Fatty elements contained in wastewater can block the pipe, causing a blockage. Fatty acids tend to cause metal corrosion and destroy pipelines, causing the sewer system to become unusable.

Grease traps for sewers, which are installed in the riser to the point where used water is discharged, will help solve this problem. In this material we will talk about the design features of these devices, their types and features that you need to pay attention to when choosing a grease trap for your home.

Design and principle of operation

The main function of grease traps, as their name implies, is to filter sewage from various fat, oil and solid inclusions that have a destructive effect on the pipeline and negatively affect the environment.

The sewer grease trap device includes the following elements:

- Main compartment designed to collect oils and grease;

- A flask with 2-3 compartments in which wastewater settles;

- An outlet pipeline connected to the sewer system;

- Inlet pipe;

- A sealed lid that prevents sewer odor from escaping the device.

All parts are enclosed in a one-piece sealed case with a lid. The cover is removable, which makes it possible to service the device and, if necessary, clean it manually. There are two pipes on the body that allow you to connect it to the general sewer system. Having understood the design, you can try to understand how the grease trap works.

The operating principle of a grease trap is quite simple. The internal space of the grease trap is divided into several communicating compartments, each of which is designed to clean the drains from various blockages. The last compartment is located near the outlet pipe, and through it the treated sewage flows into the pipeline.

The functioning of the grease trap occurs due to gravitational forces. Fat and oil particles remain in the upper part of the device, since their specific gravity is an order of magnitude lower than that of water. The sediment remaining on the filter is subsequently transported to a settling tank, from which it can be removed manually using appropriate equipment. To simplify the process and reduce the frequency of cleaning, enzymes that dissolve grease are added to the sewer grease trap.

Making a fat trap yourself

Making a grease trap for sewage with your own hands begins with calculating its parameters. We calculate the performance of the device P using the formula:

P = n x Ps, where n is the number of washes in the house, Ps is the flow rate of water in the system - the average is 0.1 l/s. If there is only one sink in the kitchen, n=1. Then P=0.1 l/s.

To determine the volume of the device, use the formula V = 60 x P x t, where t is the time of fat sedimentation, on average 6 minutes. We get 36 liters or 0.036 m³. Now it’s easy to find out the container parameters for the grease trap - 0.3 m, 0.3 m and 0.4 m.

In order to construct a grease trap with your own hands , you need to study the following step-by-step instructions:

- We find a suitable container (the shape of a rectangular parallelepiped) made of food-grade plastic, polypropylene, fiberglass, galvanized steel or stainless steel. The container must have a tight lid. You can use a plastic toy box. A duralumin corner from an old aquarium where the glass was cracked will do. It is removed, and a box is made of 6 mm thick fiberglass sheets on the frame. Cutting them is not easy, but the design will be durable and waterproof.

- We make holes on the side walls of the box for water inlet/output Ø 50 mm (with a jigsaw, or better yet, with a wood burner). Clean the edges of the holes with sandpaper. We place them opposite. The distance from these holes to the top edge of the box is 5 cm.

- Under the hole we install (at the end) a pipe Ø 100 mm, with a length equal to 2/3 of the height of the box. We glue it so that the bottom edge rises 30-40 mm above the bottom of the box. Then we place a Ø 50 mm pipe inside the pipe. Its lower edge is 50 mm higher than the lower edge of the pipe.

- We connect the tee (elbow Ø 50 mm) to the upper end of the pipe. Of the two free ends, one will go into the hole, and the other, directed upward, will act as a ventilation duct.

- We fix the pipes to the holes using sealants and epoxy resin.

- We insert 2 partitions into the box. We fix one barrier with hot glue in the upper part, at least 10 cm above the bottom. And we will attach the second partition (its length is 2/3 of the height of the box) at the bottom. Thus, the grease catcher will have three sections.

- We mount the introductory elbow and coat all joints with silicone sealant. Where the lid connects to the box, you need to glue the sealing tape. After closing the lid, wait for the sealant to harden. The device for catching grease before entering the sewer is ready.

