Septic tank flotation

Septic tank flotation

In order to live comfortably in a country house or on a summer cottage on a permanent basis, your home must be equipped with a full range of amenities that you are used to using in a city apartment. In the vast majority of cases, autonomous local heating and sewage systems are built in country houses. In addition to the reliability and efficiency of such systems, the efficiency of life support systems also plays an important role. Thus, an important element of saving operating costs of country houses is the design and construction of autonomous wastewater treatment systems, the so-called septic tanks. After treatment in such equipment, wastewater can be reused. For example, for watering the garden or washing the car, which brings significant savings to the budget. One of the representatives of autonomous cleaning systems is the flotation septic tank.

Septic tank flotation

Characteristics of the treatment plant

The first stage of wastewater passage is its settling and division of fractions into small and large. Large particles settle to the bottom of the chamber, and light-weight suspensions are sent to the second treatment tank, where the remaining waste decomposes under the influence of microorganisms - anaerobes. After decay, the waste forms activated sludge, which lies on the bottom and requires timely cleaning with its further use as fertilizer in planting fields. In the third chamber, the cleared liquid, flowing out of the septic tank, enters the filtration field, after which water purification is completed.

Model range: technical features

Flotenk septic tanks are two- or three-section (depending on the modification) containers with holes in the upper part for the necks and in the end walls for the inlet and outlet pipes.

Housings for septic tanks are made of waterproof composite material – polyester fiberglass. It consists of polyester resins and glass-reinforcing components.

Flotenk STA treatment facilities, in addition to fiberglass tanks, are equipped with:

- 160 mm cuffs (for fastening necks);

- 100 mm cuffs (for mounting pipes);

- PVC outlet;

- technical passport;

- recommendations for the use of bioenzymes (if the installation technology provides for their use).

Flotenk STA with a volume of 1.5 m³

Septic tank Flotenk STA - 1.5 is the lowest-power unit of the entire model range. It consists of a one-piece two-section body.

The unit simultaneously carries out mechanical and biological wastewater treatment with the participation of anaerobic microorganisms. The cleaning process occurs in the following sequence:

The wastewater flows by gravity through the inlet pipe into the primary settling tank (section A). At this stage, the liquid settles. Solid components settle to the bottom of the chamber, fatty components collect on the surface in the form of a film (over time they turn into a crust), and water remains in the middle part.

Simultaneously with mechanical settling, biological anaerobic processes occur in section A. They are launched as a result of the vital activity of a special type of bacteria, for which the best living conditions are an oxygen-free environment.

As a result of fermentation, biological substances (proteins, carbohydrates, fats) break down into methane, carbon dioxide and hydrogen.

- From the primary settling tank, partially purified liquid flows through the blocker holes (located in the middle part of the tank, below the greasy film, but above the solid sediment) into section B. In this chamber, wastewater treatment by anaerobic microorganisms and mechanical settling continue.

- From chamber B, the wastewater is sent through the outlet pipe for post-treatment to the filtration fields.

In the product data sheet, the manufacturer provides a table of the main technical indicators of wastewater quality before and after treatment in Flotenk STA septic tanks.

Table: characteristics of wastewater leaving the Flotenk septic tank

Characteristics of wastewater with explanation of parameters according to the official website www.flotenk.ru

Flotenk STA from 2 m³

Units with a volume of 2 m³ or more have a fiberglass body divided into three compartments.

The units are presented in models of various capacities from 2 to 25 m³.

Technical parameters of Flotenk STA septic tanks with a capacity of 2-25 m³ according to the official website www.flotenk.ru

When selecting a device model, the manufacturer recommends being guided by SNiP 2.04.01-85 standards, which regulate the average water consumption per person.

The cleaning process in the installations follows the same principle as in the STA - 1.5 model. Chambers A and B act as primary and secondary settling tanks. However, these septic tanks have a chamber C, in which the final clarification of the liquid occurs. Zone B is connected to zone C by a blocker (hydraulic seal). The treated wastewater is sent to the infiltration fields through the outlet pipe from zone C.

Flotenk STA YES

The new Flotenk STA YES septic tank can be called a modified version of the two-chamber unit described above. The device works on the same principle and also has a fiberglass body. The treatment plant differs only in its increased dimensions. According to the manufacturer, a device of this capacity can serve up to 5 people.

How the Flotenk septic tank works

The Flotenk treatment facility is a conventional three-chamber septic tank that purifies wastewater due to the anaerobic decomposition of solid particles (biomass) and gravitational clarification (settling) of the liquid.

Therefore, the working area of Flotenk systems consists of the following zones:

Septic tank for a country house Flotenk

- Primary settling chambers, at the bottom of which the heaviest particles settle.

- Secondary settling chambers where smaller particles are retained.

- Chambers for clarification of wastewater, already practically free of solid particles.

The flow of wastewater between chambers is realized by integrating overflow barriers with wide channels into the working area. That is, the wastewater will enter the second chamber only after the first one is filled. And so on. And from the third chamber, the “clarified” water flows into filtration fields, where additional purification occurs before being discharged into the ground.

Anaerobic decomposition, which destroys solid particles in the currents, occurs in all three chambers. Moreover, in the first compartment, acid fermentation occurs, decomposing organic matter into fatty acids, alcohols and hydrogen sulfide. In turn, in the second and third compartments, methane fermentation occurs, decomposing fatty acids, alcohols and hydrogen sulfide into hydrogen, carbon dioxide and methane.

Additional purification in the filtration field occurs by passing wastewater through sand and gravel filters and subsequent contact with bacteria contained in the soil. And with full compliance with the construction technology of the treatment plant, almost clean water goes into the ground.

Design and principle of operation

JSC “Flotenk” supplies the market of the CIS countries with a wide range of systems for organizing autonomous sewerage with its own treatment facility. The range includes energy-dependent and independent equipment for solving various problems of private household owners.

