Mineral wool and polystyrene foam in the best traditions of insulation

The most common materials for insulation are mineral wool and expanded polystyrene.

They also did not ignore septic tanks. And they are often used for similar purposes

When starting insulation with mineral wool, you should not think that it is very expensive - the price of the work will depend on the type of wool chosen. All of them belong to the group of mineral wools. Glass wool is much cheaper than stone wool, but it is more difficult to work with. Here the high cost of insulation will depend on your choice. Important points to consider when choosing this insulation method:

- It will be more convenient to work with rolled materials. They simply wrap all components of the sewer system.

- It is worth securing the mineral wool using wire or twine.

- Don’t forget about waterproofing, because even though it is mineral, it is still cotton wool and has a “good” ability to absorb moisture.

- When laying the waterproofing layer, do not forget to overlap it, it will not allow moisture to pass through to the insulation.

Most often, polystyrene foam is used as insulation. Here it is worth knowing that the best of them is extruded foam. It is the most durable and can withstand heavy loads. Another important advantage is minimal moisture absorption.

A new word in insulation

One of the modern options for insulating both pipes and septic tanks is the use of cables. The best option is a self-regulating cable, which is able to determine on its own where heating is needed and where it is not. It plugs into an outlet like a regular electrical appliance. This option is economical and easy to install, since you can simply wrap it around the pipes and the septic tank itself.

Another option is polyurethane foam. This foam is poured into the gaps between the septic tank and the pit. It does not need additional fastening, and it perfectly holds any finish. Its thermal insulation qualities are at the highest level.

Considering that any treatment plants, due to their functional purpose, are forced to come into contact with water, an important role is played by the thermal insulation of the septic tank and pipes. Nobody wants an autonomous sewer system to unexpectedly become a source of problems, in particular, to become clogged, and all the “happiness” that goes down into it makes itself known through clogged risers, etc. pieces. It is obvious that the insulation of the septic tank must be carried out already at the stage of its construction, in particular, when installing tanks and laying pipes.

Naturally, for summer residents who use a septic tank only in the warm season, it is enough to insulate only the container (pipes, including the aeration field pipes, do not need to be insulated), and this can be done at the end of the season - just cover the installation site of the septic tank with branches or straw, pressing it all down with boards or stones. In winter, when snow falls, this measure will significantly insulate the septic tank, preventing the water remaining in the tank from freezing.

Installation of insulation for sewer lines in the ground

The insulation is installed when all the pipes have already been laid and connected to the sewerage system itself.

In this case, all pipes run at a slope of 1 centimeter per linear meter.

When installing insulation, you should pay special attention to ensure that there are no bare areas left, otherwise this whole procedure will be useless. The beginning and end of the pipe and joints are also carefully processed

In such places, you can put several layers of insulation to be sure.

The beginning and end of the pipe and joints are also carefully processed. In such places, you can put several layers of insulation to be sure.

Otherwise, installation of insulation is very simple and takes little time.

Installation features

Having chosen the desired insulation, immediately read the instructions for it, since each of them has its own characteristics.

If you are additionally doing waterproofing, you should immediately calculate how much material you will need.

More careful insulation and waterproofing should be done on pipe bends; any of the above materials will be suitable for this. Thanks to their convenient cylindrical shape and plasticity, they can repeat any bend without breaking.

You can additionally insulate sewer pipes using a pipe heating cable. It maintains the temperature of the pipe well, preventing it from freezing.

The cable can be an independent insulation, but most often it is wrapped on top with another layer of any insulation.

You can see an approximate diagram of insulation with a heating cable in the figure below.

Insulation with heating cable

This cable provides an almost 100% guarantee that the pipe will not freeze in any conditions.

Installation rules

Insulation with the selected material is carried out before filling the pipe with earth, and all pipe edges and seals must be sealed with sealant so that moisture from the pipes does not spoil the material.

If you choose foam shells for insulation, then you just need to put them on the pipe and additionally secure it with aluminum self-adhesive tape.

If it is mineral wool or basalt fiber, then they must be laid with the foil side out, as shown in the photo below.

Installation of glass wool with waterproofing

In this case, all joints must be glued with construction tape very carefully so that there is no access to moisture.

Also, pipes are insulated only in dry weather; dirt and other debris must be removed from them so that nothing prevents the insulation from tightly joining the pipe.

Protection of an industrial septic tank from freezing

Two methods are used - conservation and insulation. The first option is used in dachas where people live during the warm season. Before leaving, carry out simple operations:

- the aerobic unit is disconnected from the network;

- drain the liquid, pump out the sludge;

- remove equipment: pump, compressor;

- fill ⅓ with water;

- insulate and seal the lid.

