Recently, a lot of people wanted to equip their dachas and houses outside the city as best as possible.

Well, of course, if you are building a house outside the city, then sewerage becomes one of the key issues in this difficult matter.

Fortunately, especially for such masters of arrangement, in recent years, more and more information and methods for solving this very simple task have appeared. And, of course, to create a normal and good sewage system, if it is naturally not a dry closet in the yard, you will need to understand structures created in the likeness of septic tanks.

- 2 How does cleaning occur?

- 3 Why is ventilation needed?

- 4 How does the aeration process occur?

- 5 What is the principle of operation of the device

- 6 Self-production

Types of equipment

All septic tanks represent the same thing, although they are divided into:

- single-chamber;

- two-chamber;

- three-chamber.

And, in fact, they are an ordinary container, impenetrable both from the inside and the outside. Contaminated water from your dacha is pumped there and processed to purify it at the primary level.

Just according to the above-mentioned chambers, and septic tanks are also distinguished by size. So single-chamber and double-chamber can accommodate different numbers of drains. But whatever the design, the treatment properties still depend on the processes that occur inside the septic tanks, and with the help of which the wastewater is cleaned.

Initial conditions

aazinusFORUMHOUSE Member

The house stands on a bolt, the floating foundation is a caisson until it leaks. High water: off-season – 30 cm; in summer - 70 cm, in drought, it went up to 1.5 meters. Five people live in the house, sometimes seven. It had to be done in winter. I refused to pour concrete. In addition, pouring concrete into a swamp requires good pumps for pumping. According to calculations, the volume of discharge is 7×150=1050 liters, in total – cubic meters. Safety factor (cleaning time) – 3.5 days. The volume of the septic tank (more correctly, local treatment station, VOC) is 3-3.5 m³.

After studying the forum, aazinus chose a design scheme with aeration:

- the first cube is a settling tank;

- the second is aerated;

- the third is aerated, but weaker, so that the sludge settles.

How does cleaning happen?

Wastewater is purified due to the biologically active substances it contains.

It is these microorganisms that live in septic tanks that feed on all such pollutants.

Ultimately, everything that can harm you flies out in the form of sediment and simply falls to the bottom of the septic tank, like ordinary neutral sludge.

At the same time, there are two types of organisms in such devices:

- aerobic - those that need air to function and survive inside the septic tank;

- anaerobic - those that do not need air at all, and they can quite easily perform their functions without ventilation of the room.

Aeration system

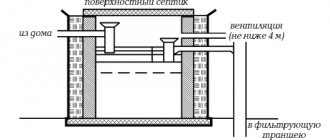

A typical septic tank consists of 2 sealed compartments. The first container accumulates waste products. The heavy dense fraction settles to the bottom. There, anaerobic bacteria take over. They process fecal deposits to form sludge. The suspended liquid flows into the second well, in which the final cleaning processes take place.

For the septic tank to function properly, there must be constant ventilation inside the device. The work of anaerobes is associated with the release of sulfur dioxide and methane. If such an amount of substance collects in a closed cavity, then there is a high probability of its rupture. In addition, these gases are toxic and explosive.

The second chamber needs additional aeration. Mostly aerobic bacteria that need oxygen work there. The delivery of this gas will increase the productivity of the septic tank and will contribute to more effective water purification.

How to deliver oxygen to a septic tank?

- There must be reliable ventilation inside the system. In homemade septic tanks, PVC pipes are brought to the surface. The first is needed to remove gases, the second to suck in air. Also, the chambers of the well are connected to each other by a separate air pipe. Such a system can be made from plastic channels intended for external sewage;

- Air can be supplied to the system using a septic tank compressor. For this, a special installation is used, which is easy to do with your own hands. We will describe its design features below;

- The easiest way is to purchase a special aerator for the septic tank. It runs on electricity, but there are models with a mechanical mode. When installed in a separate chamber, the aerator produces many small bubbles that saturate the aqueous solution and activate the liquid purification processes.

Why is ventilation needed?

