe head – we advise you to pay special attention to the careful layout and condition of the head; L – water drain valve, as an element of the protective system; M – hydraulic accumulator; N – pressure gauge – it is necessary to know the pressure in the system at all times; P – well filter – a feature of this scheme is that the filter is already at the outlet of the system; Q – check valve.

Connection with emphasis on the hydraulic accumulator

Please note that in the following picture the filter is installed in the middle and you are using water freeze protection:

- 1 – well head;

- 2 – electrical cable;

- 3 – galvanized pipe – corrosion protection is very important for devices of this kind;

- 4 – safety rope;

- 5 – sealed cable coupling;

- 6 – adapter;

- 7 – pipe;

- 8 – cable ties;

- 9 – check valve;

Connection diagram with hydraulic accumulator (see description in text)

- 10 – nipple;

- 11 – well pump;

- 12 – frost protection;

- 13 – shut-off valve;

- 14 – tee;

- 15 – main filter;

- 16 – adapter;

- 17 – electronic automation unit;

- 18 – wiring;

- 19 – hydraulic accumulator.

Extreme attention to fittings

Another option demonstrates the most careful attitude to the entire connecting system, recalling that pipelines are also the science of contacts.

We pay attention to the sensor used in working and “dry” states:

- A – position of the sensor in the operating position of the pump, when there is enough water in the channel;

- B – well head;

- C – horizontal of the upper ground level;

- D – water heater;

- E—hydraulic accumulator;

- F – total depth;

- G – dynamic, constantly changing level;

- H – minimum distance from the edge of the device to the bottom of the well;

Detailed analysis of the most loaded fitting areas (see description in the text)

I – sensor position when an emergency stop occurs due to lack of water, “dry” mode; J – position of the check valve, pay attention to the fitting system; K – submersible pump with float; L – coupling; M – fitting for 5 outlets; N - pressure gauge; P – pressure switch; Q – ball valve; R – pre-filter.

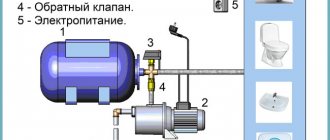

Surface pump connection

Introducing the connection of the surface pump:

- 1 – control system;

- 2 – power cord and plug;

- 3 – power cord and socket;

- 4 – circuit breaker – a mandatory element for protection against overloads and, nevertheless, maintaining the system in working order;

- 5 – power socket, the proposed circuit operates from a standard network of 220 V and 50 Hz;

- 6 – well;

- 7 – input strainer;

- 8 – check valve;

Connection diagram of a surface pump to a well (see description in the text)

- 9 – suction pipeline;

- 10 – surface pump;

- 11 – pump power cord and plug;

- 12 – discharge pipeline;

- 13 - nipple;

- 14 - tee;

- 15 – transition nipple;

- 16 – flexible liner;

- 17 - eyeliner;

- 18 – pipeline to consumers.

What allows you to increase the pressure in the system

In order for the pressure in the water supply system to be higher, you must first understand the reasons that led to such troubles. The root of the problem may be:

- leaks and breaks in pipes on the main line;

- reduction in the cross-section of the pipeline as a result of the layering of calcium salts;

- filling the coarse filter;

- meter jamming;

- breakdown of shut-off valves or check valve.

An example of clogged old pipes

If there is poor water pressure, first of all you need to contact your neighbors living on the same floor. If everything is fine with them, then you need to look for the problem yourself. Additionally, if the system allows, you can partially dismantle the water main at the entrance to the apartment, having previously closed the shut-off valves. This will help assess the pressure. In this case, you will need to substitute a bucket or basin so as not to flood the floors. The absence of pressure at the inlet eliminates the need to maintain your part of the water supply. Then all that remains is to contact the emergency service so that they can take measures to repair the water pump, or install a pressure-increasing pump.

When the problem is caused by reasons within the apartment, the following actions will help:

- filter cleaning;

- washing aerators on faucet spouts;

- changing faucet cartridges;

- installation of new flexible hoses on taps and toilet cistern;

- reinstallation of the check valve;

- replacing the meter if it is jammed;

- complete replacement of the distribution of old pipes running from the riser to the apartment's consumption points.

