Types of float valves

Float valves for toilets are divided according to the type of locking mechanism into the following types:

In a piston device, a floating float, when rising, presses on a piston moving towards the flow of water until it rests against the saddle. Piston locking mechanisms are already outdated; they do not have any unique design features.

The disadvantages of such devices include noise during filling and the constant sound of falling drops due to the loss of tight pressure to the inlet over time.

The membrane locking mechanism is activated by the action of the pusher on the rubber or silicone membrane. Among the advantages of membrane devices are fast water collection, less noise, and constant flow intensity. Disadvantage: good constant water pressure is required.

Filler valves for toilets in Yekaterinburg

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

An “Online Consultant” is available on the seller’s website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

What types can there be?

Before deciding how to choose fittings for a toilet, let’s try to understand what should be understood by the word “fittings”. This word should be understood as all the constituent elements that are aimed at ensuring the operation of plumbing, which includes, among other things, the toilet.

According to the functions performed, the following types can be distinguished:

- fittings that block the flow of water after the tank is filled;

- fittings that provide drainage of liquid.

Each type constitutes separate mechanisms, which, nevertheless, are closely related to each other. The latter circumstance leads to the fact that if one of them breaks down, the second one stops working too.

Useful tips

To ensure that all toilet systems work smoothly, you need to:

- periodically inspect fittings, gaskets, and supply hoses;

- promptly identify and eliminate system leaks;

- monitor and regulate the correct level of liquid in the tank;

- Periodically clean the parts of the water supply and drainage system from dirt.

Plumbing in a home is needed to provide some comfort in life. And its good operation depends only on the people themselves and on their knowledge of how to handle it. For information on how to troubleshoot the smooth operation of the toilet cistern valve, see the following video.

Types of drain mechanisms

Today you can find two types of drainage devices on sale:

- Single-mode;

- Dual-mode.

In the first case, draining is carried out by emptying the entire tank; the second has two buttons in its design - they are responsible for pouring out a certain amount of water. This volume can be adjusted; in addition, the use of such systems is completely justified, since water is seriously saved here.

Although the type of drain mechanism may be different, it operates on the same principle. A little differently, the impulse of movement occurs to the valve, which either opens or closes the hole through which the water leaves.

The principle of its operation depends on how this valve is designed. Sometimes this valve is placed at the end of tubular drains that act as an overflow. In other cases, a similar structure opens and closes thanks to special chains made of metal or plastic. The last type of design is far from the most successful, since such a system often fails.

Depending on who the manufacturer of this device is, the design can have quite significant differences. However, all these systems can be divided into two key components:

- Water drainage system;

- Water collection system.

Due to the water collection system, the tank is filled. It can be either side or bottom. If the design has a bottom feed, then they are very convenient for several reasons. First of all, the main positive side is the almost silent operation, but the design of this system is very complex.

It includes the following elements:

- Vertical rod float;

- Traction;

- Buoy.

The water supply shutoff unit begins to operate due to the traction, which is connected to the buoy into one common structure, which at the same time represents a water level limiter.

If water is supplied from the side, then this design will be more reliable, but when filling the tank it will make quite a lot of noise. Here the operating principle of the entire system will be much simpler. The tank contains a special membrane, thanks to which water flows into and stops the tank, as well as a small float connected to the supply tap using a lever.

When the tank is filled, the float rises and the lever begins to move, gradually cutting off the water supply when the required volume of water is collected.

Drain water from the tank from above or from the side. The side design is used mainly for hanging tanks, which are almost never used today. Most modern products use a drainage system with an upper water drainage principle.

As a rule, the trigger structure is a bulb made of rubber or rubberized plastic. This equipment is not too expensive, but at the same time very reliable.

In order for water to pass from the flush cistern directly into the toilet, a rod or a special button is placed on the lid, which will move the lever. As mentioned earlier, modern systems for draining water in tanks can have one or two operating modes.

The second type has two buttons, which release either half of the tank or the full one. This option is most suitable for people for whom saving water is not just empty words.

