It is not often possible to organize the inclusion of a private house, summer house or cottage in the centralized water supply system. Usually their owners have to decide on an autonomous water supply system for their home.

But, even if it is possible to connect to a city or village water supply running next to the house, having an independent source of water on the site is not a bad idea, both from an economic point of view, for example, using it for irrigation, and as a guarantee against sudden central system shutdowns.

general information

The autonomous water supply system of a private house consists of several components:

- water source:

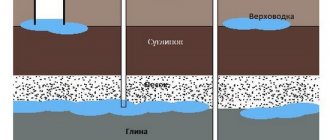

- A well is an artificial excavation-mine dug to collect underground groundwater in the surface aquifer to a depth of 10~15 m and reinforced against collapse.

- Wells . They are carried out by drilling and come in several types: Gravity : “on sand” - up to 50 m, “on limestone” - up to 150 m.

- Artesian - over 150 m.

- Abyssinian and others.

- Water consumers on site and in the house : sinks, sinks, baths, saunas, swimming pools, irrigation.

- Supply and distribution system : pumps, storage tanks, pipelines.

When designing an autonomous system, the first question that arises is the selection of a pump for the water supply of a private home, as one of the most important and, if we talk about the quality of work and durability, the most expensive part of the hydraulic equipment. And its choice is determined, first of all, by the type of water source on the site , and then by the selected water supply scheme.

Design differences

Hydraulic pumps come in the following design types:

Types by type of accommodation

According to the method of placement, water supply hydraulic pumps are divided into two classes:

- Surface type . Located away from the water source, they ensure its suction through a pipe lowered into a well or borehole.

- Submersible . They sink completely into the water to a certain depth.

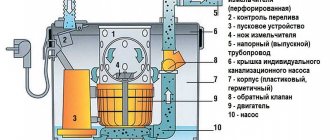

pumping stations are classified into a separate class , which are essentially a compact, self-sufficient water-pressure complex consisting of a surface pump, a membrane accumulator tank, a water pressure switch and a control circuit.

Design features

On the modern market you can find household water pumps of various models, but they all work on a similar principle. The suction of water into the internal chamber of such a pump is carried out due to the rarefaction of air, which is created in it by the main working body of the device, and further expulsion of the liquid through the pressure pipe occurs due to an increase in its pressure. Screw and gear pumps operate on a different principle, in which the pumped liquid, entering the internal chamber, is captured by meshing gears or a screw and moves from the inlet to the pressure pipe.

The pressure with which the flow of liquid is pushed out of the internal chamber determines the pressure in the pipeline system. The latter should be sufficient to ensure the transportation of water over the required distance and its supply to all water intake points.

Submersible pumps for clean and dirty water, equipped with float switches

Which one is better to choose?

Before choosing a water pump for your home, you should compare the advantages and disadvantages of their two main types:

| Surface pumps | Submersible |

| Installed permanently. Easier to maintain. | For repair and maintenance work, they require lifting from a well or well to the surface. |

| They need two pipelines: suction and discharge. | They work only for injection. |

| The maximum suction height is 10 m. The real one, taking into account losses in the pipeline and the reserve for lowering the water level in the well, is no more than 7~8 m. | Ascent from depths below 10 m. |

| They need to be filled with liquid before the first start-up or after repair work. | Ready to go immediately after diving. |

| There is a danger of the motor overheating during prolonged operation. | A pump immersed in water is cooled both by external water from the outside and pumped from the inside. |

| The need for winter preservation for the summer version of the water supply system. | For the winter, it is enough to drain the water from the system. |

| Work is accompanied by noise. | Silent. |

Pump operating principle

The principle of operation of the pump

Before choosing, it is necessary to understand in general how this device works. You will need a pumping device that operates under the influence of an electric motor. When it starts, a vacuum immediately appears inside the chamber. This is where the liquid begins to penetrate due to low pressure. The motor process gradually proceeds towards the outlet pipe. Next, the stream follows into a water pipe or into a fixed hose. In a water pump, pressure is determined through the force of water pushing out. It must be stronger than the hydraulic resistance.

Calculation example

Basic necessary data for choosing the appropriate surface pump model for water supply at home:

- Maximum fluid flow rate in l/min or m³/h.

- Suction height is the difference between the levels of the pump inlet pipe and the surface of the water in the source.

- Discharge height is the difference in levels between the highest point of the pipeline and the pump outlet pipe.

- The initial pressure for a free-flow well or well is equal to atmospheric pressure.

- Final - the required pressure in the home plumbing system.

- Pressure losses in pipelines depend on the fluid flow and the quality of the surfaces of the internal walls of the pipelines, which create friction for its movement.

The suction height of surface-type hydraulic pumps cannot exceed 10.33 m - the height of the water column creating equal atmospheric pressure.

To simplify calculations , it is rounded to 10 m , and the pressure created is equated to one technical atmosphere, 1 at = 1 kG/cm², or approximately 1 bar ~ 0.98 at.

The discharge height, or pressure, is determined by the technical parameters and power of the unit .

Often the value of pressure is confused with pressure, calling one another. These quantities are equivalent, but not exactly equal to each other. The pressure at the outlet of the pump depends only on its technical characteristics, and the pressure depends on the totality of external conditions : flow rate and liquid consumption, its temperature, altitude above sea level, etc.

When calculating, all system pressure values in pascals, bars, atmospheres and other units lead to equivalent pressure values in meters .

