The Tver aeration station is one of the most famous treatment facilities on the Russian market. , has been producing septic tanks in Tver for 27 years, since 1992. Production is located in the city of Tver. The name was initially a working one, but the septic tank quickly gained popularity. The brand became recognizable and the name remained.

The volume of Tver was calculated according to old SNiPs. This is a large, efficient and low-maintenance station. It is suitable for both seasonal and permanent residence. A large selection of models allows you to select septic tanks for any number of residents and for areas with different conditions, including areas with clay soil and high groundwater levels.

Septic tank body "Tver"

Until 2000, the septic tank was produced in a metal casing. Since 2000, monolithic polypropylene with a sheet thickness of 5 mm has been used to make the body. The sheets are joined using automated welding, the sidewalls are welded manually using an extruder. There are horizontal stiffening ribs on the sides of the body. They strengthen the body and reduce the risk of deformation under pressure. The edges of the body protruding at the ends (loading wings) serve as lugs and prevent the septic tank from floating in high groundwater.

Electrical equipment for septic tank "Tver"

The manufacturer equips the septic tank with a Hiblow compressor. It is placed in the house or in a separate box next to the septic tank. These compressors are characterized by low noise levels and reliable operation. However, even small but constant noise in the house can be annoying. Therefore, it is better to install the compressor in a non-residential area.

It must be taken into account that when installing a compressor in a house, it requires space. The air pipe from the compressor is insulated and laid with a slope towards the septic tank so that condensation does not accumulate in the pipe and the air duct does not freeze in winter.

To connect the compressor, use a HDPE pipe 20 m long and 20 mm in diameter. If the distance from the compressor to the septic tank is greater, then it is recommended to choose a compressor with higher capacity or install it in a box near the septic tank. The air duct from the compressor is connected to the septic tank through a coupling.

The manufacturer provides for connecting the pump through a heat-shrinkable sleeve. With this connection, the plug is cut off from the pump. This is a significant design flaw, since a pump with a cut off plug is no longer covered by the warranty. The connection through a heat-shrinkable sleeve is non-separable. To repair or replace the pump, it will have to be cut off again.

Tver is sold without an alarm system. The owner does not receive notifications about the septic tank overflowing and the risk of flooding is higher than, for example, in Topas or Astra. On the other hand, there are no electrical appliances inside the Tver septic tank, so material damage from flooding will be much less than in stations with an internal instrument compartment. We advise Tver owners to check the septic tank more often, so as not to spend money on calling a service engineer and eliminating the accident.

When installing “Tver” with forced drainage, we recommend installing an electrical box nearby.

What does it give:

- There is 1 cable going to the septic tank.

- There is a socket in the electrical box, there is no need to cut off the plug at the pump and the warranty is maintained.

- The connection is removable. If the pump fails, it can be replaced without cutting the cable.

- You can easily connect an alarm system. You will know in advance about the overflow of the septic tank and prevent flooding. This is especially important in winter, when the water in the station may freeze.

- The installation of the heating cable is simplified. There will be no need to run a separate power line underneath it.

Connecting electrical appliances through a remote box is an advantage of installation at Zagorod. As far as we know, other companies do not use this method when installing Tver.

Methods for disposing of treated wastewater

Before installing a septic tank in Tver, it is important to decide on the method of drainage of purified water. It is assumed that there may be several options. You just need to choose the right method that is optimal for your site.

This takes into account many factors: features of a specific septic tank model, soil type, equipment installation depth, presence/absence of a drainage ditch, and more.

Discharge of technical water by gravity

Tver treatment facilities provide a high degree of wastewater treatment, so it is possible to organize the discharge of liquid into the ground, roadside ditch, or use it for technical needs, for example, for irrigation.

Diversion by gravity is the most budget option. In this case, the most inexpensive device from the range of septic tanks of the appropriate capacity can be used without any additions in the form of a pump.

