Wells and borehole sources are the main suppliers of water in individual areas without access to a centralized water supply. One of the most common devices used to collect drinking water is pumping stations for wells, installed in close proximity to the water supply source.

When choosing a unit from the numerous modifications presented on the pumping equipment market, one is guided by its cost, technical characteristics, and the manufacturer’s brand, which determines the quality of the model, is especially important. For reliable and durable operation of the pumping unit, it is necessary to know the basic rules and connection diagrams, options for its placement relative to the water supply source.

Pumping stations on a private plot

What is included

The first thing you should pay attention to when choosing equipment is the basic configuration. Some enterprising sellers remove some items, which they then offer to purchase additionally. This clever marketing move leads to additional financial costs.

The standard configuration of the pumping station looks like this:

- The pump is usually self-priming, designed for forced transportation of liquid.

- A hydraulic accumulator is a storage tank whose capacity varies between 10-100 liters.

- Relay – ensures automatic activation of the pump when the water level drops.

- Pressure gauge – controls the pressure in the system.

- Pipeline is a highway for supplying water to intake points.

- Filters - fine and coarse filters that remove debris that enters the well.

Please note that depending on the manufacturer, the equipment may vary, however, the listed elements must be included in the basic set.

Main unit installation requirements

The station itself should also be installed according to certain rules. It is bolted to the base. The base is preferably concrete. A rigid steel frame made of rolled profiles is allowed. Its design is welded or bolted.

It is very useful to install it on a thick sheet of hard rubber - this shock absorber will reduce shock loads when turned on and reduce operating noise.

Much less often for these purposes, spring steel shock absorbers are used, placed under the base, similar to the type of fastening of the eccentric exciter of the vibration table.

But such fastening, at the slightest loosening or violation of the adjustment, can break the mounting sockets on the base of the station and create unnecessary loads on the water fittings - the vibration amplitude is too large. So the best option would be a hard rubber sheet up to 3 centimeters thick. The rigidity is approximately the same as that of a summer car tire tread.

It is important to pay due attention to the electrical part. It is mandatory to connect the station housing to the grounding loop, regardless of the choice of installation location. The use of an RCD (residual current device - the second name for this mechanism is “differential current device”) is very useful - especially if the option with a caisson is chosen or the installation was made directly in the well.

There is no point in overcomplicating the connection diagram. We do only what is necessary

In any case, the station must have an individual protective electrical circuit - at least a circuit breaker with an operating current slightly higher than the rated starting current of the installation.

In addition, the service life of the electrical part of the station is positively affected by the presence of stabilizers, network filters and uninterruptible power supplies. Maybe they won’t be able to have a significant impact on the engine itself, but for the electronics as part of the station’s automation unit, such an addition will be very useful.

Operating principle

Pumping stations operate according to a simple scheme. The work cycle consists of the following stages:

- After being connected to the network, the pump begins to pump water into the system, filling the accumulator to a certain level.

- When the pressure gauge shows maximum pressure, the pumping station automatically turns off.

- The withdrawal of water lowers the level in the hydraulic accumulator, and accordingly the relay gives a command to start the pump.

- If the tap is constantly open, water is pumped in uninterruptedly; when closed, it flows until the set level is reached.

In principle, it is an autonomous water supply system that requires only periodic maintenance.

First start

Having completed the installation of a water station, you should take a responsible approach to its first start-up. To do this, follow the instructions:

- Unscrew the plug in the pump body and fill it with liquid.

- The suction pipe is filling. Make sure the liquid has filled the entire space.

- Check the pressure in the accumulator; it should not drop. If it falls, it means the check valve is not holding. You can increase it with a car pump. If the pressure is too high, it releases through the nipple.

- After filling the system, close the cap tightly.

- Connect the pump to the mains.

- Remove air from the equipment by opening the valve slightly.

- To do this, the unit must operate for about three minutes. Water will begin to flow through the outlet.

- If the liquid does not flow out, add water to the pump and repeat the procedure.

To start correctly, it is important to know how the device works.

Pump classes

All pumping stations on the market can be divided into three groups. The classification of each category is determined not only by technical features, but also by the height of the water rise. It looks like this:

- With a built-in ejector

The heart of such a system is a jet-centrifugal pump, which is of the self-priming type. The maximum depth of water intake is 8 meters, the outlet stream can rise up to 40 meters. According to experts, the system is very reliable; the main disadvantage is the high noise level during operation. - With remote ejector

Such systems make virtually no noise and can lift water from a depth of up to 50 meters, while the output stream can rise to 40 m. The kit includes two pipes, one of which is immersed to a given depth, the second is connected to the water supply main. The disadvantages include the following: when air enters the system, the pump begins to overheat and the shutdown relay is triggered.