Let's give an example, taking the geodetic level of the pumping station location as zero:

- The fluid flow provided by the hydraulic pump is 40 m³/h. This is quite sufficient consumption for household needs.

- The water level in the well is 4 m below zero.

- The highest point of water rise is 15 m above it.

- The total losses in the inlet and outlet pipelines can be found in the tables for a specific type of pipe, but they are usually calculated based on the fact that for every 10 m of the pipeline 1 m of pressure is lost, therefore we will take them equal to (15 m + 4 m) / 10 = 1 .9 m.

- Let us take the final pressure at the top point to be 1 bar ~ 9.87 m.

If the water pumping station is installed not in a caisson located next to the well, but in a house, you should also take into account the pressure loss along the length of the supply pipeline .

For each pump there is an operational characteristic that shows the pressure drop depending on the flow rate and has something like this :

When choosing a specific pump model, you should compare the calculated parameter values with the nameplate values for the selected unit at the required operating point.

For our example we get : 2.725 x 40 x 30.77 = 3.354 kW.

For more information on calculating and selecting a pump for water supply to a country house, watch this video:

Comparative scale of technical characteristics of water pressure in pumps of various types

Global pump manufacturers use the following units for measuring water pressure for the pressure characteristics of different types of pumps:

For quick approximate household calculations, approximate ratios of these quantities are suitable:

In practice, for the normal operation of household hydraulic equipment with automation, the use of flow valves and the operation of bathrooms, the operation of geysers and boilers, it is enough to maintain the water pressure in the pipelines within 2-4 bar for all major models of household water devices.

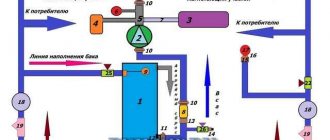

Inclusion in the water supply system

As mentioned above, ready-made pumping stations are more convenient to install and operate than others , the technical characteristics of which are suitable for supplying water to a small house for a family of 2~3 people or a summer house.

Connecting them comes down to a few simple steps:

- Choosing a location.

- Preparing a solid foundation.

- Laying out the necessary pipelines.

- The suction pipe lowered into the well must be equipped with a strainer and a check valve. It should be lowered to a depth no higher than 1 m from the surface of the water.

- Connecting the electrical network and protective grounding.

Weaknesses of pumping stations and major breakdowns

Industrially produced pumping stations, or so-called self-priming pumps, attract:

- affordable price , less than when purchasing all components separately;

- compact sizes;

- ease of installation and maintenance;

- ready for use immediately after purchase.

However, there are also disadvantages to using them:

- Suction height limited to 7~8 meters. It can be increased by a couple of meters by placing the unit in a recessed caisson next to the well.

- The need to equip a special insulated, soundproofed room.

- Small hydraulic accumulator capacity 20~50 l.

- Noise during operation.

Malfunctions of pumping stations can be caused by the following reasons:

- A sudden power outage is often accompanied by water hammer, which can cause irreparable damage.

- Contamination and poor water quality lead to increased wear of the centrifugal hydraulic pump blades and silting of the tank.

- Inconsistency of operating conditions with technical parameters.

For example, one of the common breakdowns is associated with excessive water consumption, when the frequency of switching on/off the station significantly exceeds the rated one .

This leads to rupture of the membrane in the accumulator tank. In this case, the station cannot create the required pressure in the system and the frequency of switching on increases even more. Check by pressing the nipple on the back of the tank : if water flows from there, the membrane requires replacement.

Another common malfunction is a breakdown or incorrect adjustment of the pressure switch , which leads to continuous operation of the station without shutdowns.

Residents of city houses or apartments rarely think about the fact that when they go to the faucet in the kitchen or bathroom and simply open it, they include in the work perfected for its creation by centuries of scientific discoveries, inventions and engineering solutions, a huge and complex system of water resources extraction , their delivery and distribution.

Those who have to create such a miniature system for their home truly value the value of this truly irreplaceable source of life - water.

What do you think of this article?

Vortex

In vortex submersible pumps, water is taken in and expelled using a single impeller with blades, which is located in the upper part of a vertically suspended housing next to the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side edge of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to operate in an environment with sand particles.

A special feature of vortex types used in industry is the ability to pump liquids with a high content of gases; the efficiency of household units rarely exceeds 50%.

Vortex-type devices have good pressure characteristics (the height of liquid rise reaches 100 m) and average pumping volumes (about 5 m3/h).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Vikhr, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump for water supply - design and appearance

Centrifugal

Centrifugal types are the undisputed leaders in household use among other types of electric pumps; almost all surface models have a centrifugal operating principle; they are part of household pumping stations.

Centrifugal devices have achieved such widespread popularity due to the following properties:

- Their efficiency factor (efficiency) is the highest of all analogues; in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel and is pushed out through the side pipe. This makes it possible to make multi-stage centrifugal devices in which the ejected liquid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters per hour.

- Centrifugal-type units are less susceptible to the effects of small sand particles on the working mechanism; they are widely used in sand wells, choosing a model to work with the appropriate particle size specified in the passport.

- A significant advantage of centrifugal types is their high level of automation; the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) equip their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save energy when operating the electric pump (up to 50%), but also to significantly increase its service life.

If we list all the manufacturers of centrifugal pumps that present their products on the domestic market, the list will be quite lengthy, so we will limit ourselves to the leading global manufacturers listed above. Among the domestic brands, the most famous are Aquarius, Gilex Vodomet, Vikhr, Belamos, Caliber, Unipump.

Rice. 8 Centrifugal submersible pumps - design and materials using the example of Grundfos SBA