To preserve the septic tank, it is important not to drain the liquid completely, otherwise in the spring the light tank may be pushed out by water from melting snow and increasing groundwater levels. The septic tank is insulated on the sides and top

The septic tank is insulated on the sides and top

Insulation of the aeration unit body is carried out using one of the methods described above

For VOCs, it is important that all compartments are warm. Topas and some similar models have tubes at the very top through which liquid is pumped

Severe frosts can cause them to freeze, causing the VOC to deteriorate. The risk of freezing for a simple three-chamber septic tank is that it turns into a cesspool - anaerobic processing stops.

Characteristics and types

The flexible hose for connecting plumbing is a hose of different lengths made of non-toxic synthetic rubber. Thanks to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, there is an upper reinforcing layer in the form of a braid, which is made from the following materials:

- Aluminum. Such models can withstand no more than +80 °C and retain functionality for 3 years. At high humidity, aluminum braiding is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water line is at least 10 years, and the maximum temperature of the transported medium is +95 °C.

- Nylon. This braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 °C and are designed for intensive use for 15 years.

The fasteners used are nut-nut and nut-fitting pairs, which are made of brass or stainless steel. Devices with different permissible temperatures differ in the color of the braid. Blue ones are used to connect to a pipeline with cold water, and red ones for hot water.

When choosing a water line, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that prevents the rubber from releasing toxic components during operation.

Septic tanks Bars

The Bars septic tank is used in harsh climatic zones, with high and low groundwater levels, gravity, forced wastewater disposal.

from RUB 102,505

Septic tanks Biotank

Installation for biological treatment of domestic wastewater septic tank Biotank consists of a rectangular cast body, divided inside by a cast insert into chambers.

from 42,500 rub.

Septic tanks Ecogrand

The Eco-Grand deep biological treatment station will help you solve the problem of recycling sewage in a modern way.

from RUB 72,250

Septic tanks BioDeka

The aerobic-anoxide biochemical method of operating a Biodeka septic tank is based on the processing of organic and chemical compounds by activated sludge microorganisms.

from 65,900 rub.

Septic tanks Eurobion

Get rid of unpleasant odors and regular sewer maintenance costs with a Eurobion septic tank!

from RUB 63,750

Septic tanks Kolovesi

Kolo Vesi are environmentally friendly aerobic biological stations made in Finland, the operating principle of which is to use active microorganisms that neutralize harmful organic compounds in household wastewater.

from 52,900 rub.

Septic tanks Rostock

Speaking about Rostock, it is impossible not to mention that this name bears not one, but several devices.

from RUB 26,800

Septic tanks Topas

Septic tank Topas is the best solution for arranging an independent sewerage system in a suburban or summer cottage area if utilities are not connected to the territory.

from RUB 72,297

Technology for spring re-preservation of a septic tank

In the spring, the septic tank must be properly re-opened. To do this, almost all operations that were carried out during conservation should be done in reverse order:

- remove the insulation layer;

- remove the floats;

- install pumps, compressors and other equipment;

- connect power supply.

After this, the septic tank can be used as usual. After a few days of normal use, the system will return to normal. Usually there is no need to introduce new bacteria into the septic tank.

All owners of autonomous treatment facilities know that inside plastic tanks live living bacteria (aerobic and anaerobic), which help purify wastewater so much that it can be used for watering a garden or as process water. However, the septic tank is often left unattended in winter if you leave the dacha, or if you live in the house all year round, it is exposed to low temperatures. What happens to the microscopic workers of this structure? And how to protect them and wastewater from freezing in winter? Some owners are interested in the question of how to install a septic tank that will work in winter, or how to build this structure in winter? You will find answers to these and many other questions in our article.

Some owners, fearing that the septic tank would freeze in winter, made one big mistake - they completely drained the wastewater from the treatment plant and pipeline. Most likely, they did this by analogy with the heating and plumbing system, fearing that if the water froze, the plastic tank would expand and rupture. You shouldn’t do this, because the result will always be sad:

- If you return to your dacha in the spring, you will find your septic tank on top, floating in the pit. The thing is that during a flood, groundwater will easily push an empty container upward, since its volume is quite impressive and its weight is small.

- But worse could happen. Since the soil in which the tank is dug is not static, it can move as a result of temperature changes and changes in groundwater levels. During this process, the septic tank will experience significant loads. As a result, the autonomous sewerage tank will simply burst or become deformed.

As a result of this, the septic tank in winter will become unsuitable for further use. Owners will need to replace the damaged product, buy a new septic tank and install it, which will entail considerable expenses.

Is it possible to install a treatment plant in winter?

Surprisingly, many experts advise installing a wastewater treatment plant in winter. Installing a septic tank in winter has the following advantages:

- Since construction and renovation work stops during this period, you won’t have to wait for a specialist. Also, the masters will be able to give you maximum attention.

- It is better to install a septic tank in winter for the reason that the groundwater level during this period decreases to a minimum, so digging a pit and a trench for the supply and drainage of wastewater will not arise.

- In principle, there is no difference when installation work is carried out. The only problem may be unfavorable weather conditions.

- Since no one lives at the dacha in winter, the work will not bring any inconvenience to the household.

