Repairing old and laying new water supply networks in residential premises begins with calculating the cost of the work. However, not only the price of pipes plays a decisive role. Equally important is the material from which they are made, the installation method and the ability to carry out work without the involvement of specialized specialists.

In the process of selecting water pipes for a residential premises, one should take into account possible future repairs or replacement of individual components in the event of emergency situations. Based on this, you need to focus on cost, quality and technical characteristics, which must meet all the necessary requirements.

Types of water pipes

Modern manufacturers of water fittings offer consumers two main types of water pipes:

- Non-metallic; Metallic.

Products of both types differ in technical characteristics, material, performance properties and chemical composition. Based on these signs, certain options for hot or cold water are selected.

Non-metallic pipes are made from the following materials:

- polypropylene; polyethylene; metal-plastic; PVC.

The following metals and alloys are used to produce the main types of metal pipes:

- steel;stainless steel;copper.

The main factor contributing to the widespread use of non-metallic water pipes is their durability and low cost. Scale and rust do not form on the inner walls of plastic products.

Their service life can exceed half a century, and installation and repair are much cheaper than metal analogues. Moreover, servicing or replacing a plastic water pipe does not require welding, which means any homeowner can do it if they have some experience and tools.

Criterias of choice

When choosing water pipes for your home, you need to consider:

Options for laying water pipes

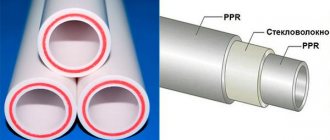

Polypropylene

This type of product is characterized by increased strength and durability. Polypropylene pipes used for hot water supply will surely last 25 years or more, and for cold water supply - over 50. The material is very light, which has a positive effect on ease of installation and transportation.

An important positive property is the invariability of the characteristics of polypropylene, even with sharp temperature fluctuations and freezing of water.

When installing polypropylene water pipes, fittings are used at bending points. Due to the increased rigidity of the material, bending it in the usual way is unacceptable.

Briefly about the main thing

It is not difficult to choose a material for installing a water supply system if you know all the features of pipes, methods of their assembly and changes in characteristics under different operating conditions. For example, if you need to choose which pipes are best for underground water supply in a private house, then HDPE or PP pipes would be the ideal solution. All types of plastic and metal-plastic products are suitable for internal wiring, with the exception of pipes made of low-density polyethylene, as well as copper ones. Traditional steel pipes can also be used, but you need to be prepared that hard water will quickly damage them, and their appearance will have to be maintained by regular painting.

Ratings 0

Polyethylene

Water pipes made from this material are highly reliable due to their ability to withstand pressure up to 16 atmospheres. Despite many positive aspects, polyethylene products are not widely used.

The temperature range in which they can be operated is from -40 C to +40 C. Given the low heat resistance, coupled with a fairly large linear expansion rate, such a water supply may not always be a suitable option for the home.

However, cross-linked polyethylene, which appeared on the market not so long ago, turned out to be more in demand. Installation of a water supply system made of such material is as simple and convenient as possible. At the joints, fittings without rubber seals are used, and a special fitting is installed on top of them.

The undeniable advantages of a polyethylene plumbing unit include:

- increased strength; resistance to low temperatures; inertness to many chemicals present in water; fittings used for installation do not interfere with permeability.

The product has a multilayer design, in which the outer and inner layers are made of plastic, and the middle is made of metal. This results in increased strength with low weight.

The elasticity inherent in metal-plastic pipes allows them to be given various shapes. Positive properties include excellent thermal conductivity of the product, easy and convenient installation.

Vulnerable places in a metal-plastic water supply are connections. When carrying out work, you need to pay increased attention to the quality of installation of fittings. The fact is that with sudden temperature changes, aluminum contracts faster than plastic and high pressure in the system can lead to an emergency.

Metal-polymer

*

Metal-plastic pipes are produced by extrusion, applying a melt of polymers to a frame made of mesh, wire or foil.