- Without ejector

This is a multi-level system of tanks, each of which is equipped with a separate pump. The main tank is installed at a certain level, which ensures natural circulation of water in the system. The liquid is taken from a depth of 9 meters, the jet height is 45-50 m. Such systems are reliable and are designed for a large number of consumers. Disadvantages include the complexity of installation and the high cost of spare parts.

Knowing these features, you can select a pumping station in accordance with individual requirements.

Well waterproofing

Why do you need to waterproof a well?

Judging by books and films, wells used to always have crystal clear water. And the wells themselves were built from the simplest materials. We don’t undertake to judge how true this is, but in any case, there is no arguing with the deterioration of the environment in recent decades. And this cannot but affect the quality of water. Therefore, high-quality waterproofing of a well is more important today than ever. Without this, it will be of little use as a source of drinking water.

Properly carried out waterproofing is the key to obtaining high-quality well water.

Waterproofing a well is necessary for several reasons:

- In order for the water in the well to be clean and suitable for drinking, it is necessary to completely prevent the ingress of surface groundwater into it. That is, located above the water surface in the well. This refers to soil (ground) moisture that is absorbed when precipitation falls or snow melts. And also the so-called “overwater” - unstable aquifers located close to the surface.

Water from the surface layers could not undergo high-quality ground filtration, and it should be prevented from entering the well through its walls.

Both can be saturated with decaying organic matter, contain microorganisms dangerous to the human body, petroleum products, compounds released into the atmosphere with industrial and automobile exhausts, chemicals used on agricultural land, and many other substances that make water unsuitable and even extremely dangerous for drinking.

- Any material from which the walls of a well are built requires protection from the chemical aggressiveness of soil moisture. By the way, concrete is no exception in this regard. Over time, under such influence, it becomes porous; cracks, chips, and areas of looseness may appear in it. Such shallow groundwater can seep into the well.

Waterproofing of joints between reinforced concrete rings of a well.

- In addition, if the well is built from concrete rings, which is practiced everywhere, gaps will inevitably form at the joints. If waterproofing measures are not taken, these seams become an entry point for contaminated ground moisture. The same applies to technological holes made in the walls and intended for connecting the pipeline.

Applying an external waterproofing layer

Prices for bitumen mastic

Bitumen mastic

The best option would be to carry out all waterproofing work at the well construction stage. This approach provides more opportunities to achieve high quality results.

External waterproofing can be applied to concrete rings both before they are installed in the pit and after installation.

Waterproofing bentonite rubber cord.

Well, as a waterproofing material for the gaps at the joints of the rings, you can use the sealing bentonite-rubber cord “Barrier” or “Gidroizol”. This elastic material tends to expand when exposed to moisture, reliably sealing the junction line of the structural parts.

When choosing waterproofing for a well, it is necessary to comply with special requirements, which somewhat limit the possible range of materials. It is clear that the materials should not pose a danger to both human health and the environment.

External waterproofing

Materials for external waterproofing work differ significantly from those that can be used for application inside a mine.

- For the external protection of a well built from concrete rings, in most cases, roll waterproofing made on the basis of bitumen is used - this can be the familiar roofing material or more modern materials. In addition, to secure the canvases, you will need special mastics, also made on a bitumen basis.

- Instead of bituminous materials, a special deep penetration waterproofing solution can be used - this is the second option for external protection of the well tank.

- Another method is shotcrete using non-shrinking or expanding waterproof cement mortar. However, for such processing one cannot do without special equipment and without the skills to work with it. In any case, you will have to invite a team of specialists. It cannot be said that this method is popular in the construction of wells.

You can resort to shotcrete concreting of the outer surfaces of the well walls. But this technology is not cheap, it requires special materials and equipment, and the involvement of specialists.

- To prevent atmospheric precipitation from entering the well, a reliable clay castle is created around it, which diverts rainwater away from the walls of the well. A good owner, in addition, high-quality blind areas will be concreted around the well.

To carry out external waterproofing of the walls of a well using any of the above methods, it is necessary to carry out preparatory work consisting of the following steps:

— If the well has been in operation for more than a year, then its outer walls will have to be cleared of soil to the maximum possible depth, which should be at least 3000÷4000 mm.