- In winter, discounts often appear on many building materials and services provided, so you can save money.

Installation of a septic tank in winter is carried out in the same sequence as at other times of the year:

- First, a pit and trenches are dug for the supply sewer pipeline and the discharge of treated wastewater.

- After this, sand cushions are made at the bottom of the pits, which are then compacted.

- A septic tank is installed, a pipeline is laid and connected.

- The pit and trenches are backfilled.

Basic materials

First, let's figure out what exactly needs to be insulated. The pipe inlet and its upper part are most exposed to cold. It is recommended to insulate the entire installation to fully protect it from frost. Most importantly, it is prohibited to use organic materials for protection. They won't be of much use and are also susceptible to rotting. We list the main materials that can be used.

Expanded clay

The use of expanded clay is a budget method of insulation. This material has fairly good thermal characteristics. The minimum thickness of the expanded clay layer is 20 cm. It is poured between the walls and edges of the pit.

Mineral wool, glass wool

These materials can protect the septic tank well, but are not resistant to liquids. Therefore, additional waterproofing is necessary. Getting wet causes a lack of thermal insulation properties.

Roll materials are used for installation of thermal insulation. The septic tank and pipes are wrapped, and they can be secured with reliable wire. Waterproofing of materials is done using roofing felt. You can also fasten roofing felt with wire.

Tip: mineral wool and glass wool are materials that can be used on a limited budget. If possible, it is better to choose more expensive materials.

Expanded polystyrene

Among all materials, extruded foam is most often used. It has sufficient strength, which has a positive effect on protection from soil influence. Expanded polystyrene also has good waterproofing characteristics. It is necessary to protect the pipe with a foam plastic shell, and the septic tank itself should be covered with foam plastic using an adhesive solution.

Foamed polyurethane

Polyurethane has:

- excellent thermal insulation;

- protection against exposure to liquids;

- vapor barrier.

Polyurethane foam can be applied to any material. No mounting hardware is required, so simplicity is guaranteed. After applying the foam, the pit is backfilled with soil.

Electric cable

This method is expensive. Thermal insulation is carried out by a cable connected to the electrical network. The heating capacity is enough to warm up the pipes and septic tank. In addition to purchasing the cable itself, you also need to purchase waterproofing materials and insulation. The use of cable is suitable for septic tanks with an aerator: then the problem with supplying electricity is eliminated.

Now you know how to insulate a septic tank for the winter, how to choose the right material. We recommend that you do not skimp on purchasing insulation so that the sewage system retains its properties and is durable.

https://youtube.com/watch?v=mQLrgCvGuFw

How to protect sewer pipes from freezing

- engineering;

- using insulation;

- active.

Engineering method

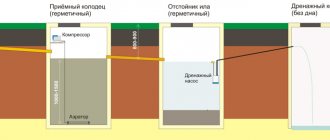

The engineering method is the simplest solution to the question of how to insulate sewer pipes on the street. It consists of the following - pipes are simply laid below the freezing level of the soil. As practice shows, for this they sometimes have to be laid to a depth of 2 m or more. For each region, depending on the climate, the laying depth will be different. This method is implemented as follows:

- A trench is dug to a given depth under the drain pipeline with a slope of 1 cm per meter of its length. The depth can be found in a special table for each region.

- At the bottom of the dug trench, make a sand cushion or a cushion of fine gravel (grain size no more than 20 mm), at least 10 cm thick.

- The pipes are being laid.

- Cover them with a layer of sand or fine gravel. The layer must be located above the pipe at a height of at least 20 cm and be thoroughly compacted.

- Fill the trench with previously removed soil.

Scheme of laying a sewer pipe below the freezing level

Thermal insulation method

What insulation to use is indicated above. The choice of material depends on many factors, among which, first of all, cost and thermal insulation properties should be highlighted.

So, let's look at how to properly insulate a sewer pipe. Installation of an external drainage system using thermal insulation material must be performed in the following sequence:

- The place where the trench will pass is marked.

- A trench is dug, and its width must be at least 60 cm, and its depth must correspond to the design data with a margin of 5–10 cm. The trench is constructed with a mandatory slope (1 cm per 1 linear meter) to ensure gravity flow.

- Sand or gravel at least 10 cm thick is poured into the bottom of the trench and compacted.

- The pipeline is assembled on the surface next to the trench.

- The seal and the edge of the pipe must be lubricated with sealant.

- The insulation is put on the pipe and fixed (usually with tape) so that it does not move.

- The pipe is lowered into the trench, covered with a layer of sand or gravel, and then compacted.

- Next, the trench is finally filled with soil, making sure that it does not contain stones, broken glass or hard soil.

Internal sewerage, as a rule, is not insulated. Only the riser exit to the roof of the house is subject to thermal insulation, since with a sharp temperature change it can simply burst. The material for insulating the riser can also be either mineral wool or foam polystyrene.