In addition to the fact that these organisms cannot survive on their own, without ventilation, they also emit toxic compounds of various gases, which simply must be removed from the filter.

Thus, not only ventilation is necessary, but also aeration (oxygen saturation) of the septic tank.

Therefore, if you want your septic tank to be useful and function normally, then it is in your hands to provide it with normal aeration and ventilation of all those toxic substances that are retained in it.

For this purpose, septic tanks are often equipped with ventilation pipes, which, under pressure, remove all these gases to the outside. Moreover, it is very important that such a pipe is at least 0.5 meters above the ground.

Such ventilation allows you to remove all those substances that can harm you and clog the septic tank. Well, in order for the septic tank to function normally, it is necessary to use aerators.

You may be interested in an article about aerators for ponds and aquariums. Read an article on how to choose a septic tank for a private home here.

What can a septic tank be made from?

What can a septic tank be made from? Example of brick walls

Ready-made designs of local treatment facilities are available on the market. They are expensive, so many owners prefer to equip even an aerobic septic tank for a bathhouse with a toilet with their own hands. In this case, accessible and inexpensive materials are used. The advantages and disadvantages of the most popular of them are presented in the table.

Septic tank made of concrete rings

| Type of material | Advantages | Flaws |

| Concrete rings | low price of building material; durability; resistance to soil pressure; large volumes of rings. | the need to hire a crane and provide access for it; loss of tightness of the seams between the rings, which is especially dangerous at high groundwater levels. |

| Monolithic tank made of concrete mortar | low price; durability and strength; no seams that could become a source of leaks. | additional physical and time costs for arranging the container and drying the concrete. |

| Brick septic tank | low price; availability of material and the possibility of using used bricks. | the possibility of leaks in the seams; labor-intensive construction process. |

| Plastic tanks (Eurocubes, containers made of large-diameter thick-walled polyethylene pipes, etc.) | a light weight; the possibility of using used Eurocubes, which reduces the cost; container tightness; durability. | the possibility of floating under the influence of groundwater; less resistance to soil pressure compared to other materials; the price of the finished special container is quite high. |

Note! In Russia, a concrete base must also be made for plastic containers. After all, during the flood season they often float up under the influence of groundwater. Seasonal or permanent high groundwater level is typical for most territories of our country.

Having selected and purchased the material in accordance with the required volumes, you can begin installing the device.

An example of a septic tank made of corrugated pipes

How does the aeration process occur?

Aerators are used to distribute the oxygen that the compressor can supply to the total volume of water.

And it is in septic tanks that it is used most often.

Well, if we consider various types of aeration, from the point of view of efficiency, then the most effective is aeration with fine bubbles.

But if you want, for example, to save money, then it is not always necessary to buy a professional aerator for yourself; no one is stopping you from making it yourself. To do this, we need to understand from the very beginning how aerators work.

Materials and components

Topikstarter purchased Eurocubes cheaply - three pieces for two thousand rubles. Looking ahead, we can note that such a low price is associated with the specifics of the application - the containers were used for chemicals (raw materials for superglue), while food containers are much more expensive. The remaining contents were cleaned and disposed of (washed with gasoline/acetone/solvent on an iron tray, the drain was burned, the coals were packaged and thrown into the trash). In addition to the cubes, for a future installation aazinus bought:

- compressor made in China (3 thousand rubles);

- finely dispersed aeration elements (2 x 800 rubles);

- American load for bacteria (2 thousand rubles) - in fact, just a plastic mesh, but expensive, so I sawed it and made loads from plastic mesh for fences.

The rest of the additions - all that was left from the construction was insulation (EPS), and sewer pipes (110 mm), and other “small things”.

What is the operating principle of the device

Scheme of operation of a septic tank with an aerator. (Click to enlarge) On what principles does the aerator work:

- Under strong pressure, oxygen is pumped through any perforated materials that have a large number of pores.

- Because of this, a large number of oxygen bubbles begin to form in the liquid.

- They, in turn, begin to move under the force of Archimedes towards the water surface.