Metal-plastic materials combine the advantages of metal and polymer types of pipes for heating or plumbing:

- resistance to corrosion, chemical attack;

- low thermal expansion;

- wear resistance;

- simple installation using detachable, crimp or press fittings;

- operating temperature range up to 95°-110° and pressure up to 10 bar, withstands repeated freezing;

- service life up to 30 years.

Metal-plastic retains its shape when bent and does not release harmful compounds into the water.

Pipe made of metal-plastic

Disadvantages of water pipes made of metal-polymers:

- lower mechanical strength than steel pipes;

- not used at pressures exceeding 10 bar and temperatures above 110°;

- some types are susceptible to fatigue failure.

The combination of positive qualities makes this material promising for wide use in various fields of construction.

PVC

Pipes made of polyvinyl chloride are in many ways superior to their plastic counterparts in strength and resistance to aggressive chemicals, and the permissible pressure in such a water supply can reach 46 atmospheres.

Resistance to high temperatures allows the use of polyvinyl chloride water supply for hot water supply. It confidently withstands temperatures up to 90 degrees Celsius.

Installation does not cause any particular difficulties and you can do all the work with PVC water supply yourself without welding. The process requires only couplings and angles, which makes installation cheaper compared to analogues for which it is necessary to purchase fittings.

Metal pipes have been used for decades. Despite the emergence of new materials, they still have not lost their relevance. Metal, like plastic, has its pros and cons.

The biggest advantage of metal water pipes is mechanical strength. However, its service life is only a few years. In addition, complex installation and welding work increases installation and maintenance costs.

During operation, growths form on the walls of a metal water pipeline, which lead to a drop in pressure and throughput.

Stainless

*

Pipes made of alloyed corrosion-resistant steel are durable and not subject to the destructive effects of water. They can last up to 400 years. Oxidation products do not accumulate on the wall and do not enter the household water supply. Increasingly, stainless steel products are replacing conventional carbon steel, despite the higher price of the material and the complexity of installation.

Their stainless steel profiles

Stainless steel structures comply with sanitary and hygienic standards, withstand water shocks well, and are resistant to critical temperatures. Water with excess chlorine can damage stainless steel, so after disinfection it is recommended to thoroughly rinse the system.

Stainless steel pipes are used in various fields:

- water, heat and gas supply;

- fire fighting;

- installation of ducts for air conditioning;

- laying “warm floor”;

- for protecting power electrical cables.

The water supply is assembled using press fittings, also made of stainless steel, by welding with a tungsten electrode in an inert environment. In industrial conditions, laser welding is used.

Water supply systems made from flexible corrugated pipes are becoming increasingly common. Their advantages are the possibility of laying in hard-to-reach places, installing long-distance lines, and resistance to dynamic or vibration loads.

Which pipes to choose for water supply (video)

The disadvantages of such water pipes include heavy weight, complex installation and corrosion. However, modern manufacturers have learned to coat the inner surface with a non-metallic layer, which increases the service life of the product and avoids corrosion.

Stainless steel products are superior to conventional ones in all main characteristics, but their cost differs significantly, which leads to a significant increase in the cost of the entire water supply system.

Copper

The throughput of copper water supply is higher than that of others. This is achieved due to a smoother internal surface, so smaller diameter pipes can be used. Copper has disinfectant properties, due to which copper pipes are widely used for drinking water supply systems.

The undoubted advantages of copper products include their presentable appearance, resistance to corrosion and long service life, which can reach 70-100 years.

However, the high cost of copper pipes and installation work is not affordable for everyone. Such water pipes are usually found in luxury homes, where luxury is considered one of the important indicators.

In order to competently design and arrange a water supply system, it is necessary to carefully examine various types of water pipes, comparing their technical, operational and aesthetic characteristics. In this case, the choice of pipe type will depend on its purpose: either an internal water supply and drainage system (sewerage) is planned, or installation of external communications is required.