Externally, the Flotenk septic system is a cylindrical container installed horizontally or vertically. Inside, the cavity of the device is divided into two or three sections of different sizes.

To move wastewater between different sections of the septic tank, special overflow holes are provided in the partitions.

Image gallery Photos from Treatment plants for autonomous sewerage Material for the manufacture of the body Septic tanks settling tanks of the FloTenk STA series Three-chamber design of settling tanks System of ground wastewater treatment Pit in clay soil FloTenk BIO Purit series station Manhole of the Flotenk sewerage station

The first compartment is the largest and acts as a sump. All wastewater coming from the house is first collected here.

The wastewater gradually accumulates and settles. The solid component of wastewater, as well as contents that cannot be processed by microorganisms, accumulates at the bottom.

A fatty film forms on the surface from those wastes that are lighter than water. During the accumulation of primary wastewater, the volume of the contents of the sump increases and the liquid level rises. Over time, it reaches the overflow hole, through which the liquid, partially purified during settling, enters the second compartment of the septic tank.

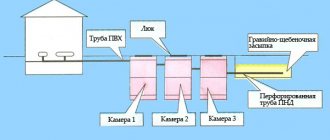

The diagram shows the structure of the Flotenk septic tank, consisting of three chambers of different sizes. In the first, wastewater is settled, and in the other two, it is actively purified (+)

Here microorganisms continue to work on treating wastewater, already freed from solid fractions. As the volume of wastewater in the second section of the septic tank increases, the liquid level rises again and reaches the overflow hole leading to the third section.

Here, the wastewater is finally clarified to a degree that is considered acceptable for the resulting liquid to be transferred into the surrounding soil. To remove liquid treated wastewater from a septic tank, it is necessary to create a special filtration field in the soil.

This diagram allows you to get an idea of the operating principles of the Flotenk brand septic tank. Wastewater from domestic premises enters the device, undergoes biological treatment and is discharged to the filtration field (+)

To do this, a series of trenches or a pit are made at a distance from the septic tank, at the bottom of which a sand and gravel filter is installed. It includes layers of sand, crushed stone and gravel. First, a layer of filtering gravel-sand backfill is laid in the trenches, on top of which a system of perforated pipes - drains - is placed.

The drainage sewer system is wrapped in geotextile and backfilled. Each branch of the filtration field is equipped with its own ventilation riser to remove the methane generated during wastewater processing.

Additional purification using such a filter will make the resulting wastewater completely safe for the environment. Moreover, the microorganisms contained in the soil aeration zone also continue the process of processing the remaining substances received along with wastewater.

A filtration field for ground tertiary treatment can only be installed in permeable soils: sand, gavia, pebble, crushed stone deposits - in rocks capable of absorbing and passing processed wastewater. In addition, there must be at least a meter between the groundwater level at the construction site and the bottom of the drainage system

At the top, each section of the Flotenk septic tank has an operational opening that provides constant access to the device. This provides conditions for the successful functioning of aerobic bacteria, and also allows gases obtained during the biological processing of wastewater to be removed from the container.

Of course, solid waste will gradually accumulate in the sump. A significant part of them will turn into neutral sludge. The more waste, the less capacity of the septic tank, i.e. its performance. The first compartment of the septic tank should be periodically cleaned using a suction pump.

Tips for choosing a septic tank

- The first thing you should do is decide what you want from a septic tank, because this is a long-term purchase and it is unlikely that you will have a great desire to change the local sewage system every year, and it will cost a pretty penny.

- If you are 100% sure that you will not permanently live on the site and will only use wastewater occasionally or periodically (seasonally), then you can take a storage septic tank, but you should not take one that is too small. Try to make an approximate calculation of the required volume of the septic tank, for example, using our calculator. According to SNiP, each person receives approximately 200 liters of wastewater per day, so proceed from this figure. But if you plan to live permanently in the near future, it is better to consider a flow-type septic tank with soil filtration.

- Before installing the container, it is necessary to check its tightness, as an unpleasant odor may appear. and to avoid flooding of the house, it is recommended to install a sewer check valve on the sewer pipes.

- Remember, by choosing the optimal size of the container, you can not overpay much for the design and not have to frequently clean the container with a sewer machine when filling it.

- It is necessary to provide access to the septic tank so that it can be pumped out without problems.

Recommendations for use

The performance of the Flotenk wastewater treatment system depends on many factors:

- temperature of liquid discharged into the sewer (10-35˚C is considered optimal);

- presence of organic components in wastewater (the more of them, the better);

- amount of chemicals (there should be as few as possible), etc.

After all, colonies of microorganisms are involved in the process of wastewater treatment. Therefore, the operation of the entire system directly depends on how favorable the conditions are for the life of bacteria inside the septic tank.

Owners of autonomous sewers must:

- monitor the load on the sewer system (both overloads and long downtimes are harmful to it);

- do not throw garbage and leftover food into drains;

- do not use chlorine-containing detergents;

- Avoid acid-based cleaning products;

- Use low-foaming powders for washing.

Recommendations for arranging a cesspool made of concrete rings

If you decide to build a storage septic tank for your dacha, then you can use reinforced concrete rings for this

To begin with, it is important to determine how many people will constantly use the system. The basis is one cubic meter per person

Thus, for a family of 3 people, 12 cubic meters of storage septic tank will be enough. In this case, natural needs are taken into account and it is assumed that there will be a washing machine in the house. Such a system will need to be cleaned approximately 2 times a year.

When storage septic tanks are installed, containers can be selected from different materials. Installation of drain pipes must be laid during the construction of the house

If the building is quite old and there is no sewage system provided, then the pipes are laid to a depth of 80 cm, and it is important to maintain the slope. The final removal of the pipes is necessary at the last stage

When deciding on rings for the sewerage system, it is preferable to purchase factory-made products. It is not recommended to use those that have already been in use. During this time they could lose their tightness. During the installation of reinforced concrete rings, it is impossible to do without special lifting equipment. This is one of the disadvantages of using such rings. After all, renting equipment will entail additional costs.