Thermal insulating shell for external sewerage pipes

Active method

The most expensive method of thermal insulation is the so-called active insulation. It consists of laying electric heating cables along the pipes. These cables, when heated, transfer heat to the pipeline and prevent it from freezing. The heating system is regulated by a temperature sensor with automatic equipment connected to it. As soon as the temperature around the external sewer system approaches zero, the sensor is triggered and the cable heats the pipeline. When the ground temperature rises, the system automatically turns off.

When using active insulation in practice, you will also need to install an insulation system, because the heating cable will heat the ground, not the pipes. This method is quite expensive both during implementation and operation, and not everyone can afford it.

How to insulate a drain pipe facing the street? The simplest and cheapest method is a foam shell, which will insulate it well. In everyday life, glass wool is more often used, which is simply wrapped around the drain pipe and tied with tape.

Scheme of heating a sewer pipe with a heating cable

Insulated external sewer pipes will last longer if one of the thermal insulation methods described above is implemented. In addition, when laying the system, it is recommended to use smooth pipes made of polyvinyl chloride and polypropylene with an orange surface.

Cheap option for insulating a septic tank

It is not necessary to invest large amounts of money on insulating a septic tank. After all, it is quite easy to cope with such a task using cheap materials.

This section of the septic tank is the most delicate. Organic materials are not suitable for its insulation due to their short service life. Indeed, straw and sawdust retain heat very well. But they quickly deteriorate, thereby losing their beneficial qualities. The summer resident will have to regularly replace rotted material to prevent the septic tank from freezing in the cold.

Expanded clay - a cheap insulation option

Expanded clay allows you to save your family budget. It is famous for its thermal characteristics. And the price for this material is quite low. Another advantage of expanded clay is its naturalness and lightness. With its help, the summer resident will be able to insulate the pit on his own. For expanded clay to be beneficial, it should be laid in a layer of at least 20 centimeters. They are recommended to tightly fill the upper part of the septic tank, as well as the conducting pipe.

Average price category of insulation

If you are willing to spend more on the work, you can use other materials:

- Mineral wool . Stone and basalt varieties are used. The choice of this option is supported by good protection from freezing, getting wet, and biological effects. The insulation does not rot and tolerates temperature changes well. The product is sold in rolls or briquettes. It is most convenient to use briquettes with septic tanks. To increase the degree of moisture protection, you will need to use additional impregnation.

- Glass wool . It has the same advantages as mineral, but is even more resistant to water. Does not deform, tear or stretch. You don't have to worry about mold and other problems. It is important to remember that when installing glass wool you need to use personal protection methods. Fine dust is dangerous for mucous membranes; it should not be allowed to get on the skin, eyes or respiratory tract.

- Expanded polystyrene . It is best to choose extruded foam. It is made of polymer materials, protects well from the cold, and practically does not absorb water. Another advantage is protection from ground movement. This helps strengthen the structure of the septic tank. Strength is achieved due to the fact that the material inside is filled with many cells with air. A special casing for pipes is produced, which is selected according to the diameter. For the main container of the septic tank, you can use sheets of material glued together with special sealing compounds.

Conservation of septic tank Topas

Activated sludge contains bacteria that consume human waste, convert it into harmless substances, and then can be used as fertilizer. If you completely drain the water from the septic tank for the winter, then a critically low temperature below -15 ᵒC can completely destroy all existing living flora.

In addition, in the spring, an empty tank can be torn from the foundation by the lifting force of groundwater and raised to the surface, which will lead to complete failure of all equipment.

All purchased Topaz septic tank models are supplied with detailed instructions on how to prepare the septic tank for winter. Popularly it can be stated as follows:

1. First of all, the installation must be completely disconnected from the electrical network at the main electrical distribution panel. If the design allows, it is advisable to lock the switchboard to avoid accidental switching on, which can lead to electrical injury.

2. All chambers of the septic tank and the filter are cleaned of solid, undecomposed residues. The activated sludge remains intact in the chamber so that bacteria do not die.

3. All removable electrical equipment, such as a compressor for water aeration and a sump pump, is turned off and dismantled.

3. The level of water that remains in the septic tank for the winter must be at least 75% of the optimal level. Excess water must be pumped out, and the missing water must be added from the water supply network.

4. Even with careful insulation, water may freeze. To prevent the formed ice from crushing the septic tank, plastic bottles can be placed in the water. They are filled with sand to 1/3 of their volume in order to take a vertical position. Each bottle is tied with a rope to the body of the septic tank so that they can be easily removed in the spring.

5. The septic tank lid is carefully insulated. For this, polystyrene foam, sawdust, hay and straw are used. The insulation layer must be covered with plastic film or other similar material. In this case, it is imperative to ensure active air exchange inside the tank in order to support the vital activity of bacteria. You can make small holes in the foam.

6. How to insulate a septic tank for the winter determines its performance for the entire summer period. The main thing is to preserve the vital activity of bacteria.