There are quite a lot of options, so it is worth considering this issue in detail to avoid unnecessary mistakes and extra costs. Pipes for water supply. Main characteristics of water pipes First of all, you should take into account the types of water supply and sewerage networks (sewage systems). They are divided into: external networks, internal networks. In both options, pressure pipes are used, designed to supply hot and cold water under the appropriate pressure. The pipes are connected using a special soldering machine. The main operational characteristics of water pipes include the following parameters: corrosion resistance; chemical resistance; service life; resistance to different temperature operating conditions; throughput. Classification of water pipes by material All pipes for supplying and discharging water are divided into three main classes: Metal pipes (cast iron, steel, copper). Polymer pipes (plastic). Metal-plastic pipes (polymer materials are combined with metal). Each type has its own advantages and disadvantages due to the physical properties of the material. Metal pipes Types of plastic water pipes have a long service life. Cast iron water supply. Due to the fragility of this material, communications made of cast iron require special care during installation and transportation.

Connection and sizing pose a major challenge for installers. Although, in comparison with water pipes made of steel, cast iron pipes last longer (according to some estimates, up to 80 years) and do not “overgrow” so much from the inside, the use of cast iron in the construction of water pressure systems is gradually being reduced. Steel water pipes. The disadvantage of this type of pipe is its short service life - approximately 20 years.

Low corrosion resistance over time leads to the formation of rust inside the pipe, which significantly deteriorates the quality of drinking water supplied to the system. Reduced communications flow negatively affects the costs of supplying water to the consumer. Compared to Europe, the cost of water supply in our country is 1.5 times higher.

Metal corrosion leads to accidents and breakdowns during the use of steel systems. It is also worth noting the high labor intensity when installing and replacing sections of steel water supply. The method of connecting such pipes is either threaded adapters or welding joints.

All this increases the time and cost of installation and maintenance of such systems, however, one should pay tribute to the high strength and relatively low cost (compared to copper) of this type of pipe. Copper pipes. As a rule, they are used only indoors due to the high cost and specific connections. This type of pipe is not compatible with galvanized steel products, which makes them difficult to replace or repair (professional help is required).

Nevertheless, the durability of copper water pipes exceeds all other metal systems (operation without leaks is possible for a whole century). This material has an unusually smooth internal surface and, as a result, there is no corrosion “overgrowth” and a decrease in throughput. The absence of corrosion keeps drinking water clean and makes this type of pipe very popular when installing both hot and cold water supply systems and heating systems. Such pipes are today most often used in water supply systems around the world.

What is the reason for such popularity? Let's consider the main advantages of these types of pipes: the service life is very long (plastic does not deteriorate for centuries); the smooth inner surface does not contribute to “overgrowth”; the low sound conductivity of plastic reduces the noise characteristic of water pipes; the quality of water does not deteriorate because there is no corrosion; the material is lightweight, therefore transportation and installation work have a low cost (assembly is carried out by simple cutting and subsequent connection using soldering or fittings); high strength; low cost of the pipes themselves; these advantages encourage specialists to willingly design networks with polymer types of pipes; in fairness, it is worth noting some disadvantages, which types of polymer materials have: with increasing temperature, an increased coefficient of change in the dimensions of the product is observed; diffusion (penetration) of oxygen through the walls of pipes, affecting the quality of operation. Types of polymer pipes The connection of pipes must be as tight as possible. Polyvinyl chloride (PVC) pipe - used for both internal communications and external ones. An economical option due to the low cost of products. Polypropylene pipes are widely used not only for plumbing systems, but also for sewerage, heating, and irrigation. Polyethylene pipes are used in seismically active areas (for example, in Japan), because polyethylene is very elastic and can stretch up to 7% of its volume without collapsing.

The same property makes polyethylene systems indispensable in conditions of low temperatures and during water hammer. Pipes made of cross-linked polyethylene (PEX) - polyethylene produced under high pressure is used. The material has improved characteristics of resistance to high temperatures and loads. Used in hot water supply and heating (including for “warm” floors). Metal-plastic pipes (PEX-AL-PEX) This type of pipe is increasingly being used, since, thanks to the reinforcement of a conventional polyethylene pipe with aluminum, its protection from diffusion, resistance to high pressure (10 bar), high temperature (up to 95°) and deformation. Although this type has a slightly higher cost than conventional plastic pipes, its quality characteristics make these products indispensable when constructing open systems. Share a useful article :Similar articles:

Today, the choice of pipes for installing a water supply system in an apartment or private house is so large that it is very difficult for an ordinary buyer to make a choice. In order to choose the right option, you need to take into account: the temperature and pressure of the liquid, the diameter of the pipes, the cost of the elements and the required service life of the system, the ease of its installation. Let's consider the main types of pipes for the water supply system in the house.

