Cast iron pipes are used primarily for the installation of sewer structures. And even after the advent of more modern polymer materials, cast iron parts continue to be used everywhere. This is due to the fact that they have a long service life and are also able to withstand heavy loads when transporting liquids.

Pipes for sewer systems made of cast iron must meet all GOST requirements

Advantages and operational scope of cast iron pipes

Like any other product, a cast iron pipe has its advantages. Let's consider the advantages of cast iron parts over modern plastic ones:

- they are distinguished by high strength characteristics;

- cast iron pipes are wear-resistant;

- cast iron has good soundproofing properties;

- parts made of this material are fire resistant;

- are resistant to temperature fluctuations;

- have a low stretch coefficient.

Helpful information! These products are regulated by the relevant state documentation (GOST). According to GOST, cast iron parts for sewer networks are best used for installation inside structures in which the load exceeds economic standards.

Let's consider in what cases it is recommended to lay pipes made of cast iron:

- at industrial enterprises that belong to the food industry;

- in factories;

- on farms;

- in buildings equipped for sanatoriums (if there is access to geothermal sources);

- in buildings equipped for healthcare purposes;

- in educational institutions.

Cast iron pipes are suitable for underground and above-ground drainage systems

Cast iron pipes are heavy, so their installation is quite labor-intensive. Products with large cross-sectional dimensions require the use of special equipment during installation.

Reasons for replacing cast iron with polymers

What is the reason for the growing popularity of polymer products that are being sought to replace cast iron?

As it turns out, the main reasons are:

- risks of cast iron corrosion from damage by stray currents of electromagnetic fields;

- lack of additional protection of the internal walls of pipes from aggressive environments;

- rigidity of products, which has a positive effect on an individual pipe, but provokes a displacement of the total soil loads at the joint points on a pipeline assembled from a dozen or more pipes;

- technical difficulties that inevitably arise during the repair process or in the event of creating new communication connections.

Polymer pipes are much more often used than cast iron pipes to create autonomous sewage systems in private homes.

You will learn about which pipes are best used in the construction of the external part of the sewer system in a suburban area from the following article devoted to this difficult issue.

Production of cast iron pipes

Cast iron pipes are made by casting. Today, there are two types of casting for making these sewer parts. Consider these two casting options:

- centrifugal;

- semi-continuous.

The first method involves using a special form. Cast iron is poured into it, after which, due to rotation, it is evenly distributed over the walls of the mold, resulting in the formation of a finished part. The thickness of the wall depends on the amount of liquid cast iron used.

Let's consider the main advantages of this method:

- high speed of pipe production, which affects productivity indicators;

- good quality of cast iron product cast using this method;

- saving raw materials and electricity;

- the possibility of automating this method;

- simplification of the process due to the absence of the need for additional steps (forming and drying);

- This process saves not only time and money, but also space, as it eliminates the need for additional equipment.

Pipe production using centrifugal casting is the most economical

However, centrifugal casting also has its disadvantages. Among the disadvantages of this method are the following:

- the pipe can only be made of a certain shape, in accordance with the shape of the workpiece;

- the need for strict control of the amount of raw materials entering the workpiece (to obtain the required wall thickness).

The semi-continuous casting method involves filling a mold with liquid cast iron. In this form, the cast iron solidifies and the finished product is obtained. After partial hardening, the part is removed from the mold and divided into the required sections. The cooling process is carried out using ordinary water.

Let's look at the main advantages of this method:

- using this method, you can obtain a long product, which is subsequently cut into parts of the required length;

- the accuracy of the geometric parameters of the product is maximum;

- possibility of saving liquid cast iron.

The disadvantages of this method include:

- not very high performance;

- The finished pipe is quite difficult to remove from the workpiece.