What models does the manufacturer offer?

The treatment equipment of the Triton line involves biological treatment of wastewater with additional treatment in the ground. Models differ in the volume of wastewater processed, size, and installation method.

Triton-Mini

Capacity volume – 750 l, wall thickness – 8 mm. A small, economical sump model, easy to operate and install, able to withstand severe frosts. Suitable for serving a family of 2 people.

Within two days, the Triton mini septic tank is capable of cleaning 500 liters of wastewater at maximum load (if there were 5 people living in the house). To prevent the container from becoming clogged with solid waste, it must be pumped out once a year.

Triton-Mini is an excellent option for a septic tank, the installation of which is not so difficult to do yourself

Septic tank Triton-Micro

Volume – 450 l, productivity – 150 l/s. The best option for non-permanent residence of an average family (from 1 to 3 people). Small in volume, easy to transport and install. The compact Triton micro septic tank can be used autonomously for a guest house or bathhouse. It is attractive due to its inexpensive price: a set with an infiltrator, a lid, and a neck costs about 12,000 rubles.

Triton-Micro is suitable for installation during the construction of a country house

Septic tank Triton-N

Storage capacity from 1000 l to 40000 l. Wall thickness – 14-40 mm. A good choice for owners of a personal plot with a small area (there is no possibility of equipping a filter platform), as well as a high groundwater level. The wear-resistant and durable Triton septic tank is sealed, made of polyethylene, and can serve for more than 50 years.

Triton-N septic tanks are made to order, if the ready-made model does not fit

Septic tank Triton-T

A three-chamber polyethylene tank representing a small independent treatment station. Volume - from 1000 l to 40000 l. Easily serves a large house with 1 to 20 people or more. If the Triton T septic tank is located below the infiltrator, install a drainage pump that pumps partially purified water out of it onto the filter field.

Triton-T is an excellent option for a country house for permanent residence

Septic tank Triton-ED

Volume – 1800-3500 l, productivity – 600-1200 l/s, available in horizontal and vertical shapes. The design consists of two-section modules in which water is purified from contaminants. Moving from section to section, the water is purified by 65%, then enters the infiltrator zone, and from there into the ground. The dimensions of the absorption area depend on the volume of the septic tank. The material for the production of the product - extruded polyethylene - is so durable that the Triton Ed septic tank is ready to serve for more than 50 years.

When installing a septic tank, do not forget about the access route for the sewage disposal truck.

Model overview

Modifications

Flotenk septic tanks are produced in a wide range. There are models of different capacities and designed for different volumes of daily waste. We list a few of the most popular models:

- STA 1.5 – the volume of the entire septic tank is 1500 liters, productivity is 0.5 m3 per day;

- STA 2 – the volume of the entire septic tank is 2000 liters, productivity is 0.7 m3 per day;

- STA 3 – the volume of the entire septic tank is 3000 liters, productivity is 1 m3 per day;

- STA 4 – the volume of the entire septic tank is 4000 liters, productivity is 1.3 m3 per day;

- STA 5 – the volume of the entire septic tank is 5000 liters, productivity is 1.7 m3 per day;

- STA 6 – the total volume of the septic tank is 6000 liters, productivity is 2 m3 per day.

In addition, they also produce larger models that can process wastewater from several country houses at once.

The size of the septic tank will depend on its capacity. Thus, the smallest device with a capacity of 1500 liters has a diameter of 1 meter and a length of 2.1 meters. The largest of the above septic tanks has dimensions (1.6 × 3.2 m), respectively.

Also, as productivity and volume increase, cost also increases. But still, due to the lack of electrical equipment, the price of a Flotenk septic tank is relatively low. So a device with a volume of 1500 liters will cost less than 40 thousand rubles.

How to choose the right model?

The range of Flotenk septic tanks is quite extensive, which allows you to choose a device suitable for servicing a specific home, family or even a group of houses. Septic tanks are marked with the letters STA, next to which there are numbers.

The higher the number, the higher the volume and productivity of the septic tank:

- Flotenk STA 1.5 processes 500 liters of wastewater per day;

- Flotenk STA 2 processes 700 liters of wastewater per day;

- Flotenk STA 3 processes 1000 liters of wastewater per day;

- Flotenk STA 4 processes 1300 liters of wastewater per day;

- Flotenk STA 5 processes 1,700 liters of wastewater per day;

- Flotenk STA 6 processes 2000 liters of wastewater per day;

- Flotenk STA 10 processes 3,300 liters of wastewater per day.

In addition to performance, individual models of Flotenk septic tanks differ in size, volume and, of course, price.

The cost of the device increases depending on its performance. The numbers start at about 30 thousand rubles for the Flotenk STA 1.5 model, and for the Flotenk STA 5 model you will already have to pay 90 thousand rubles.

“Flotenk” septic tanks have a fairly wide range of models, which allows you to choose the right device for almost any home, even for a small hotel

Of course, these numbers may vary depending on region, supply and demand, and other factors. It is better to find out the specific price directly from the supplier.

When choosing a suitable “Flotenk” septic tank model, you should definitely take into account its volume and dimensions, which can be:

- 1500 l, 2100 mm in length and 1000 mm in diameter for the Flotenk STA 1.5 model;

- 2000 l, 2700 mm in length and 1000 mm in diameter for the Flotenk STA 2 model;

- 3000 l, 2900 mm in length and 1200 mm in diameter for the Flotenk STA 3 model;

- 3000 l, 3900 mm in length and 1000 mm in diameter for the Flotenk STA 3 model;

- 4000 l, 3800 mm in length and 1200 mm in diameter for the Flotenk STA 4 model;

- 5000 l, 2700 mm in length and 1600 mm in diameter for the Flotenk STA 5 model;

- 6000 l, 3200 mm in length and 1600 mm in diameter for the Flotenk STA 6 model;

- 10000 l, 5200 mm in length and 1600 mm in diameter for the Flotenk STA 10 model.

