When planning a bathroom design, every owner must take into account as many factors as possible regarding the color scheme, shapes and sizes of plumbing equipment. In the combination of parameters, special attention is paid to the standard height of the bathtub from the floor.

When selecting the configuration of a bathroom, its own dimensions are taken into account, and how the equipment planned for use fits into them in the form of household appliances that can be placed in it.

The main plumbing device located in the bathroom is the font itself. It should be safe and easy to use.

The standard height of the bathtub from the floor in relation to the top edge is 70 centimeters from the floor level, but there are certain tolerances. So, if young children live in the house, the bathtub can be located at a height of 60 centimeters. The same rule applies to older people.

The main criterion in relation to this parameter is to ensure safe conditions of use.

Types of baths

There is a wide range of bathtubs on the sanitary equipment market.

Each buyer can purchase a model he likes, made of steel, cast iron, acrylic, or a new sanitary ware product - a quarry product. You can also choose the bathtub volume, width and length. The choice depends on the size of the bathroom, personal preferences and financial capabilities of the consumer. The steel option is considered the most affordable. This bathtub is light in weight and does not cause problems during transportation. The use of steel as a manufacturing material allows the product to be given different geometric shapes. But the service life of such a bath is short, since it does not sufficiently withstand mechanical stress. The product does not hold heat well and makes a lot of noise.

The classic tank is a heavy tub made of cast iron. This product is characterized by reliability and durability. It does not have a wide variety of shapes, but can have an original design. Water poured into a cast iron bath retains heat for a long time. Prices for these products are several times higher than for steel products.

In recent years, the types of tanks described above have been replaced by acrylic bathtubs, which have become very popular. They are lighter in weight, but at the same time retain heat excellently. High-quality acrylic products can last at least 10 years. The height of the acrylic bathtub from the floor is standard.

The advantage of this product is a large selection of colors and shapes. But the presence of numerous intricate lines leads to a decrease in strength indicators. Since there are no pores on the surface of acrylic, pathogenic microorganisms do not multiply in such a bath.

A pleasant novelty on the plumbing equipment market is products made from the composite material quaril, which includes:

- quartz;

- acrylic;

- polymer additives.

The long service life of these baths justifies their high cost. Quaril is a hygienic material with a hard surface and resistance to ultraviolet radiation. Models made from it are heavier than acrylic products - their weight reaches 50 kilograms. The cost of quaril baths is quite high, since they are produced exclusively in Europe.

Let's talk a little about the structure and principle of operation of a jacuzzi

The times are not so far away when the presence of a jacuzzi in a house was a sign of the owner’s wealth. Today, such a hot tub is found in many homes and serves as a necessity, allowing you to relax and recuperate after a hard day at work.

Watch the video

But purchasing such a device is only the first and not the most difficult step. The main thing is to install it correctly. Naturally, you can invite an experienced specialist, but after studying the procedure in detail, you can cope with this task yourself.

The hydraulic massage bath consists of the following main elements:

- a bowl-shaped vessel, also called a font;

- hole for water intake;

- nozzles for releasing water jets and air;

- piping of the hydromassage system and aeration network;

- pumping station for pumping liquid through the hydromassage system;

- compressor for intake and pumping of air in the aeration system;

- drainage hole for transferring runoff to the sewer system;

- adjustment and control unit;

- support system with position regulators during installation;

- mixing device for adjusting the water temperature while filling the font;

- Remote Control.

The operating principle of a hydromassage device is simple - the bathtub is filled with water at the desired temperature through a mixer, and some of the liquid enters the piping of the hydromassage system.

The pump creates pressure, and the liquid bursts out of the nozzles at high speed, exerting a massaging effect on the human body.

In addition to this effect, you can turn on the aerator and get additional air action in the form of a pure stream or mixed with water. The entire process is controlled by a pneumatic or electronic system.

Modern hydromassage installations are equipped with additional functions intended for various purposes - playing music, radio, television, as well as creating color effects. Air aromatization, ozonation and other options are possible.

Standard bath sizes

When choosing a bathtub, it is important to take into account several operational factors, the main one of which is its dimensions. A bathroom of incorrect dimensions will cause clutter in the room, reduce the functionality of the room and, most likely, cause significant discomfort.

The key criterion when determining the size of the structure is whether it is comfortable to take a bath. Convenience is a highly subjective criterion that varies from person to person and depends on body type, height, duration and preferences for taking hygiene procedures. Therefore, the length, width, height and depth for bowls are in the following range:

- length varies from 150 to 180 cm;

- fixed width indicators - 70-85 cm;

- depth and height can reach 65 cm.

Bathtubs are divided into small, medium and large sizes:

- small – from 120 to 130 cm in length and 70 cm in width;

- medium - from 140 to 150 cm in length and 70 cm in width;

- large - from 170 to 185 cm in length and from 70 to 85 cm in width.

Standard bathtub sizes: no matter what calculations

In this case, you should pay special attention to several aspects on which a comfortable position in the bathtub depends:

- It is preferable that during hygiene procedures a person can take a reclining position. To do this, choose a bathtub that can accommodate your outstretched legs.

- The width of the bathtub should also be proportionate: the standard is calculated taking into account the volume of the human body and at least 5 cm to the sides on each side when a person is immersed in water.

- The depth of the bowl will differ for different designs, but the most preferred parameters are 50-60 cm. This bath depth is the standard for safely positioning the body in the water and the head above its surface.