- In order for the partitions to withstand the pressure of water, it is better to use epoxy resin instead of hot glue, and it is better to wrap the partitions themselves with rubber bands.

- The connections from the sink sink to the grease trap, and then from it to the sewer, are made from corrugated plastic pipes with rubber seals.

Purpose and advantages of grease traps for sewerage

There are many models of fat traps that can be used in different areas. For example, complex and powerful grease traps for sewage are actively used in large enterprises where there is a significant volume of wastewater saturated with solid, fat and oil particles.

There are a number of sanitary standards that require the installation of grease traps. Thus, in the production of meat and dairy products and in public catering establishments, a sewer grease trap is a mandatory element. Industrial traps are installed at the outlet of the treatment system, which provides primary wastewater treatment.

The main purpose of the devices in question is the primary purification of wastewater from fat and oil contaminants, which is what the operating principle of the grease trap is aimed at. As a result, the sewer pipeline will receive clean liquid that can be transported further. Without a trap, the sewer system may become clogged and fail. In addition, grease traps trap harmful impurities, thereby protecting the environment from their effects.

However, grease traps are also used in everyday life, and it completely coincides with the purpose of industrial products. The operating principle of a sewer grease trap provides reliable protection of the sewer pipeline from blockages and grease valves, completely retaining these elements during the cleaning stage.

The grease trap operation scheme consists of two stages. First of all, the home sewer drain is supplied to the device. The water goes through the primary purification stage. After this, another stage of purification is carried out, during which all fats are completely removed from the wastewater. As a result, the sewer system receives purified water without any impurities.

Grease traps have a number of advantages:

- Tightness

. The grease trap design is completely sealed, and any possibility of foreign impurities or liquids getting into it is excluded. - No characteristic odors

. When fats decompose, an extremely unpleasant odor is released. Thanks to the sealing of the grease trap, the smell does not escape beyond the equipment. - Versatility and practicality

. The operating principle of the grease trap allows it to be used in almost any system. In addition, there are a number of additional devices that can be used to complement the basic equipment - for example, you can always install a sensor for the accumulation of harmful substances. - Easy to install

. Installation of grease traps is carried out with a minimum set of tools and skills for installing such equipment. - Easy to maintain

. Regular cleaning does not require special effort or equipment - all work can be done independently using available tools. - Availability

. Compared to other types of filters, grease traps are much cheaper. - Durability

. All types of grease traps are made from high-quality materials that are wear-resistant. This ensures a long service life of the equipment.

Advantages of a septic tank without pumping

If you decide to make a biological septic tank with your own hands at the dacha, then the option of arranging a dacha sewage system will entail a lot of positive aspects.

- First of all, wastewater, which, according to SNiP, is 98% purified in such a septic tank, does not pose a threat to the environment and to humans.

- A country septic tank, built on the principle of biological treatment, does not require the constant use of sewage disposal equipment. This means that the family budget will be saved.

Classification of grease traps

There are two main types of fat traps:

- Household;

- Industrial.

The first category of devices is suitable for use in private homes, apartment networks and small catering establishments. In addition, a household grease trap is required for installation in any restaurant, since a large amount of grease deposits are formed during the dishwashing process. Cleaning of such devices is carried out manually. Standard household products are used in networks where the total liquid flow does not exceed 1.5 cubic meters/hour.

Industrial equipment is intended for installation in large enterprises with a wastewater volume of 2 cubic meters per hour or more. There is a need to install a grease trap if the enterprise works with substances, the processing of which releases fat, oils or other impurities that are not intended to enter the sewer in their pure form.

Features of the grease separator

Operating principle and differences between models

So, as mentioned above, there are two types of grease traps:

- Industrial.

- Household.

The latter are a small septic tank, which is located under the sink. During the process of cooking and washing dishes, the device takes over primary wastewater, cleaning it from grease.