Pipes are either pressure or non-pressure, with or without a socket

Types of cast iron pipes according to GOST

All cast iron pipes according to GOST are divided into 4 types. Let's look at them:

- pressure ductile iron (high-strength cast iron with nodular graphite) pipes through which the working medium moves under pressure. The required pressure levels are usually pumped using pumping equipment;

- non-pressure, which are used in the installation of sewer communications;

- socketless. Pipes that are produced without a connecting element - a socket;

- pressure with a socket.

Pressure products are produced in a diameter range from 100 to 300 mm. The spherical structure of graphite affects the main characteristics of such pipes:

- high resistance to the destructive effects of corrosion;

- the service life of ductile iron pipes is 3–5 times higher than that of steel products;

- good resistance to temperature changes;

- resistance to aggressive chemical compounds;

Helpful information! Ductile iron pipes have high strength characteristics, so they are often used when laying pipelines under the road surface or at great depths in the ground.

Ductile iron pressure pipes can be connected in two ways:

- using a special rubber seal;

- using a socket.

The presence of a socket greatly simplifies the installation of cast iron pipes

Gravity pipes made of gray cast iron and used in the installation of sewer structures have the following characteristics:

- plastic;

- the strength characteristics of these products are inferior to those of ductile iron pipes;

- reusability.

They are usually installed in those places of the sewer structure where heavy loads are excluded. Free-flow sewer pipes are often used in combination with polymer products. The joining of cast iron and polymer parts is made using special rubber transition elements.

Socketless pipes are made of cast iron, which contains quite a lot of graphite. The inner walls of such parts are treated with an epoxy compound at the production stage. This procedure avoids salt deposits on the pipe walls and also increases corrosion resistance. Let's consider other characteristics of socketless cast iron parts:

- high noise insulation coefficient;

- fire resistance;

- high strength;

- resistance to high temperatures.

Such pipes are connected to each other using clamps, which makes it possible to obtain a hermetically sealed connection between two parts without the use of additional sealing materials.

Bell-shaped pressure products are highly corrosion resistant and are used for installation of sewer lines. The main advantage of these parts is their long service life, and the main disadvantage is the fragility of the cast iron material, which complicates the installation of sewerage.

Pre-insulated products

The cast iron products of the TML classifier group are complemented by products that are pre-insulated cast iron pipes. Such modifications are successfully used in environmental conditions with low temperature values.

Essentially, these are the same high-strength socketless or socketed pipes (1), additionally coated with technological layers (2, 3, 4) of thermal insulation.

A variant of a socketless cast iron pipe, supplemented with a thermal insulation element. Products in this design are called “pre-insulated pipes”. They are intended for use in low ambient temperatures

Thermosetting foam (3) or a similar material with a dense structure and non-flammable properties of class A2 is used as an effective heat insulator. The heat insulator is covered with a casing made of galvanized steel sheet (4). The thickness of the casing sheet is at least 1 mm. The casing is fixed with clamps (2), also made of galvanized steel.

Pre-insulated cast iron pipes are designed to withstand humidity conditions up to 75%. Insulation eliminates the formation of condensation at low and critically low temperatures. There are modifications with the introduction of a heating cable directly into the structure of the heat insulator.

Internal sewerage. Main characteristics

Internal sewerage, which is made of cast iron parts, as well as auxiliary connecting elements, is described by GOST 6942–98. This regulatory document regulates all geometric dimensions, as well as the quality characteristics of these products and the rules for their operation.

According to GOST, their production is permitted without connecting sockets. However, socketless production must first be discussed with the customer. For socketless production, it is also necessary to ensure that connecting fittings are included in the delivery package.

The cross-sectional indicators of such products according to GOST can be:

- 50 mm;

- 100 mm;

- 150 mm.

The length of cast iron pipes ranges from 75 cm to 2.2 m. The main parameters of internal cast iron sewer pipes are presented in Table No. 1.