- Bathtubs, similar in appearance, often differ in volume. This is due to the angle of inclination of the internal walls, as well as the presence or absence of armrests and sides.

- Bathtubs that exceed standard sizes not only increase water consumption and the time it takes to fill and drain, but are also considered less safe. Therefore, we recommend installing bathtubs of standard dimensions, which have been tested over many years of use.

The dimensions of bathtubs depend not only on the regulations and standards applied to them, but also on the material from which they were made.

How to choose a bathtub size

First of all, the proportionality with the bathroom is taken into account. The width of the latter should at least correspond to the largest dimensions of the plumbing fixtures plus one centimeter on each side. For small bathrooms up to 4 m², wall and corner tanks are suitable. Round ones are installed in rooms from 8 m². The relevance of the bathtub dimensions for a particular bathroom is determined by calculating the available area. The dimensions of the space for a washing machine and washbasin, toilet, if any, are subtracted from the overall indicator. The resulting result is used to determine the maximum allowable width of the bath along the protruding edges, as well as the largest area it occupies. In square bathrooms, calculating the space for the bowl will not cause difficulties, but in the case of oblong options, much depends on the placement of the sink and household appliances. The length of the plumbing will most likely have to be coordinated with the narrow side of the room.

It will be better if you plan everything in advance: if necessary, the machine can be moved to the kitchen or placed under the sink countertop.

Why is there a common standard?

Important! Recommendations for the height of the bathtub when placing it are given in SNiP (Building Norms and Rules) 3.05.01.85

.

The height of the bathtub from the floor standard means the distance from the floor to the edge of the side. SNiP (GOST) recommends installing the bathtub at a height of 60 cm. This value is calculated taking into account safety when immersing in and exiting the bathtub and is the best option when calculating the average height of a person and the height of the font. The parameter was adopted based on the fact that it is convenient for a person to raise his leg exactly this distance.

Increasing or decreasing this value can lead to discomfort and dangerous operation of the plumbing equipment. Domestic bathtub models have parameters of 150*70, foreign models have a standard size of 180*80. Both of them already have the required height of the legs, which, when installed, will correspond to the standard parameter for the height of the bathtub from the floor to the side.

Effect of materials on size

The parameters of the font often depend on the material from which they are made. Manufacturers are often limited by the capabilities of their existing equipment. Cast iron, steel and acrylic are usually used to make bathtubs.

Cast iron products are extremely popular. They can retain heat well for a long time. The disadvantage is that cast iron plumbing is too heavy. The product is installed on cast supports attached to the body. Bowls are available in three sizes:

- miniature sitting baths can have a length from 100 to 130 cm, a width of 70 cm, a depth of half a meter, the volume of such models is 140 liters;

- medium models usually reach 150 cm in length, and in width - from 70 to 75 cm, in height - half a meter, the container holds up to 170 liters of liquid;

- large comfortable bathtubs have standard dimensions (170x75 cm), height 50 cm and volume 195 liters, although there are modifications with dimensions 185x85 cm.

The most affordable option is steel plumbing. Buyers are attracted by the lightness of the models. This type of plumbing product is easy to install yourself. The dimensions of steel structures are no different from their cast iron counterparts. The longer the font, the more comfortable it is. The standard height is 40-60 cm. Steel is easier to process than cast iron, so you can find steel oval, round, corner and rectangular designs. The disadvantages include the rapid cooling of water and noise when filling the container with liquid.

The acrylic model is made from fiberglass and covered with a 3-4 mm layer of acrylic on top. A lightweight, durable box can have a length from 120 to 190 cm, a width from 70 to 170 cm, a height from 38 to 65 cm. The largest design holds 400 liters of liquid. The parameters of acrylic bathtubs do not always comply with standards. There are curved and rounded shapes of the models.

The bathtubs are secured using adjustable screw feet to special supports. Polymer sides have low thermal conductivity, so the liquid in the hot tub does not cool down for a long time. Asymmetrical acrylic modifications are in demand. Some designs are equipped with headrests and handrails. The corrugated surface of the bottom prevents slipping.

The downside is the fragility of the acrylic product, the sides are especially vulnerable. Proper installation of the bathtub can eliminate this disadvantage.

Cast iron bathtubs - advantages and disadvantages

Products made of cast iron have a particularly durable structure. They do not deteriorate from impacts and temperature contrasts. In high-quality cast iron bathtubs, the enamel layer fits tightly to the tank and does not leave pores. Enamel retains color for a long time. The coating can withstand the effects of strong cleaning agents, but abrasives are still best avoided.

The heavy weight of the products should be put first on the list of disadvantages. Bathtubs place serious stress on the flooring. The internal structure of the material makes it difficult to create unusual shapes.

Rectangle and oval are a few traditional options. Unlike acrylic containers, water cools faster in cast iron containers: literally in 10-15 minutes, although in this sense they are better than steel ones. Among other things, enamel coatings lose their integrity from impacts.

A few more positive qualities of cast iron:

- The products do not require special care or careful monitoring of their condition.

- The material absorbs noise well. The sound of falling water will not disturb those around you.