Dimensions and diameter

When choosing a diameter, you should be guided by the principle “the further from the water entry into the house, the thinner the pipe.” In this case, in an apartment, all pipe products are usually installed the same size in diameter. The length of the water supply in it from the riser to the plumbing fixtures is not too long. In this case, it is not difficult to plan the layout of pipelines for hot water supply and hot water supply; you can easily create a diagram yourself.

Internal water supply wiring diagram

For a cottage with several floors and a large number of plumbing fixtures, the design of the plumbing system should definitely be ordered from a specialist. Here it is better to trust a professional who can competently make the necessary pipe calculations in all respects. Otherwise, you may end up with a situation where, when you open the tap in the kitchen, no water will flow in the bathroom due to lack of pressure.

How to calculate pipe diameter

For intra-house wiring, water pipe diameters are most often used with an internal cross-section of 15–32 mm. It is not recommended to install less, the pipeline will make noise or the pressure will be too low. For the street area from the cottage to the well or the centralized water main of the village, it is customary to use larger products - 32–50 mm.

Metal pipelines

Nowadays, metal pipes are practically not used for laying water pipes inside buildings.

More recently, various types of metal water pipes have been used everywhere.

Now they are practically not used for laying water pipes inside buildings. And they are used primarily where high mechanical strength of the system and a large diameter of pipelines are required: on city streets, under highway overpasses, etc., as well as for laying high-pressure networks (for example, at pumping stations).

For your information. Metal-plastic pipes are fire-resistant, so they are also used for laying fire water pipes.

The advantages of this type of pipes include:

- high strength; low coefficient of linear expansion when heated; relative ease of installation - the connection is made using couplings and adapters with sealing of threaded connections with flax or fume tape; welding is rarely used.

Flaws:

- Possible corrosion of some types of metal pipes. The appearance of rust is promoted by condensation accumulating on them. Therefore, insulation of pipelines is often required; The roughness of the inner surface leads to the deposition of slag there, the so-called “narrowing of the lumen” of metal pipes occurs; Due to the large weight, such pipelines require reinforced fastening; Difficulty in bending.

Polyvinyl chloride

Everyone knows that socketed PVC pipes are used for various sewage systems. But there are also water pipes in this category, which mainly belong to the pressure group. They differ from all the others in the absence of a socket at one end of the pipe. Therefore, the connection is made using fittings that are installed with an adhesive composition.

Although socketed PVC pipes are used today for external pressure water supply networks. It is the absence of a welding process that makes it possible to reduce the cost of the installation process. Although PVC pipes themselves are already the cheapest of all polymer products.

By the way, PVC pipes were the first plastic products that were used for laying water pipes. Back in 1934, the first PVC pipes were produced in Germany, from which the first plastic water supply system was built.

Steel pipes

Black steel pipes are intended for hot water supply

Black steel pipes are intended for hot water supply, galvanized types of pipes are intended for cold and drinking water, but not vice versa.

They are durable and low cost. They rust over time, so they will have to be replaced after a maximum of 25 years. They are afraid of low temperatures.

Classification of steel pipes according to the method of their manufacture;

Cast.

Smelted in the pipe foundry shop of metallurgical plants; Seamless. The blanks are made by forging; welded. They are formed by bending a steel sheet and welding with a longitudinal or spiral seam.

They differ from each other in strength and cost. Outer diameter: from 10 to 165 mm.

Classification of pipes by wall thickness:

- light; ordinary; with a reinforced wall; ordinary.

