Underground concrete structures need protection from the aggressive environment in which they will operate. Local wastewater treatment plants are no exception, which is also aggravated by the possibility of harming the environment in the event of a leak. Agree, such a catastrophe, albeit of local significance, must be prevented.

Properly executed waterproofing of a septic tank made of concrete rings will prevent the occurrence of corrosion of the structure. Eliminates the possibility of direct communication of the contents with the surrounding soil. The water-repellent material will protect concrete and compounds used to treat joints from erosion.

The article introduces the types of waterproofing used to increase the stability of concrete. We described in detail the protection technology and assessed the effectiveness of the options. Photo collections and video instructions will help you get comfortable with the topic faster.

Sprayable water barrier

This type of insulation allows you to create a monolithic, seamless layer. Water-repellent emulsions are sprayed onto the surface of concrete rings under high pressure. The composition penetrates into splits, cracks, pores and completely fills them, blocking drains in a confined space.

The spraying composition contains a polymer composite, water and fillers such as talc, calcium carbonate, titanium dioxide, barium sulfate.

The use of waterproofing applied by spraying provides many advantages:

- Speed of execution.

- Excellent adhesion to concrete surfaces.

- Fast hardening.

- Durability. It can be used for up to 20 years without loss of initial efficiency.

- Resistant to rapid temperature changes.

Sprayed waterproofing significantly improves the performance characteristics of the septic tank, thereby preventing the penetration of wastewater into the soil surrounding the structure.

To spray waterproofing you will need special equipment. This is an expensive method, but very effective.

This type of waterproofing provides adhesion to the surface of concrete rings at the molecular level. It can be applied over the old layer by spraying. The main thing is to remove excess moisture from the surface before doing this.

Why is it needed?

The reasons for the need to treat the walls of the sewer are outlined in the table:

| Causes | Characteristic | Consequences |

| Frame structure corrosion | Under the influence of sewage and groundwater, metal destruction occurs | Collapse of structure elements |

| Movement of well rings under the influence of processes in the soil | Leads to violation of the tightness of joints | Pollution by soil runoff, ingress of surface water into the reservoir |

| Aggressive effects of household chemicals | Cracks and structural changes appear in concrete | Violation of the integrity of the container, its further destruction |

| Liming process | The appearance of stalactite-like growths on the walls of the structure | Material destruction |

| Hygroscopic processes | Water entering the material structure | Concrete breaks down under the influence of low temperatures |

| Biological corrosion | Wastewater microorganisms affect concrete | Material destruction |

| Penetration of wastewater through the walls into the ground | Due to the gradual destruction of the structure, wastewater enters the ground | Unpleasant smell |

| Soil contamination by microorganisms | ||

| Penalties from supervisory authorities |

Coating compositions for protecting septic tanks

Compared to other waterproofing technologies, the advantage of using coating materials is that they can be applied to surfaces with any geometry. No special devices or mechanisms are required.

Classification of water-repellent materials

There are 4 groups of coating compositions, differing in the basis for which they are used:

- bitumen;

- cement;

- polymers.

The 4th group includes mastics containing sealants. Regardless of the base, coating waterproofing fills the slightest cracks, eliminates defects and makes the surface monolithic.

Some brands of bitumen-polymer mastics contain volatile toxic compounds. Sometimes they provoke disorders of the nervous system and lead to poisoning, therefore, you need to work only using protective equipment - a respirator, gloves, special overalls.

Bitumen-based coating waterproofing is very popular, but is not very durable

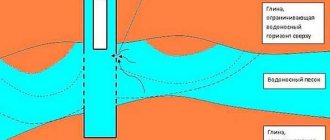

If the groundwater is at great depth, then the insulation of the lower ring of the septic tank is strengthened. If they lie high, then the sealing of the top of the structure must be strengthened.