The most important condition for successful operation of the system in the case of gravity flow is that the discharge point of treated wastewater should be located below the level of the septic tank outlet pipe. In this case, all recommended pipeline slopes on the way to the discharge site must be observed.

It is possible to connect not one, but several buildings to the septic tank. But even in this case, all the above conditions must be met.

Discharging purified liquid using a pump

If the discharge point of clarified waste is located above the level of the septic tank outlet pipe, you can use the option of connecting a pump. It is desirable that the purchased modification of the Tver septic tank have a pump compartment.

With a pump, it will be much easier to arrange the removal of the purified mass over long distances for disposal outside the populated area.

If you have already purchased a structure designed to drain water by gravity, you will have to purchase additional equipment.

For forced drainage, special modifications with a pump compartment are used. If the distance over which the liquid is supplied is large, a larger volume of the pump compartment is required (+)

This can be an additional storage module or a caisson, from where purified water will be pumped. The costs of their purchase, maintenance and installation will significantly increase the cost of the entire project.

It must be remembered that vertically oriented septic tanks do not have a modification with a pump compartment. When using the pump method of water removal, the range of its supply is limited only by the performance of the pump.

Discharge of technical fluid into a filter well

It is assumed that water will be supplied by gravity or pump to a special absorption well. This design is an independent drainage structure, in which additional purification of the liquid occurs.

Construction of such a well is possible only in sandy soils, peats and plastic sandy loams with a low content of clay particles.

It is impossible to drain the purified liquid into an absorption well on clay soils. The conditional bottom of the structure must be in sandy loam or sand so that the liquid leaves it. Further treatment of wastewater is carried out by a layer of crushed stone or gravel backfill with sand filler, a soil filter can be at least a meter (+)

In loams and hard sandy loams, installing such a system is pointless, since water will not drain from it. The depth of the structure should be such that there is at least a meter between the top of the crushed stone filter and the inlet pipe, which is necessary for normal accumulation and filtration of wastewater.

Discharge of purified water to the filtration field

In this case, the purified liquid will be discharged onto the drainage filtration field. The structure will help to evenly distribute process water and provide additional purification.

The dimensions of the filtration field depend on the performance of the septic tank and must be determined by specialists. Errors in calculations will inevitably lead to disruptions in the operation of the septic tank.

Image gallery

Photo from

Laying geotextiles at the bottom of trenches

Laying and backfilling drainage pipes

Ventilation pipe on a drainage branch

Collector well of drainage system

This method of discharging purified water is absolutely not suitable for areas with typical seasonal floods. In such situations, the drains will flood in the spring/winter and the surrounding soil will not be able to absorb the drainage.

The liquid will begin to stagnate, causing the discharge to stop, and as a result, the septic tank will not work. In addition, stagnant water will become a source of unpleasant odor and contamination of soil and water in the area.

Installation of a septic tank "Tver" on a turnkey basis

The depth of the supply pipeline for standard modifications is 30 cm. With such an insertion, the depth from the ground level to the top of the supply pipe is only 20 cm and with the correct slope of 2 cm per 1 m and a distance to the house of more than 10 m, the pipe will come to the surface! Septic tanks with a standard insertion depth are not suitable for everyone, but when making their own selection, customers often do not take this circumstance into account. Installation of Tver is preceded by a survey engineer visiting the site. He finds the outlets from the house and determines the depth of the pipe connection.

The installation team arrives at a time convenient for the customer. The pit is dug so that there are 20 mm gaps between the walls of the pit and the body. A layer of sand 10 cm thick is poured at the bottom of the pit, and the sand is leveled.

The treatment facility is lowered into the pit and leveled. The station is then covered with sand and filled with water. Sand is poured into the pit in layers of 15-20 cm and spilled. Water is poured in simultaneously with sprinkling. If you sprinkle on an empty container, the walls may be pressed in under soil pressure. At this stage, the station is sprinkled and filled to the overflow level.