Prices for cleaning clogs in the kitchen

Products for cleaning clogs in the kitchen

Connection procedure: step-by-step instructions

Not everyone knows how to properly connect a pumping station. When installing block equipment, assembly involves combining the pressure and suction pipelines. A filter with valves is connected to the pipe immersed in the well, and it is brought out through an adapter or head.

The suction line is carefully sealed. Otherwise, air will enter the water supply system, which will damage the pump. The pressure part is equipped with a valve.

12 steps to connect a pumping station:

It is worth considering how the pumping station is connected to the well when choosing modular equipment. Connecting a well to a pumping station includes the following steps:

- Hydraulic accumulator piping. First of all, install a fitting with 5 pipes. It is connected directly. After this, the protective relay, pressure gauge and water inlet are configured and installed. The remaining outlet is used to connect the pressure pipe. Submersible pumps are installed in wells more than 10 m deep. This avoids the problems caused by the need to install an ejector and a suction part.

- Pipeline outlet. Produced through the source head. Pressure pipes are laid in a trench leading to the house. The elements must be located below the soil freezing depth.

- Connection to the electrical network. During the installation process, the station's starting block is installed, and the output is connected to it with copper wires. The pump must be powered through a separate automatic switch.

After completing the assembly process, the tightness of the connections is assessed. For the first time, the accumulator is filled slowly so as not to damage the integrity of the membrane.

Types of pumps for wells and their functions

Pumps for supplying water from a well can be immersed in narrow wells to great depths or mounted on the surface. The operating principle of the device and its installation is as follows:

- Its main elements are impellers mounted on one shaft.

- Their rotation occurs in diffusers, which ensures the movement of liquid.

- After the fluid passes through all the wheels, it exits the device through a special discharge valve.

- Fluid movement occurs due to pressure differences, which are summed up across all impellers.

There are several types of such equipment:

- Centrifugal. Such a pump allows the supply of clean water without large contaminants.

- Auger. This is the most common device, capable of pumping liquid with an admixture of particles per cubic meter of no more than 300 grams.

- Vortex. Transfers only water purified from contaminants.

Despite the differences, all types of pumps serve to perform similar functions:

- Supply groundwater to private houses and cottages.

- Participate in the organization of irrigation systems.

- Pump liquid into tanks and containers.

- Provide comprehensive water supply in automatic mode.

When choosing a pump for a site, the following criteria are taken into account:

- Initial equipment dimensions. They need to be taken into account to ensure certain technological tolerances when placing the pump in the well.

- Power of the electricity source. Borehole pumps are manufactured single- and three-phase.

- Device power. This parameter must be determined in advance based on the calculated pressure and water consumption.

- Pump cost. In this case, it is necessary to choose the right price-quality ratio of equipment.

Types of household pumps

Pumps for wells are divided into submersible and surface. Such units have some advantages over others:

- Large water intake depth, which is inaccessible to any other type of pump.

- Ease of installation.

- No rubbing parts.

- Low noise level.

- Long service life.

The photo shows the types of submersible borehole pumps.

Submersible Well Pumps

Advice: It is very important to ensure that the equipment is properly and correctly arranged and to use only high-quality materials. Violation of installation technology or the use of poor materials can lead to:. Violation of installation technology or the use of poor materials can lead to:

Violation of installation technology or the use of poor materials can lead to:

- Pump breakage.

- Its premature failure.

- When dismantling, it is impossible to lift the pump.

Wilo PB-088EA

This unit is quite compact and is equally suitable for transporting both hot and cold media. The equipment is cooled by liquid passing through it. The device can operate in automatic and manual mode. The automatic mode is activated by a special sensor that monitors water consumption. The Wilo pump is resistant to overheating and makes virtually no noise while pumping liquid.