— After the walls are freed from soil, it is necessary to inspect the entire surface. If damaged, loose areas of concrete are found, they must be removed using a hammer drill or jackhammer.

Cleaned outer wall of the well.

— Then the surface must be cleaned and washed from dirt, fragments of destroyed concrete, accumulations of mold and salt deposits. For this purpose, metal brushes (for example, attachments for an electric drill or grinder), chisels, spatulas and other hand tools are used. Then, all the dirt is washed off with water under high pressure - mini-washes are well suited for this. After the walls have dried, they must be carefully inspected again and dust removed from the surface as much as possible.

— If, after removing weakened loose concrete, part of the reinforcing belt of reinforced concrete rings is exposed, then traces of corrosion should be removed from the metal parts and then coated with an anti-corrosion compound.

As a rule, simultaneously with digging up the walls of the well, a trench is also dug for laying a pipeline from the well to the house. If installation conditions allow, the pipe should be placed at a depth of approximately 300÷500 mm below the soil freezing level. This way there will be less hassle with its insulation or heating.

Having completed the preparation, you can proceed directly to waterproofing the walls of the tank from the outside.

Waterproofing using roll material

Waterproofing using roofing material or its analogues is carried out as follows:

- A primer is applied to the concrete, which will ensure high adhesion for the materials. It is especially necessary to treat areas where loose areas of concrete were removed. The best option for primers are compositions like “Betokontakt”.

- After the soil has dried, it is necessary to repair the damaged sections of the walls, making them as smooth as possible. Potholes, cracks, and large cavities are sealed with concrete mortar having a thick consistency. To quickly set and dry the concrete, PVA glue is added to it. After carrying out the repair work and waiting for the solution to dry, the surface must be primed again.

At the same stage, a hole is usually punched for laying a pipeline into the well shaft.

Waterproofing a well using roofing felt.

- The next step is to apply a coating of bitumen mastic to the walls, onto which the first layer of roofing material is glued. It is recommended to make two or three such layers. Roofing felt sheets are fixed with an overlap of 150÷200 mm. The seams of the last outer layer of material are additionally coated with mastic.

Some owners refuse roofing felt, using only mastic for waterproofing. But this is not recommended, since such bitumen-based coating may crack over time from contact with the ground, and all the work will be done in vain.

Prices for roofing material

Ruberoid

Waterproofing external walls with deep penetration impregnation

When choosing a special deep-penetrating hardening impregnation for waterproofing, no other primer composition is required. This solution performs two functions at once: it strengthens the concrete walls and makes them waterproof.

- The first step is to prime only those areas that require repair with cement mortar.

- After the soil dries, the damaged sections of the well wall are repaired. For this, a cement-sand composition with the addition of PVA or, better, a special repair composition is also used. An example of such a special repair composition is CERESIT CN-83.

For repairing damaged or worn concrete surfaces, a special composition is well suited - dry construction mixture “CERESIT CN-83”

- When the repair patches have hardened, the walls must be moistened.

- Now you can apply a deep penetration waterproofing compound to the surface. One-component impregnations such as, say, Penetron, Elakor-PU Ground, Neogard and others are suitable for work. The characteristics of these compositions must directly indicate that they serve to strengthen the waterproofing (waterproofing) of concrete surfaces. The applied composition is absorbed into the structure of the material, and upon drying it crystallizes, completely clogging its pores, thus making the wall waterproof.

Some deep penetration impregnations by themselves make concrete completely waterproof

- After waiting 72 hours, a second layer of impregnation is applied to the surface.

- During the drying process of the impregnation, the walls should not be subjected to mechanical stress.

Prices for deep penetration primer

Deep penetration primer

* * * * * * *

In any case, the outer surfaces of the well walls should be covered with waterproofing up to the top edge. When the work is completed, the space around the well between its walls and the wall of the pit is filled with gravel-sand mixture to a level just below the freezing line of the soil, approximately 100÷150 mm.

At this stage, a pipe is laid from the well to the house. This stage will be discussed in more detail below.

Waterproofing the internal surfaces of the well

If external waterproofing of a source of drinking water is impossible for some reason, then in this case it is possible to protect the well from the penetration of groundwater from the inside.

With this approach, special attention should be paid to waterproofing compounds. They must be completely safe for human health.

As an example, consider products.

Coating waterproofing mixture.

"AQUAMAT-ELASTIC" is a cement-polymer elastic two-component mixture. This composition is applied by coating. The mixture is an environmentally friendly material that does not in any way affect the quality of drinking water.

Composition with increased elasticity and high adhesive capabilities.

