Drainage sewerage is a system of perforated pipes, called drains, that function as one with the house's sewer system and septic tank.

At the same time, very often drainage sewers are made to remove wastewater from the bathhouse, because it does not contain large fractions and such water, which has passed through a layer of crushed stone and sand, can be passed into the ground without worrying about the state of the environment.

Storm drainage can also be installed. It is necessary to drain rainwater from the ground surface. In this case, trenches will be laid around the house, equipped with receivers of water coming from the drain.

Drainage sewer

Types of filtration structures

There are 3 types of main drainage systems for a septic tank:

- Filter wells;

- Aeration fields;

- Tunnels.

Their choice depends on the performance of the device and individual conditions on the site.

Filter drainage wells

They are a well with a gravel cushion - a bottom filter at the bottom. Through it, wastewater seeps into the soil, undergoing preliminary treatment.

Fields of underground filtration (aeration)

This is a system of perforated pipes that are laid on a crushed stone bed. The top is covered with soil and covered with geotextile. Unlike wells, they can have a significantly larger wastewater dispersion area and high productivity.

Drainage tunnels

They are a type of underground filtration fields. Instead of pipes, special tunnels or, in other words, drainage elements are used here. They perform the same function as pipes in an aeration field, dispersing runoff. But due to their shape and size, the tunnels significantly increase the effective contact area of the wastewater with the soil and the efficiency of the system.

Installation of a septic tank in a private country house

The wastewater from the house is sent to a container called a septic tank and accumulates there. A septic tank is a mandatory element of local treatment facilities for an autonomous sewage system in a private home.

| Single-chamber septic tank made of concrete rings |

Wastewater treatment in local treatment plants with ground drainage takes place in several stages.

How a septic tank treats wastewater

The first preliminary stage of wastewater treatment takes place in the septic tank .

In the septic tank, particles heavier than water settle from the incoming sewage water and settle to the bottom.

Grease and other substances lighter than water gradually accumulate on the surface of the drain

and create a floating crust that prevents the flow of oxygen.

The presence of a fatty crust on the surface of the liquid in a septic tank creates the necessary conditions for the process of anaerobic (without access to oxygen) fermentation of organic contaminants in the wastewater.

In a septic tank, contaminants in the effluent are decomposed by anaerobic bacteria

, releasing mineral particles heavier than water, suspended and dissolved solids, and gases.

Freed from most of the contaminants, clarified sewage flows from the septic tank to ground treatment facilities for further treatment. , sediment in the form of sludge gradually

the result of the decomposition of contaminants.

Gases are removed from the septic tank

through the sewer ventilation system.

It is necessary to strive to increase the degree of wastewater treatment in the septic tank. The less contaminants in the effluent at the outlet of the septic tank, the slower the process of siltation of soil drainage, the longer its service life.

Filtration drainage wells

Drainage well diagram

Popular structures. They are made of plastic, concrete rings, brickwork.

The most modern options are plastic wells. When choosing, attention should be paid to the quality of the product, the reliability of the locking connections, and the thickness of the walls. It is better to give preference to well-known brands, they are carefully calculated.

Compared to reinforced concrete options, plastic drainage wells are easier to install, since creating masonry, as well as installing rings, is a rather labor-intensive process. Factory wells usually have special perforation, which increases the effective area of the structure.

Regardless of the material, the main element in any drainage is the bottom filter. They are backfilled with crushed stone of a fraction of 15-30 mm, placed inside the well. The height of the bottom filter should be from 30 cm to one meter, depending on the load.

Get a response within 3-12 hours from a specialist

The useful surface of the well is calculated by the sum of the areas of the bottom of the well and its internal walls, plus the height of the filter.

Example:

Let's take a drainage well 1.5 m high, 1 m in diameter with a filter thickness of 0.5 m. Remembering the formulas for calculating the area of the walls of a cylinder and a circle, we will establish that with the given parameters, the useful rounded surface is equal to 2.35 m².

Next, using the filtration coefficient table, we calculate the permissible load, which will depend on the type of soil on the site.

The correction factor for wells is 1-1.2.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Order installation of a septic tank

To equip a treatment facility, you need crushed stone of the middle fraction (from 20 to 40 mm).

Installation of drainage wells

Installation includes:

- Digging a pit;

- Well installation;

- Backfilling of the bottom filter;

- Backfilling with crushed stone around the structure.