Sizes and shapes

The width of cast iron bathtubs is 70 or 75 cm - this is true for most reclining models. Sedentary bathtubs are wider than 80 cm. The largest semi-reclining bathtub had dimensions of 190x85 cm and was considered the most comfortable before the spread of Jacuzzis began. The dimensions and markings of cast iron plumbing fixtures are in GOST 18297-96. Baths made of this material are designated by the abbreviation HF. The standard model HF-1500 is considered a classic. Its length is 1500 mm, width - 700, and depth (height) from the top edge of the sides to the bottom - 400 mm. The HF-1600 modification, in accordance with the name, has a length of 1600 mm, and its remaining parameters correspond to the HF-1500 version. The HF-1700 model has a length of 1700 mm, a width of 750 mm and a depth from the top of the side to the bottom of 400 mm. The diameter of the drain holes is 52 mm.

Steel

The most economical option would be a steel bathtub. Such models are relatively light in weight - up to 30 kilograms. Also, steel baths have thin walls, the thickness of which does not exceed 3 mm.

Its length ranges from 150 to 180 cm, its width varies from 70-85 cm, the height of this model is 65 cm. The standard dimensions of a steel bathtub are indicated in the table (see the figure for designations).

| L | L1 | L2 | H | S | |

| 120 | 1200 | 550 | 1060 | 380 | 700 |

| 140 | 1400 | 550 | 1250 | 400 | 700 |

| 150 | 1495 | 695 | 1322 | 400 | 710 |

| 160 | 1595 | 770 | 1422 | 400 | 710 |

| 170 | 1695 | 840 | 1522 | 400 | 710 |

Acrylic

Acrylic bathtubs have only recently been sold on the market, but have already managed to attract the attention of numerous buyers with their positive aspects. Such bathtubs have a high heat resistance and can be installed indoors without any problems. The standard dimensions of an acrylic bathtub are shown in the following figure.

Quarilic

Quaril bathtubs stand out among other models due to their high strength. In addition, this type is distinguished by a special surface that remains clean for a long time. Such bathtubs have dimensions similar to acrylic models.

SNiP regulations regarding bath products

Installation work on equipment for this type of plumbing requires compliance with installation standards and regulations. The most important parameter is the height of the bathtub from the floor covering. According to SNiP rules, the height should be 60 centimeters from the floor, regardless of the bathroom model.

This value remains unchanged no matter where the product is installed. The bath can be placed in the center of the room or along the wall. The most important requirement when placing it must be met: leave at least seventy centimeters of space around the bathtub for free movement. According to SNiP, the threshold of a bathroom has a height of up to three centimeters.

The structures that are installed in hospitals and children's institutions have a height of 50 centimeters. The requirement to install a bathtub sixty centimeters from the floor surface is considered optional for plumbing equipment in the house. The installation may be affected by the height of the residents.

Attention! To ensure a comfortable bathing procedure, it is allowed to vary the height parameters up to 10 centimeters, down or up.

Types of baths

Modern models are presented in different materials. There are containers made of cast iron, acrylic, steel, the last type is a quaril bath. The parameters of the room for installing a bathroom bowl and the price of the container dictate the choice of product.

Types of baths:

- A steel bathtub is considered a practical, economical plumbing option. It is easy to transport due to its light weight. A bathtub made from this material can have any fancy shape. The material is inferior in terms of wear resistance because it is subject to mechanical stress on the body. The disadvantages also include the poor properties of the bathtub to retain heat and low noise insulation.

- The classic model is considered to be a cast iron container. The bathtub is reliable and has a long service life. The design does not have such a wide range, differing in shape, but there is still a variety of devices. The bathtub has high thermal insulation, but the price of the product is several times higher than that of steel.

- Acrylic structures are actively replacing bathtubs made of steel and cast iron.

They are light weight but have high thermal insulation. The service life of the container reaches twenty years. Acrylic products come in a variety of colors and shapes. Attention! The more bends an acrylic bathtub has, the less strength the product has. The surface of the material is smooth, without pores, this property allows it to resist corrosion and the proliferation of harmful microorganisms. - Modern technology has created quaryl baths.

Quaril contains quartz, acrylic and polymer substances. Attention! The additives contained in quaril enhance the properties of the acrylic material. The added substances give quaril bathtubs richer colors, shine and elasticity, and also provide a high level of sound insulation. Quaril structures are much more expensive than other bathtubs, but the expense is justified by the beneficial properties of the plumbing. The bathtub is not exposed to UV rays, is hygienic, and has a smooth, hard surface. The model weighs more than its acrylic counterparts, approximately fifty kilograms. The products are made in Europe, so the price is high.

In addition to commonly used materials, bathroom products can be wooden, made from artificial or natural stones. All devices have strictly regulated dimensions, prescribed in SNiP.

Possible deviations

Let's say right away that the height of the bathroom of 60 cm was not taken by chance. It was calculated as the optimal option for average human height and standard bowl depth. However, when installing this equipment, the issue is resolved individually, depending on the wishes of the owners and the size of the bathroom. In addition to the standards prescribed in SNiP, there is an acceptable height range. It ranges from 50 to 70 cm, by which the bath can be raised above the floor level.

Below is a list of factors that influence the optimal height of the bathroom above the floor:

- Average height of family members. There is a pattern here that the smaller the user of the bathroom, the lower it needs to be installed. It is logical that with a height of 150 cm, it will be quite difficult to throw your leg higher than 70 cm. But if a person is tall, then it will be convenient for him to use a bath located at a level of 65–70 cm so that he does not bend too low.

