An individual hydraulic extraction point provides many advantages for residents, including an independent supply of liquid, good pressure, and high quality of the resource. But all this can be achieved only if the well or borehole is created taking into account all the nuances, features of housing and terrain. In the article we will talk about how a home water supply pumping station is designed, its design principle and pump operation diagram, the composition of a water installation for a summer house or private home. This should help you choose the equipment that is right for you based on the required power, pressure, number of consumers and other aspects.

Purpose and advantages of equipment

If there is a need for hydraulic extraction for a small summer cottage with a house for seasonal living, then usually residents do not focus on high water pressure and constant pressure; they prefer a conventional, inexpensive pump. And even if it is not very reliable, it copes with its task quite well - providing watering for the garden for several months a year and satisfying the small needs for household water for 1-2 people.

But if an individual water intake point is required for a large private house, then the structure in question is installed. It has more power and has a number of advantages. But first, let’s look at what a water supply pumping station is needed for and how it is used – application and purpose:

- Autonomous water supply for housing. There is no need to connect to the main water supply. Residents are not dependent on the water utility, which means that they receive a constant amount of a resource of good quality. No outages associated with scheduled line repairs or emergency situations.

- Industrial use. Large wells with appropriate pump power are used in factories and production workshops. Water is supplied not only from the bowels of the earth, but also from open reservoirs and liquid storage tanks. Often large volumes are required for cooling, for example, in the field of metallurgy and energy.

- Watering greenhouses, gardens, vegetable gardens. Irrigation systems can be designed for industrial agriculture or for individual purposes. In addition to irrigation, the supply of moisture for livestock is no less important in the agricultural field; it can also be automated.

So let's summarize. The purpose of pumping equipment is known to everyone - it is lifting liquid from a reservoir (well, well, reservoir, storage tank) and supplying it to a house, production workshop or irrigation system. This creates a certain pressure and, accordingly, pressure. But, unlike a standard submersible pump, the operation of a water pumping station also depends on its design and components. Thus, additional elements ensure its autonomy and automatic operation; the relay allows you to determine the number of pascals and some other indicators. But in order to consider the purpose of each part separately, it is first worth talking about the system as a whole.

Important points in maintenance and operation

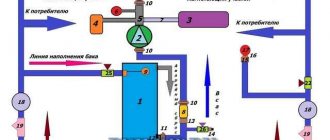

Pumping station connection diagram

The basic principles of operating the system allow you to extend its service life and avoid complex repairs. They boil down to the following:

- The room, caisson and pipeline before and after the pump must be insulated, otherwise the water in the system will freeze in winter.

- If living in the house is not expected in winter, the water from the hydraulic tank and pipeline must be drained before the onset of frost.

- Regularly (once a month and after each preservation of the system) you need to check the correct operation of the pressure switch.

- It is important to clean the coarse filters regularly. The frequency of the operation depends on the degree of contamination of the water at the source.

If the filter becomes clogged, this will cause the pump to run idle and the equipment may burn out.

What does the water supply apparatus consist of?

Depending on your preferences and skills, you can install two system options:

- In factory configuration. Then all the components will be assembled compactly and will not take up much space. They will correspond to each other in terms of technical characteristics, and the entire set will have a warranty from the manufacturer, instructions for use, installation and repair work. In our opinion, this is the most preferable option. As a result, it will also save you money.

- Assembled with your own hands. First you need to know exactly what the pumping station consists of and its operating principle. Then you need to find all the components, check their operation separately, and then assemble them correctly. This is relevant, for example, if you already have some elements of the system, and you only need to purchase part of it. With the right approach, this option can be more economical.

There are people who make their own devices, excluding one of the elements. For example, they remove the hydraulic accumulator. Indeed, without a storage tank it is possible to maintain a certain pressure directly in the pipes, automation will be achieved and costs will be minimized, however, the savings will only be temporary. In fact, the absence of this necessary element will lead to an increased impact of water hammer. The fact is that when the tap is turned on and off, a pressure surge occurs. And without a water tank, shocks will fall directly on the pump, which will lead to its rapid wear.

Based on the reasons presented above, we will consider the structure of a purchased pumping station. It consists of the following components:

- Electric pump. It can be submersible or surface, it depends on which reservoir is chosen as the source (well or surface of the reservoir). It can be centrifugal or vortex type.