The depth of the trench for the supply pipeline must be at least 20 cm. A 10 cm sand bedding is made at the bottom of the trench. The pipes are laid with a slope of 2 cm by 1 meter. The slope of the outlet gravity pipeline must be at least 0.5 cm per 1 meter, and the outlet pressure pipeline must be at least 1 cm per 1 meter.

In forced models, a pump is installed in the last chamber. The pump cable with the plug cut off is connected to the cable to the house through a heat-shrink sleeve, if an external electrical unit is not installed. The compressor is installed in the house. The cable from the pump and the air duct from the compressor are laid in the trench of the supply pipeline.

After connecting the compressor, set up aeration. In the first aeration tank it should be active (2/3 of the total air supplied to the station), in the second there are enough small bubbles (1/3 of the air supplied). Aeration is controlled by two valves.

After laying the pipes, cables and air ducts, the trenches and the septic tank itself are finally backfilled. The covers should rise 10 cm above the ground level to prevent rain and melt water from entering the septic tank.

In the Tver septic tank there is no need to cut in and seal the pipes. The manufacturer makes them at the factory. But there is a risk of making other mistakes - filling the station with excavated soil, not spilling sand when filling, filling an empty septic tank, etc. To ensure that mistakes are avoided, it is better to buy a septic tank with turnkey installation. The Zagorod company will install Tver sewerage on your site in 1 business day. We dig the pit by hand, there is no need to provide access for equipment and worry about the landscape of the site. All work is carried out by experienced engineers and installers, strictly according to technology. Workers take photographs of each stage of installation and send photo reports to the company for quality control.

Criterias of choice

The Tver septic tank modification should be selected based on the following parameters:

- The number of people living in the house. Each family member should have a capacity of approximately 0.2 cubic meters. per day. That is, if the capacity of the septic tank is 1 cubic meter. per day, then this installation can easily serve 5 people (1:0.2=5).

- Groundwater level. For wetlands or areas with high groundwater levels, only models with forced drainage should be selected.

- The depth of the sewer pipeline leaving the house.

Attention! How correctly the choice of modification is made will determine not only the efficiency of the installation, but also how convenient it will be to maintain the Tver septic tank during operation.

Diagram of an option for placing a septic tank on the site

Maintenance of autonomous sewage system "Tver"

To pump out Tver, they turn to the sewage disposal service. It is enough to call a vacuum cleaner once a year. The sediment is pumped out from the first chamber. Maintenance is simple, but pumping out 1 cubic meter. m. in St. Petersburg costs about 1000 rubles. In addition, the sewer truck must approach the septic tank within the length of the hose (20-30 meters). This must be taken into account when choosing a location near Tver.

Before pumping out the septic tank, sludge is redirected from two settling tanks to the first chamber. To do this, open the valves on the air supply pipes. After pumping, the station is immediately filled with water; it cannot be left empty.

In addition to pumping out sludge, you also need to check the operation of the compressor, aerators and pump, and adjust aeration if necessary.

Periodically it is necessary to change the expanded clay and limestone loadings. Limestone dissolves over time, and new limestone is added to the station. Expanded clay is difficult to remove if it is heavily silted, so it is recommended to replace it on time.

It is very important to maintain wastewater treatment plants in a timely manner. Customers often delay service. At first this does not affect the operation of the station, but over time there is so much silt that it no longer allows water to pass through. The station becomes completely clogged and even the sewer truck cannot pump it out. You have to clean the septic tank manually, and this often leads to broken air ducts, dented housing and, as a result, expensive repairs. We advise you not to bring Tver to this state and pump out the sludge at least once a year.

We also recommend calling a service engineer to diagnose faults. If you conclude a service agreement with the Zagorod company, then the engineer’s visits will be scheduled and at a lower price. The service contract is concluded for 5 years, while the warranty for installation work is also extended to 5 years. No other company has such a long warranty on installation. We give this guarantee because we are confident that we work with high quality.

Which is better: “Tver” or “Topas”?