- Do children or elderly family members live in the premises? It is logical that old people and children will not be able to comfortably enter a bathtub whose height from the floor is 65–70 cm. Their movement is limited. Therefore, it is better to install plumbing equipment at a height of 50 cm. Tall family members will tolerate it, but for children and older people this will be an ideal option.

- The choice of height is also influenced by the depth of the bowl. If it is, for example, 50 cm, then taking into account the allocated 15 cm for installing the siphon, the minimum size by which the bath can be raised will be 65 cm. Accordingly, if you need to make a smaller distance, then the depth of the bowl is chosen smaller.

These tips must be followed so that all family members are happy with the use of the bathroom. Before you begin installing a bathtub, you should ask yourself who will be using it and what the average height of the family members is. In addition, it is important to think about the elderly and children. Another nuance is the choice of finish. But what does finishing have to do with it? The fact is that the same tiles that are used in the bathroom have their own size. To make the finish look beautiful, you should start laying it immediately at the level of the edge of the bathtub.

Does the bathtub material matter?

The modern market is full of various models of bathtubs that can be installed in the bathroom. The range is really wide. But most often, users prefer to use the following types of products:

- steel bathtubs protected by enamel;

- cast iron bathtubs;

- acrylic products.

They all differ in the material they are made from. Is there a difference at what height to install one or another option? First, let's look at the features of each type.

The heaviest and largest is a cast iron bathtub. The material itself is strong and durable, however, quite heavy. Such baths were widely used in the Soviet Union and are still popular today. It has cast iron legs fixed to the body. Thanks to its properties, it can be installed anywhere, in the center of the bathroom, in a corner or near a wall. The main feature of the bathtub is not its weight, but its ability to retain the heat of the water inside for a long time. This is an ideal option for those who like to soak in a hot bath for a long time. The only caveat is that you should accurately select the distance from the floor to the edge, since after installation it will be very difficult to correct anything. Installation option for a cast iron bath:

Note! The size of such products is standard, as is the shape, which is rectangular.

Acrylic products are a more modern option. Their advantages are light weight, ease of installation and modern, beautiful design. There are equipment of various sizes and shapes. If we talk about the disadvantages, they are low strength. If there are people in the family who are heavy, the bathtub may become deformed or crack. In addition, it is important to properly care for it in order to extend its service life. Repairing and restoring the product will be problematic. However, the bathroom itself is warm and retains heat well inside. The legs are fixed at the bottom. It is better to install the structure near the walls, since it will not be as stable in the center. Here is an example of installing an acrylic bathtub:

Important! The range of acrylic bathtubs is truly amazing. Thanks to the simplicity of production, it becomes possible to create equipment of various configurations and sizes, depending on the needs of the consumer.

Steel products are somewhere in between the weight of cast iron and acrylic options. It looks good, however, the metal makes a lot of noise during operation. It retains heat poorly, but heats up and cools down quickly. Ideal for busy people who don't need to lie in the bathroom for a long time. It is recommended to install in a corner. Example of installing a steel bath:

Basic principles of container installation

Before installation, the height of the bowl is determined based on knowledge of the height of the youngest person living in the house. The installation height is affected by the material used to cover the walls. If a tiled coating is used, then it is worth considering the tiled parameters. When installing a bathtub with a height of sixty centimeters, tiles are laid in several rows on an area with the same area, without leaving a residue.

Main installation requirements:

- Maintaining the horizontal position of plumbing fixtures. Inspection is carried out using a building level, guided by the side of the container, which is attached to the wall.

- The wall with the side of the bowl should form a right angle. Using a large triangle, this parameter is periodically checked.

Attention! The installation of the bathtub on the floor covering must be level. Next, the bowl legs are adjusted, a siphon is attached, and the drain system is set up.

Metal spacers, which are plates measuring 100 x 100 x 5 millimeters, ensure the horizontal position of the sides of the container. Installing a gasket under the plumbing supports is a prerequisite when performing installation work on a base that is softer than the screed. For example, on laminate or parquet, wood flooring.

Without metal gaskets that form rigidity under the base, the structure will sag over time.

Reference! In Russia they produce bathtubs of standard sizes 1.5 by 0.7 meters, or 1.5 by 0.5 meters. Imported products are made in a larger format, usually 1.8 by 0.8 meters.

Determining the height of the bowl of the structure ensures the normal operation of the siphon, with a built-in water seal; for this it needs a space equal to 15 centimeters.

Altitude standards and distances

The placement of plumbing fixtures should ensure:

- safety;

- functionality and comfort;

- maintainability;

- aesthetics.

Baths

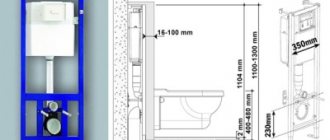

The standard bathtub height from the floor is 600 mm, regardless of size. The distance from the floor to the side of cast iron models (H1) according to GOST 18297-96 should not exceed 630 mm. The installation height of the bathtub can be adjusted using adjustable legs or pads.

Dimensions according to GOST and adjustable supports of a cast iron bathtub.

The bathroom occupies a key place in terms of size and functionality among the equipment. Produced range: 170x70; 160x70; 150x70 cm correspond to the dimensions of typical rooms.

Typical bathrooms, bathrooms

Remember: the installation height of an acrylic bathtub is determined by the frame, and this also applies to a steel bathtub installed on brick supports. The possible slope of the sewer depends on the level of the bottom of the bowl.