Types and design of the cistern flush valve, toilet flush design

Today it is impossible to imagine that people once lived in houses without toilets. At the same time, the bathroom must have the most modern equipment, otherwise there will be no comfort and ease of use. The central place in any toilet room is given to the toilet. The design of its drain mechanism usually differs slightly between different models. The release device deserves special attention, more precisely the device of the drain tank valve. Let's take a closer look at it; we only pay attention to it when it breaks.

Adjustment and repair

When using the toilet, problems periodically arise - sometimes it flows, sometimes, on the contrary, water does not fill into it. Sometimes, tired of the inconvenience, people buy new toilets. But in vain. Most faults are resolved in 10-20 minutes. Moreover, everything is so simple that anyone can do it. You don't have to call a plumber. You can do everything yourself.

Adjusting the water level

We will talk about devices with bottom water supply. After installation, the toilet cistern must be adjusted. By default, they come from the factory set to the maximum amount of water in the container. This amount is often excessive. With the help of simple adjustments we can reduce the volume of water in the tank. For this:

- Turn off the water supply and drain the water.

- Unscrew the button.

- Remove the cover.

- There is a plastic screw on the float mechanism. By unscrewing/twisting it we change the amount of water. If you need to reduce the amount of water, tighten the screw, lowering the float down. The next time you fill (you can turn on the water), the water level should drop.

- Reinstall the cover and button.

The same procedure is necessary if water is constantly leaking from the tank. One of the reasons is that the float is raised too high. Because of this, water flows through the overflow system.

With a side water supply and a float mechanism, adjustment is even simpler - we change the position of the float by bending its lever. On the one hand it is simpler, but on the other hand it is more difficult. You have to bend it many times to achieve the required level.

By bending the float lever we change the water level in the drain tank

Toilet tank is leaking

If the water in the toilet constantly leaks and its level is normal, we move on. There are several reasons for this leak. And if so, then the methods of elimination will be different.

- The rubber seal under the drain valve in the tank has silted up, dirt has gotten under it, and a groove (or several) has appeared on its surface. The method of treatment is to clean the existing gasket or replace it with a new one. To resuscitate the old one, you need to: turn off the water, drain it,

- remove the drain mechanism by unscrewing the plastic nut from below;

- pull out the drain valve, remove and examine the gasket, clean it of settled particles, if necessary (there are grooves), sand it with very fine sandpaper until smooth;

- install it in place, connect everything and check operation.

The trigger mechanism itself was demolished. To check whether this is the case, you can lightly press the mechanism with the cover removed. If the leak stops, that means this is the problem. If it still leaks, you should try cleaning the gasket (described above) or replacing it. If the flow stops when pressed, you can replace the fittings or make the glass heavier.

Where to put the weighting agent

To do this, remove the release mechanism and place something heavy in its lower part. This could be several pieces of metal, a sock filled with pennies, sand, etc. We install the device in place and check the operation.

https://youtube.com/watch?v=OE_lWt7Xqp8

Water does not fill

Another problem that you can fix yourself is that water does not fill into the drain tank. Most likely the problem is a blockage - the filter or tubes are clogged. It's a long story, better watch the video.

https://youtube.com/watch?v=U_6q_MFVt5U

Tank valve repair

First, let's consider the problem when the valve of the drain tank does not hold. Even when the tank chamber is completely filled, the valve continues to allow liquid to pass through in small volumes. Excessive amounts of water overflow the top of the flush mechanism and flow into the toilet. To eliminate a leak, you must perform the following steps:

- Shut off the water.

- Remove and disassemble the float fittings.

- Take a used toothbrush and clean the inner chamber of the valve from plaque, pieces of rust and other blockages.

- Assemble and install the fittings in place. Turn on the water supply and check that it is working properly.

If the leak is not eliminated, you will have to purchase new shut-off valves. There are no other repair methods, or they will be more expensive than purchasing a new part.

As a second malfunction, consider the case when the toilet cistern leaks through the valve. The reason for this is the wear of the sealing gaskets installed between the fittings and the hole at the bottom of the tank.

- Turn off the water and unscrew the nut under the tank. This will release the fittings and allow you to get them out.

- Remove and replace all existing seals. In some cases, there are two elastic bands, inside and outside. But often the seal is installed only inside. You can buy it at the market or at a specialized plumbing store.

- After installing the new rubber gasket, reassemble the fittings in the reverse order.