Preservation of septic tank Unilos

In this case, the algorithm of actions is approximately the same. First of all, the stabilizer tank is cleaned or from various solid residues that cannot be decomposed. Considering that septic tanks from this manufacturer are intended for use all year round, then such cleaning must be performed periodically.

The water level is brought to 1/3 of the total. All existing equipment is disconnected from the power supply, dismantled and placed in a warm place.

The maintenance hatch can be insulated in any way, but air circulation inside the septic tank must be ensured so that bacteria do not die. In case of possible freezing of water, it is necessary to perform approximately the same measures as in the previous version.

Preservation of septic tank Astra

These cleaning plants are equipped with a special device called an airlift. With its help, you can clean the tank from silt and other sediments. Therefore, before conservation, this procedure is performed without much difficulty.

Using a drainage pump, the septic tank stabilizer is cleaned and the filter is washed. The power is turned off and electrical equipment is dismantled. The septic tank lid is insulated using all available means.

High-quality and timely conservation ensures long-term operation of such devices. Only specialized enterprises can provide full preparation for the winter period, which, for a relatively small fee, will carry out all the work in accordance with the regulations.

Useful tips for preserving a septic tank for the winter

Local treatment facilities in the form of an inventory septic tank are a rather complex device. Therefore, after the installation has been installed and put into operation, it is advisable to carefully study the attached installation and operating instructions.

All manufacturer’s recommendations must be followed strictly so that you can operate the Tver septic tank in winter and summer without unwanted breakdowns.

Insulation of hood for sewerage background riser

Separately, it should be noted the need to insulate the external sewer system, which means a ventilated background riser (exhaust) - a sewer pipe led to the roof (or to the surface of the ground from a septic tank) and providing ventilation for the pipeline.

The background riser is designed to suck in air so that the pressure in the system is equalized when the toilet is flushed. And in the septic tank, gases are formed from the activity of bacteria, which are also removed through the background pipe.

The ventilation (background) pipe can freeze (condensation freezes and an ice plug forms) and needs to be insulated. Any material that is reliably protected from moisture and destruction by ultraviolet radiation is suitable for thermal insulation. For example, you can put a Stenoflex “stocking” on the pipe. The part of the pipe that is located above the roof is insulated. And you cannot put a cap on top of the pipe; it must be free, otherwise it will freeze in this place.

How to insulate a background riser with your own hands

On the forum, one user suggested an interesting way to get rid of the build-up (freezing) of condensation in a background pipe.

You need to take copper wire (necessarily from pure copper, without braiding, this is important), wind it into a voluminous, but at the same time “liquid” lump (so that air can easily pass through it). Place this lump of wire into the pipe from above, and bend the ends of the wire so that you can secure the wire at the top of the pipe (otherwise it will fall inside)

Place this lump of wire into the pipe from above, and bend the ends of the wire so that you can secure the wire at the top of the pipe (otherwise it will fall inside).

The point lies in the chemical properties of copper; it has very high thermal conductivity. Warm air rises through the pipe, the copper accumulates heat and melts the freezing condensate.

Conclusion

Insulation of sewerage in a private house is an important measure that will maintain the normal flow of sewer pipes in winter, prevent freezing of the pipeline and extend its service life

Defrosting with hot water

Insulating sewer pipes, especially if they are made of plastic or metal, usually takes a lot of time. Therefore, their freezing does not occur so often. Unfortunately, the same attention is not paid to the cesspool itself. Therefore, it sometimes happens that the waste inside the container is covered with a durable layer of ice, although the drain pipe continues to function with due force.

In this case, regular hot water may be enough for defrosting. Some people simply pour it down the drain, which is not entirely effective. It is best to open the hatch of the cesspool itself and pour boiling water into it.

There should be enough of it so that it can completely cover the entire layer of ice and be above its level at a height of 15–20 cm. So the amount of hot water primarily depends on the volume of the container.

Defrosting with water is only effective when you notice the problem early enough and the ice has not yet hardened. In more advanced cases, you will have to resort to other methods to defrost the cesspool.

Insulation with mineral wool or glass wool

These materials are fairly cheap, and such insulation for a septic tank will not be very expensive, which allows it to be classified as budget. A mandatory requirement for such insulation will be the creation of a waterproofing layer, since when moisture enters, mineral wool and glass wool completely lose their ability to retain heat.

The question often arises of how to insulate a septic tank as reliably as possible. For insulation, you can use materials collected in a roll. Installation in this case will be significantly simplified: the sewer pipeline and the septic tank itself are wrapped in a layer of thermal insulation, which is secured with twine or wire. To create waterproofing, you can use roofing felt or other material with appropriate properties. It is important to overlap the material to ensure it performs its functions.

The advantages of this method of insulation include its extremely low cost: nevertheless, the materials are not highly reliable and of good quality.

Bury pipes deep into the ground

The most reliable way of insulation is to deepen them into the ground. The deeper the pipe is, the less likely it is to freeze. After all, at a certain depth the temperature does not change even in winter.