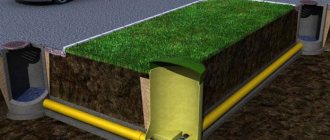

In the photo - an industrial grease trap

This septic tank works on the principle of a septic tank. As a rule, it is a rectangular container, inside of which there are partitions that divide the space into several chambers. Since fat particles are much lighter than water, they are retained in a special settling chamber, and the water freely flows into the sewer.

It should be noted that household grease traps come in two types:

| Autonomous | The device does not require an electrical connection to operate. |

| Electrical | In this case, the liquid is pumped out into the sewer system forcibly using an electric pump. Accordingly, for the device to operate, it must be connected to a power supply. |

In addition, the products differ in the principle of water intake:

| Salvo | They are distinguished by the ability to receive a large amount of wastewater during peak discharge. This model should be used if you wash dishes by pouring water into the sink, after which it is drained in one burst. |

| Sewage | Designed for cases where dishes are washed under running water. |

Household grease traps for sinks differ from industrial ones primarily in that they are designed to process a small amount of wastewater. As a rule, this figure fluctuates in the range of 0.5-1.5 cubic meters per hour.

Grease separator design

Design

Almost all household grease separators for sinks have the same design. As mentioned above, the body of the container has a rectangular shape.

The following elements are located inside it:

- Inlet pipe – designed to supply wastewater into the container.

- Flow damper - reduces the speed of incoming water.

- Partition – ensures retention of sedimented masses and thereby prevents the overflow of settled sludge.

- Air vent – designed to ventilate the container.

- Outlet pipe – ensures drainage of grease-free wastewater into the sewer system.

As we can see, the design is extremely simple.

The device takes up minimal space under the sink

Advantages

The main advantage of a grease trap is, of course, the protection of the sewer system from contamination.

But, besides this, this device has other positive qualities:

- It has compact dimensions and light weight, so connecting the device does not cause any difficulties.

- All parts are made from environmentally friendly materials.

- High efficiency - fatty and oily substances are captured by 95 - 100 percent.

- Cleaning the grease trap under the sink is quite simple and does not take much time.

- A wide range of models, so you can always choose the appropriate device model.

- Durability due to the simplicity of the design.

- Affordable price, especially for autonomous household models.

Thanks to all these points, grease traps have become widespread in everyday life.

Flaws

As for the shortcomings, there are few of them. The main one is that the grease trap under the sink needs to be cleaned periodically.

This can be done using any available means or a special spatula, which is included in the kit. With its help, the sludge is simply scooped out of the container, after which the grease trap is washed.

Cleaning the container

In addition, devices equipped with an electric pump increase energy consumption, and in the absence of it, do not work at all.

Selecting a grease trap

Choosing a suitable fat trap is always an individual matter. When choosing, you need to take into account a number of parameters, starting from the purpose of the device and its operating conditions to the set of additional functions. However, one thing is for sure - if the equipment is suitable for a specific situation, then its effectiveness will be quite high.

Installation methods

Depending on the installation features, all fat traps are divided into two categories:

- Outdoor, intended for installation outside the building;

- Home ones, which are installed exclusively indoors.

There are also combined solutions suitable for installation in any conditions - but such devices are practically not found on sale. However, the range of standard models is so wide that choosing the best option for specific operating conditions is not difficult.

Regardless of the type, grease separators are installed directly in the sewer system, but the specific installation point may vary. For example, household equipment can be mounted either directly under the plumbing or in the basement. Sometimes grease traps are installed in a separate room. Of course, when installing in a building, you need to take into account the size of the equipment and how convenient it will be to maintain.

With external separators the situation is more complicated. For the manufacture of such devices, more durable materials are used, since the equipment must withstand greater load and exposure to external factors. Outdoor grease traps must be installed underground. This process is quite complicated - you first need to prepare the site, concrete the area, and only after that can the separator be installed. For such work, it would be best to involve specialists.