The third problem may be the lack of water shutoff due to the incorrect position of the float. When the tank is already filled and liquid begins to flow into the toilet bowl, the float is fixed too high. Twist the plastic rod to lower the float lower. The float pushed out by water will begin to act on the valve, cutting off the flow.

The article discussed the valve of the drain tank, the principle of its operation, its design and possible malfunctions. Repairing the inlet valve of the drain tank involves cleaning it from contaminants. If one of the device components breaks down, the owner will have to buy new fittings, since spare parts are usually not provided. Replacing rubber gaskets in devices with bottom connections will help eliminate water leakage to the outside.

How are shut-off and drain valves adjusted?

If the tank and fittings set were purchased separately, the drain and shut-off valves require adjustment: the user determines the volume of water entering the container and the installation height of the drain valve.

Adjusting the Float Stop Valve

The products are available in two versions:

- with metal lever for float. To increase the volume of incoming water, it is bent so that the float is higher. To reduce the amount of liquid, do the opposite: bend the lever so that the float is lower;

- with plastic float lever. This lever does not bend. The position of the float is adjusted with a special screw.

Usually inside the tank there is a mark for the optimal water level - you should follow it.

Sometimes it is not possible to adjust the filling level of the tank by moving the float; possible reasons:

- The shut-off valve is clogged. In this case, less water is supplied than the required volume. Having shut off the water supply to the apartment or on the branch to the tank, the valve is dismantled, disassembled and washed;

- The shut-off valve diaphragm is worn. Water flows continuously and flows through the overflow pipe into the toilet. Valve replacement required.

Adjusting the drain mechanism

It is necessary to install the bulb valve at the required height.

The procedure depends on the design and is described in the manual. When setting up a drain mechanism with a button, the button assembly is set so that it is located at a distance of 3-7 mm in relation to the lid. This ensures reliable fastening of the cover.

Then the flush button is screwed into the hole in the lid. To center the thread, first make a couple of turns counterclockwise and only then screw the element clockwise. No tools are required - just tighten by hand. The installation is completed by checking the drain mechanism.

When making adjustments, it is important to prevent the moving parts of the water filling valve and the drain mechanism from coming into contact. It is also necessary to ensure that none of the elements touch the wall of the tank

How to install new fittings

Included with the new fittings are instructions for use. First of all, let's get acquainted with the instructions.

- 1. We install a valve that regulates filling using gaskets and adapters. There are plumbing models in which the inlet and filler mechanisms are installed simultaneously.

- 2. The fittings can be inserted into the tank before installing the toilet; we place the gasket on the upper surface of the drainage system and place the device in the tank, fastening it with nuts.

- 3. Rubber gaskets are used for internal fasteners, and plastic gaskets for external fasteners. The internal gaskets can be lubricated with silicone sealant for sealing. We replace old gaskets after disassembling the device.

- 4.If possible, the gasket connecting the tank and toilet bowl is also lubricated with sealant.

- 5. The fittings must be located at a distance of at least half a centimeter from the walls of the drain container.

- 6. Having completed the installation, the tank is attached to the toilet bowl.

- 7. Close the tank with a lid by screwing on the drain button.

- 8.Connect the water and perform a test drain.

Conclusion

Now we have looked at the design of the drain valve, which is used in the toilet cistern, and the circumstances under which the equipment may fail. With this knowledge, you will be able to cope with these problems on your own. The video in this article will allow you to find additional information on the above topic.

| Exhaust | In addition, they are called stock ones. This is due to the fact that in order to activate the device, it is necessary to lift the rod up using the handle, after which the drain hole will open. New models of toilets produced recently do not have such a system. |

Setting up plumbing toilet cisterns

The completion of the assembly of plumbing does not mean the end of all work on its installation. Often the toilet cistern fittings need to be adjusted, after which the filling, overflow and flushing functions must be performed flawlessly. Also, sometimes it is necessary to adjust mechanisms during their long-term operation or replacement.

Adjusting the cistern with a button

What should you pay attention to when setting up modern “push-button” plumbing?