How to determine the optimal depth for laying pipes? It is impossible to give universal advice for every locality. In each climate zone, the soil freezes to a different thickness. In some areas it is enough to bury it a meter deep. In others, the ground can freeze up to two meters. Having consulted the climate atlas of your area and determined the depth of freezing, you will be able to carry out excavation work correctly. True, builders advise adding extra space and going a little deeper.

Burying pipes deep into the ground is a good option. However, in practice, this effective and low-cost method of insulation is not always used. Why? Excavation works cause complications even in cases where pipes must be buried a meter deep. If you need to dig deeper, you want to come up with another way to insulate a sewer pipe. In addition, the sites are often located in areas where excavation work is either impossible or very expensive.

By digging deep, you will create another problem. Let's say there is a problem with the system. You're not even sure if there's a leak, but you need to check the pipe. And to do this, you will have to turn over mountains of soil again, inspect, look for damage and bury them back. What if you need to replace one or more sections?

Septic tank Tver 0.75…

Add to cart Go to catalog

Expanded clay

Expanded clay granules differ from the above insulation materials according to the principle of application. The trenches and pipe structures installed there are backfilled with granules. After backfilling, the mineral granules are compacted, resulting in the formation of a high-quality thermal insulation layer. The only disadvantage of expanded clay is its high water absorption, so it is recommended to use them only on dry soils. If you still decide to use mineral granules in a wet area, you should first lay a two-layer waterproofing sheet in the trenches.

Installation work

It is easiest to work with pre-prepared forms of insulation for 110 mm pipeline networks. In another way, they are called shells, consisting of a different number of parts. The edges have a rectangular shape with fixation according to the groove/tongue principle or overlapping protrusions. This multilayer design also provides space for a heating cable. To put it simply, a heat-insulating jacket is created that is put on the products. For fixation you can use:

- Glue;

- Staples;

- Clamps;

- Scotch.

Some owners install additional moisture insulation on such a “pie”. The following raw materials are used in the production of molded insulation:

- Expanded polystyrene;

- Styrofoam;

- Foamed rubber;

- Polyurethane foam;

- Foamed polyethylene.

When choosing rolled mineral wool, the formation of overlaps is not required. However, the edges should fit together as closely as possible. Taking into account the inexpensive cost of this heat insulator, it is chosen for large projects. Private owners prefer metallized casings, which are easy to install and reliable.

Conclusion

External pipe insulation is not required if your site is located at southern latitudes with a mild climate. However, for residents of the northern regions, this is a mandatory procedure that allows them to extend the operational life of expensive septic stations. Freezing of an autonomous sewage system leads to blockage of the pipeline and immediate failure of plumbing or household equipment.

Popular goods

- 87,975 rub. View

Why insulate it?

To be on the safe side, the septic tank needs to be insulated first of all because if it freezes, the entire sewer system will stop functioning. And this is the biggest nuisance in winter. Especially if you live outside the city. It should be remembered that if the septic tank is properly installed, freezing is impossible: even in the most severe frosts at such a depth, the temperature remains above zero.

But no matter how ideally the septic tank is designed for your home, and no matter how excellent professionals install it, do not forget: lately the temperature has been unstable in both summer and winter, so it’s still worth being on the safe side.

Main stages of the process

Insulating a septic tank with your own hands is not a difficult task and is feasible for any owner of a private house. Different materials can be used as insulation; they differ in both price and method of installation (backfilling). Insulation features:

Pay attention to the thickness of the insulation - it should be at least 15 cm. But this figure can be greater or less - depending on climatic conditions, the depth of the septic tank and the selected material. In regions with a harsh climate, it is also worth insulating it on the top and on the sides, below the freezing level. With the correct slope, the pipes are unable to retain wastewater, which means they will not freeze

But if the temperature is extremely low, then during glaciation their diameter will constantly decrease until the pipes are completely at the mercy of ice. If the septic tank is installed in a country house where you do not plan to go during the cold season, then it is rational to mothball it, which must be done correctly. But that's a completely different story.

Recommended reading: Comparison of septic tanks: Topas or Tank?

Cheap and cheerful

You can insulate a septic tank without involving large financial resources. Of course, these will not be improvised materials, but they will not be expensive

When insulating a septic tank, it is important that the most delicate part of the system is the upper part of the sewer pipe. When insulating, you should not use organic materials, such as popular straw or sawdust.

Why? Everything is very simple: they may retain heat, but their service life is limited to a year, well, maximum two, then these materials simply rot. That's all: the process must be repeated.

The cheapest insulation option is expanded clay. Its thermal characteristics are at a high level, and the price is significantly lower than other insulation materials. Plus, it is natural and lightweight; the process of insulating a pit can be completed by one person. It should simply be poured between the walls of the septic tank and the pit. In order for expanded clay to be effective, the layer thickness must be at least 20 cm. In addition, it is necessary to fill the upper part of the septic tank and the supply pipe.