Table 1

| Du, mm | Length, m | Weight, kg |

| 150 | 0,75-2,2 | 15,7-43,4 |

| 100 | 10,5-27,1 | |

| 50 | 0,75-2 | 4,5-1,1 |

In addition, GOST specifies the design features and dimensions of shaped elements and other auxiliary parts. Let's consider these details:

- bells;

- bends;

- pipes;

- tees;

- crosses;

- couplings;

- audits;

- stubs.

All fittings for cast iron pipes must also comply with GOST parameters

The finished product must not contain any defects that could impair the performance characteristics of cast iron products. Defects include:

- growths on pipe walls;

- drops of metal.

Chill marks on the outer walls of cast iron sewer pipes should not be deeper than 1 mm, and on the ends - deeper than 2 mm. Permissible variations in the cross-sectional parameters of cast iron pipes and fittings should be no more than 2 mm, and length deviations may not be higher than 0.9%.

Note! The mass of cast iron sewer pipes must correspond to a certain accuracy class. If the weight of the product exceeds the permissible value, then its operation is allowed only in one case - when other technical characteristics comply with the standards.

After laying the pipes, the structure must comply with all standards and must withstand the pressure indicators stated in the regulatory documentation. This rule especially applies to cast iron parts, the pressure indicators of which must be no less than 0.1 MPa.

How are SML and SME pipes connected?

Socketless sewer pipes made of cast iron are connected one to another using special tightening fixing devices. These connecting elements consist of a steel clamp and an elastic coupling, which is applied to the joint area.

In practice, two modifications of steel clamp ties are used - one screw (CE) or two screws (CV). The material of the elastic coupling ensures a high quality of tightness, and the properties of the steel of the tightening ring prevent the occurrence of corrosion.

Metal clamps and couplings, supplemented with elastic inserts, are usually used to connect socketless cast iron pipes together. There are several modifications of such fastening elements

Connecting clamps are used not only to connect individual pipes when constructing a pipeline. The same components are used for connections with shaped parts.

Clamps are produced for various mounting diameters and are designed for the entire range of operating pressures. There are modifications of clamps with a sound absorption effect, used in silent sewage systems. Their installation does not require the use of additional sound insulation in places where pipelines pass through the ceilings.

Image gallery

Photo from

Using clamps and fittings

Installation of a sewer system in the basement

Sewer system assembly options

Laying on thermal insulation and between insulation boards

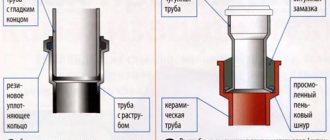

Bell-shaped elements are connected by the principle of inserting the straight end of one pipe into the bell-shaped part of another. The softness of the connection and tightness, as a rule, is ensured by a rubber ring, which is pressed into a groove on the inner surface of the socket of a cast iron pipe.

There is also a scheme where the tightness of the connection in the socket (and softness) is achieved by filling the gap between the pipes with sealing material.

The practice of constructing sewerage systems based on socketed cast iron pipes involves the use of one of five connection options (A, B, C, D, E). Four of them with seals in the form of rubber rings (5, 6) and one in the form of a tarred rope (3)

The following types of sealing and fixing of connections are typical for socket elements:

- Embossing with asbestos cement filler.

- Installation of the sealing collar.

- Installing a self-sealing ring.

- Use of a bolt-on slip-on flange.

- Application of a tenon.

The technique of fixing a pipe joint using hot and cold welding is also practiced, but it is used extremely rarely. This is explained by the complexity of cast iron welding technology. In addition, welding work on cast iron requires specialists, professional welding tools and expensive nickel-based electrodes.

An article will introduce you to the specifics of choosing pipes for the construction of an internal sewer system, in which all the arguments are presented in detail and the characteristics of various types are considered.

Internal sewerage. Quality control and labeling

Pipes for internal sewerage communications are made from gray cast iron. Anti-corrosion compounds, based on bitumen, are usually applied to the internal and external walls of such parts. The bitumen composition can withstand temperatures up to 60 °C. The service life of cast iron products for internal sewerage ranges from 80 to 100 years.