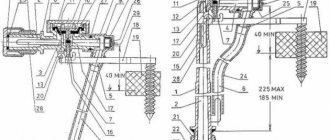

Figure No. 2

- The height of the flush valve is set (Figure 2). Its design must correspond to the dimensions of the storage container under the lid, taking into account the button (1). Disconnect the rod (2) from the latch of the overflow tube. Release the rack clamps (3) on both sides. Move the racks (5) in the required vertical direction, guided by the scale marked on them. Secure the clamps and rod in the new position.

- The height of fixation of the overflow tube is adjustable. There are two requirements for this parameter: the surface of the water in the toilet tank should be 15-20 mm below the overflow edge, but at the same time, the fully pressed button should not touch the top of the tube. To do this: Set the size of the gap between the edge of the overflow and the top (4) of the rack (5), (Figure 2). To perform this operation, you will have to release the rod (2) and the pressure ring or clamp on the tube. Lower or raise it to the required height. Fix overflow and draft.

- The functionality of the filling fittings is configured in accordance with the requirements of the previous paragraph regarding the filling volume. In order for the inlet valve to ensure the optimal water level in the cistern, the position of its float must be set. If you need to set an early cut-off of the supply, then the float is lowered lower or fixed higher if the volume of liquid is insufficient. Changing its position is carried out by rearranging the rod similar to the rod on the drain valve.

Adjusting the two-level drain

In modern push-button toilet sets, it is not uncommon to have a two-level water discharge. Such models require small and full drain settings.

Adjustment of two-button drain mechanism.

We regulate the discharge of the entire volume of liquid by using a damper, increasing this parameter, moving it down and, decreasing, moving it up. The partial discharge of water is set by a small flush float, which, after opening the lock, we move down or up, respectively increasing or decreasing the flow rate.

You can learn more about adjusting the two-button release mechanism from the video:

Adjustment of old models

In conclusion, it is worth mentioning the adjustment of “classic” systems with lateral water supply. The design of an old-style toilet cistern involves only adjusting the inlet valve.

Its work depends on the position of the float, which is lowered or raised. For this purpose, if the rocker arm is brass (steel), then it is simply bent into the desired position, and if it is plastic, then the geometry of the lever changes after loosening and then tightening the mounting screw.

Adjustment of the overflow and exhaust valve is not provided in such models, and problems arising with them, as a rule, lead to repair work or complete replacement of the mechanisms.

How to choose a valve

The main characteristics that you need to pay attention to when looking for fittings:

- suitable tank height;

- parameters of the connection hole for the inlet valve, drain hole and hole in

- reservoir cover for the start button.

If the diameter for the start button is not suitable, in some cases the problem is resolved by lining the adapter ring.

Plumbing fixtures with an inlet valve for a toilet with a bottom supply, due to the inconspicuousness of the supply hose of the plumbing system, look more aesthetically pleasing.

Other advantages of such models include reduced operating noise. In a device for a toilet cistern with a side water supply, the mounting hole is located above the filling level of the cistern, so there is less chance of leakage.

The choice of drainage method is determined by the requirements. Touch and single-mode pressure devices are usually installed in public places with high traffic, where the main importance is given to regular flushing and good flushing of the toilet bowl, rather than saving water consumption. For apartments, models with two modes or a “stop” function are more suitable.

Drain mechanism device

The tank fittings include two components:

- water supply valve;

- flush mechanism for flushing water into the toilet.

The fittings can be separate or combined.

Separate fittings

This is the most common option. Both components are not connected to each other. At the entrance to the tank, a valve with a membrane is installed, connected to a lever with a float at the end. When the water rises to the desired level, the float will be at the same level and the membrane will block the flow area of the valve. The drainage mechanism is a vertical rod with a bulb valve at the bottom.

By lifting the rod by the handle (outdated version), the user removes the bulb from the saddle and opens the drain hole. In modern models, this requires pressing the button at the top. The most practical version of the drain mechanism has a double button: one part empties the tank only half, the second completely.

The bulb valve is made of buoyant material, therefore, after being removed from the seat, it is held in the body of water and does not block the drain hole. After the tank is emptied, it falls back onto the saddle and, when the tank is filled, remains in this position, since the water presses on it only from above.

Advantages of the solution:

- low cost;

- ease of adjustment;

- cheap repairs: if damaged, only the failed component is replaced.

Combined reinforcement

This is a more expensive option, used in luxury plumbing fixtures.