- The water begins to gradually become saturated with air.

- The air stops supplying as unnecessary.

- And after completing the entire oxygen saturation process, the pores close to prevent the entry of foreign bodies.

With such a simple diagram, it is quite easy to make an aerator yourself.

You may also be interested in an article about well water aerators. Read an article on how to make a septic tank from a Eurocube with your own hands here.

After reading this article, you will learn about the benefits of using sewage pumping stations.

Aerator for sewerage

Types and design of aerators

You can buy a ready-made aerator or you can equip it yourself. It must be resistant to corrosion as it operates in a hostile environment. It must also be reliable because it is mainly installed at the bottom of the septic tank and replacing it is not the easiest solution. Its operation should not be accompanied by constant noise, which will naturally irritate those living in the house.

Aerators can be tubular or disc shaped. The tubular model is the simplest option.

The tubular device has positive qualities:

- are flexible;

- long service life;

- minimal likelihood that the holes may become clogged;

- it has a function for maintaining the supplied pressure;

- distributes oxygen evenly throughout the medium; The material is resistant to mold formations.

The disk model is no less convenient to use.

Disk device properties:

- very durable and reliable;

- has no connection, i.e. has structural integrity;

- easy installation;

- resistant to corrosion formations;

- has maintainability;

- there is no risk that water or dirt may get into the device;

- slight decrease in pressure;

- it can be used in high-performance systems.

Making your own aerator

You can modify a conventional septic tank, manufacture and install an aerator installation yourself. This is not difficult and even an inexperienced master can do it. Moreover, there are a lot of training videos on the Internet.

Self-production

As a rule, aeration of septic tanks, if you do not want to buy expensive aerators, occurs according to this type:

- A PVC pipe is purchased, all the same as described above, 0.05 m in diameter. And in length, about one or two meters.

- A plug is inserted into one end of the pipe and a hose into the other to supply air.

- Thus, we get a homemade aerator, but in addition to this, as we remember, numerous holes are needed. They are drilled into a pipe from two hundred to three hundred, and it is very important that they are distributed evenly over the entire surface and have a diameter of two millimeters.

- And after this, oxygen is supplied to the resulting perforated material under pressure.

Watch the video in which the user shares his experience of maintaining a septic tank aerator with his own hands:

How to calculate the volume of a septic tank?

How to calculate the volume of a septic tank

The main parameter that determines the size of the tank is the required productivity or water consumption, depending on the number of residents. According to the standards, when calculating the station’s productivity, it is assumed that one person generates about 200 liters of wastewater per day. It is not difficult to guess how to calculate the consumption.

You may be interested in information - aerobic septic tank

This value must be tripled to obtain the volume of the septic tank, because the wastewater remains in it for three days. In this case, the largest one is usually the receiving chamber.

Note! Do not forget that if the house has a bathtub, dishwasher and washing machine, then the volume of the septic tank should be increased by about 20%.

Why is an aerator needed in the cleaning system?

It is this element that provides air supply inside the cleaning chamber, which increases the activity of microorganism colonies

The design of the water purification system is aimed at processing and purifying waste sewer streams from accumulations. The structure consists of a tank containing:

- pump;

- piping system.

compressor for septic tank;

It’s clear why pumps and pipes are needed, but compressors for septic tanks raise questions. But it is this element that provides air supply inside the cleaning chamber, which helps to increase the activity of colonies of microorganisms responsible for processing and decomposing waste. Compressors for septic tanks, as shown in the video, force air masses inside, accelerating the process of dissolving biological accumulations.

Selection criteria and maintenance features of a compressor for aerating a septic tank

In autonomous sewage treatment systems, biological treatment methods are often used. Biofilters can consist of anaerobic and aerobic bacteria. Aerobic microorganisms require oxygen to maintain their vital functions, which is why manufacturers of wastewater treatment plants equip their models with compressors. In addition, many owners themselves purchase additional equipment for aeration. How to choose a compressor for a septic tank? Which brand should you prefer? What is needed for normal operation of the device?