It should be noted that the Flotenk STA 3 model comes in two dimensions with the same volume and performance. The buyer can choose a model that is slightly shorter and larger in diameter or a longer and narrower device. The length and diameter of the container affect the size and configuration of the pit that will be needed to install the septic tank.

The most expensive and productive septic tank model from the Flotenk STA 10 brand is so spacious that it can be used to service several houses or even a small cottage community at once. Such a device is also suitable for a large cottage with a large number of residents, for example, for servicing a private hotel or mini-hotel.

This table allows you to study the main parameters of Flotenk septic tanks in order to select the appropriate device taking into account the needs of a particular home

“Flotenk” septic tanks are selected depending on the number of people permanently living in the house. It is believed that for a small summer cottage or a family of three, the ideal choice would be the minimum performance option - Flotenk STA 1.5.

For four to five people, the Flotenk STA 2 model is suitable. For a family of six people, it is recommended to use the Flotenk STA 3, and the Flotenk STA 4 model is more suitable for a house where there are always eight residents. The Flotenk STA 5 modification is designed for use in a house inhabited by ten people. But Flotenk STA 10 can serve a building with 17 permanent residents.

When choosing a suitable model, you can use simple calculations. You should multiply the estimated number of residents by 600 liters and focus on the resulting volume. It makes no sense to take a large-volume septic system as if “in reserve” if there is no plan for a sharp increase in the number of residents in the house in the near future.

The “Flotenk” septic tank is a simple and reliable device that allows you to provide private households with an effective and very easy-to-maintain autonomous sewage system

The larger the septic tank, the higher the costs of its installation, and the more difficult it is to maintain. If it turns out later that the container is a little “small”, you will just have to order a suction pump to clean it a little more often. Considering that the Flotenk septic tank usually needs to be cleaned approximately once every one and a half to three years, this will not cause any big problems.

Sometimes a decision is made to install not one, but two small septic tanks on a site, for example, for a house and separately for a bathhouse. Such a solution can have a positive impact on the quality of biological wastewater treatment, but will require additional costs. Purchase of two septic tanks with a volume of 1.5 cubic meters. m will cost about one and a half times more than buying one device with a volume of 3 cubic meters.

The most popular is the Flotenk STA 3 model, which holds 3000 liters of waste. It is optimal in terms of volume and price ratio. Its cost is four times lower than the high-performance version Flotenk STA 10.

Advantages and disadvantages

Flotenk septic tanks are quite widely used in country houses. This is facilitated by the advantages of these devices:

- The design of a septic tank is very simple. It is easy to install and also easy to operate. The septic tank does not require any special maintenance. It is enough to pump out the accumulated residues once a year or three years (depending on the model and intensity of use).

- The entire structure is made at the factory, so all pipes and blockers are already installed in their places. The septic tank will work as it should immediately after installation. In addition, modern materials are used in production, which guarantees a long service life;

- The Flotenk septic tank does not require a power connection. This feature is very convenient for installing autonomous sewage systems in country houses of non-permanent residence.

Installation features

Model range overview

Septic tanks of the Flotenk series are available in various modifications. Every owner of a country property can easily choose a device that is suitable for his conditions. The following septic tank models can be found on sale:

- Flotenk STA 1.5 - the device is designed to serve a family of three. The septic tank is capable of processing up to 0.5 cubic meters of wastewater per day. The cost of such a product is about 30 thousand rubles;

- Flotenk STA 2 - the device is designed to serve a family of four. The septic tank is capable of processing up to 0.6 cubic meters of wastewater per day. The cost of such a product is about 38 thousand rubles;

- Flotenk STA 3 - the device is designed to serve a family of six people. The septic tank is capable of processing up to 1.0 cubic meters of wastewater per day. The cost of such a product is about 49 thousand rubles;

- Flotenk STA 4 - the device is designed to serve a house with eight permanent residents. The septic tank is capable of processing up to 1.4 cubic meters of wastewater per day. The cost of such a product is about 76 thousand rubles;

- Flotenk STA 5 - the device is designed to serve a house with ten permanent residents. It is capable of processing up to 1.6 cubic meters of wastewater per day. The cost of such a product is about 90 thousand rubles;

These models are the most popular among owners of country houses. But besides this, the company also produces more powerful Flotenk septic tanks. So you can buy a Flotenk STA 10 device; such a septic tank is capable of processing up to 3.2 cubic meters of sewage per day. This device can serve several homes at once.

Flotenk – non-volatile septic tanks

Uninterrupted operation of an autonomous sewer system is the dream of every owner of a summer house or private house. And to ensure such comfortable living, the owners need to not only properly install the sewer pipeline, but also equip the system with a storage tank for collecting waste water and feces.

A modern analogue of a sewage pit is a septic tank for sewerage - a full-fledged household-type treatment facility, presented on the domestic market in a wide range. Domestic presents to the attention of buyers cleaning systems that do not depend on power supply.

How to install?

When installing septic tanks, it is necessary to take into account that these devices do not provide complete wastewater treatment. Therefore, in addition to installing the septic tank itself, it is necessary to allocate space for a filtration field - a special system of trenches and pipes that provides additional purification of pre-clarified water.

Installation work includes the following steps:

- Digging pits and trenches. A trench 1.5 meters deep is dug from the house to the installation site of the septic tank. A sewer pipe will be laid here. The pit is dug with a margin of 0.6 meters around the perimeter to ensure easy installation of the septic tank in the ground.

- A network of filtration field trenches is removed from the pit. Each family member requires approximately 10 meters of trench. The bottom of the trenches is covered with agrofibre and filled with crushed stone to a depth of 40 centimeters.