Both components are combined into one system. The advantage is significant reliability. Disadvantages: high cost both in purchase and in repair - if it breaks down, you have to replace the entire complex. The design of the fittings depends on the method of supplying water to the tank - from the side or from below.

But the adjustment of both options is carried out almost identically.

Intake valve mechanism

The inlet fittings in the tank have their own operating principle, which should be understood before proceeding with its replacement or repair. Let's consider the phases that replace each other in the process of moving water to the tank.

So, the first phase is characterized by the fact that the valve is in the open position. At this time, water is drawn into the tank. The membrane, following the direction of water flow, moves away. This means that water can easily flow into the tank.

The mechanism of operation of the drain device

At first, water fills only the preliminary compartment. To allow water to enter the tank itself, a special hole is provided in this compartment. This process is very similar to what occurs in devices equipped with valves with a stem, but here there is a membrane that is stretched over the piston. The membrane has a lumen through which a plastic rod passes, which also has a 1 mm diameter lumen. Due to this, some of the water enters the filling compartment. It is formed by the membrane itself and the piston.

If the float is lowered, a small hole opens in the piston, only about 0.5 mm. Through it, a small part of the water can enter the tank. Thanks to this mechanism of action of the diaphragm valve, the same pressure is ensured in the preliminary compartment, in the filling compartment and behind it. This is the difference between this design and the one that has a valve with a stem.

The second phase is when water splashes into the tank and at the same time raises the float up. Along with it, the level of the rod with a rubber seal increases. The seal closes the hole. With further movement of the rod, both the piston and the diaphragm will be pressed against the seat. This seals the filling compartment.

Due to the fact that the pressure from the water in the filling compartment adds up to the pressure of the float, which rises, the membrane is tightly compressed with the seats. And this, in turn, stops the supply of water to the tank.

Flushing the toilet

The third phase is the release of water. When the water comes out of the tank and splashes into the bowl, the pressure of the float on the rod stops. The hole in the piston is no longer closed by the rod, so the pressure in the filling compartment decreases. It remains only from the water supply network; it is this that acts on the membrane and the piston, moving them to the side. As a result, the mechanism goes back to the first phase.

Types of drainage system

In addition to the internal configuration, the shut-off valves of the flush tank differ significantly in the material of manufacture, which affects the quality and service life of the toilet itself.

Material options for the production of toilet fittings:

- Plastic: Due to the low cost and availability of the material, polymers have rapidly conquered the market in absolutely every industry. However, plastic is a fickle material; the quality and durability of the components, as well as the direct operation of the drainage system, depend on its composition. Previously, the quality of shut-off valves could be judged by the cost of the product itself, however, today there are too many new young manufacturers on the market offering high-quality products at low prices. And established well-known brands allow defects, which leads consumers to doubts. Therefore, today it is very difficult to distinguish reliable toilet fittings from fake ones. Unfortunately, this difference is revealed only during the operation of the toilet.

- Metal: a material that provides high strength and significant service life of shut-off valves. To produce drain systems, modern manufacturers use brass and bronze compounds, because they are truly resistant to mechanical damage and the effects of water. The fittings of the cistern, made of similar metals, do not corrode for several years, maintaining all functional qualities. Metal shut-off valves are typical only for expensive models produced in the appropriate style.

As practice shows, toilets with plastic fittings are in greatest demand, which is understandable. Affordable cost and the ability to repair at any time determine our choice.

The cistern fittings are the basis for the operation of the entire toilet. Water is supplied in two ways: side or bottom. Side water supply is characteristic of our domestic plumbing and is characterized by rather high noise. The lower water supply is much quieter than the upper mechanism.

Before you begin repairing a toilet, you need to familiarize yourself with its design.

Both with side and bottom water supply, the valve closes under the influence of a control rod connected to the float. A float is a kind of plastic container or a small foam element.

Regardless of the type of water supply, the float is carefully balanced during installation of the fittings. Such work is necessary for the efficient and reliable operation of the cistern, which directly depends on a certain water level in the system.

A few words about the design of the tank fittings

Before I tell you why a toilet tank may leak, I will introduce you to the design of the fittings so that you understand the principle of its operation.

Of course, there are currently a great many options for mechanisms.