Bitumen-polymer mastic contains polymer additives and latex, due to the presence of which the characteristics of the material change for the better. When applied to the surface, an elastic, very durable layer is created that retains its qualities at low temperatures. But for the bitumen-polymer composition to work, it must be applied in several layers.

The mastic is relatively inexpensive, you can apply it yourself, and if leaks appear somewhere, the layer can be easily restored.

The presence of polymers in the mastic makes it very effective. The low popularity of mastics of this type is explained by the high cost

In addition, compared to other waterproofing technologies, the advantage of using coating materials is that they can be applied to surfaces of any geometry.

No special devices or mechanisms are required. There are mastics with a bitumen base and with additives in the form of polymers for cold and hot application.

Mastic for application using the hot method is first heated to 160 degrees C so that the bitumen goes into a plastic state. Afterwards they cover the surface of the concrete rings. Cold compositions are diluted with a solvent, which evaporates after the insulating layer hardens.

There are one- and two-component mastics. Bitumen and polymer are necessarily present in their composition, and additives that provide individual properties vary. Depending on the second component, the compositions are called: bitumen-latex, bitumen-rubber, bitumen-oil, bitumen-polyurethane.

Polyurethane and rubber make the material particularly elastic. The coating stretches well without forming cracks. The mixture with rubber is applied cold. It has antiseptic properties and high heat resistance.

Rubber mastic resists the influence of aggressive environments well and withstands hydraulic pressure

The surface coated with a mixture of oil ingredients does not harden. It is sticky, resists well the aggressive influence of groundwater and soil, does not crack, and withstands both frosts down to -50 degrees C and high temperatures.

Rules for applying coating protection

Waterproofing is applied after sealing the inter-ring seams and places where the pipes enter the septic tank.

The process itself consists of 5 successive stages:

- Cleaning the surface from dirt, identifying defects, cracks and eliminating them using sealants or putty.

- Application of bitumen primer as a primer. It is first prepared following the manufacturer's instructions, then the surface is covered with a construction brush. You can make a bitumen primer with your own hands, for which you take gasoline or waste machine oil, heat it and add crushed pure construction bitumen. While stirring, the mixture continues to be heated to 200 degrees C, after which the primer is ready for use. Apply the first layer, and after it dries, apply the second.

- Leave everything for 24 hours. During this time, the primer will dry completely and its fine particles will penetrate deep into the concrete.

- Apply the mastic with a construction brush, after thoroughly mixing the composition. If the mixture is too thick, it can be diluted with any organic solvent. After completing the first layer, allow time for it to dry and repeat the procedure.

- Check the quality of the applied layer after it has dried. If flaws are found, treat the surface again and leave for 2-3 days to dry.

Bitumen mastic is much cheaper than bitumen materials with polymer additives. It adheres well to the concrete walls of the septic tank, has good water-repellent characteristics, and is resistant to chemicals.

Bitumen mastic does not tolerate sub-zero temperatures well, the coating becomes brittle and becomes covered with microcracks. Such waterproofing will be enough for 5 years, maximum 7.

Liquid bitumen has elasticity and good adhesion to the concrete surface. This keeps the layer from tearing and cracking. There is only one drawback - short service life

Some brands of bitumen-polymer mastics contain volatile toxic compounds. Sometimes they provoke disorders of the nervous system and lead to poisoning, therefore, you need to work only using protective equipment - a respirator, gloves, special overalls.

How to prevent well rings from moving in the future

The shift of the lower elements of the well is not eliminated due to the difficulty of performing repairs in waterlogged soil. Correct the joints of 2-3 upper rings.

To prevent displacement of the concrete support during further operation of the well , 3 methods are used:

- Replace the previous barrel elements with links with a rebated lock. The end parts of the rings are formed according to the groove-protrusion pattern. With such a docking, horizontal shift becomes impossible.

- Secure the concrete support element from displacement relative to the axis of the excavation by tying adjacent rings using metal brackets. Holes for them are punched at a distance of ≥25 cm from the joint.