- The bottom of the pit is being concreted. Reinforcement must be used! After the concrete hardens, a septic tank is installed. It must be secured using cables and loops already installed in the concrete base.

- A pipe is being laid from the house. It must be insulated by placing it in a special “sleeve” made of heat-insulating material, and then connected to the body of the septic tank using a fitting.

- Perforated pipes are laid on the filtration field. They are covered with agrofibre on top and covered with crushed stone.

- At the final stage of work, the pit and trenches are covered with soil and compacted. Technical pipes for pumping out sludge are first installed in the upper sockets (hatches). The upper part of the septic tank is insulated.

Installation

How to position the Flotenk

The Flotenk septic tank is installed quite simply. First, the installation location is selected in accordance with the requirements of sanitary standards. Then a pit is dug, and its dimensions should be larger than the dimensions of the septic tank itself. This is necessary for ease of use.

Particular attention should be paid to attaching the device to the bottom of the pit. As already mentioned, the septic tank weighs quite little

Therefore, if the site has heaving soils (sandy loam, loam or clay), then during seasonal soil movements it can simply be pushed out. To avoid this trouble, a concrete screed is constructed at the bottom of the pit or a reinforced concrete slab is laid. The septic tank itself is attached to it using anchors and stainless steel cables.

Septic tank installation

After installing the container in the pit, backfilling with soil begins.

Also, special attention should be paid to the insulation of the septic tank. If the device is located above the ground freezing level, then a thermal insulation layer is required

Advantages of installations

Before purchasing a Flotenk septic tank, you should get acquainted with the advantages of the model, and also find out whether the model has any disadvantages. Advantages of the models:

- The body of the Flotenk STA treatment plant is manufactured using seamless technology using industrial equipment. Thanks to this, the model has high strength indicators.

- The inside of the Flotenk STA unit has an absolutely smooth surface without protrusions or roughness; this circumstance ensures operation and cleaning.

- Flotenk STA units are non-volatile, that is, they do not require connection to a power line during installation. This allows you to operate a septic tank even in villages with unstable power supply. In addition, after the installation is put into operation, its maintenance costs will not increase.

- All connections are made using elastic cuffs, this facilitates installation work and ensures complete tightness of the connections.

Installation of a Flotenk septic tank

The installation of this septic tank is carried out on the basis of the same rules as the installation of other treatment plants. First you need to prepare a pit where the tank is located. Trenches lead to it from two opposite sides. Trenches are needed for subsequent pipe laying. When installing a sewer pipe, you need to take into account that for the unhindered passage of domestic wastewater, you will need to maintain an angle of inclination. On average it is 5 cm per 1 linear meter of pipe. If the soil freezes strongly, then the pipes are insulated. This process will be required to avoid sewer problems during the winter.

What is important to consider when installing a septic tank

Laying of the sewer pipeline can be carried out in drilled holes. The soil in the pit for the treatment tank is removed, and a sand cushion is installed at the bottom. The sand base is strengthened with reinforcement. To do this, a grid of separate sections is welded, and the finished crate is filled with concrete mortar.

A strong slab is formed at the bottom, which can withstand heavy loads. It will help the septic tank to remain motionless and not move under the influence of soil displacement. The septic tank is installed on a concrete slab. To prevent the structure from moving, you need to strengthen the septic tank with a stainless steel cable. Fastening is carried out using anchor rings. After fastening is completed, the septic tank is covered with soil that was removed from the pit. Before starting operation, water is poured into the treatment plant.

The supply pipes need to be insulated, a fan riser and upper extension necks must be installed. When installing a septic tank, an infiltration tunnel is installed, which is connected to the pipe. The infiltration tunnel under the pedestrian area is deepened by 30 cm. Under the parking area or roadway by 50 cm. Now you need to install a filtration system from several modules. Installation can be done sequentially or in parallel.

If you study the reviews about Flotenk septic tanks, then you will notice that in most cases they are positive.

Owners of septic tanks note the following advantages:

- energy independence, which allows you to use a septic tank during a power outage;

- high reliability of fiberglass, which guarantees many years of operation without changes in tightness;

- easy installation.

Of course, the Flotenk septic tank is not ideal and has a drawback. It consists in the fact that to remove the solid residue you need to turn to vacuum cleaners. The frequency of cleaning depends on the activity of using the septic tank. On average, cleaning needs to be done every 2-3 years.

Installation of a septic tank "Flotenk"

So in the FloTenk-STA septic tank there are three containers. The body of such equipment is made of high-strength fiberglass. Wastewater coming from the sewer pipeline system sequentially passes through three treatment chambers. In each of them, heavy suspended particles settle to the bottom, where the so-called “activated sludge” is formed.

Microorganisms living in such sludge carry out their life activities without the presence of atmospheric oxygen and process all accumulated organic substances. After sequentially passing through all purification chambers, water from the float septic tank can be sent to the filtration field or reused.

Septic tank installation

All cleaning sections are housed in a single housing made of durable fiberglass.

- The sewer inlet pipe fits into the first section. The first section functions as an initial settling tank, collecting coarse sludge from the wastewater. The inlet pipe in this section goes directly into the water column. Under the influence of gravitational forces, fat particles and other substances with a specific gravity lighter than that of water rise to the surface, where over time they form a crust that is removed during regular cleaning. Particles with a specific gravity less than that of water settle to the bottom, where, under the influence of colonies of anaerobic bacteria, they decompose into elemental chemical components.

- Primary purified wastewater enters the second section through a water seal. Partially purified water is further settled.

- Liquid also penetrates into the third section through the water seal. The final gravitational clarification occurs in it. The transition hole is also located below the water level, which allows water to be transferred to the second tank without floating or settling contaminants.

- After undergoing purification in the third section, the water can be directed through the drainage system directly into the ground or used for watering crops.