However, the principle of operation of the tank always remains the same, since any fittings include three main elements:

shut-off mechanism - is a tap that automatically shuts off the water as it enters the tank. The float is responsible for the water level at which the shut-off valve is activated;

Tank fitting options

- discharge system - is a valve that closes the drain hole. The valve is controlled by a button or lever;

- overflow system - prevents flooding of the apartment in case of failure of the locking mechanism. If the water in the tank rises above a certain level, the overflow system ensures that it is drained into the toilet.

Features of the tank

The mechanism for draining water from the tank is of two types. In the first, all the water is drained when you press a button or when you lift the handle up. The first option provides two buttons for rational use of water. When you press one of them, the water is partially drained, and using the second you can remove all the water from the tank.

If the flush works normally, then water flows into the toilet bowl quickly and without delay with a characteristic sound. If problems arise, the flow of water either does not stop and the walls of the toilet are constantly wet, or the water overflows from the tank.

This kind of breakdown can cause flooding of the toilet room, or provoke the formation of limescale on the walls of the toilet and, undoubtedly, lead to high water consumption due to its constant supply. Another sign of a malfunction may be the appearance of condensation on the cold water pipe that leads to the toilet.

Sometimes, to eliminate a leak, it is enough to clean the tank and parts from plaque and rust. They appear due to poor quality water and failure to follow simple plumbing hygiene rules.

To avoid further problems and eliminate the leak, it is important to find out the cause of the leak and determine in which part of the tank the breakdown occurred and check all the parts. To do this, you need to turn off the water in the riser, then clean the tank and study the design

Flush design device

If previously the tank body was made of cast iron, today ceramics, earthenware or special plastic are used. All the main elements of the tank are connected to each other.

There are only three key mechanisms: inlet, adjustable float, flush and overflow systems:

- The inlet or fill valve stops the flow of water into the tank after it is filled. The required water level is “measured” by the float.

- Locking or drain mechanism. This is the flapper/valve that opens during flushing.

Modern models have buttons for this. They can be single or double to adjust the amount of water flushed. Old Soviet toilets use a chain, lever or rope that is attached to a lever with a bulb. These elements are connected by traction. And the pear is at the bottom of the tank.

The standard tank design is quite simple. In some models, the flushing mechanism consists of a siphon. Its membrane is the weak link and often fails, as do the spokes connecting the flush and the float

The toilet float regulates the operation of the locking mechanism and controls the level of water drawn in, the design of which depends on the type of water supply to the tank (bottom or side).

There are several types of floats, but each one has air inside:

- The first, hollow, is made of rubber. It is located at the bottom of the reservoir and functions as a rocker arm.

- The second, plastic, glass-like float. Located at the top of the tank. When the tank is filled with water, it rises up and works almost silently. The latter type is used only in older models; the first type is installed in modern toilets.

The overflow system protects the entire toilet room from flooding if the filling mechanism does not work for some reason. When more than normal water gets into the tank, it is the flush tank fittings that drain it into the toilet. If you find a leak, then do not panic, but remove the toilet lid and figure out what the problem is.

Design and operating features

A modern check valve has a durable hexagon-shaped body, the inside of which is divided into several separate compartments: a receiving compartment, a limiter with reliable fixation of the shut-off unit and the function of a small inspection window, as well as an outlet compartment.

The receiving area is located directly in front of the locking mechanism, which connects the entrance to the product with the sewer. A special limiter is necessary for the free movement of the drained liquid in only one direction.

If water begins to move in the opposite direction, the device closes instantly. The outlet compartment is needed to quickly remove waste from the restrictor section, therefore it is considered a connecting element between the mechanism and the outgoing circuit.

The operating principle of the check valve is based on shutting off the pipeline using a shutter mechanism. This occurs when the free movement of waste along the circuit completely stops.

A working sewer check valve works like a clock.

The device equalizes the pressure in the system, and the constipation due to gravity closes the pipeline and closes the valve.

The device is controlled mechanically or automatically. The nominal size of manufactured devices ranges from 50 to 300 mm. Due to its design features, the device can be mounted at a specific junction of two horizontal or vertical pipes. It is also connected to the main riser or to each drain of plumbing mechanisms.