Insulation for sewer pipes

Since we are talking about insulating the external sewer system in a private house, let’s consider how to insulate pipes with your own hands

The most important thing in the process of insulating external sewerage is the choice of material that will determine the installation features and provide a given level of reduction in heat loss

It should be noted that sewer insulation, as a separate type, is a non-existent material. Those. There is no single solution, and in each case it is necessary to select insulation based on the individual characteristics of the pipeline.

Thermal insulation of sewer pipes is carried out by any of the thermal insulation materials on the market.

There are only two determining factors when choosing insulation:

climate zone. The lower the winter temperature, the lower the thermal conductivity index the insulation should have;

pipe laying method. The choice of pipe insulation depends on the depth to which the pipes are laid (below or above the freezing level). The technology for insulating external sewers using thermal insulation comes down to two methods: the pipe is wrapped with insulation in several layers or a box is built around it.

Which insulation for sewer pipes is better to choose?

A good building thermal insulator must meet a number of requirements:

- low thermal conductivity coefficient;

- ease of installation;

- resistance to various factors: moisture, biological activity, ultraviolet radiation, mechanical or chemical influences;

- tightness of insulation;

- resource of use;

- price.

Insulation of septic tanks

Theoretically, a well-constructed septic tank cannot freeze during year-round constant operation. This statement is based on the following:

- The septic tank, as a rule, is located in the ground at depths of about two meters, where even in the most severe frosts the temperature rarely drops below plus five degrees;

- the septic tank is heated from the inside due to a certain amount of heat generated by bacteria during their life activity when cleaning household wastewater;

- household wastewater that comes from the house to the septic tank, at its initial temperature from plus 20 to plus 40 degrees, will not have time to cool significantly when passing through the pipeline leading to the septic tank, which will create additional heat.

But still, the danger that the septic tank may freeze really exists; such fears are expressed even by specialists who are professionally involved in the construction and maintenance of septic tanks. Therefore, it is better to play it safe and perform at least the simplest insulation of the septic tank. Of course, it is more rational to carry out insulation measures during the construction of a septic tank.

The pit for installing a septic tank should be dug so that at least a third of the height of the septic tank is below the freezing depth of the soil. In this case, it is enough to insulate only the remaining part of the structure. The septic tank is insulated from all sides and from above.

Foam and mineral wool boards or other heat insulators (izol, expanded clay, etc.) can be used as insulation.

On the side of the septic tank, a two-centimeter layer of insulation is enough, then the space between the wall of the pit and the insulation is filled with sand, poured with water and thoroughly compacted. Insulating the top of a septic tank requires the use of insulation up to 20 cm thick. The insulation layer must also be covered with sand, poured with water and thoroughly compacted.

If the shape of the septic tank is complex, polyurethane foam or a similar insulation of the same class can be used as insulation. Polyurethane foam, laid in several layers, is guaranteed to insulate a septic tank of the most complex shape, and such insulation will be completely airtight.

The decision on how to insulate a septic tank is made by everyone depending on their financial capabilities.

How does he work

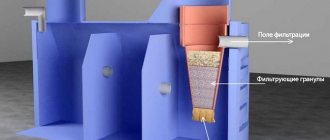

All used water and wastewater flows from the house through pipes into the septic tank. There they settle and undergo primary purification with the help of special microorganisms. At the end of this process, the wastewater can be transported to filtration fields.

According to the technology, the tank goes deep into the ground to a depth of one and a half to two meters, this is enough to avoid the need for additional insulation. Indeed, in most of Russia, the ground simply does not freeze that deeply. In addition, a small amount of heat emanates from the container itself, generated due to the activity of bacteria and chemical reactions during the decomposition of organic substances.

In any case, it is worth taking care of sufficient thermal insulation of the pipes connected to it, since they do not lie so deep and can freeze even in slight frosts.

But if for some reason the container is on the ground or you live in a region where the thermometer drops significantly below zero, then it is necessary to insulate the septic tank in advance.

How to properly insulate a septic tank for the winter

1. Budget methods for insulating septic tanks

2. Insulation with mineral wool or glass wool 3. How to insulate a septic tank with polystyrene foam 4. Expensive methods of insulating septic tanks 5. Preservation of septic tanks for the winter

Sewage systems can be called quite demanding in terms of operating conditions. Taking into account seasonal freezing, the structure should be as insulated as possible so that low temperatures do not lead to malfunctions.

As a rule, a good method of protecting sewers from freezing is to install them at a depth greater than the freezing depth of the soil.

The problem is that not all types of treatment facilities can operate in such conditions, so this article will discuss the main methods of insulating septic tanks.

How to insulate a septic tank with polystyrene foam

This material is used quite often for insulating septic tanks. As a rule, extruded foam is used, the strength of which is quite high and can withstand the load exerted by the soil layer located above the structure.

The advantage of expanded polystyrene is its fairly low level of moisture absorption. Sewer pipes are usually insulated with a special shell made of polystyrene foam for these purposes.