To ensure that the septic tank does not stop operating even at sub-zero temperatures, its upper part must be insulated. In all three sections there are colonies of microorganisms that effectively decompose organic matter even in the absence of an influx of oxygen from the atmosphere, working on the anaerobic principle.

We calculate the capacity of the Flotenk septic tank

Flotenk septic tanks are produced in various modifications, differing in the volume of water being treated. Before purchasing such a septic tank, it is very important to determine the possible maximum volume of wastewater from your home and other premises where the sewer system is used, for example from a bathhouse.

Septic tank use diagram

In general, the standard amount of wastewater is taken to be the volume of wastewater used per day by one person, multiplied by the number of permanent residents. The daily volume of wastewater has already been calculated by construction engineers according to SNiP 2.04.03.85, which determines the parameters for the construction of external sewer networks and structures and is in the range of 170-210 liters per person per day.

Septic tank power calculation

Advantages of septic tanks "Flotenk"

- Flotenk septic tanks are made from high-strength composite using industrial equipment. But they do not have seams on the body, which significantly increases their strength characteristics. There is no roughness on the internal surfaces of the septic tank, which makes it easier to operate and clean.

- This septic tank does not require connection to a power line, which significantly reduces operating costs.

- This equipment does not require constant maintenance. Depending on the capacity of the tanks, you will need the services of a sewage disposal truck maximum once a year.

- All pipelines inside the septic tank are connected using rubber seals, which ensures good tightness and facilitates installation during installation.

- Inside the Flotenk septic tank there is a water seal system, which prevents grease film from entering the next tank.

The procedure for self-installation of septic tanks "Flotenk"

Diamond foundation drilling

If you have not made a hole for the sewer drain pipe, you must first punch a hole in the wall of the foundation.

To place the Flotenk septic tank, a pit is dug manually or mechanically, at the bottom of which a sand cushion about 15 centimeters thick is laid.

Manual excavation of soil into a dump

For a more stable placement of the septic tank, a supporting foundation slab is formed at the bottom of the pit. Inside it there must be a reinforcing frame made of metal rods, the edges of which must not extend beyond the surfaces of the foundation base.

Knitting reinforcement

Installation of reinforced concrete septic tank base slab

If the walls of your pit absorb water well, then it is advisable to strengthen them with waterproofing material. Filling of cement-sand mortar is carried out with mandatory jointing or treatment with a vibrating drill in order to remove cavities with air from the thickness of the concrete mortar.

Instead of pouring a concrete base, a ready-made reinforced concrete slab can be placed at the bottom of the pit.

A septic tank “float tank” is placed in the prepared pit.

Installation of a 3 cubic meter FloTenk septic tank. m.

Backfilling a septic tank

An inlet sewer pipeline is connected to the installed septic tank.

Laying and insulation of the supply pipe

After this, a drainage riser is mounted on the body of the septic tank.

Installation of extension necks

Then the extension necks are attached.

At the final stage, a pipeline is connected that discharges the treated wastewater to the filtration field or for reuse.

Backfilling is carried out after the septic tank is completely filled with water to prevent it from being crushed by soil.

Creation of a drainage (infiltration) system for septic tanks “Flotenk”

In order to drain purified water into the ground, you can create a specialized system designed for drainage or infiltration. There are already ready-made solutions, which are modules in the form of tunnels. You can install one or more modules.

Calculation of the filter field

In order to effectively discharge treated sewage wastewater, it is necessary to calculate the size of the filtration field. You can already use some solutions that show the dependence of the filtration field value on the working volume of the septic tank.

Using ready-made modules provides the following advantages:

Ready-made modules allow them to be placed under high-load areas, for example, under a parking lot in a suburban area. They can withstand a weight of up to 3.5 tons when buried half a meter.

Drainage system

Ready-made tunnel modules are easily connected to pre-formed fasteners, which allows the formation of extensive infiltration fields. Such modules are easy to install and do not require special technical knowledge when installing them, which significantly speeds up construction work. At the initial stage of construction, finished modules can be stored on top of each other, which significantly saves space on the construction site. The modules are transported on pallets, each of which contains 40 elements, which makes it possible to form a field with a volume of 12 cubic meters.

Connecting elements allow pipelines of various diameters, with a cross-section from 10 to 30 centimeters, to be connected to finished modules.

| Model | Price | Dimensions |

| Septic tank FloTenk (Flotenk) STA-1.5 | RUB 32,215 | 1000×2100mm |

| Septic tank FloTenk (Flotenk) STA-2 | RUB 40,715 | 1000x2700 mm |

| Septic tank FloTenk (Flotenk) STA-3 | RUB 49,215 | 1200x2900 mm |

| Septic tank FloTenk (Flotenk) STA-4 | RUR 67,915 | 1200x3800 mm |

| Septic tank FloTenk (Flotenk) STA-5 | RUB 84,915 | 1600x2700 mm |

| Septic tank FloTenk (Flotenk) STA-6 | RUB 101,915 | 1600x3200 mm |

| Septic tank FloTenk (Flotenk) STA-8 | RUB 118,915 | — |

| Septic tank FloTenk (Flotenk) STA-10 | RUB 161,415 | 1600x5200 mm |

| Septic tank FloTenk (Flotenk) STA-12 | RUB 203,915 | 1800x5100 mm |

| Septic tank FloTenk (Flotenk) STA-15 | RUB 254,915 | 1800×6200 mm |

| Septic tank FloTenk (Flotenk) STA-20 | RUR 314,415 | — |

| Septic tank FloTenk (Flotenk) STA-25 | RUB 382,415 | — |

Application of a storage septic tank

Plastic storage containers

By and large, storage septic tanks are more advanced drainage pits that are completely sealed, which indicates their environmental friendliness and allows them to be used near reservoirs and water sources.