If apartment owners are bothered by unpleasant odors, they need to take care of installing a ventilation valve for the sewer system.

Types of fittings for flush cisterns

The principle of operation of a regular tank is not complicated: it has a hole through which water flows and a place where water is discharged into the toilet. The first is closed with a special valve, the second with a flap. When you press a lever or button, the flap rises and the water, in whole or in part, flows into the toilet, and then into the sewer.

After this, the valve returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens a hole for water to enter. The tank is filled to a certain level, after which the inlet is closed. The water supply and shut-off are regulated using a special valve.

The fittings for the flush tank are a simple mechanical device that allows water to be drawn into a sanitary container and drained by pressing a lever or button.

There are separate and combined designs of fittings that collect the volume of water required for flushing and drain it after activating the flushing device.

Separate and combined options

The separate option has been used for many decades. It is considered cheaper and easier to repair and configure. With this design, the fill valve and damper are installed separately, they are not connected to each other.

The shut-off valve for the tank is designed in such a way that it is easy to install, remove or change its height

To control the flow and shutdown of water, a float sensor is used, in which sometimes even a piece of ordinary foam is used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to lift the damper or open the valve. This is a typical option for retro-style models, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with double buttons have been very popular, which allow you to empty the tank not only completely, but also halfway, in order to save some water.

The separate version of the fittings is convenient because you can repair and configure individual parts of the system separately.

Combined type fittings are used in high-class plumbing; here the drain and water supply are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks down, repairs will require completely dismantling the system. Setup can also be a bit tricky.

The fittings for a toilet cistern with side and bottom water supply differ in design, but the principles of setup and repair are very similar.

Materials for making devices

Most often, toilet fittings are made of polymer materials. Typically, the more expensive such a system is, the more reliable it is, but this method does not provide clear guarantees. There are also counterfeits of well-known brands, as well as quite reliable and inexpensive domestically produced products. The average buyer can only try to find a good seller and hope for luck.

Fittings made of bronze and brass alloys are considered much more reliable, and such devices are much more difficult to counterfeit. But the cost of these mechanisms will be significantly higher than that of plastic products.

Metal filling is usually used in luxury plumbing fixtures. With proper configuration and installation, such a mechanism functions smoothly for many years.

In bottom-fed toilets, the inlet and shut-off valves are very close. When setting up the fittings, you need to make sure that the moving parts do not touch

Water supply point

An important point is where water enters the toilet. It can be done from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant to others.

If water comes from below, it happens almost silently. The lower water supply to the tank is more typical for new models produced abroad.

But traditional domestically produced tanks usually have a side water supply. The advantage of this option is its relatively low price. Installation also differs. Bottom water supply elements can be installed in the tank before it is installed. But the side supply is installed only after the tank is installed on the toilet bowl.

For replacement, the fittings are selected taking into account the option of supplying water to the plumbing tank; it can be side or bottom

Operating principle of shut-off valves

During operation of shut-off valves, the following parts are involved:

- Float

- Lever design

- Valve

- Union

At the inlet there is a fitting through which water can enter from the system. When filling the cistern, the water level rises, causing the float to act on the lever system. She, in turn, presses the valve to the fitting and blocks access, blocking the liquid.

When filling, three types of location of the filling fitting are used:

- Top position

- With side water supply

- Bottom position

Each of them has its own subtleties in the operation of the system as a whole.

Toilet fittings with top connection

This type is used quite rarely. Due to the peculiarity of this design, filling the tank with water was accompanied by a high noise level. Subsequently, manufacturers abandoned production with such filling.

Toilet fittings with side connection

For lateral connection, the shut-off valve has two versions:

- Rod

- Membrane

The operating principle remains unchanged. The main difference is that the membrane is not able to block the access of water gradually, so when filled, access is blocked instantly.

The rod valve has the ability to close smoothly. At the moment when the float rises, the lever system gradually acts on the rod, thereby smoothly closing the access to water.

Fittings for toilet bowl with bottom connection

This method has a number of advantages over other supply connections:

- Silent filling

- Convenient location

- Possibility to hide water supply systems

- Large selection of varieties

- Availability of components

Due to the fact that the connection is made at the bottom, the toilet allows you to hide all water supply systems. It is for this reason that overhead tank designs are no longer used in apartments and residential buildings.