Compact combined bathrooms are equipped with floor-mounted shower trays. The level of the top of the side according to the current standard is 400 mm, according to the manufacturers' instructions - up to 300. Corner modifications require a minimum of space.

Minimum free zone at the front: bathtub – 100×70 cm, shower stall – 80×90 cm. Based on ergonomics, the distance to neighboring plumbing fixtures is 20 – 30 cm.

Distances and free zones

Sinks, sinks, washbasins

Mounting at a level of 0.85 m from the floor ensures comfortable use of the sink; a kitchen sink is installed in the same way. Washbasins found in dormitories, according to SNiP 3.05.01-85, are fixed at a level of 0.8 m.

Hanging models allow height adjustment during installation

The floor cabinet eliminates height adjustment. With a combined faucet, the sink is placed with an overlap of the side of the bathtub by 5 cm. The dimensions of the empty area in front of the sink with a mirror are 1.0 × 0.7 m.

The height of the floor stands is determined by the manufacturer

Toilets, urinals, bidets

For people of average height, the optimal distance from the “ground” to the top of the earthenware rim of the toilet is 40 cm. This is the standard value for floor-standing models; wall-hung toilets allow you to slightly change the value based on individual needs.

According to the standard, the installation height of a urinal should be 650 mm from the “finished floor”. It is recommended to install the bidet similarly to the toilet.

Ergonomic bidet installation

Urinal dimensions

The “finished floor level” is taken to be the top of the finished floor covering. Foreign analogue – AFF: “Above Finish Floor”.

An area of 60x80 cm is reserved in front of the devices, and gaps of at least 20 cm are provided on the sides.

Center distance between bidet and toilet

Free space around the toilet

Mixers, taps, watering cans

The fittings are placed vertically from the finished floor (mm):

- 800 – bath mixers;

- 1100 – combined taps, shower mixers;

- 2100 – 2250 – bottom of the mesh of a stationary shower head;

- 1700 – 1850 – also in cabins for the disabled.

Wall-mounted mixers are placed 200 - 250 mm above sinks and hot tubs. The shower set holder is screwed to the partition within 2000 mm from the bottom of the tank.

Location of shower fittings

Extract SNiP 3.05.01-85

Accessories

Most toilet accessories are placed in the range of 1000 – 1700 mm. Soap dishes, corner shelves for bottles, and shaving sets are mounted 200–300 mm above the side of the sink or bathtub so that they do not interfere with the user’s bending over, also in order to reduce the ingress of water. Shelves for rarely used items and household chemicals occupy the upper tier within hand reach.

The mirror, protecting it from splashes, is hung above the sink and the floor by 20, 120 cm, respectively. The upper edge is taken approximately along the border of the door - up to 200 cm. The toilet paper holder is hung at the level of 0.6 - 0.7 m, stepping back 0.2 m from the toilet.

Mirror mount

Paper holder

The minimum distance from the bottom of the heated towel rail to the floor is 0.6 m, from the top – a maximum of 1.7. The rule applies to heated towel rails - hangers, hot water supply coils; the norms for the placement of heating devices do not apply to the latter. Shower doors and curtains should not obscure the heated towel rail when opened.

Hot water heated towel rail

Anthropometry and ergonomics

Anthropometry and ergonomics

General installation rules

The height at which the bathtub is installed from the floor must be determined in advance. To do this, you need to know the height of the shortest person in the family.

The installation height of the bathroom is influenced by the type of wall cladding in the room. If it is a tile, then you need to know the dimensions of its sides. On an area of 60 centimeters you can lay 2 - 3 rows of facing material.

Correctly performed installation of the hot tub, taking into account the height at which the bathtub is installed, provides for:

- Its strictly horizontal location is controlled using a level, which is set along the side located near the wall.

- The angle between the side and the wall should be 90 degrees. Therefore, for installation, a large triangle will be required, allowing for constant verification of compliance with this condition.

To make it easier to ensure horizontal sides, metal spacers are used in the form of plates measuring 100x100x5 millimeters. Their presence under the supports is mandatory if the product is mounted on a base with less hardness compared to the screed, which can be laminate, parquet or wooden flooring.

In this case, the tank will sag during operation if stiffeners are not applied. When deciding at what height from the floor to install the bathtub, it is necessary to take into account that a siphon will be located under its bottom. For its stable operation, a free space of approximately 150 millimeters is required.

The height of the installed bath and possible deviations from the standards

In any case, the standards are not unconditional, so there may be some exceptions. For example, the optimal height of a bathtub from the floor in medical institutions is 50 cm.

So at what height should you place the bathtub in your home? In this matter, it is best to be guided by a sense of comfort, because the standard of 0.6 m is simply an indicator that professionals have determined to be the most favorable. The fact is that it is easy for the average person to raise their leg to exactly this height. But it is you who will use your bathtub, and not the average person; at what height to install the bathtub, try not to go beyond 0.5-0.7 m.

Keep in mind that not only entering, but also exiting the bath should be comfortable. To figure out what height to place your bathtub at, simply test it by stepping in and out of it several times.

The golden mean of bathroom heights

As in the case of sinks, the bathroom cannot be installed in any order; first of all, its design will not allow this. The permissible height above the floor to which a bathtub of a standard design can be raised does not exceed 70 cm; these are the technical restrictions introduced by the manufacturer for the standard for metal and cast iron bathtubs.