"MEGACRET-40" is a repair mixture consisting of cement supplemented with polymer modifiers. This composition has high adhesive properties and does not shrink. The material is easy to apply, so even a master without plastering experience can handle the job.

This composition is able to quickly and reliably plug the resulting leak.

" AQUAFIX" is a cement mortar that hardens very quickly, which occurs under the influence of water. The material is used to install a “hydraulic plug” in places of possible or identified leaks. Excellent for sealing cracks and potholes formed in walls during the period of operation, as well as for sealing joints of concrete rings.

Work on internal waterproofing is carried out as follows:

- The first step is to pump water out of the well in use using a pump, so that the upper joint of the lowest concrete ring is exposed. While work is being carried out, it is necessary to ensure that the water does not rise above this level.

Internal waterproofing of a well - treatment of joints between concrete rings.

- Next, the surfaces are inspected to detect damage, dirty deposits, as well as areas of loose concrete.

- The next step is to clean the damaged areas from the loose layer to the “healthy” concrete. The cracks should be widened to a depth and width of 25÷30 mm, concrete fragments should be removed from the gaps with a metal brush.

- The gaps at the joints of concrete rings also need to be widened to a depth of 30÷35 mm. If a leak is discovered during cleaning of cracks and joints, it must be immediately sealed with a “hydraulic plug” from the “AQUAFIX” composition.

- Next, the wall surfaces are cleaned of dust and dirt. All extended cracks, joints, potholes, as well as cavities formed in the concrete, are closed with MEGACRET-40 mortar, which is leveled flush with the main surface. After completion of the repair work, the well is left until the composition completely hardens.

- The next step is to apply AQUAMAT-ELASTIC coating waterproofing to the walls. Before carrying out this procedure, the surfaces must be moistened. The composition is diluted to such a consistency that it can be applied with a wide brush.

- The composition is applied from bottom to top of the container in two layers. The second layer is applied only after the first one has completely dried. There is no need to moisten the walls before applying the second layer. Complete hardening of the composition occurs after a day.

After such waterproofing has completely dried, it becomes completely neutral for drinking water.

Equipment types

According to the principle of operation, pumping stations are divided into 4 groups. Let's look at the key features of each category.

- Vibrating

Practical and inexpensive devices with vertical installation. The design excludes complex elements, which determines the final cost. The main disadvantage is the technical impossibility of installing water level control sensors, which is why such pumping stations are used in summer cottages to fill containers. - Screw

The equipment is based on an “Archimedes screw”, which uniformly supplies water through the outlet pipe. Such pumps provide stable water pressure, but show relatively low efficiency during operation, so they are used very rarely.

- Centrifugal

A wheel with intake blades, which is driven by an electric drive, is responsible for supplying water. This type of design is the most common and is installed on most pumping stations.

- Vortex

The operating principle of such products is reminiscent of centrifugal analogues, however, the design is simple. The shape of the intake elements gives the fluid turbulent acceleration, which has a positive effect on performance.

The pumps easily absorb air into the system and do not emit noise or vibration during operation. However, the equipment is demanding on the purity of water, so even a slight presence of suspended solids can cause device failure.

These pumping stations differ not only in cost, but also in service life. In terms of durability, vortex pumps are noticeably inferior to other models.

Construction of a water supply network

From a technical point of view, the algorithm for connecting the complex can be divided into 2 stages of work, corresponding to 2 sections:

- area to the station served by submersible pumps:

- the area after the station where all tasks are performed by the hydraulic accumulator (including fluid flow and maintaining pressure).

Scheme of arranging a water supply system from a well.

Intake part of the water supply system

Located between the station itself and the well itself. This is where the system is powered.

The intake part has a simple design. During its installation, HDPE pipes are used (i.e., made of low-density polyethylene - a material that is not afraid of corrosion, is resistant to water hammer and tolerates low temperatures well). Recommended diameter is 32 mm. With such parameters, the pipes do not create unnecessary load on the well pumps.

1 end of the pipe is immersed in water, 2 is connected to the station. On the side that is lowered into the liquid, a casing coupling is fixed, and a check valve is installed on it to prevent water from moving back into the well. That is, the system will constantly remain full. It is recommended to install a mesh tip on the valve, which acts as a coarse filter that traps dirt particles.

The pipe is removed from the well so that it is below the freezing level. Theoretically, it can be run over the top, but then the system needs to be insulated, which means additional costs for a heat-insulating shell and a special heating cable.

Water supply after the pumping station

Scheme of water supply in a dacha from a well.