What does aeration give?

Does it make sense to modify a septic tank by installing aeration? Installing and connecting the aerator allows you to:

- significantly reduce the time of wastewater treatment and increase the efficiency of treatment;

Advice! By reducing the cleaning cycle time, you can reduce the volume of the chambers, that is, make the septic tank more compact while maintaining the same performance.

- eliminate the appearance of unpleasant odor, which inevitably spreads when using anaerobic settling tanks;

- reduce costs for vacuum cleaner services;

- The risk of contamination of water and soil with sewage is completely eliminated.

So, an aerator for a septic tank is an installation through which the cleaned environment is saturated with oxygen necessary for the life of aerobic bacteria. Modifying a septic tank by installing an aerator and connecting a compressor to it will significantly increase the efficiency of the treatment plant and get rid of unpleasant odors.

Equipment features and recommendations for selection

The main task of compressors for a septic tank is to supply air masses into the chambers

It is important to note that the devices only work when power is supplied. The main task of compressors for a septic tank is to supply air masses into the chambers, which means that the selection of models depends on the volume of the tank: in large settling tanks it is better to install several aeration devices. Such a system will allow for more thorough wastewater treatment. Most often, the system is equipped with a compressor in the septic tank, and this is a device built into the pump complex, the installation of which is not required separately.

When choosing a device for a sump tank, you need to pay attention to the following parameters:

- settling;

- fermentation;

- aerobic decomposition.

The flawless operation of the settling tank depends on compliance with these parameters. And if the first two indicators are carried out in a sealed chamber, then for the latter you need an air aerator, otherwise - a compressor for equipping septic tanks. If you immediately purchased a septic tank that does not have a compressor, then it is quite possible to retrofit the system by choosing a device based on such indicators as:

- reliability;

- resistance to aggressive environments, since compressors for septic tanks work with biological waste;

- resistance to corrosion;

- long service life;

- sufficient power;

- low noise threshold.

Expensive equipment for a sump pump in a country house will not be entirely appropriate, especially if the system is used only in the summer, so the price of the device is also important. As for the power of the device, the aerator must ensure the normal functioning of bacteria, therefore both increased and decreased oxygen supply is harmful.

The most popular models are devices from Japan. Distinguished by their versatility, Japanese compressors for septic tanks come in single and double versions. These membrane aeration systems have low energy consumption and are equipped with a silencer chamber, which allows the devices to operate extremely quietly and without pulsation. Some Hiblow brand models have a magnetic core, so such compressors for household septic tanks are installed even for home systems. The complete absence of moving parts in the equipment and the moisture-proof housing are also advantages, since the device wears out significantly less during operation and can be placed in a humid environment.

Assembly and installation of a septic tank

I cut out “windows” on the top of the Eurocubes, drilled holes for the pipes (inlet/outlet/overflow), inserted the pipes, secured them with sealant, first connected them with wire, then welded the connection to the frame of the containers. I installed the aerators on stainless steel and hung the loads in the second and third cubes. The cubes were insulated with EPS sheets as ballast between the wall and the cubes so that they would not float up during the installation process; I used sand and expired building mixture. Meanwhile, no one is talking about force majeure. I buried it, insulated it and left it until the next stage.

I continued the assembly in the spring, with the installation of the cover.

To lift the second and third sludge chambers from the bottom, aazinus made airlifts - an idea he spotted at a thematic exhibition at one of the foreign companies. I implemented it in relation to my conditions: air is supplied through a thin tube from the bottom, due to which aeration bubbles break up the resulting crust. The air rises and the silt sinks to the bottom.

Installation

Installation of a compressor for a septic tank can be easily done with your own hands. Let's look at how to do this using the example of the Hiblow model from Techno Takatsuk. It should be noted that before installing the compressor, you need to calculate the required power - this parameter depends on the required performance of the device and is determined according to individual technical parameters.