The reasons are quite obvious:

- Ensuring the stability of the metal structure;

- Reduces the risk of injury. For elderly and sick people, the standard height from the floor is limited to even 50 cm instead of the standard 60-70 cm.

For the same reasons, the height of the sides is limited; the most common steel and acrylic bathtubs have a side height of 47-55 cm. Acrylic bathtubs are much easier to manufacture than a steel or cast iron bathtub. Therefore, for people with non-standard height or build, acrylic models of increased sizes or non-standard heights are produced.

Features of installation of bathtubs of any design

Regardless of the material of manufacture, shape and size of the font, during installation there are a number of general rules that must be followed:

- The legs are installed on the bathtub in such a position that the siphon fits freely into the sewer pipe outlet without distortion. Before inserting it, you need to apply silicone sealant to the pipe.

- During installation, you need to ensure that the bottom slopes properly towards the drain hole. In this case, the top edge should be parallel to the floor. The slope is provided by the design of the vessel.

- When the font is located near a wall, reliable sealing of the joints is necessary. It is ensured by sealing the cracks with cement mortar and laying a border of ceramic corners. The outer seam must be painted over with moisture-resistant acrylic paint.

- Large gaps are sealed with bricks or covered with any suitable sheet material, followed by finishing with decorative materials.

- The bathtub must be equipped with grounding. It is performed with a thick copper wire or shredder. It is permissible to use steel strip.

- When using a hydromassage bath, it is necessary to lay additional communications from the electrical and water supply systems. Even at the stage of choosing such a device, it should be taken into account that for its normal operation it will require a water pressure in the network of about 4.5-6 atmospheres. If this condition is not met, you will have to worry about purchasing and using additional equipment in the form of a pump that increases the pressure in the water supply system.

Tips and tricks

Even if you have certain skills in performing construction and plumbing work, do not neglect the advice of experienced specialists.- When installing a bathtub with hydromassage, you will definitely need the participation of a professional; it will not be possible to do such work yourself.

- When configuring plumbing fixtures for a combined bathroom, you need to ensure free access to each of the fixtures.

- When choosing plumbing equipment, you should pay attention to the Ideal Standard product line. This is high-quality European bathroom equipment that satisfies any requirement. Produced in Europe and distributed throughout the world. There are practically no fakes on the market.

Watch the video

At what height should water sockets be installed?

Particular care should be taken to seal the drain hole in the floor and joints on sewer pipes.

How to install correctly

The recommendations given by SNiP also take into account other parameters. For example, the maximum threshold in a bathroom should be 3 cm. As for the placement of the bath itself, there are two most common installation options:

- in the center of the room;

- close to the walls.

In apartments, many install bathrooms near the walls. This installation is due to the small size of bathrooms. They try to install the bathroom in such a way that there are supports of three walls around it at the same time. This is the correct safe approach. Even after slipping, a person will be able to lean against the wall while maintaining balance.

In private houses and apartments with a large square area, the distance allows the use of the second placement option. Here the bathroom is installed in the middle of the room. This design solution is considered a classic option. It gives the bathroom a more luxurious and sophisticated look. However, there is a strict standard that must be taken into account.

The distance between the edges of the side to the nearest walls must be at least 1 meter. Such passages will allow you to easily walk around the bathtub from any side, without difficulty entering and exiting it. In any case, the decision about which choice to make and where to install the bathroom should be made based on the area and design of the room.

Mounting the acrylic model

Bathtubs made from acrylic are often equipped with a metal frame. It has adjustable legs, using which you can adjust the height of the acrylic bathtub with frame from the floor.

The included set contains:

- different-sized metal profiles with holes for fasteners;

- 4 support legs;

- 4 stud-shaped stands;

- 4 thrust bearings;

- self-tapping screws;

- 16 nuts.

Before installing and adjusting the height of the acrylic bathtub from the floor, the assembled frame with legs is placed in the middle of the center of the bottom of the bowl, which is located upside down on the floor. The legs are attached to the frame. Two supports are placed under the bottom, two along the wall of the room and three along the front edge.

The legs are adjustable to the desired height of the acrylic bathtub. The product is turned over and the horizontal position is checked with a level. If there are no deviations, proceed to connecting the siphon. Next, the edges of the bathtub are attached to the walls using corners or special hooks. Finally, a decorative screen is placed.

When the frame is missing, the bowl is placed on bricks, making a kind of podium out of them.

Sometimes brick columns are laid out, the number of which depends on the length of the model. The standard standard for the height of a bathroom is 170x70 from the floor and is advisory in nature. The same applies to products with other parameters. When purchasing plumbing fixtures, specific needs and circumstances are the first consideration.

Errors

The following omissions cause discomfort during operation:

- Failure to comply with recommended levels and spacing between equipment.

- Lack of unoccupied space at the front.

- Problems with installation marks of plumbing fixtures with sewerage and flooring.

- Unaccounted for blocking access, creating obstacles with doors, curtains, and rotating parts of equipment.

- Ignoring the individual characteristics of users: height, age, physical limitations.

People with disabilities.

Mismatch between bowl and niche sizes . With the right choice of type, the gaps between the cladding and the flanging are covered with a suitable plinth, otherwise you have to sew up the gap.

Grooving the partition.