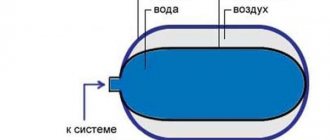

- A membrane hydraulic tank, also known as a storage tank or hydraulic accumulator with a “pear”. Due to the expansion of the membrane, switching on and off occurs.

- A device for measuring pressure - a pressure gauge.

- Relay. It turns the pump on and off automatically when the sensor requires it.

- Connecting fittings.

We mainly consider the composition of a compact installation, that is, equipped not with a submersible, but with a surface pump. On the water intake side, a coarse filter must be installed (you can order it at), and on the outlet side, a pipeline is connected that supplies liquid directly to the building.

Here is a view of one of the common models:

Device types

- Superficial.

- Submersible.

In most cases, surface devices are used.

They are mounted on a frame. It has a hydraulic accumulator and automation. The pump has two outlets for pumping/supplying into a private home. Surface type units have the following advantages and disadvantages:

Pros:

- Ideal for sources with small diameter.

- The optimal solution for wells whose depth is no more than ten meters.

Minuses:

- If the water level drops, problems will arise.

Submersible well units are ideal for deep wells.

Automation and other equipment, except the pump, remain on the surface. This system allows you to lift water from a depth of about 50 m. Pros:

- If it is not possible to dig a well, then a submersible installation will allow you to lift liquid from deep wells.

Minus:

- Air in the line makes it difficult to start the pump. Therefore, it is necessary to install a check valve on the supply pipe.

Pump design and design diagram of a water pumping station for water supply at home

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

The presented system is on average designed for a pressure of 1.5 atmospheres (maximum - up to 4.5), which is usually sufficient for a two-story cottage with permanent residence of 4-5 people and the use of all household appliances that consume resources.

During installation, it is important to note that the device is compact and does not require concreting or any other foundation. The heaviest element is the hydraulic accumulator; its weight directly depends on the maximum volume of accumulated fluid. When installing, it is necessary to prepare a separate room or use a room for domestic purposes, remote from residential ones, for example, a basement or storage room on the ground floor. This is necessary because the station makes a hum.

Sometimes a reasonable solution is to install a caisson, that is, a separate chamber. This allows you to create sound insulation, protect equipment from precipitation and other environmental influences, and also make access for maintenance and repair easy.

Let's give a diagram of the pump for installation:

Popular models

Now we invite you to familiarize yourself with the list of which system is better. Let's compare several units according to parameters and different price categories. This will help you choose a device for your garden.

| Manufacturer | Description |

| Quattro Elementi Automatico 801 | From 6 thousand rubles. Chinese manufacturer. At a low cost, a solid service life is observed. The package includes a check valve, filter, etc. The installation is also equipped with automation, resulting in an ideal unit. Productivity – 3.2 m3/hour |

| GARDENA 3000/4 | From 10 thousand rubles. It is distinguished by its silent operation, low weight and high-quality body. Among the disadvantages is the plastic tee installed inside the pump. It often breaks down. The outlet/inlet pipes have weak threads. Productivity – 2.8 m3/hour |

| GILEKS Water cannon PROF 55/90 House | Cost from 25 thousand. Easy to install. An obvious disadvantage is the short lifespan with regular use, about four years. Productivity – 3.3 m3/hour |

| Wilo HMP 603 1 | Cost from 30 thousand. The high price is fully justified by the excellent quality of the installation. Additionally, you should purchase a dry running relay. Otherwise a great option. Productivity – 8.1 m3/hour |

| ESPA Aquabox 350 TP 15 4 M | Cost from 80 thousand rubles. Ensures uniform and stable water supply. Automation increases operating comfort. The price is fully justified by its technical characteristics. Productivity – 3.6 m3/hour |

Control unit - what it is and how it works

The main advantage of the pumping station is automation. That is, you don’t need a special person to monitor the pressure in the network and turn the device on and off. All this is done automatically. And it consists of two main semi-automatic components:

- pressure gauge - a device that measures the pressure in pipes; when it is low, a signal is sent to start the pump;

- relay - consists of two springs that open and close the circuit to apply pressure and remove it. It works based on the liquid level in the tank.

It is important to pay attention to the factory settings, as they usually correspond to the values of the shut-off valves, but in some cases it is necessary to change the extreme values on the relay.