- Attach the links by installing steel plates outside and inside the walls of the rings on bolts Ø12−14 mm.

Ground movements leading to displacement of hollow concrete blocks occur on watered heaving soils. Loads from frozen rocks are higher; at least 4 brackets or plates are placed on the upper rings. Below the freezing level, 2 fastenings are sufficient.

Construction of a clay castle

A good result is obtained by treating the rings with bitumen mastic and then installing a clay castle. This means that the space between the concrete rings and the soil is filled with clay without any impurities. It is needed to prevent water from entering the septic tank after snow melts or heavy rain.

The clay castle prevents the concrete walls of the septic structure from being exposed to flood waters, melted snow and rainfall.

It is recommended to do it not immediately, but after the soil has settled and compacted. A castle made earlier will be destroyed when the ground subsides. The clay is poured in small layers and compacted thoroughly each time. The material must adhere to the entire surface. The slightest voids are not allowed, otherwise the work done will not yield results.

Roll waterproofing of septic tank surface

This type of material is used to waterproof the outer surface of reinforced concrete rings. First, to improve adhesion, the surface of the rings is primed using compounds such as “Betokontakt”.

When the layer dries, visible defects on the walls of the septic tank are eliminated by filling the depressions and cavities with a solution including cement, sand and PVA glue. The seams are sealed between the rings. When the repair patches dry, they are primed.

Rolled waterproofing should be installed after all defects on the surface of the concrete rings have been eliminated

To secure the rolled material to the surface of the rings, the walls are coated with tar or bitumen mastic, and then waterproofing is glued. One layer is not enough; it is practiced to make 3-4 layers. At the end, take the mastic and apply it to the seams between the strips.

Image gallery

Photo from

Step 1: Bitumen mastic for gluing

Step 2: Finishing seams and holes

Step 3: Applying mastic to the walls of the septic tank

Step 4: Gluing the Roll Material

Plaster under pressure

Pressure plaster is also used for internal and external waterproofing. Non-shrinking waterproof cement is supplied under high pressure created by compressed air. The sealing layer is uniform and dense.

The use of this method is not always justified due to considerable financial costs. To implement it, you need to have a special device, the so-called “cement gun”. The work is carried out at a temperature of at least +5 degrees C, 2 layers are laid, the thickness of each is from 5 to 10 mm.

To apply the next layer, you have to wait until the previous one has completely set, and this sometimes takes up to 2 weeks. To prevent cracking of cement on a hot day, it is moistened every 3.5 hours. In cool weather, the interval is increased to 12 hours.

Applying plaster under pressure to the walls of a septic tank is not practical from an economic point of view. Renting equipment to perform the work will significantly increase the cost of the structure

Penetrating or capillary waterproofing

This type of waterproofing is the most reliable. The materials, after being applied to the concrete surface, penetrate into the pores, crystallize, and fill all the voids. Thread-like crystals penetrate into the structure of concrete, bridge microcracks and become one with its body. They do not impair the breathability of the surface, but, by compacting its structure, they do not allow water to pass through.

Penetrating insulation improves the quality of concrete, making it strong and moisture resistant

Crystalline hydrates do not decompose and are not washed out of concrete, so this type of septic tank protection lasts a long time. The layer on the surface of the rings only fixes and retains for some time the active chemical components that play a major role in creating high-quality waterproofing of the structure.

Some manufacturers claim that once all chemical processes are complete, the layer can be removed.

The duration of crystallization and the depth of penetration of the insulating material into the thickness of concrete is influenced by the degree of porosity and humidity of the septic tank rings. At high humidity parameters, crystals form faster, and when this indicator decreases, the process slows down. In concrete surfaces treated in this way, microcracks heal on their own.

The use of penetrating waterproofing to increase the strength of concrete rings and resistance to aggressive environments is the most affordable, reliable and easy-to-implement method

The application of penetrating waterproofing is preceded by careful surface treatment. It is completely cleaned using special chemical solutions or a mechanical method.