When choosing a place for a pit, it is necessary to take into account that the setback from the boundary of the site in accordance with “SP 53.13330.2019” (SNiP 30-02-97) must be at least 1 m. You also need to take into account the minimum distance to a private house - 8 m.

At the same time, the well walls must have perforation with an area of 10 percent to the height of the bottom filter. Factory designs have this parameter. You need to worry about compliance with it if you are strengthening the walls of the well with brickwork; gaps must be left here. However, such archaism makes no sense today.

Between the walls of the well and the pit, a backfill of 30 cm is made to the height of the bottom filter. The supply of wastewater to the well is carried out in the center of the filter, the recommended height of its location is 10 centimeters and above.

The drainage well must have a hatch and ventilation, which is done with the outlet of the fan riser at a height of 70 centimeters above the ground. The diameter of the ventilation pipe is from 110 mm or more.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Order installation of a septic tank

Note! On the Internet you can find recommendations for laying geotextiles between the bottom filter and the soil.

This advice is wrong. Geotextiles will silt very quickly and become an excellent waterproof material, rendering the filter well inoperable.

How can you improve sewer efficiency?

The quality of operation of an autonomous sewer system can be improved both by installing additional equipment and purely by installation parameters. To do this, you just need to correctly distribute the slope of the highways. A slope of 3 cm/m is considered the most effective. But for greater efficiency of the sewer system, you can increase this parameter to 4-5 cm/m. This will be quite enough for the efficient operation of the system and not enough for the rapid formation of grease or dirt deposits on the inner walls of the pipes.

Modern means are very effective in combating deposits on the walls. But you shouldn’t expect a miracle from them if a serious blockage occurs. Advertising may claim that the product can easily cope with any of them, but this is not entirely true. In fact, such products are good for periodic prevention. If the pipe is already thoroughly clogged, then there is nothing better than a good old cable.

Many people insulate sewer pipes with mineral wool - a pretty good solution

Speaking about additional equipment, one cannot fail to note the benefits in preventing blockages of such equipment as a household waste disposer under the sink. It prevents large scraps and other debris from entering the sewer pipe. Everything that goes down the drain after grinding has the consistency of liquid porridge, which is not capable of clogging the main line.

Aeration filtration fields

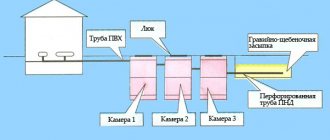

Filtration field diagram

This soil treatment system is preferable for large daily volumes of wastewater. The aeration field is a system of perforated pipes in the ground connected to a septic tank, laid on a gravel bed.

The diameter of the pipes is selected from 100 mm, and perforation is preferable in the form of cuts of half the diameter. The width of the cuts is made in 5-10mm increments of 10 centimeters.

The arrangement of pipes can have two types and be:

- Parallel;

- Radial.

With a radial arrangement, the drainage pipes extend from the septic tank or distribution tank of the filtration field in all directions, and with a parallel arrangement they are located side by side. The latter arrangement is in most cases more convenient, since it allows rational use of the site area.

Calculation of the productivity of underground filtration fields is done based on the area of their sand-crushed stone base, using a coefficient of 0.4-0.6, according to the calculation table.

Installation of aeration fields

Installation of aeration fields includes:

- Preparation of the base;

- Soil cutting;

- Filling the gravel base;

- Pipe laying;

- Backfilling with gravel;

- Covering with geotextiles;

- Burial.

Before you begin installing irrigation fields, please note that their sanitary zone for a productivity of up to 15 m³ is 15 meters.

If possible, fields should not be located near large trees. As the roots grow, they clog the drainage pipes, damaging the structure and ultimately the septic tank.

Installation begins with digging a pit for a filtration field of the required area. Separate trenches for each drainage pipe or a general pit for the entire system are possible. Next, a gravel-crushed stone base with a thickness of 20 centimeters is prepared. On clay soils, additional sand bedding should be provided.

Important! Under no circumstances should a rammer be used to level the base of a pit! Moreover, the soil cannot be leveled by adding soil. It is carried out exclusively by cutting off the top layer of soil. Before adding gravel and sand, the top layer must be cut away to open the natural pores of the soil. A tool such as the “Fokina flat cutter” is well suited for this.

Otherwise, the trampled soil will become a kind of waterproof layer and will not allow the aeration field to work effectively! It is also necessary to take into account the depth of soil freezing in the region. The infiltration field must be below this mark so that its operation is not disrupted in winter.