An additional element is the flow controller. When there is no water in the system or the flow becomes smaller for some reason, the device signals this. Its actions lead to minimizing the risk of engine overheating.

Below is a diagram of the electric pump control unit:

Water supply installation

We suggest you study the installation features. There are several important criteria:

- Electricity. The selected location must be accessible to connect the device to electricity. Often, a caisson is installed near the source, and electricity is supplied to it.

- Location. The hydraulic system is installed at a distance that will allow the pump to operate without load. That is, those must be taken into account. characteristics of the unit. It is important to take into account the depth of the water surface and the length from the pump to the tap.

- Immersion depth. It’s good if you can install it in a warm place. Otherwise, a caisson is installed. It is made at a depth that is inaccessible to frost in your area. A natural change of air must be ensured to prevent the formation of condensation.

- Soundproofing. If the system is installed inside the house, the room should be properly soundproofed. Otherwise, the operation of the device will interfere with a calm and quiet life.

Please note! The unit must not be leaned against a wall, as vibration will be transmitted to the room above. Therefore, installation is only on the floor.

Installation errors

Incorrect installation leads to malfunctions. Common mistakes:

- Wrong choice of equipment. A heavy-duty pump is installed that has greater productivity than the well's flow rate.

- No filter. Because of this, sand gets into the system, which can destroy important structural elements.

- Significant waste of water. You need to understand which system to choose. If the consumption is expected to be 3 cubic meters per hour, then you should not take more, otherwise the unit will wear out. This option provides a different connection scheme for a submersible pump with a hydraulic accumulator, which reduces the frequency of pump activation.

- Anticipate power surges. If the power goes out frequently, this can damage the installation.

- The well system is selected based on capacity.

- Selecting a smaller pipe diameter than the thread on the device.

- Buying a small cross-section cable. An incorrect choice will result in engine overheating.

- Lack of RCD. The station for supplying water from a well must be equipped with an individual automatic power shut-off system.

- Lack of measuring instruments: sensors, etc.

Operating principle of a pumping station with a hydraulic accumulator

When you choose a connection with a hydraulic tank, it is important to decide on the volume of the tank. It directly depends on the expected daily amount of water consumed (this should be calculated in advance, taking into account how many people live in the house and what equipment they use). For a large family you need a tank of 100 liters or more. The smaller the tank, the faster the membrane wears out, since pumping is done more often. But if little fluid is used and the accumulator is too large, then the unused resource can stagnate and deteriorate, so the axiom “the more the better” is not relevant here.

The operating principle is shown in the diagram:

The meaning is this: inside, like into a car tire, air is pumped through the nipple, creating an internal pressure of 1.5 atmospheres. When the pump operates, water enters the cavity on the back side of the membrane. Thus, the more liquid, the more the bulb compresses - the pressure value increases. When the moisture supply does not work, water flows into the tap due to the influence of oxygen.

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

In standard models, the space for water takes up about ⅓ of the total volume of the tank, the rest is compressed air. Its main purpose is to maintain constant pressure in water pipes. The second task of the hydraulic tank is to reduce the impact of water hammer on equipment. A modest-sized tank is also suitable for these purposes. However, the smaller it is, the more on/off cycles occur, and this negatively affects the equipment.

Which pumping equipment to choose

Factory-built pumping stations come with a surface hydraulic pump, often having an internal or external ejector. However, hydraulic accumulators can also be used with submersible pumping equipment, but are given the slightly different technical term "pumping system".

When operating in tandem with a station, membrane tanks may be smaller in volume than hydraulic tanks for systems with submersible pumps. This is due to the fact that submersible pumping units have less permissible on/off switching times per hour than surface pumping machines.

Surface pumps with an internal ejector have serious limitations on the depth of water intake. They can only lift water from 7–8 meters. However, they produce a powerful water pressure at the outlet with a water column of 40–60 meters (4–6 bar).

Selecting a location

The closer the water intake point to the house, the better. This is explained by the fact that every 10 meters of the pipeline reduces the suction characteristic by 1 m. This must be taken into account when choosing a pump and its maximum depth.

Suitable location:

- Outside the building in a special chamber in the ground near the well.

- The outside of the premises is in a pavilion with insulation.

- In the basement of the house.