When you end up with a flat surface, it is saturated with moisture by pouring water from a hose under high pressure. The active components of the waterproofing composition will penetrate to the same depth as water.

Processing begins with the seams. It is better to do this while installing the rings. They are laid on a layer of cement mortar, then treated with a penetrating mixture. Next, apply the mixture to the entire surface, strictly following the manufacturer’s instructions, otherwise the waterproofing layer will not meet the stated requirements.

The mixture is prepared in small parts. To mix it with water, use an electric drill operating at low speeds and equipped with a spiral nozzle. The composition is applied to the surface of the rings using a sprayer, roller or paint brush. You need at least 2 layers with an application interval of 1.5 to 3.5 hours.

The second treatment begins when the first layer has not yet dried completely. The result should be a coating with a total thickness of 1.5-2 mm. A lot of material is used - about 1 kg per 1 sq. m.

For penetrating waterproofing, the following compositions are used:

- "Lakhta". Inexpensive dry mix made on the basis of cement.

- "Salmatron." The composition includes Portland cement, sand, patented active reagents.

- "Hydro S". Waterproofing coating based on mineral raw materials.

- "Penetron". A penetrating mixture that creates a barrier that prevents capillary suction of liquid.

If you treat the septic tank from the outside and inside, you will end up with a durable, sealed structure with a uniform structure.

Materials for sealing inter-ring seams

The seams between the reinforced concrete rings are the weak link of the septic tank. Most often, the first leaks appear here. For this reason, they need to be sealed. Reinforcing fabric, rubber tape seals, rubber gaskets with bentonite granules, polymer cement in combination with jute or hemp rope are used as insulators.

Water begins to seep through the seams between the rings first, so waterproofing should begin by sealing them

In the first and second cases, the insulation is effective, but it is expensive, and the reinforcing fabric must also be irradiated with ultraviolet light. Rubber gaskets are cheaper, they fill the cracks, creating a plastic layer. They are selected based on the wall thickness of the concrete rings.

Manufacturers producing penetrating waterproofing produce auxiliary mixtures. They not only seal the seams between the rings, but also seal pipe entries and repair wide cracks. They also contain high-quality cement, quartz sand of the finest fraction, and chemically active additives. They have excellent adhesion to concrete.

To seal a seam or crack, use a grinder and a hammer to make a groove along it to a depth of 2.5-3 cm and the same width. Clean it from dust and small particles, moisten it with water, and apply a primer. When the primer composition dries, fill the groove with an auxiliary composition. Afterwards, the seam and part of the surface around it are treated with the main waterproofing mixture.

Additional materials include a group designed to eliminate pressure leaks. They are characterized by rapid setting with simultaneous expansion. The surface around the leak is simply cleared, then a hole is made with a hammer drill, resembling a “dovetail” in shape.

A plug is formed from the mixture, with dimensions slightly larger than the sample dimensions, pressed forcefully into the leak site, and held until completely set.

Leaks are a common occurrence in a septic tank, so you should always have a remedy on hand to fix it.

When water stops flowing out, the cavity is primed with the main composition, completely filled with additional solution, allowed to dry, and moistened. Next, apply a 2-layer coating using the basic waterproofing mixture. If the technology is followed, the probability of a leak reappearing is 0.

Popular auxiliary compositions include:

- "Waterplug" . A hydraulic seal is used to eliminate weak leaks. Sets within 3 minutes.

- "Peneplug" . The quick-setting mixture stops the most intense leaks in 40 seconds.

- AQUAFIX . A hydraulic plug that hardens under the influence of moisture in a short time, therefore it is well suited when you need to eliminate a leak.

- "Penecritus" . Used for sealing joints and places where pipes enter the septic tank.

- MEGACRET-40 is a cement-based repair composition containing polymers. Suitable for both sealing inter-ring seams and sealing cracks. It has excellent adhesion to the concrete surface, is easy to apply, and does not shrink.