Operating rules

When using a grease trap for a home sink, you must follow several specific rules that will allow you to achieve maximum efficiency in the operation of the equipment, prevent flooding and the appearance of an unpleasant odor in the kitchen.

In particular we are talking about the following:

- Mineral and synthetic oils should not be present in water waste.

- It is not recommended to connect the equipment to the toilet.

- It is forbidden to install a pump in front of the grease trap to avoid the formation of an emulsion that does not settle well.

- The inlet pipe should be located at a minimum distance from the sink and at a slope of at least 2 degrees.

- Purified water must immediately go into the sewer system.

- It is recommended to connect the equipment in the ventilation system shaft (if there is a corresponding hole in the wall or ceiling).

Materials for production

One of three materials can be used to make the grease trap body:

- Plastic;

- Fiberglass;

- Stainless steel.

Plastic products are distinguished primarily by their good appearance and relatively low throughput. The power of such models is not very high, so most often they have a purely domestic purpose and are installed inside the building, and not outside. Often, plastic devices are supplemented with various devices that improve the operation of the system or simplify its control.

The most prominent advantages of plastic separators are:

- Environmental friendliness

- plastic belongs to the category of materials that do not pose a threat to human health and the environment; - Practicality

, which is expressed in the possibility of creating both standard models and custom-made products; - Easy to maintain

– the grease trap is not complicated, and no tools are required to clean it; - Long service life

- standard plastic products can last up to 30 years.

Fiberglass is a composite material that contains fiberglass and polymers that perform bonding functions. This material is highly durable, which makes it possible to use fiberglass models of grease traps both inside and outside the building.

Fiberglass products have a number of characteristic properties, including:

- High resistance to any aggressive environment, which allows the separator to easily survive harsh climatic conditions and the impact of most substances passing through it;

- High mechanical strength, which not only allows the grease trap to be used under thick soil, but also provides the device with a long service life;

- Easy to maintain.

Finally, there are also models made of stainless steel. This material is quite durable and reliable, which affects the cost - metal grease traps are more expensive than plastic and fiberglass analogues. You can find cheaper models made of galvanized steel on the market, but their characteristics are an order of magnitude lower than those of stainless steel products.

Among the advantages of metal separators, it is worth noting their high strength, which makes it possible to install such products anywhere. In addition, such products are characterized by good hygienic properties and high performance indicators, including long service life and excellent corrosion protection.

How does it work?

Grease traps operate on the principle of gravitational settling. A household grease separator is a plastic container divided inside into chambers by partitions. The first and last compartments have connections for connecting pipes.

The design has a removable cover. The principle of separation is based on the fact that when settling, the liquid is divided into layers depending on density. The process goes like this:

- contaminated liquid entering the sink drain enters the first chamber of the grease trap through the incoming tube;

- separators installed in the transverse direction separate part of the fatty impurities rising upward;

- the water flow moves to the next compartment, where fat removal continues;

- the collected fat is transferred to the storage tank;

- From time to time, the storage chamber needs to be cleared of fat.

What are they made of?

Grease traps can be made from different materials:

- stainless steel;

- plastic;

- fiberglass.

Household models are made mainly from polymer materials (polypropylene), since this material is the cheapest and most practical. Industrial grease traps can also be made of steel.

Types

Depending on the installation location, the following options are distinguished:

- models for installation under the sink;

- grease traps for installation in the next room;

- option for installation at the sewer outlet from the house;

- outdoor devices.

Performance

An important criterion for choosing a grease trap is the performance of the model. The greater the water consumption, the greater the throughput of the grease trap should be. In domestic conditions, installations with a capacity of 0.1-2 liters per second are used. Models with higher productivity are classified as industrial.

Operational characteristics of grease traps

Imagining the operating principle of a sewer grease trap, you can consider its characteristics. The most important indicators that determine the efficiency of this equipment are power and productivity. If the device’s performance varies from 0.1 to 2 l/s, then such equipment is suitable only for home use. All devices with higher power are considered industrial.