Unaccounted for or excessive thickness of the finish makes it difficult to fit the bowl in the opening. The groove firmly holds the side, the tiles fit together beautifully, but replacing the product will result in damage to the tiles.

The non-perpendicularity of the lined panels leads to similar consequences if the linear dimensions are calculated without a margin. The corner pallet will have a wedge gap, the distortion will be noticeable under the curb.

Square check.

Slow water flow often occurs due to insufficient slope of the sewer outlet connected to the riser. Mud deposits partially block the cross-section of the pipe and reduce the original angle.

The optimal slope is maintained when assembling the site before installing the font. The gasket is controlled using a bubble level, laser tools or a cord stretched along the extreme marks.

Highly raised bowl . Maintaining the slope of the route with a remote riser results in lifting the structure - suffering when landing in the font. It is advisable to place the tank with the drain neck towards the riser, then the length of the pipe is minimal.

Excessive rise

Solution

The advice to raise the floor with a screed will entail an unwanted additional load on the floor, the difference in the threshold. It is preferable to lower the riser tee, but it will not be possible to implement the plan without destroying the tiles. The idea can be recommended for a shower room being renovated from scratch.

A thorough approach

the slope of the bathroom intentionally towards the drain, so that “the water flows out completely.” Don’t repeat the misconception: modern models have a bottom slope that eliminates any remaining liquid. The drainage problem is solved by proper sewer installation and timely cleaning of the system. An inclined installation is disharmonious with the finish, especially with tiles.

"Slide"

Horizontal alignment.

Container deformation . The situation is typical for acrylic and steel modifications installed on a flexible frame (supports). Don’t skimp on the frame; choose profiles with reserve.

Pliable supports for the acrylic model.

Many practitioners advise placing the container on a brick support and foaming the space between the slab and the bottom with foam. The solution guarantees rigidity, and the foam provides warmth and sound insulation. However, ventilation under the tank is disrupted, and access for cleaning the siphon and pipes may become worse.

"Floating" legs . The standard supports of budget products have a flimsy design; purchase a replacement, taking into account the connection method and the weight of the filled tank.

"Flimsy" supports.

Popular stick-on legs are inferior to classic types of fastening; adhesion strength depends on many factors. Defects in the floor surface are corrected before installation.

The lag of the curb occurs due to the movement of the bowl. The disadvantage is eliminated by increasing the rigidity of the structure, as suggested earlier. The edging is glued by filling the volume with water so that the structures assume a loaded position.

Hidden leaks . The screen is performed after completion of plumbing work. The tightness of the connections and the functioning of the drain are checked by completely filling the container. If the results are positive, stitching begins. They provide an inspection hatch, a movable or removable section.

The hatch (on the right) is not blocked. Sources

- https://kanalizaciyadoma.com/montazh/kakaya-vysota-vanny-ot-pola-schitaetsya-standartnoy-normy-i-pravila-montazha.html

- https://J.Etagi.com/ps/razmery-vanny/

- https://roomester.ru/interer/vannaya/razmer-vanny-standartnoj.html

- https://vplate.ru/vanna/razmery/

- https://o-vannoy.ru/vanny/razmery-vanny/

- https://iseptick.ru/santekhnika/vanny/vysota-vanny-ot-pola-standart-vysoty-ustanovki-avtosoxranennyi.html

- https://remont-om.ru/vannaya/vysota-vanny-ot-pola.html

- https://bouw.ru/article/visota-vanni-ot-pola

- https://santatrade.ru/skol-ko-vysota-vanny-ot-pola-standart/

What do you think of this article?

How to install, install and connect - instructions

Renovating a bathroom with replacing plumbing always requires an answer to the question – what, where and how to install it. First of all, it is necessary to resolve the issues of rational water supply and sewerage.

Next, you need to level the vertical and horizontal surfaces for subsequent finishing. In this case, you must remember to arrange slopes in the direction of the drainage grate.

The easiest way to install a bathtub is made of cast iron. Due to its large mass, it is the most heat-resistant and silent when filled with water. It must be installed strictly parallel to the floor in compliance with the installation height requirements described above.

Its significant weight can be considered an undoubted advantage, since thanks to it the bath remains stable during use and does not require additional measures to strengthen it at the site of use.

The most popular in terms of price-quality ratio are steel bathtubs with an enameled inner surface. They are much lighter than cast iron and therefore easier to install.

But their significant disadvantages are two features. The first is noise when filling with water, the second is rapid cooling due to the high thermal conductivity of the material. To get rid of such troubles, proceed as follows:

- The bathtub directly at its location is tipped upside down.

- The surface of the bottom and sides are thoroughly cleaned of dirt and degreased with acetone.

- Polyurethane foam is applied to the surface of the sides and bottom and carefully leveled.

- Polymerization of the applied layer occurs within 24 hours.

Further, if necessary, strongly protruding fragments can be leveled with a sharp knife.

This treatment of the outside of the font significantly increases its heat resistance and reduces the noise level when filling.

The weakness of the body of such a vessel due to deformation during filling and use also deserves attention and additional refinement. It is common practice to install such containers on an additional brick foundation that compensates for the load on the bottom.

In this case, the height of the bathroom 170 x 70 from the floor is standard and is 70 centimeters.