They are easy to install, light in weight, do not require additional arrangement of the site with infiltrators and drainage wells, and, as a rule, they are not affected by high groundwater levels. This all relates to their positive qualities.

Along with this, there are also negative aspects - due to the fact that there is no cleaning process in the tanks, as in multi-chamber structures, they can fill up quite quickly due to the limited capacity of the tank, which can cause some inconvenience in the need for frequent cleaning with a sewer machine. However, they will not be affected by discrete wastewater use and are energy independent.

Conclusion. Storage septic tanks are better suited as a septic tank for a summer residence. where you visit less often than as a septic tank for a private home. where you live permanently, there will be quite a lot of wastewater.

Storage containers can be made from different types of materials:

- Fiberglass storage septic tanks.

- Plastic storage septic tanks.

- Metal.

- Made from concrete rings.

Storage tanks can be equipped with tank fullness sensors - when filled to a certain level, they notify users about this. They are produced in various volumes, from 1000 to 100,000 liters.

Arrangement of infiltration fields

The design of the wastewater treatment plant is developed before installation work begins. It necessarily provides for a system of soil-based wastewater treatment.

The design of structures for soil additional filtration is selected taking into account:

- soil type;

- terrain;

- groundwater rise level;

- climate features.

The soil treatment system can be:

- Filter well. Installed in areas with sandy and sandy loam soil. This structure is usually built of brick or reinforced concrete. The bottom of the well and the interior space are filled with crushed stone. The filter backfill must be at least 0.5 m above the groundwater level.

- Absorption trench. Suitable for sandy and sandy loam soils. It is mounted from perforated pipes laid to a depth of 0.6-0.9 m. The bottom of the structure is covered with crushed stone, gravel or broken brick.

- Filter trench. Settles on low-filtration soils (loam, clay). This is a depression filled with sand or crushed stone, with a network of irrigation pipes. It is installed near natural ravines, swamps, and reservoirs in such a way that treated wastewater flows into them by gravity from the filter trench.

- Infiltration tunnel. This is a ready-made facility for soil post-treatment of wastewater, part of the product range of the manufacturer Flotenk STA. Used on different types of soil. Can consist of any number of modules. The required number of elements is calculated depending on the capacity of the septic tank and the type of soil.

Table for selecting the number of infiltration tunnels according to the official website https://www.flotenk.ru

Appearance of the infiltration tunnel

Good to know! According to the manufacturer, one infiltration tunnel with a volume of 300 liters can replace a filter structure consisting of 36 meters of drainage pipes and 800 kilograms of crushed stone.

Installation of plastic containers

Do not forget that the reliability and durability of the sewage system depends not only on the correct choice of the septic tank, but also on its installation.

Installation is possible without the use of heavy equipment, but, nevertheless, you need to know some rules for this procedure.

First, excavation work is carried out, which consists of:

- preparing the pit - it must be definitely higher than the tank being installed;

- pouring a concrete base for a septic tank;

- anchoring - for attaching special belts it is better to use stainless steel bolts;

- backfilling the sand cushion - this is done after the concrete has completely hardened (after about 2 weeks). The thickness of the compacted layer should be 20 cm.

The time when the concrete base hardens is best used for pipeline construction. To do this, you should use corrugated polyethylene pipes, which are brown-orange in color. They are intended for outdoor use and can be laid directly on a sand bed. During the construction process, do not forget to maintain a slope, which will ensure the movement of water into the plastic septic tank.

Installation diagram of a storage septic tank

The final stage of installation is the direct installation of the container. To minimize the risk of freezing, it must be buried to a depth of 1.5 m. In order to preserve the shape of the container, it must be filled with water before burying.

If the treatment station is volatile, then the electrical cable must be laid after installing and connecting the pipeline, but before backfilling the pit. It wouldn’t hurt to further insulate the container by placing sheets of foam plastic between its walls and the edges of the pit. Expanded clay can serve as insulation.

Photo: installation of a storage septic tank

If installed correctly, a modern model of a plastic septic tank will become an alternative solution for wastewater treatment. If you take all the necessary protective measures, it will not deform and will not float.

Conclusions and useful video on the topic

This video clearly shows the stages of wastewater treatment in a Flotenk septic tank:

This video allows you to get an idea of the quality of products manufactured at Flotenk factories:

The “Flotenk” septic tank is a moderately priced and reliable choice for a home, cottage or cottage. With proper installation and operation, such a device will solve the problem of waste disposal for many years.

What option and brand of septic tank did you choose for arranging your own suburban area? Tell us what was the decisive argument before making a purchase. Please write comments in the block below, share useful information and photos on the topic of the article, and ask questions.

Features of plastic containers

Today, plastic containers for septic tanks for sewerage are the most popular. This is due to the fact that containers made of polymer materials have a number of advantages over other materials.

It is worth noting that the word “plastic” is a general word for materials based on plastic. In view of this, there are several options for the material from which elements for local sewage can be made.

Polyethylene container for septic tank

But the distinctive characteristic of polypropylene is its long service life, which can exceed 50 years, and there is no need for repair work or serious maintenance.

Polypropylene container

The most expensive niche in the range of products described is occupied by fiberglass storage septic tanks. This is due to the fact that, due to their low weight, they have the best resistance to aggressive environments, as well as mechanical stress.

Fiberglass septic tank

Modern manufacturers assure that the containers are absolutely sealed and do not lose their distinctive characteristics over time. By the way, the hatches of such products have unified dimensions, which means that almost any cover will fit them.

Installation of the Flotenk treatment plant

Installing a Flotenk septic tank is not much different from installing other treatment facilities: you need to dig a large hole under the tank and connect pipelines to it on both sides. Domestic wastewater moves into the septic tank by gravity, so when laying sewer pipes, a small angle of inclination should be ensured - approximately 4-6 cm/meter. If pipes are laid in a zone where the soil freezes, you need to consider their insulation.