Get a response within 3-12 hours from a specialist

An important aspect is the distance between the pipes. When positioned parallel, it ranges from 1.5 m on sand and up to 3 m on clay (loam).

With a radial arrangement, the divergence angle is critical, which should be maintained at 30 degrees or less. The entrance to the pipelines must be at the same level.

Note! The length of each drainage pipe should not exceed 15 meters. Otherwise, the wastewater will not reach its end and part of the structure will be inoperative.

At the end of each pipe there is a ventilation riser with a diameter of 10 cm, with an outlet height above the ground of 70 cm or more. Next, the pipes are covered on top with a 5-10 centimeter layer of crushed stone and a geotextile membrane is laid to prevent soil from entering the gravel backfill. After this, the treatment plant is finally backfilled.

Septic tank maintenance and cleaning

In a new septic tank, it is necessary to create conditions for the rapid accumulation of microflora, which carries out anaerobic digestion of contaminants.

To colonize the new septic tank with the necessary microorganisms, two weeks after the start of use, it is recommended to load mature sediment from the existing septic tank in an amount of approximately 20-30 liters per 1 m3

useful volume of the septic tank. Without introducing external microflora, the normal cleaning process will start only after a few months.

There are preparations on sale - bioactivators, which contain microorganisms necessary for the operation of the septic tank. Be careful - you should buy drugs designed to activate anaerobic septic tanks.

Loading a bioactivator intended for an active aerobic septic tank into an anaerobic septic tank will cause harm.

The bioactivator is useful for using for a new septic tank, as well as in case of disruption of the septic tank, for example, after a long winter break at the beginning of the summer season. Constantly using bioactivators for an anaerobic septic tank, as advertising sometimes advises, does not make sense.

to clean the septic tank from bottom sediments and floating crust once every 1 - 5 years.

.

It must not be allowed to

the amount of liquid in the septic tank, due to accumulated bottom sediments, greatly decreased and became less than 80% of the calculated volume. The lower surface of the floating crust should not fall to the lower edge of the tee. The level of sediment is controlled by lowering a wooden strip into the septic tank.

Cleaning begins by removing the crust using a mesh scoop with 3-4 mm holes.

To pump out sediments, a sewage disposal machine is usually used - a sludge sucker. The sludge extractor uses a special vacuum pump to suck a fairly thick sludge mass from the bottom of the septic tank into its tank.

When cleaning by hand, the sludge is scooped out from the bottom with a long-handled ladle. Before cleaning, use a special fecal pump to pump out the water.

To ensure that the wastewater treatment process is not interrupted after removing the sediment, approximately 15-20% of sludge is left in the septic tank

from the volume intended for it.

Inspection and cleaning of tees

It is recommended to do it at least 2 times a year, in spring and autumn. The contaminants accumulated in them are usually pushed down.

Should not go into the septic tank

large quantities of rough paper, fabric, pads, pads, packaging film, vegetable waste - everything that slowly decomposes.

If the process of decomposition of contaminants in the septic tank proceeds normally, then the acidity of the wastewater at the outlet of the septic tank should be within the range of Ph = 6.5 - 7.5. The color of the sludge in the septic tank is dark gray. When the wastewater leaves a properly operating septic tank, it should be dirty brown in color, transparent and without the smell of hydrogen sulfide.

If wastewater from a septic tank is stored in a jar for several days, sediment will form and an unpleasant odor will appear. This is the result of the decomposition of contaminants remaining in the drains by aerobic bacteria.

To prevent the soil filter after the septic tank from quickly silting up, the concentration of suspended solids in the wastewater after the septic tank should not be higher than 100 mg/l.

A few months after the new septic tank is put into operation, it is recommended to take samples a couple of times and determine this indicator and the acidity value - Ph - for wastewater from your septic tank in the laboratory. The cost of the analysis is small, but it increases confidence in the correct operation of the septic tank.

Some sources of information claim that in European countries multi-chamber septic tanks of increased volume are used, designed to store wastewater in a septic tank for 10 days (and not 3 days, as in the Russian Federation). As a result of a longer stay in a septic tank, the degree of wastewater treatment increases. The concentration of suspended solids in wastewater at the outlet of such a septic tank is less than 25 mg/l. Effluents with such concentrations in Europe can be discharged onto the terrain, into water bodies.

According to sanitary standards in Russia, wastewater with a concentration of suspended solids of no more than 2 mg/l is suitable for discharge into water bodies. Therefore, in the Russian Federation they use septic tanks with a 3-day capacity with additional treatment facilities.