The thread parameters at the outlet of the pumping station are 1 inch. But it is believed that when arranging the structure, the diameter can be halved.

Although reducing the cross-section of the pipeline leads to an increase in load, this does not play a special role. So experts often recommend installing a transition footer. A ball-type shut-off valve is installed on it.

It is necessary when it is necessary to carry out repair or maintenance work. The tap provides access to the house water supply system.

The features of its design depend on the pipes used - polypropylene, metal-plastic or metal alloys.

A flask with a cleaning filter must be mounted directly behind the tap. There is no point in installing them in front of the station, since they will not work fully. A uniform flow of water is required, and it can only be provided after the pumping station, since the movement of water masses in front of it occurs impulsively, and power surges are possible. The hydraulic accumulator allows you to stabilize all this.

After the filter, the main branch is branched into a water supply system with hot and cold water. And before the filter, you can provide for the drainage of liquid for watering the area, since untreated water is also suitable for plants.

Well water filters.

When choosing a filter, the indicators of the liquid in the well itself matter. It is advisable to obtain an official opinion on its composition in order to make the system as effective as possible. You may have to install more than one filter (to get rid of not only ferrous compounds, but also limescale contamination).

If you do not plan to use the system in winter (typical, for example, for country houses), then you need to install fittings for draining water. This is a standard tap that is installed at the lowest point of the system.

Selection by power indicators

The main criterion when choosing a pumping station is the power and performance of the equipment. The average power of household models varies between 600-1,500 W. If we are talking about a small country house, where the water intake will be carried out for one mixer, an internal pressure of 1.5 atmospheres is sufficient, which will ensure a jet height of approximately 15 meters.

For large buildings, it is necessary to select such models so that water is consistently supplied to the most remote point of intake. In this case, the optimal performance of the pumping station will vary between 3,000-6,000 l/hour.

This information is indicated by the manufacturer in the technical specifications of the product.

First start-up and verification of correct installation

For the first start, you need to fill the system with water. The liquid is poured through a funnel, which is cut off from the pump by a special tap. You can also pump the unit with a manual piston pump, which is connected to the outlet pipe of the station. Then check the air pressure with a car pressure gauge and open the shut-off valves.

When starting up the device and further operation, it is necessary to maintain the standard parameter values recorded in the technical documentation of the pressure unit. A properly adjusted relay mechanism turns the pump on and off in a timely manner and ensures an even supply of water.

What else to pay attention to

In addition to performance and power, we recommend paying attention to the following parameters of the pumping station:

- Hydraulic accumulator volume. It is important to take this into account in case of a power outage, so that the water supply is sufficient for the needs of the household.

- Suction depth. This parameter determines the depth of the well from which water will be drawn.

- Lifting height. Necessary to determine the number of consumers.

- Protection. Helps prevent equipment failure in cases of overheating or air intake.

In addition, you can select the type of equipment control: manual, automatic or remote. These nuances determine ease of use.

How to properly assemble and connect the system to a well?

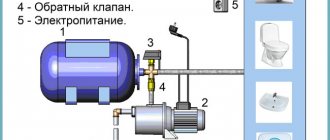

Below is a diagram of connecting a hydraulic accumulator to a household submersible pump; let’s look at the main features step by step:

- Before connecting a deep-well pump to an installed hydraulic accumulator, the pump itself should be placed in the well.

- The pump is lowered by a steel cable. A power cable and a pipe for pumping out liquid must be connected to it.

- The water level sensor must be immersed. It will transmit information to the control unit.

- The installed control unit will have a relay and dry-running protection. If the water level drops, a signal is sent to turn off/on the device.

- Afterwards the HA with an air valve is installed. Its installation is carried out in a dry and warm place, inaccessible to frost.

- To prevent the pressure in the accumulator from dropping, a check valve must be installed.

- After this, the pipeline is led to the water intake points and into the house.

The best pumping stations

Here are a few units that attract attention with their affordable price and good performance.