Copper

They are beautiful, durable, and are not afraid of temperature changes or rust. They are light, plastic, flexible, have a long service life, and are not afraid of a single freeze. Used for drinking water and heating systems.

Important! Copper pipes are not used for acidic liquids, for water with solid impurities, or at high fluid flow rates. They are not recommended to be connected to aluminum radiators.

Mounted using threaded connections or special welding.

Nuances of choice

For internal cold water supply, you can take any of the above options. For hot water supply, metal-plastic or steel is more suitable. Copper is also good in both cases, but is expensive. For external water supply pipelines, you should choose only steel or polyethylene products. They are not afraid of low temperatures in winter, and if the water in these pipes freezes, they will definitely not burst.

When choosing pipes for water supply, you must also take into account the expansion coefficient of the material at high temperatures.

Plastic pipes

This type of pipes is not afraid of corrosion, they do not need to be painted, they have a beautiful appearance

This type of pipes:

- not afraid of corrosion; no need to paint, they have a beautiful appearance; durable; does not lose lumen; has a long service life; economical, has a low cost; does not deteriorate the quality of water; easy to install; has low thermal conductivity, does not take away heat from the water, therefore often used for heating systems; does not resonate, therefore suppresses the noise of water flow.

Flaws:

- Not used for acidic liquids; Lose their strength under high loads; Not used in fire-fighting pipelines; Need protection from rodents. Not all types of pipes are suitable for hot water supply.

Copper

The advantages of copper are durability, corrosion resistance and bactericidal qualities that help disinfect tap water. The disadvantage is the high cost (from 300 rubles per linear meter).

The appearance of copper pipes allows them to be laid openly: the water supply does not spoil the design of the room at all

Characteristics

- Temperature - up to 150 degrees;

Note: in this case too, the temperature is limited by the heat resistance of the connections. Copper itself can withstand heating up to 400 degrees or more without loss of strength; it melts only at 1085°C.

- Recommended operating pressure - up to 25 kgf/cm2 at a breaking pressure of 200 - 240 atmospheres;

- Service life is estimated. In practice, the oldest copper water pipes have been functioning properly for more than a century without repairs or leaks.

Fitting

| Image | Description |

| Solder fittings are equipped with sockets that form a gap with the pipe of 0.1-0.5 mm. After stripping and fluxing, the pipe and fitting are heated in the flame of a gas burner or in a stream of hot air from a hair dryer, after which a solder rod is inserted into the gap between the socket and the pipe. Capillary action causes the molten solder to fill the entire cavity. After cooling, we have a maintenance-free connection with an unlimited service life. |

| Compression fittings are very similar to those used for installing metal-plastic. However, they use a conical copper ring as a seal. The plasticity of copper allows it, when tightening the union nut, to fill all the unevenness of the connection and ensure the tightness of the connection. |

| Press fittings are sealed with a rubber ring. The fitting is crimped onto the pipe using mechanical or electrical pliers. |

Pipelines made of polyvinyl chloride (PVC, PVC, CPVC, CPVC)

Used for cold water supply systems, because...

at temperatures above 60°C they lose their shape. For hot water and heating systems, chlorinated polyvinyl chloride (CPVC) is used (allowable water temperature up to +82°C). Due to their toxicity and flammability, they are prohibited for use in European countries.

They are connected either cold (with plumbing glue) or by welding (using cuffs). They are lightweight, chemically resistant, and mechanically strong. Their weak point is the joints.

Installation

What does it look like to install plumbing pipes yourself in each of the listed cases?

Plumbing, heating

| Material | Installation methods |

| Steel (dark and galvanized) | Gas welding, electric welding, threaded connections, compression fittings, flanges |

| Corrugated stainless steel | Compression fittings with silicone seals |

| Metal-plastic | Compression fittings, press fittings, push fittings |

| Copper | Soldering, compression fittings |

| Polypropylene | Low temperature welding using socket fittings |

| Polyethylene | Compression fittings with rubber seals, electric welding fittings |

| Cross-linked polyethylene | Fittings with sleeves - clamps |

Sewerage

| Cast iron | Chasing the sockets with a heel, filling with sulfur, less often - ring rubber seals |

| PVC | Rubber seals, in pressure sewers - adhesive connections |

| Polypropylene | Rubber seals |

| Polyethylene | In non-pressure sewerage - shaped with rubber seals, in pressure sewer - low-temperature butt welding |

Polypropylene (PP, PN?)