This compressor is very popular because its characteristics are suitable for the most common septic tanks (Astra, Unilos, Tank) and has excellent performance characteristics. A notable feature of the operation is the absence of moving parts in the aeration device.

- A container with a compressor is installed in the equipped drainage well. The output is connected to a separate pipe leading to the surface of the earth. This is necessary to build up pressure inside the system;

- The aerator is mounted using bolted or other available connections (they depend on the modification). Connects to the network (if you have a mechanical model powered by hydraulics, then you can skip this point);

- The compressor is covered with a lid and connected to the sewer system according to the manufacturer's instructions. After the septic tank can be sealed and the air duct started.

Periodically you will need to clean it and check for serviceability. Planned repairs are carried out every 3 years. If for some reason you cannot install the device yourself, then this service is provided by manufacturing companies and official dealers. Installation cost approximately $20.

Photo - HP-60

Video on the topic:

Common breakdowns and repairs

Compressor failure can be caused by a number of reasons:

- Frequent and sudden changes in voltage in the electrical network.

- Septic tank overflowing or flooding.

- Natural wear and tear of individual elements.

Often devices become unusable due to mechanical damage: careless removal from the septic tank before storing the system for the winter, falls, etc.

Damage to the compressor can be caused by heavy special equipment hitting the septic tank cover. In such a situation, the housing of the device, as well as other VOC elements, may be damaged.

Eliminating the negative impact of voltage surges in the electrical network is relatively simple. To do this, just install a stabilizer.

Owners of membrane compressors are forced to replace the membrane approximately once every five years, which fails due to natural wear and tear.

It is quite possible to carry out such repairs yourself by following these steps:

- Disconnect the compressor from the power supply and from the aerator.

- Unscrew the mounting bolts and remove the device housing cover.

- Remove the soundproof cover.

- Remove elements blocking access to the membrane.

- Unscrew the fasteners holding the membrane cover.

- Remove the cover.

- Unscrew the central nut.

- Remove the membrane block and disassemble it.

- Replace worn membranes with new elements.

- Assemble the membrane block and install it in its original place.

- Reassemble the compressor in reverse order.

Detailed repair recommendations and descriptions of nuances can be found in the instructions and technical data sheet of the product. For many models, special repair kits containing a set of new membranes are sold. As a tool for replacing the membrane, a regular or Phillips screwdriver is usually sufficient.

To replace the membrane in the compressor, it is necessary to disassemble the device body, remove the old membranes and replace them with new ones, and then reassemble them

Features of the functioning of homemade septic tanks

Two types of bacteria are involved in wastewater processing produced by local treatment plants: aerobic and anaerobic.

The first species can live and act only in an environment saturated with oxygen, the second exists excellently and performs vital functions in an oxygen-free space.

Treated wastewater from a septic tank, whose operation involves anaerobes, is discharged to a filtration field for post-treatment. The presence of a compressor in biological processing stations makes it possible to do without such additional filtration, because Aerobes purify wastewater up to 95%

To protect the soil from contamination by unprocessed sewage, the septic tank compartments are made airtight. Their walls not only prevent the penetration of bacteria and impurities into the ground, but also block the access of oxygen into the system.

In such conditions, only anaerobes can exist, and aerobes need to ensure the supply of vital gas.

A septic tank for the needs of a small family consists of two or three sections. In the first section, wastewater is settled, fermented by anaerobes, and mechanical filtration of the settled mass is carried out.

In the following compartments the process is repeated, but the result of multi-stage separation in rare cases reaches 65 - 70%. Therefore, the sewer system with settling tanks is supplemented with ground treatment devices - infiltrators, absorption wells, filtration fields.

To increase the degree of processing and ensure the possibility of free discharge of water from the septic tank onto the terrain, anaerobic microorganisms and their ability to digest organic matter are needed, purifying wastewater by 95-97%. Aerobic organisms require a regular supply of O2. Read more about bacteria for septic tanks below.

Septic treatment plants using aerobes have an extremely high degree of purification, especially compared to septic tanks operating on the principle of settling tanks and anaerobic digestion