Such systems, in turn, have also been modernized over time. In order to reduce water consumption, two-button fittings began to be used, which include 2 drain modes. The first mode allows you to slightly open the drain valve of the fittings and release water gradually.

The second mode is designed to drain a large amount of water in a short time. The model range with a bottom connection is equipped with a two-button fitting at the manufacturer’s factory, but if desired, it can always be replaced.

Toilet fill valve - which is the best?

Fill valve for a toilet - which is the best (preferably with a side connection).

discussion started here » > (but there is a lot of unnecessary stuff)

1) My negative experience: all the filler valves with the float and the lever on which it is mounted work normally for three months - no more - the lever is healthy and gradually crushes the rubber band; several years ago I tried everything that was available on the market and in the plumbing supply store: - I tried the brass “Italian” design and all types of plastic ones and a device with a metal valve without using rubber bands

I'm adding comments: here's what I tried (at least in appearance): "> 28110 valve lat. with float for water containers (tanks) (pcs.) 28116 valve brass. with galvanized rod and float 28115 valve brass. with rod and float 28105 plastic valve. with rod and float 28108 toilet valve, vertical. 1/2″

2) My almost positive experience: in the end, only valves with a large rubber band (there is a hole inside) work (for a couple of years) "> 27833 side intake mechanism. 1/2″ CH11 ALKAPLAST (pcs.) 27832 side intake mechanism. 3/8″ CH11 ALKAPLAST (pcs.) 27834 lower intake mechanism 1/2″ A12 ALKAPLAST (pcs.) 27835 lower intake mechanism 3/8″ A12 ALKAPLAST (pcs.) Moreover, it looks like these valves are counterfeited - I bought exactly the same ones but "Moscow Region". Everything would be fine, but the large rubber band inside “deteriorates”, and I couldn’t find spare ones anywhere - I have to buy a new valve and rearrange the rubber band from there. Recently, rubber bands have begun to serve less and less, and the valve has risen in price from 70 rubles to 150-250 rubles.

3) BV advised “LLC” INKOER” GOST or TU TU-4953-072-00284581-99 Shut-off valves for the tank “only what I talked about above the button. and was not made in Moscow"

The fittings I was talking about are IncoEr, a group of companies. On the link she says: “> this is an option with a twitch on top, there is an option with a single button, and there is one with a double chrome button. The button can be placed in the lid with both a small hole and a large one. They have a representative office in Moscow tel 495: 6860527, 6821587, 6821532

Production is located in the Kirov region, Kotelnich. Vympel-M LLC The fittings are certified: Hygienic conclusion and Certificate of conformity. There are instructions for assembly and setup."

Main problems with drain fittings

From time to time, small malfunctions arise in the operation of the toilet flushing system, which, if desired, can be easily fixed with your own hands.

- Systematic flow of water into the toilet bowl;

- Water constantly flows into the flush tank.

A systematic stream of water that flows into the toilet indicates damage to the bulb in the system. The pear stops sealing the drain hole in the initial stage. To solve this problem, you can attach some kind of weight, thus weighing the pear down and returning it to its normal position. If the drain system fittings are equipped with a membrane, then in this case only replacement of this spare part is necessary.

Installation of drain fittings

If water constantly enters the tank, it means the float is deformed. If the float is skewed, it is quite easy to correct it. There is a more severe version of such a breakdown - depressurization of the float; to check it, you need to remove it and lower it into a container of water; if it sinks, it means it is unsuitable for further use and needs to be replaced.

Tank valve

The inlet valve is responsible for collecting and shutting off the incoming water into the toilet.

In Soviet era systems, valves with a rod float valve were installed. It was characterized by slow, uneven water intake and high noise levels. The only advantage of such a system is the ability to operate normally even with unstable or extremely low water pressure. The new compact toilets are equipped with fittings with a membrane valve. The water supply occurs quickly and almost silently, and the supply is shut off without delay. For uninterrupted operation, a pressure is required, not lower than 0.05-0.1 atmospheres and not higher than 1-2 atmospheres. In addition, the water entering the device must be free of pieces of rust and other contaminants, otherwise it will lead to rapid clogging and the need for frequent disassembly for cleaning.