Installation instructions

Installing a bathtub is a responsible operation that is best entrusted to a specialist or performed independently under his guidance. In this case, you must adhere to the following rules:

- In accordance with the requirements of SNiP, the bathtub must be installed on a perfectly flat horizontal surface. The load-bearing characteristics of the finishing material of the floor must correspond to the weight characteristics of the font plus the mass of poured water. In particular, for cast iron vessels it is better to use porcelain stoneware tiles.

- To protect the bathtub during installation, it is installed last, when the main finishing work has already been completed.

- It is necessary to determine in advance its location, including the design of the supporting device. The installation method is taken into account - on a foundation, a metal frame or directly on standard legs.

- In some cases, when using a metal bathtub, standard legs do not provide performance characteristics. Over time, where the legs rest on the bottom, the enamel may crack and peel. Therefore, housings made of thin metal sheets must be installed on a special support, which increases the support area.

- Of course, the standard height of the bathtub from the floor is maintained.

How to raise a bathtub?

There are basic ways to explain how to raise a bathtub higher:

- How to increase the height of a bathtub if it is less than 0.5 m? If you purchased acrylic or metal plumbing fixtures, you can adjust its height using special screws on the support. Their length varies over a wide range, so the height of the installed bath can be adjusted without problems;

- How to raise a bathtub above the floor if it is cast iron? This option is not easy, but those who know how to work with gas welding may like it. Cast iron is a heavy material. Therefore, products made from it are installed on cast non-adjustable supports, for the manufacture of which you will need:

- steel corners;

- grinder with a metal disc;

- gas welding machine.

The resulting structure must be strong and stable. Before starting work, determine at what height the bathroom will be placed. And only then start welding the steel corners cut to the required size.

- How to make a bathtub taller if it has beautiful designer legs? Under no circumstances should a beautiful designer font be hidden in brickwork or metal frames. The ideal solution to the problem would be to construct a pedestal. It will also be relevant if the question arises of what to do if the bathtub is high. Installing a font on a podium with small steps will bring novelty and creativity to the interior of any room.

Does the installation height depend on the bathtub model?

How exactly the bathtub will be installed will definitely affect the choice of the purchased model:

- With supports and a metal frame - such structures are used when installing bathtubs made of steel or acrylic. In this case, both standard values and other distances more suitable for the user can be used.

- On a brick or block podium - in this case, for the convenience of immersion in the bathtub, it is possible to install an additional step so as not to violate the standards adopted for installation.

- On legs - this type of support can be solid or adjustable, no more than 20 centimeters long.

Preparation of the foundation according to SNiP

The document provides for maximum quality during preparatory work. For example, if floors are planned on the ground, then according to SNiP it is recommended to remove the top fertile layer of soil and then fill the resulting pit with gravel and sand. The most optimal layer thickness should be observed - according to the regulations, it should be from 20 to 50 cm, depending on the conditions.

“Pie” option for floors on the ground.

This bedding is done in layers. Each layer has a thickness of 10 to 12 cm and is recessed. It is necessary to carefully compact the layers - this requires the use of special electrical, mechanical or manual tools.

If the soil is sufficiently porous, it is removed and replaced with bulk substrate materials. In soils that do not have stable indicators in terms of density and bearing capacity, the concrete base should be made from cement grades from B20 to B40.

Fill the base in parts. In this case, the strip should be up to 4 meters wide. It is recommended to fill the seams that will form between such strips with special means.

Thermal insulation materials are placed on top of soil or concrete rough foundations. The standards for this provide for bulk mixtures, such as expanded clay or perlite. In addition, the use of board materials such as polystyrene is allowed.

For bathrooms, SNiP provides for mandatory waterproofing, which is 150 mm or more for each wall. Waterproofing is also provided in any rooms with high humidity.

If it is necessary to level the base, the use of a screed is recommended. For their arrangement, SNiP data should be taken into account. Thus, for concrete floors the layer thickness is provided from 30 to 50 mm. As for tolerances, a slope of 2 mm per 2 m of screed length is allowed. This is an acceptable deviation.

Features of installation work when installing a cast iron bathtub

The parameters with which cast iron plumbing fixtures will be installed are selected before its installation, because the weight of the structure will not allow you to adjust the height after completion of the work. The bathtub has monolithic supports, which may differ in different designs. The legs are attached to the bathtub using metal wedges or tie bolts. These items should be included with the bathtub.

Attention! For the bathtub to become a decoration of the room, it should be installed in the middle of the room.

If you intend to install the container using non-adjustable stands, then their size must be adjusted by cutting and sanding. The floor surface for the device equipment must be made of durable material and level. If necessary, metal spacers are placed under the support legs; their circumference should be at least five centimeters, and their thickness should be at least five millimeters.

To prevent the container from slipping on the coating, the legs are lubricated with waterproof glue for polymer materials. If it is possible to adjust the height of the legs by twisting, this means screwing in the screws to the required size, then tightening them with nuts. The structure must be leveled based on one side and end, using a level. If it is necessary to adjust the height of the legs after installation, the bowl is moved by tapping. The manipulation is carried out with the legs closest to each other.

Attention! When connecting a cast-iron bathtub to a steel water supply, be sure to provide the plumbing equipment with grounding. This type of work should be entrusted to a professional.

To carry out grounding work, modern devices have an eyelet for connecting a wire. Previously, containers were grounded naturally, because the structure was connected to a cast iron pipeline. Today, plastic is used instead of cast iron; grounding must be done with your own hands. To do this, you need to drill a hole in the place where the bottom of the bathtub is attached to the support.