All manufacturers claim that their mixtures have a unique patented composition. In fact, their characteristics, as well as the methods for creating a protective layer, are approximately the same. The final result is influenced by how well the surface and waterproofing composition are prepared.

Waterproofing works

Hydraulic seals on a well made of concrete rings, if it is already ready, can be installed from the inside or outside. To achieve an enhanced protective effect, it is recommended to use two methods at once.

External waterproofing

The main purpose of this procedure is to eliminate the impact of groundwater on the outer walls of the well. It is most convenient to implement it at the stage of laying the rings, otherwise you will have to dig out the finished trunk manually. Sewage and inspection wells must be completely exposed, and drinking wells - 50 cm from the water level. The air temperature during work should not be below +5 degrees.

Waterproofing a well made of concrete rings from the outside is carried out in the following sequence:

- Preparing the base . To ensure that hydroseals adhere well, they are applied to a dry base. This means that the existing well will have to be drained first. Next, a careful inspection of the outer walls is carried out: they must be cleaned of dirt, salt accumulations and loose concrete. All protruding parts of the metal reinforcement of the rings are treated with an anti-corrosion compound. The joints must be widened and deepened for further installation of sealant. This also applies to detected cracks with a length of 20 mm or more.

Hydroseals must be installed at all joints and cracks Source pt.decorexpro.com

- Primer . Cleaned and dried outer walls are impregnated with primer. The brand of composition used depends on the type of well. Drinking facilities are treated with safe ready-made impregnations. A bitumen-gasoline solution is suitable for inspection and sewer shafts. The priming of the seams is carried out more carefully: they are pre-glued with a special tape sealant. Thanks to this, additional tightness of the joints is achieved.

- Aligning the outer surface of the rings . To seal cracks, differences and chips, a repair sand-cement mixture reinforced with PVA glue is used.

- Installation of a hydraulic seal . The most popular material for external protection is bitumen rolls. In this case, tar mastic acts as an adhesive: the surface treated with it is tightly wrapped several times with strips of waterproofing. The joints between individual sections of the winding are additionally treated with mastic.

- Sealing of external seams . For these purposes, special penetrating compounds are often used, before applying which the primer does not need to be used (it is replaced with plain water).

One of the options for external waterproofing can be mastic Source ko.decorexpro.com

- Completing the procedure . After waiting for the finished walls of the well to dry, they are covered with earth. A clay castle and a concrete blind area are used as recommended protection against precipitation.

Conclusions and useful video on the topic

Here you will see how active leaks are repaired:

When using any option for waterproofing a septic tank, remember that the guarantee of obtaining a high-quality, durable coating is strict adherence to the technology. Do not neglect the manufacturers' recommendations regarding both the preparation of mixtures and their application.

Would you like to share a new product or effective method for sealing a septic tank? Did you have any questions on the topic or found any shortcomings in the presented material? Please write comments in the block below.

Use of ready-made structures

To ensure high reliability of the waterproofing layer, plastic liners are used. They have standard sizes, but they are slightly taller than the rings, so the cylinders will have to be trimmed during use. Their use completely eliminates the risk of contaminated wastewater entering the soil or groundwater inside the structure.

Before installing the tabs, holes are made in them for the inlet pipes. These places are cleaned and treated with silicone sealant. The connection should not be rigid, since when the structure moves due to changes in the soil, it may crack. A jigsaw is used to adjust the cylinders to the desired height.

After the end of the winter cold, the functionality of the septic tank must be checked. It is necessary to determine whether there are holes or displacement of the concrete rings. Restoration of tightness is carried out as soon as possible.

The use of any materials to seal the septic tank from the inside will protect against unwanted consequences that are possible when wastewater gets into the soil. For maximum effectiveness, it is better to combine protection methods. Do not neglect the rules for preparing insulating mixtures, since their technical characteristics depend on this.