The septic tank is simply covered with sheet material, to attach which to the structure you can use any suitable mixture.

To ensure maximum protection of local sewerage from the effects of negative temperatures, it will be necessary to use materials that have a high cost, but the return will be the most complete.

Insulation can be carried out in the following ways:

- Using an electric cable for heating

. By installing the cable along the entire structure, you can provide the system with high-quality heating in winter: the amount of heat generated is sufficient to prevent freezing of the pipeline or septic tank. In addition, by using an electrical cable in volatile systems, you can get rid of the problem of supplying electricity to the structure. When installing the cable, it is necessary to cover it with a layer of thermal and waterproofing. - Insulation with foamed polyurethane

. For insulation, polyurethane foam is often used, which boasts high performance indicators. One of the characteristic features of the material is the ability to connect with most materials, so during installation it will be possible to do without additional fasteners.

In any case, when the insulation layer is installed, you must fill the structure with soil, and everything will work perfectly. If you use a septic tank only in the summer, it must be preserved for the winter. There is no need to wonder how to insulate a septic tank for the winter - just follow these steps:

- First the power supply is turned off;

- then the compressor and pumps are removed;

- the water is partially pumped out from the septic tank (the remaining part will hold the structure in the soil during the spring flood);

- at the last stage, all technical openings are closed, and the structure is insulated superficially.

Conclusion

Insulating a septic tank or preserving it are very important actions that will extend the service life and quality of operation of an autonomous sewer system. After reading this article, any owner will know how to insulate a septic tank as reliably and efficiently as possible.

Methods for insulating sewer pipelines

One of the most effective ways is to lay pipes in the ground below the seasonal freezing depth. The exit is certainly good, but in the northern regions of our Motherland this depth is more than 2.5 meters, add to this the need to create a mandatory slope to create gravity flow of domestic wastewater. Of course, this will require a huge amount of excavation work and significant financial costs, which is unlikely to be advisable in most cases. In addition, in the event of a sewerage failure, not necessarily due to severe frosts, it will be necessary to carry out a large amount of excavation work to carry out repair work (dig a trench, then fill it up again with layer-by-layer compaction and level it).

Using a heating cable. Burying sewer pipes is possible only in external sections of pipelines, but there are also separate sections running along the streets or in unheated rooms. In this case, you can use a special electric cable to heat the pipeline. The cable is laid directly inside the pipes. The result is regular, weather-independent heating. The main disadvantages of using this method are the significant costs of consumed electricity and complete dependence on its availability. In rural areas, power outages are quite common, and the use of autonomous power sources is extremely expensive.

Application for insulation of various thermal insulation materials:.

Cesspools with overflow mechanism

Another deeper septic tank is dug next to the cesspool. Its walls are reinforced with reinforced concrete rings, and the bottom is left earthen. Through holes in the upper rings, the pits are connected by overflow pipes. The pipes should be laid at a distance of at least 500 mm from the soil surface, that is, below the freezing zone. If the region has very severe winters, then this figure can be increased to 800 mm.

A septic tank made of two wells is the optimal solution to the issue of sewerage insulation.

Features of gas connections

When connecting gas stoves, water heaters and other types of equipment, flexible hoses are also used. Unlike water models, they are yellow and are not tested for environmental safety. For fixation, end steel or aluminum reinforcement is used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- made of synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

Don't forget about the aeration field

Provided that the drains of the filtration field are located at a depth above the HGT, care should be taken to insulate them. To do this, any heat-insulating material is spread over the layer of crushed stone covering the drainage pipes, thereby reducing heat loss and reducing the GGT. During the winter season, it is better to cover the septic tank ventilation somehow to avoid freezing of the effluent that has not been absorbed into the soil.

Sources

- https://vivoz-gbo.ru/septiki/yteplenie-septika-na-zimy

- https://kimberia.ru/novosti/uteplenie-septika.html

- https://domcoms.ru/kanalizaciya/septiki/kak-uteplit-septik-na-zimu.html

- https://www.CleanCit.ru/articles/uteplenie_septika_na_zimu_pravila_i_sovety/

- https://kanalizaciyadoma.com/septik/kak-uteplit-septik-na-zimu-pravilno.html

- https://oburenie.ru/septiki/chem-uteplit-septik.html

- https://dompraktika.ru/prostoe-uteplenie-septika-na-zimu/

- https://iseptik.com/uteplenie-septikov/30-uteplenie-septikov.html

- https://fundamentt.com/%D1%83%D1%82%D0%B5%D0%BF%D0%BB%D0%B8%D1%82%D1%8C-%D1%81%D0%B5% D0%BF%D1%82%D0%B8%D0%BA-%D0%BD%D0%B0-%D0%B7%D0%B8%D0%BC%D1%83-%D1%81%D0%B2 %D0%BE%D0%B8%D0%BC%D0%B8-%D1%80%D1%83%D0%BA%D0%B0%D0%BC%D0%B8/

- https://Oseptike.ru/uteplenie-septika