Drainage tunnels

Scheme of operation of drainage tunnels

They are a close analogue of underground filtration fields. The main difference is that instead of perforated pipes, special elements are used here - infiltrators. They are containers with an increased area adjacent to the ground and do not have a bottom. Their volume, depending on the manufacturer, ranges from 300 liters or more.

The effective area of this structure is calculated, as with aeration infiltration fields, based on the area of the sand-crushed stone base. However, in accordance with the calculation table, the coefficient here is 1.4-1.6 versus 0.4-0.6 (for conventional aeration fields).

In other words, the productivity of drainage tunnels is approximately 3 times higher.

Installation of drainage tunnels

The process of installing filtration tunnels

The principle is almost identical to the creation of aeration fields, with the only difference being that instead of perforated pipes, drainage elements are installed.

Installation work consists of:

- Pit preparation;

- Cutting soil from the bottom;

- Gravel base dumps;

- Installation of drainage elements;

- Backfilling with gravel;

- Coverings with geotextiles;

- Final backfill.

Sanitary standards for drainage tunnels are similar to aeration fields and are 15 meters.

After digging a pit, soil is cut from its bottom. Next, a gravel cushion with a thickness of 200 mm is poured. Infiltrators are installed on it, connecting pipes to the septic tank and to each other. At the end of each tunnel, a ventilation fan riser is made with an outlet to a height of 70 cm above the ground level.

If drainage elements with a continuous arch are used, located close to each other, then final backfilling with soil is possible without the use of geotextiles.

If there are gaps between them, geotextiles should first be laid on the walls of the pit to protect the gravel base from mixing with the soil. Next, the drainage tunnels are filled to the top with crushed stone and covered with geotextiles.

For the final backfill, the previously selected soil can be used.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Order installation of a septic tank

All of the above structures do not work at high groundwater levels. When groundwater is close, it is possible to use a filter embankment made of crushed stone with drainage tunnels laid in it. The height must be at least 1 m. However, such a system will be expensive. Drainage from the septic tank by gravity is not possible in this option. Forced supply with a drainage pump will be required.

Drawing up a sewer system diagram

The first thing you need to do is draw a floor plan of all the premises of the building. It is more convenient if such a diagram is available - quite often during construction, just such diagrams are drawn up. In this case, it can be copied and sewer routes can be “laid” along it. Having indicated the installation points of plumbing fixtures, we begin measurements. Every millimeter can play a role here.

Important! When installing thinner pipes (for example, from a sink), if they are longer than necessary, there is a danger of them being bent. In this case, the water will stagnate, which will lead to a build-up of grease and dirt and clog.

If possible, it is better to place all plumbing fixtures in close proximity to the riser - this will allow sewerage to be carried out with the greatest efficiency. All tie-ins into the riser are indicated. A prerequisite is to connect the toilet flush directly to the main pipe, without additional connections. The drain of the bathtub and sink can be combined - this will save material and get rid of extra pipes and tie-ins into the main riser.

The layout of sewerage pipes in the basement must be of high quality and neat.

Deadly septic tank

When pollutants decompose in wastewater, toxic gases are formed

- carbon dioxide, methane, hydrogen sulfide. Gases from the septic tank are removed through the natural ventilation system of the sewer riser in the house.

concentrations of dangerous gases that are lethal to humans may remain in the septic tank

Gases are heavier than air, and some of them are contained in the sediment at the bottom of the septic tank. Natural ventilation often fails to reduce the concentration of these gases to safe levels.

It is strictly forbidden for anyone to enter the septic tank.

without implementing security measures.

Immediately before descending into the septic tank, it is necessary to forcefully ventilate the septic tank for at least 30 minutes , supplying air from a compressor

or other air blower

.

The end of the hose must be near the bottom, and the amount of air supplied to the septic tank during the specified time must be at least ten times the volume of the septic tank.

The air supply should not be interrupted while working in the septic tank.

During work, be sure to protect the open hatch of the septic tank. Hatch - the septic tank lid should not be easily opened without the use of a tool - this is safer for children

.

At the next stage of treatment, wastewater from the septic tank enters the drainage system - an absorption field, a filter well or a filtration field.

From the following article you will learn:

- How to make an absorption field or filtration field

with your own hands. - Correct filter well.

- How to protect sewers from freezing

. - Sewer ventilation