Good fat separators allow you to purify wastewater from fats up to 20 mg/l. In any case, before choosing equipment you need to find out how large the volume of sewage will be. The device performance must be higher than the obtained value.

In addition to the characteristics described above, there is also such a parameter as the cleaning method, which can be presented in two variations:

- Manual cleaning

. Devices of this type usually have a relatively small throughput and are most often installed in buildings. Such grease traps are located in places with easy access, and their cleaning is carried out using the means at hand. - Mechanized cleaning

. This cleaning method is used in industrial grease traps designed to process large volumes of wastewater. The cleaning element in this case can be pumps or specialized vehicles. As a rule, devices with mechanized cleaning are equipped with various automation and sensors that notify the operator about the need for regular cleaning.

Outdoor installation

To properly install a grease trap for external sewerage, you will have to put in a lot of effort. Of course, all problems can be avoided by using the services of experienced specialists - but this option, of course, will cost an order of magnitude more than installing it yourself.

Before installing the grease trap, you need to perform several preparatory steps:

- First of all, you need to find a place suitable for the separator. In the selection process, it is worth starting from the characteristics of the site and the need for any work to be carried out subsequently.

- The next step is to determine the dimensions of the pit for laying the equipment. The depth of the pit is calculated so that the upper part of the grease trap (where the lid is located) protrudes from the ground by about 4 cm.

- Next you need to start digging a hole of the selected size. At the bottom of the pit, a solid formwork is formed, which is subsequently filled with a sand-cement composition (for sandy soil and loam, a ratio of 1:5 can be used).

- All you have to do is wait until the solution hardens completely. This usually takes at least two weeks.

Having finished with the preparation, you can begin installing separator equipment, which involves performing the following operations:

- The grease trap body is installed on the prepared site. To fix the device, loops are used, which must be embedded in the concrete during pouring. However, if there are no loops, you can use an anchor fastening.

- You need to install plywood walls around the perimeter of the device. The role of these walls is to prevent soil from shedding during operation of the device. If the region where the equipment is installed has a harsh cold climate, then the grease trap must also be covered with a layer of thermal insulation. It is best to use mineral wool or polystyrene foam as a thermal insulation material.

- The next stage is connecting to communications so that the principle of operation of the grease trap can be demonstrated in practice. The outlet pipe is connected to the drainage system, and the input pipe is connected to the sewerage system. All joints must be treated with sealant to create a solid structure. The cavity between the device body and the edges of the pit is filled with soil. There is no need to look for new soil for this - it is best to use the one that was previously in the prepared hole.

- The last stage is the installation of a vent riser, which is necessary to remove gases accumulating in the sewer system. You need to choose the diameter of the pipe and their number depending on the load on the sewer system. It is best to read the corresponding article about the installation of a drain pipe and the features of this work.

And yet, the best option would be to involve professionals who understand what the concept of a grease trap looks like and can implement it. In addition to skills, an experienced team also has a set of tools that allow them to complete all the work quickly and efficiently.

Unit for prevention

A grease trap is an installation that, figuratively speaking, separates the wheat from the chaff. It is built into the sewerage system to prevent fatty deposits in pipes. And this technique is based on one simple principle - fat always rises to the surface of a certain volume of cool water. Most often, such devices are used in canteens and cookeries, where this is justified by sanitary standards. But you can also make a homemade grease trap at home. After all, its advantages are obvious:

- it prevents very unpleasant blockages in the sewer;

- the device of such a household installation is simple;

- Maintenance of such equipment is minimal.

Let’s first consider what the simplest “filling” of a household grease trap is. The main elements that a simple separator includes are given below.

- Inlet pipe.

- Partition.

- The outlet pipe to the sewer, usually in the form of a tee.

- All this is located in a box-shaped plastic case, the inlet and drain pipes look out.