The sewer pipeline is laid in holes laid using diamond drilling. The soil is removed by hand, and a sand cushion is placed at the bottom of the hole.

Before pouring the sandy base with concrete mortar, it is strengthened using reinforcement: a frame connected in the form of a lattice is placed on the bottom

Prepare a concrete solution and fill the base of the pit so that a strong slab is formed. It guarantees stability and immobility for the treatment equipment.

The septic tank is installed in a pit. To ensure immobility, additional fixation is used - a stainless steel cable attached to anchor rings mounted in the base

The treatment plant is backfilled by placing the excavated soil in the pit. Before using the septic tank, pour clean water inside

The supply pipes must be thoroughly insulated, then a fan riser must be installed. The last thing to do is install the top extension necks.

Together with the septic tank, an infiltration tunnel is installed, equipped with plugs and connected by a pipeline.

The foundation pit for the filtration tunnel is dug taking into account what will be located above it. If you install it at a depth of 50 cm, then you can arrange a driveway or parking above it

The filtration system can be represented by several modules, which are located in one serial or several parallel lines.

The principle of the biological treatment used

Purification of domestic wastewater occurs gradually as it sequentially passes through all sections of the septic tank.

Contaminated water flows by gravity through the sewer pipe from the house to the first section of the structure. In order to prevent clogging, the pipe is inserted in such a way that the outlet is below the level of the drains. This compartment retains most of the contaminants: fats and films that float to the surface, and heavy particles that settle to the bottom.

The treatment tank is equipped with pipes extending to the surface - one from each section. They are necessary for pumping out solid sludge.

Oxygen deficiency is the cause of the anaerobic process, which can be divided into two stages:

- Sour fermentation. All substances, including fats, decompose until they turn into lower fatty acids (butyric, formic, acetic), alcohols, hydrogen sulfide, and carbon dioxide.

- Methane fermentation. Alcohols and fatty acids finally break down, forming hydrogen, carbon dioxide, and methane.

Having overcome the blocker, the wastewater enters the second section for further settling. The overflows are located above the level of sedimentary masses and below the fatty films floating on the surface. In this compartment, in addition to mechanical processing, anaerobic processing also continues.

The septic tank is located near the house and taking into account the fact that a separate plot of land will be occupied by an equipped filtration field

In the third section, suspended organic particles form sediment, and almost purified water flows through a pipe to the filtration field for final purification.

When installing a filtration tunnel (drainage field), it is necessary to take into account the distance to certain objects, for example, groundwater must be at a distance of at least 1 m

Design and main characteristics

The material for the manufacture of the body of the Flotenk STA septic tank is durable fiberglass. The housings of the units are manufactured in the factory under strict quality control, so there is no doubt about their tightness and reliability.

Externally, the body of the Flotenk STA septic tank resembles a regular tank, that is, it is a horizontal cylindrical container. Inside, the container is divided into three sections by partitions. Containers are produced in different volumes and, accordingly, different performance.

The lineup

Today, 7 variants of the Flotenk STA septic tank are produced. The junior model in the line is capable of processing 500 liters of contaminated liquid per day, and the total capacity of the tank is 1.5 cubic meters. The most productive model in the series can clean 3.3 cubic meters of sewage drains per day, and its total volume is 10,000 liters.

Installation diagram

There are three insulated tanks inside the Flotenk STA septic tank. During treatment, wastewater flows sequentially through all three sections of the treatment plant:

- The receiving section of the Flotenk STA installation performs the functions of a settling tank in which the largest impurities undissolved in water are deposited;

- The sediment at the bottom of the settling tank undergoes anaerobic (taking place without access to air) fermentation. Conventionally, this rather complex process is divided into two stages. At the first stage, the so-called acid fermentation occurs, in which organic matter decomposes with the formation of fatty acids, alcohols, hydrogen sulfide and carbon dioxide. Next, methane fermentation occurs, during which fatty acids and alcohols decompose to form methane, water and carbon dioxide;

- Having settled, the water, through an overflow device, enters the second section, where the process is repeated. The wastewater settles again, and particles that did not have time to settle in the first section are separated from the water. The sludge is also subjected to anaerobic processing;

- Already clarified water enters the third section; during the settling process, small particles in the form of suspensions are released from the wastewater;

- Then the water is removed from the installation and supplied to filtration platforms or filter wells.

High quality at an affordable price

Products that combine a full list of objective advantages of the Flotenk brand and are not inferior to it in either technical or technological parameters are produced by SBC. At the same time, the price of our equipment will be more interesting for optimizing estimates, which will attract the attention of the widest possible range of consumers. SBC has its own high-tech production base and accepts orders for the production of not only standard, but also unique sewerage and engineering structures that meet the most stringent international standards.

Quality can come at a reasonable price - SBC proven!

Advantages of Flotenk products

Products mass-produced under the Flotenk brand, be it the Flotenk OP desander or the Flotenk KNS complete pumping station, are a universally recognized standard of operational reliability. Its main advantages include:

- use of advanced European technologies;

- strict selection of raw materials and components;

- comprehensive quality control, not only of finished products, but also of their assemblies;

- providing operators with the widest range of related services;

- development of own research programs.

Septic tank maintenance

A septic tank with three sections needs maintenance, like any other sewer tank. Flotenk septic tanks require pumping out water and non-decomposing sediment that accumulates in the first chamber. In order for bacteria to colonize a new portion of wastewater as quickly as possible, it is necessary to leave one fifth of the sludge at the bottom of the section. Thanks to this technique, the septic tank can immediately continue uninterrupted operation.

If the septic tank is used every day, its volume is selected correctly, pumping sludge from the first section is necessary no more than once a year. Using a sewage disposal machine, this operation can be completed in 15 minutes.

After the contents of the first section have been pumped out, it must be filled with water. Thus, the septic tank is ready for use again.

If you need a long break from using the septic tank, there is no need to preserve the system.