The performance indicators of this model are as follows:

- Maximum head – 9.5 m;

- Temperature limitation – from 0 to +60 degrees;

- Power – 0.09 kW;

- Productivity – 2.1 m3/hour;

- The diameter of the inlet pipes is 15 mm or ½ inch.

How to choose

To choose the right model, you need to answer several questions.

- How much liquid should be pumped out at a time?

- From what depth should pumping be carried out?

- How often will it work?

- What is the level of water pollution and what is the maximum size of solid particles in it?

- Acceptable price.

The video shows how to choose a drainage pump for a well:

Below are the main models of submersible and surface drainage pumps that have gained popularity in the Russian market.

Gilex Drainer

The Jilex fecal submersible with a grinder is used for cleaning septic tanks, country sewers, and drainage wells. Power – 400 W, productivity – 9 cubic meters. per hour, the maximum permissible size of solid particles is 35 mm. Price – 3,400 rubles.

Power – 900 W, productivity – 16 cubic meters. at one o'clock. Price – 4,000 rubles.

GRUNDFOS

The company produces various models of submersible drainage and sewage pumps. The average price for models with a power of 300-500 W and a capacity of 5-10 cubic meters. per hour starts from 10 thousand rubles. The pumps are equipped with a built-in float sensor and dry-running protection.

Types of submersible pumps for wells

Most often, owners of private houses give preference to submersible pumps for pumping drinking water from a well. Compared to their surface counterparts, they make less noise, are more durable, more compact and are not as susceptible to fluctuations in outside air temperatures. Plus, a unit on the surface is not always able to lift water from great depths.

All models of submersible well pumps are divided into two categories:

- Vibrating.

- Centrifugal.

In the first case, water is pumped due to vibrations of a special membrane, and in the second, thanks to a rotating disk with blades.

Vibrating

When choosing a vibrating pump, it is important to understand that they all have a negative impact on the integrity of the well. The vibration created by such units slowly but inexorably destroys it. Plus, the soil at the bottom and around the lower end of the well structure also gradually changes its structure when the deep-well pump is operating.

As a result, the siltation process in many cases accelerates sharply

Plus, the soil at the bottom and around the lower end of the well structure also gradually changes its structure when the deep-well pump operates. As a result, the siltation process in many cases accelerates sharply.

Examples of vibration models

However, vibration pumps have many advantages, including:

Vibration pump installation diagram

A vibration pump is the ideal choice when you need to pump or clean a well. Along with the water, it also lifts all the silt from the bottom. This is both a plus and a disadvantage of these models. This liquid is not suitable for drinking without additional filtration. However, to flush the strainer at the end of the casing, a vibrating well pump is ideal.

Centrifugal

A centrifugal pump for a well has higher productivity. One or more impellers with blades rotate inside it, which create a vacuum in the center of the unit, into which water is drawn from below. Centrifugal borehole pumps are practically silent and are capable of lifting liquid from very great depths.

Centrifugal models

Their only significant drawback is sensitivity to impurities. The purity of the water flow entering them must be high. Otherwise, the working elements of the hydraulic pump will begin to wear out and fail. Before choosing a pump of this class for your home, it is necessary to analyze the water in the well. If the mechanical impurities are more than 100 g/cubic meter, then you will have to install a vibration analogue.

Operating principle of centrifugal pumps

Why is low pressure unacceptable?

Insufficient pressure in an apartment can cause a number of troubles:

- breakdown of the washing machine and dishwasher;

- ineffective operation of the hydromassage box and drinking water filter;

- failure to turn on the instantaneous water heater;

- slow filling of the bathroom and toilet cistern.

As for the disadvantage of slow filling of the bathroom and toilet tank, this can still be tolerated, but low water pressure in the pipes can cause damage to household appliances. If the pressure drops below 2 atmospheres, the washing machine and dishwasher may fail if there is no special protection. If they don’t break, they simply won’t turn on until the pressure is restored. The inability to wash clothes in a machine forces you to do it manually, which is completely unacceptable. In addition, instantaneous water heaters, in particular gas water heaters, refuse to start if there is insufficient pressure.

Poor pressure on the faucet