Our clients often ask us to explain how Tver differs from Topas and which sewage system is better. Topas is a station with a receiving chamber-averaging chamber, and Tver - with a receiving chamber-settling chamber, like in a simple septic tank. Compared to the Topas septic tank, in which wastewater is pumped by airlifts, in Tver all overflows are gravity-fed. This reduces the likelihood of blockages and makes drain maintenance easier. In Topas, when servicing, you need to disconnect the airlifts and wash them with a high-pressure washer.

The compressor in Topas is located under the station cover, in the instrument compartment. If the septic tank floods, you will have to change the electrical equipment. In Tver, the compressor is installed in the house. On the one hand, this prevents damage to the devices in the event of an accident, but on the other, as already mentioned, the compressor will make noise, and the air duct may become clogged with frozen condensate in winter. At the same time, Topas is equipped with an alarm system that notifies the owner about the overflow of the septic tank, so the likelihood of flooding is significantly reduced.

If you compare the price, then Tver is more expensive than Topas. For example, the Topas 5 model with a capacity of 1000 l/day costs about 113,000 rubles, and the Tver 1P model with the same capacity costs about 127,600 rubles. The difference is significant.

Model range of cleaning equipment

The manufacturer produces eight septic tank models of different sizes. They can process from 0.75 to 10 m3/day. For example, the most productive modification Tver 10 is designed for processing wastewater coming from a small cafe or hotel.

has the lowest productivity 0.75 . This septic tank is designed to serve residential buildings inhabited by no more than 3 people.

In addition to performance, the equipment also differs in design features. About four to five modifications of each model are produced, differing in housing dimensions, number of compressors, etc.

The location of the inlet pipe also varies, which can be located at a depth of 0.6 m or 0.3 m. Depending on this, the dimensions and shape of the inspection well change.

The model range of Tver brand septic tanks is focused on the difference in the volume of processed wastewater. The installation process for modifications is generally similar, but depending on the modification of the device, some nuances arise

The design features of septic tanks are indicated by letters that are present in the names of the models. For example, modifications with the letter P are made of polypropylene. The inlet pipe in these models is located 0.34 m above ground level.

Variations with a compartment for a drainage pump are marked PN . Septic tanks with a compartment for a fecal pump are designated NP , and the NPN indicates the presence of two pump compartments at once.

Advantages of the Tver septic tank:

- Large working volume.

- The drain is purified up to 98%, odorless and safe for the environment.

- Purified water is discharged to the ground without further treatment. This saves space on the site, as well as time and money for maintaining a well or filtration field.

- The body is made of homogeneous polypropylene, reinforced with stiffening ribs, and equipped with loading wings to protect against floating.

- Overflows from chamber to chamber are gravity-fed. There is no risk of blockages and maintenance is simplified due to the absence of airlifts.

- The compressor is installed and connected in the house. There is no risk of flooding of electrical appliances when the septic tank overflows. The compressor pumps warm air from the room into the septic tank, which promotes the development of microflora and good wastewater treatment.

Disadvantages of the Tver septic tank:

- Installing the compressor in the house or in a remote box near the septic tank. The compressor in the house takes up space and creates noise. It should also be taken into account that there is usually less oxygen in a living room. If installed incorrectly, condensation may freeze in the air duct in winter.

- The pump is connected to the cable through a heat-shrink sleeve. Problems may arise with such a connection, and manufacturers do not provide a warranty on a pump with a cut plug.

- The alarm is not provided by the manufacturer. The owner does not receive notification of an accident and needs to check the septic tank more often.

- The loading wings are thin (5mm) and look flimsy. There is a risk that they will break under the weight of the soil. Although in our practice such problems did not arise, probably due to the stiffening ribs on the septic tank body.

- The station is horizontal, voluminous and requires space on the site.