LEO XSHM 1500

Centrifugal pumping station from Chinese manufacturers. The immersion depth of the equipment is 9 meters, the height of water rise is 16 m. The average productivity is 1.44 m3/hour. The model is equipped with built-in overheating protection and can pump water with a low content of suspended solids.

| Performance | 16200 l/h / maximum / |

| Pressure | 16 m / maximum / |

| Maximum working pressure | 10 bar |

| Operating principle | centrifugal |

| Suction lift | 9 m |

| Content of mechanical impurities | 10 g/m3 |

| Max. t liquid | 40 °C |

| pH value | 6.5 – 8.5 |

| Suction system | multi-stage |

| Exit connection hole/pipe | 2″ |

| Entrance. connection hole/pipe | 2″ |

| Power | 1100 W |

| Nutrition | electric |

| Mains voltage | 220 V |

| engine's type | asynchronous |

| Power cable length | 1m |

| Protection class (IP) | X4 |

| Housing material | cast iron |

| Impeller/Auger Material | plastic |

WILO PW-175EA

A German pump that takes water from a depth of 8 meters and raises the jet to a height of 35 m. Average productivity: 2.1 m3/h. The equipment is installed horizontally and has built-in overheating protection. The pump has a low noise level; users note the unreliability of the on/off relay.

| Performance | 2100 l/h / maximum / |

| Pressure | 35 m / maximum / |

| Operating principle | centrifugal |

| Device | self-priming |

| Suction lift | 8 m |

| Max. t liquid | 40 °C |

| Accumulator volume | 2 l |

| Suction system | single stage |

| Exit connection hole/pipe | 1″ |

| Entrance. connection hole/pipe | 1″ |

| Power | 125 W |

| Nutrition | electric |

| Mains voltage | 220 V |

| Protection class (IP) | 54 |

| Manufacturer country | Germany |

| Housing material | cast iron |

| Impeller/Auger Material | brass |

GRUNDFOS MQ3-45

The equipment is manufactured in Denmark, has compact dimensions and a long service life. The productivity of the equipment is 4.1 m3/h, water is taken from a depth of 8 m, the height of the liquid rise is 45 m. The disadvantages include the high cost and complexity of installation.

| Performance | 4200 l/h / maximum / |

| Pressure | 43 m / maximum / |

| Maximum working pressure | 7.5 bar |

| Operating principle | centrifugal |

| Device | self-priming |

| Suction lift | 8 m |

| Max. t liquid | 35 °C |

| Accumulator volume | 1 l |

| Suction system | single stage |

| Exit connection hole/pipe | 1″ |

| Entrance. connection hole/pipe | 1″ |

| Power | 1000 W |

| Nutrition | electric |

| Mains voltage | 220 V |

| Protection class (IP) | 54 |

| Manufacturer country | Denmark |

| Housing material | stainless steel |

| Impeller/Auger Material | stainless steel |

| Accumulator material | steel |

| Weight | 13 kg |

In addition, you can pay attention to the GARDENA 3000/4 and Gilex “Water Jet” models, which are standardly equipped with fine and coarse filters.

How to choose for a private house or cottage?

Technical characteristics that will tell you which pumping station to choose.

| Options | Description |

| Performance | Determined by the power of the device. It is important to know the real capabilities of the source (flow rate). The performance is indicated in the data sheet. The optimal solution would be an installation with a capacity of up to 6 thousand l/hour |

| Power | Several factors are taken into account: the length of the route from the mirror to the pump, the number of shut-off valves (points), the height of the water rise and the resource of the source. Household water appliances have a power of 0.6 to 1.5 W |

| Hydraulic accumulator | The larger its volume, the higher the price. It is necessary to understand that if its volume is large, the pump will not turn on so often, and during a power outage there will be a sufficient supply of water. A smaller number of cycles of its activation significantly affects the duration of operation. In addition to installing it, you need to know how to connect a submersible pump to a HA |

| Intake depth and water supply height | It takes into account how far the device will be installed from the well, that is, the horizontal section. The resistance in the pipes, coarse filter and valve (return) is also taken into account. Therefore, the device for the well must have a power reserve of 15% |

| Housing material | Water units for wells have different housings: cast iron, stainless steel, metal and thick PVC. The polypropylene body does not rust and does not make much noise. In case of mechanical impact, the plastic may crack. Some types of stations have a steel body. It makes a lot of noise and can resonate. Cast iron ones are almost silent. It is believed that the best devices are made of stainless steel. Their high cost is fully compensated by their quality. |

| Filter | It is an important element that can protect the pump from the penetration of various particles |

| Protection against dry running and overheating | Automation will significantly extend their service life. If there is no water in the supply pipeline (for various reasons), a special relay sends a signal to turn off the pump. Additionally, the device is equipped with an overheating relay. Especially relevant in case of high water consumption at high speeds |

| Automation | The automatic submersible device eliminates intervention and control over the system. It is important to set it up correctly. If it will be used in a house or country house seasonally, then it is better to use manual control. Therefore, before connecting the automation, decide what is best for you |