Some types of pipes are coated with bitumen to prevent corrosion

The quality of cast iron products for sewer networks is checked at the enterprise. This check includes a number of stages and is carried out at special stands. The main indicator that these products must meet is tightness. The tightness test is carried out by filling the cast iron part with water, as well as pumping the required pressure (for example, 0.1 MPa). During such a check, the following phenomena are strictly prohibited:

- flow;

- formation of condensation on the outer walls of the part.

The compliance of the geometric parameters of products is checked using special tools that can provide the necessary measurement accuracy. Deviations from the norm should not be higher than those specified in GOST.

Marking on cast iron pipes for sewer communications is carried out on the socket. In some cases, the marking is applied behind the socket. There are two options for marking:

- The marking is applied using a special paint, which is distinguished by the fact that it cannot be washed off.

- The marking is cast on the product.

The marking must contain the following information:

- trademark;

- corresponding GOST;

- vendor code.

External sewerage is installed from pipes that are characterized by increased strength

After production, cast iron pipes for internal sewerage must be sorted into containers or bundles. The warranty for such products must be provided by the manufacturer for at least 2 years.

External sewerage. Main characteristics

The dimensions of cast iron pipes used for external sewer networks and the requirements for them are set out in the relevant documentation (“Cast iron sewer pipes GOST 9583–75”). According to this document, the cross-sectional indicators of pressure pipes for external sewer lines range from 65 to 1000 mm.

The main characteristics of external cast iron sewer pipes are shown in Table No. 2.

table 2

| Du, mm | Length, m | Weight, kg |

| 1000 | 4–6 | 525,6–627,9 |

| 800 | 359,8–429 | |

| 600 | 4–10 | 222,9–266,6 |

| 400 | 118,5–141,4 | |

| 300 | 4–6 | 77,6–92,7 |

| 250 | 60,1–71,6 | |

| 200 | 44,6–52,9 | |

| 150 | 3–6 | 30,5–36,4 |

| 125 | 24,5–29,1 | |

| 100 | 18,9–22,3 |

The length of such products can vary from 2 to 10 meters. External sewer pipes made of cast iron are divided into 3 classes, depending on the wall thickness and, accordingly, on the weight:

- A;

- LA;

- B.

Deviations from permissible standards for these pipes are:

- for mass - 5% of the total.

- phosphorus content should be no more than 0.7%;

- the sulfur content should be no more than 0.12%.

For external systems, cast pipes with a protective coating are used

Note! Such pipes are made from gray cast iron, and their internal and external walls must be treated with a special protective layer made of environmentally friendly materials.

The surface of such parts must comply with all standards and exclude the presence of the following defects:

- dents;

- cracks;

- peeling areas.

Features of structure and application

The main feature of cast iron pipes from the TML classifier group is that they are intended for installation underground at a depth of 0.8 to 6 meters. Created specifically as elements of TML external systems, the pipes are characterized by an increased degree of strength and anti-corrosion protection.

The operational parameters of compression resistance make it possible to lay sewer lines, for example, under a road surface with large weight loads, without fear of damage. But during installation it is necessary to comply with the standards DIN EN 877, 1610, GOST, which provide for the creation of an appropriate supporting foundation and floors.

The structure of a modern socketless cast iron pipe consists of a two-layer internal coating with epoxy resin (1), an external coating with epoxy varnish (2), a working layer of cast iron with lamellar or spheroidal graphite (3), a protective zinc coating (4)

Among the features of high-strength cast iron pipes, the presence of an effective coating (external and internal), including on shaped parts, should also be highlighted. The coating is carried out using zinc and epoxy resins, which ensures high reliability of corrosion protection even in highly aggressive environments.

These pipes can be successfully used for laying in soils with high pH levels (0-10). The internal varnish epoxy coating of cast iron sewer pipes has a smooth (sliding) structure, which minimizes the coefficient of resistance when moving wastewater.

Structure of modern TML cast iron pipe:

- Coating with modified epoxy resin in two layers (layer thickness 120 microns).