- A sewer truck is called in to pump out the sludge; this is a waste of time, money, and often nerves (there are different types of sewer trucks). In addition, the owner must understand a little about the structure of the septic tank. Before pumping, special taps are opened and sludge is pumped from the settling tanks into the receiving chamber. During maintenance, it is also necessary to regulate aeration using valves on the air pipes.

- Tver is noticeably more expensive than other SBOs in the middle price category, such as Eurolos BIO, Unilos Astra, BioDeka.

Principle of operation

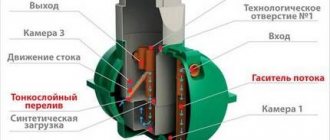

The Tver septic tank combines all three possible wastewater treatment technologies. In the first - receiving - compartment, mechanical cleaning occurs, as is customary with classic septic tanks. In the other two there is aeration and processing of wastewater by aerobic microorganisms, like in aeration units (AU) and in two - processing by anaerobic microorganisms (without oxygen), and at the outlet there is a biofilter that completes the purification. This is such a complex system, but according to the manufacturers, the output comes out with water that is 98% purified and can be discharged directly onto the ground or discharged into a reservoir.

Septic tank Tver from the inside

The Tver septic tank differs from other installations for autonomous sewerage in its horizontal layout - sequentially located compartments in which water overflows. Its device can be seen in the photo below.

Septic tank installation Tver

The cleaning procedure is as follows:

- The wastewater goes into the first reservoir - the septic tank. In it, as in a classic septic tank, heavy particles settle to the bottom, while light, fat-containing particles rise to the top.

- From this chamber, through the upper overflow, the wastewater enters the second compartment - the anaerobic bioreactor. In this chamber there are brushes on which colonies of microorganisms multiply. Here bacteria process particles that are difficult to oxidize. In parallel, the remaining contamination continues to settle/float.

- After processing, the wastewater enters an aeration tank with aerobic bacteria. The pump supplies air here to ensure their vital functions. At the bottom of this chamber there is expanded clay, which breaks the air into small bubbles. The activated sludge accumulated at the bottom, which processes wastewater, mixes with water in streams of air bubbles. Bacteria actively transform organic residues, and the degree of purification becomes even higher.

- The next compartment is the settling tank, where contaminants settle/float. The settled sludge, due to the original structure of the walls, falls back into the aeration tank.

- Already fairly clean water from the settling tank enters the second aeration tank with brushes, where the cleaning is completed. There is crushed limestone here, which binds phosphorus. It is difficult to remove by other means and few people worry about it.

- The last stage is the third settling tank, where sludge settles again and clean water is separated.

- A chlorine cartridge is installed at the outlet of the Tver septic tank. This is a cylindrical device made of porous material. Inside it is a mixture of chlorine and sand. After this, the water can be dumped onto the terrain - it has no color or smell.

Not to say that the process is simple, there are many nuances, but the cleaning result is not bad and the installation does not require daily attention and works reliably.

The process of building a budget septic tank from concrete rings is described here.

Reviews about the septic tank "Tver"

Users note that the Tver septic tank is reliable and unpretentious. All overflows in it are gravity-fed, the compressor and aerators work stably, and you don’t even have to think about the sewage system on the site. Tver is not suitable for all customers. Many people prefer to install stations with a receiving chamber for averaging (Topas, BioDeka, Astra), which are considered more efficient. But customers who bought Tver are satisfied with their choice. On our website you can see an overview of the installation and customer feedback about this treatment plant.

Recommended products

Conclusions and useful video on the topic

Design and principle of operation of a septic tank Tver:

Design and operation of the Tver septic tank, its advantages in comparison with other systems. Tips for preserving for the winter:

The Tver septic tank, due to its versatility, is used for private houses and summer cottages located on areas with any type of soil. More productive versions are suitable for recycling wastewater from small production sites and warehouses remote from central communications.

Share with readers your experience of using a septic tank Tver. Please tell us about the features of its maintenance and operation. Participate in discussions and ask questions that interest you - the comment box is located below.