Polypropylene pipes are used for both cold and hot water supply

The following types of polypropylene water pipes are available for sale:

- PN10– for cold water supply, their wall thickness is 1.9-10 mm, water temperature up to +20°, maximum pressure 10 atmospheres; PN20– for hot water, water temperature +80°C, maximum pressure 20 atmospheres; PN16, PN25– used in heating systems.

Outer diameter: from 20 to 32 mm. They are light, strong, durable, non-conductive, and have a high degree of noise reduction.

The method of connecting pipes by heat welding deserves special attention.

The process takes place at a temperature of +260°C, which ensures the strength of the joint. There is a large selection of different fittings, adapters, etc. on sale.

conclusions

The selection of material for water pipes and the diameter of the water pipeline should be carried out depending on the highways and the volume of water that will be transported through them. It is also necessary to select the wall thickness and connection method.

Literature and sources used:

- Universal reference book for a builder / V.S. Alekseev. - M.: Ripol Classic, 2006.

- Terminology for construction thermal physics, heating, ventilation, air conditioning / B.A. Krupnov. - Moscow

- Engineering networks, engineering preparation and equipment of territories, buildings and construction sites / L.V. Weather. - M.: Dashkov and Co., 2010.

- Wikipedia article about plumbing

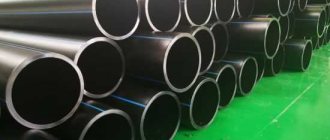

Polyethylene (PE)

They are distinguished by their elasticity, which allows them to be used in seismically hazardous areas.

There are three types of polyethylene pipes:

- HDPE – for use in high pressure systems; PSD – for medium pressure systems; HDPE – for low pressure. They are black in color, used for supplying drinking water, like well casing pipes, but are practically not used in everyday life due to their low density.

They are not suitable for hot water supply, as at elevated temperatures they become viscous and soften.

In addition, they are afraid of direct sunlight and age quickly. Not used at air temperatures below -20°C (except for some types stabilized with carbon black). Outer diameter: from 20 to 160 mm.

Formation of threaded connections

A thread is a spiral or helical surface used to make a threaded connection. The use of threaded pipe connections in plumbing systems is a classic installation method.

It is used where it is possible to periodically monitor the joints, because threads tend to weaken under the influence of various factors.

To connect elements using threads, simply screw in two parts that have suitable cross-sections. They are also easy to disconnect - by unscrewing.

There are different types of pipe threads. Each of them is characterized by such parameters as the profile of the surface on which the thread is applied, direction, location, and number of thread starts.

The list of the most popular types of pipe threads includes:

- cylindrical or Whitward;

- conical;

- round;

- NPSM

The first of them is designated by the letter G and has 2 accuracy classes. The profile visually resembles an isosceles triangle. At the apex there is an angle of 55⁰. They connect pipeline sections with a diameter of up to 6 inches, which are subject to special requirements for tightness, using inch threads. For larger diameters, welding is used.

Inch-type conical threads are used for conical connections and to create joints of conical threads made on the outside and cylindrical inside the pipe. The letter R marks the external thread, the internal thread - Rc, LH - directed to the left. The sealant is the thread itself plus the sealant.

To connect frequently disassembled plumbing fittings: water stop taps, faucets, round threads are mainly used. It is designated by the symbols Kr.

The table summarizes the main thread parameters for a pipe that you can cut with your own hands. An important value for an inch thread is its pitch. This is the distance between adjacent ridges or troughs. Its value along the entire length remains unchanged, otherwise the thread will not work

The NPSM thread profile has a triangle shape and an angle of 60⁰. The size range in inches is from 1/16 to 24. This American standard thread is a type of cylindrical thread. It differs from the domestic one only in the size of the profile angle.