- Protective coating with epoxy varnish (layer thickness 60 microns).

- Cast iron base layer with high carbon content.

- Protective coating with zinc powder (spray density 130 g/m2).

The standard pipe length (3000 mm) can be easily shortened to the required size if necessary, for example, with an electric pipe cutter. When cutting a cast iron pipe, you need to ensure an accurate, even cut. This approach guarantees reliable sealing when assembling drain lines.

In addition, the edges of the cut are usually painted with special paint and covered with Pro-Cut insulating tape. For aggressive environments, special seals are used. These measures further increase and eliminate the risk of leaks.

In this way, a joint is created at the edge of a cut cast iron pipe, when Pro-Cut insulating tape is used as a protective and sealing element

The list of features of cast iron sewer pipes is impressive. Compared to polymer products, which are quickly gaining popularity due to their low cost, cast iron products have many advantages.

Cast iron is not afraid of fire and high temperatures, while plastic pipes soften already at T = 100º, and at higher temperatures they begin to deform and can melt.

Cast iron pipelines are characterized by a low noise level during system operation and do not require the installation of expansion joints. They can be laid in the thickness of concrete without fear of rupture due to compression/expansion of materials.

Thus, the acquisition costs are very quickly offset by the economical operation of cast iron pipes. Their use does not require the creation of fire and noise insulation; the turnaround period is several times longer than the same period for plastic communications. The service life is not even limited to 100 years.

External sewerage. Quality control and labeling

The surface of cast iron parts used for installation of external sewer lines should not soften at a temperature of 60 °C. The tests that pipes must undergo are carried out after their manufacture directly in production and include a set of the following measures:

- test of strength;

- checking geometric parameters using special tools;

- hydraulic tests;

- hardness test.

The marking is usually located at the end of the bell and includes the following information:

- trademark;

- nominal diameter cross-section indicator;

- production date.

Products with small cross-sectional dimensions (up to 150 mm) are allowed to be transported in packages. The total weight of such a package should be no more than 3 tons. Storage of parts in this case should take into account their sorting into stacks. The surface on which such stacks are located must be level. It is recommended to lay each subsequent row on wooden boards. The height of such a stack should be no more than 3 m above ground level. It is recommended to provide side supports to strengthen such stacks.

Marking

When choosing cast iron pipe products, you should pay attention to their markings, which indicate all the parameters of the pipe, starting with its type, namely:

- type of product;

- production standard;

- length;

- conditional capacity.

For example, the marking ТЧК-150-2000 GOST 6942-98 designates a bell-shaped non-pressure product with a diameter of 150 mm and a segment length of 2 meters.

Tips for installing and operating cast iron pipes

The main advantage of cast iron pipes over plastic ones is the noise insulation characteristics of the former. Their walls dampen any sounds that appear as a result of the movement of the working medium through the pipes. However, the weight of cast iron products affects the labor costs when installing sewer structures, which in any case affects the speed of all necessary work on their installation.

The specific service life of these products must be at least 50 years, however, in many sources the shelf life can reach 100 years. In any case, in order to extend the service life of cast iron sewer pipes, it is necessary to strictly follow all the rules for their installation.

It is very important to remember that ordinary cast iron is not recommended for use in structures that will transport aggressive chemicals. For such situations, it is better to use pipes with higher resistance to aggressive chemical compounds (for example, ceramic). However, there is also a nuance here - for domestic sewerage, laying steel products will be too expensive.

Important! To fill the free spaces at the joints of cast iron pipes, it is recommended to use a special sealant called a cabling. Kabalka is plant fibers impregnated with resin-bitumen mastics, and in some cases with oil solutions. After filling the free spaces with cable, it is necessary to cover the joint with cement mortar.

It is not recommended to fill the joints of cast iron pipes with sulfur, since when heated it emits vapors harmful to human health. In addition, sulfur is highly flammable and cannot be extinguished with water.