Diagram of a household grease trap

If all these elements are present, the operating principle is as follows: water with fat enters through the inlet pipe from the kitchen sink. Inside our unit, liquid fills the primary chamber, where it settles a little, and meanwhile the fat rises to the top. This chamber is separated from the rest of the device by a partition.

However, this wall does not stretch all the way to the top. Its height is approximately two-thirds of the height of the box. So there remains a gap. It is through this upper “vent” that fat-free water flows into the adjacent chamber and at the very bottom enters the outlet pipe, most often made in the form of a tee. After which, in fact, the liquid flows into the sewer.

At the same time, all the collected fat remains on the surface of a constantly maintained volume of the working medium. Therefore, the described separator is serviceable. As the unpleasant suspension accumulates, the device must be completely disconnected from the line and then emptied of its contents. This operation must be done at least once every two weeks. It all depends on the amount of dirt and the intensity of use of the sink. Next, we will consider the process of creating such a home appliance that needs to be cleaned periodically.

Installation in a building

It is much easier to install a household separator, which is largely due to the absence of the need for earthworks. One of the most important conditions for the correct installation of a grease trap is the correct choice of location. It should be easily accessible, firm and level. In addition, the equipment must be located near the plumbing and in such a way that the gravitational principle of the grease trap can ensure the operation of the device.

The installation technology is as follows:

- The outlet pipe is connected to the sewer and sealed with a gasket included with the equipment;

- The inlet pipe is connected to plumbing or a general pipeline;

- The grease trap is filled with water and checked for leaks;

- If the device operates correctly, then the cover can be installed on it, thereby completing the installation process.

Independent connection under the sink

The compact grease trap can be connected independently under the sink without the use of tools.

Table 1. Connecting a grease trap under the sink

| Illustration | Description |

| When installing a grease trap, you will need 2 couplings to connect the corrugated hose. | |

| Disconnect the existing corrugated pipe from the sewer. | |

| The siphon is turned towards the inlet on the grease trap body. | |

| The connection point on the device body is marked with an “input” sticker. | |

| A coupling of fiftieth diameter is installed on the outlet hole. | |

| The adapter coupling is attached to a corrugated hose, since its diameter is 40 mm, and the outlet coupling is 50 mm. | |

| The hose is attached to the outlet on the grease trap body. | |

| On the other side, the hose is connected to the sewer. | |

| To service the grease trap, open the lid, remove the basket for large debris and clean the surface of the first chamber from grease. |

How to get rid of clogged pipes if there have never been such problems before and you don’t know where to start? The main thing is to choose the right remedy against pipe blockages. In a special article we will try to help you deal with this problem, and we will tell you about the most effective methods and remedies for blockages that will save the pipeline in a few minutes.

Popular manufacturers

Finding a model with the required characteristics will not be difficult - there is a wide range of grease traps on the market. By and large, there is no particular difference between the products of different manufacturers, because all separators work due to gravitational forces. The only nuances may be in the set of additional functions and the materials used to manufacture the device parts.

Among the most popular manufacturers of fat traps, it is worth noting the following companies:

- Helyx. This company is primarily engaged in the production of industrial grease traps, which are used as the first stage of cleaning in various industries.

- Wavin Labko. This manufacturer specializes in the production of environmentally friendly devices made of fiberglass and polyethylene, equipped with modern electronic systems that monitor all operating parameters of the grease trap. Most often, products of this brand are used in public catering establishments.

- Evo Stock. Products produced under this brand are made of reinforced plastic, which can easily withstand the effects of corrosion and high temperatures. The equipment is equipped with hermetic seals that completely prevent sewer odors from entering the room.

- Flotenk. This company produces grease traps for industrial and domestic use. Reinforced fiberglass is used to create products. Products of this brand are highly efficient and have a long service life.

- UE "Polymerkonstruktsiya" This domestic company produces simple but very reliable fat traps. A special feature of the products is the large depth of the outlet pipe, which minimizes the likelihood of fat slipping through the filter.