If all-season operation is planned, then it is necessary to bury the pipes to the depth of soil freezing and, accordingly, insulate them. Installation diagram:

Correct use of equipment

Pumping stations are designed for long-term autonomous operation in continuous mode. They can be used for domestic water supply and fire extinguishing purposes. Modern models of the Jumbo brand are distinguished by excellent characteristics and high reliability. They require minimal maintenance. During their normal operation it is necessary:

- periodically carry out an external inspection for the absence of omissions and extraneous sounds;

- wash the coarse filter at least once a year;

- in case of a long break for the winter period, empty all cavities of water and store the dismantled equipment in a heated room;

- At the first start after depreservation, check the correctness of all connections and make sure that the pump operates smoothly.

What are the advantages of an installation with a hydraulic tank?

Let us list the advantages of pumping stations and their components:

- Automation of all processes. A person is not obliged to regulate the operation of the device, monitor the water level, pressure in the system - the control panel is responsible for all this. This not only frees you from unnecessary actions and minimizes labor costs, but also reduces the risk of breakdown, since there is no human factor. And the device is responsible for preventing overload.

- Cost savings up to 50%. The presence of a hydraulic accumulator (a reservoir for temporary storage of water) allows you to reduce the number of pump starts and stops. Moisture accumulates in the tank and is gradually consumed. And only when it reaches the minimum level, the sensor is triggered, indicating that the system needs to be turned on. This device involves reducing energy consumption.

- Maximum reliability. Depending on the model and the components of the pumping station, it will have different service life, however, it will significantly exceed the period of use of a conventional pump with the same volumes of pumped resource.

- Relative autonomy from the electrical network. The presence of a hydraulic accumulator allows you to use the water supply for some time after a power outage. The amount of water in reserve depends on the volume of the storage tank.

- Uninterrupted pressure. A conventional pump can produce different pressures in the pipeline. This will depend on many parameters, including the groundwater level. And with a hydraulic accumulator, the pressure remains constant.

Installation steps

Installation of equipment for pumping water from a well/well takes place in several stages:

- The fully assembled system is equipped with filters.

- Connect the unit to the suction line and be sure to ensure grounding.

- Fill the membrane tank and system with water, adjust the pressure switch.

- Turn on the pumping station.

To dampen vibrations, a special anti-vibration gasket must be placed under the equipment. The room or caisson for installing the station must be insulated so that the water in the tank does not freeze in winter.

What to consider during installation

An important point: even before installation, care should be taken to ensure the availability of rough water treatment. Otherwise, soil particles and other contaminants will enter the pump, which will quickly lead to equipment failure. It is best to order filtration systems from - there is a large selection and excellent quality.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

You should also not forget about the check valve. It should be installed to prevent water from flowing back into the well when the system is not working.

Special attention should be paid to electrical safety, since the combination of moisture and electricity is not the best tandem. Be sure to install an RCD to avoid short circuits.

Otherwise, the station is very easy to connect.

How to assemble and connect a household system to a well?

It is necessary to prepare all the components: pump, accumulator, automation, pipe, cable, filter, check valve and adapters.

Knowing the connection diagram, you will understand the sequence in which the installation should be assembled:

- A HA is attached to the pumping apparatus for the well.

- The pump is connected through a special adapter.

- An automation system is mounted on the same adapter: dry running relay, sensors, etc. It is important to know how to properly configure the automation for its correct operation.

- A check valve and a coarse strainer are attached to the end of the pipeline, and all this is lowered into the source.

- Additionally, you can mount a check valve in front of the hydraulic accumulator in case the first one fails.

- A hydraulic station with an electric drive necessarily requires the installation of an individual RCD.

- Before connecting the unit to the well and starting it up, it is important to make wiring around the house and install shut-off valves.

The water supply device itself from the well is installed in a clean and dry basement, on a rubber gasket to level out possible vibration. This option is suitable for a summer residence.

Advice! In addition to the coarse filter, the well station can be equipped with a system for retaining fine fractions. The quality of the water influences the decision. The fine filter is mounted on the surface.

Pumps and ejectors

Pumping equipment can be:

- Centrifugal. Inside the chamber there are two parallel wheels that rotate and, with the help of blades on them, set the liquid in motion. This type is the most popular.

- Vortex. It implies the presence of a working area in the form of a ring. While moisture flows through it, it swirls in vortices.

An ejector is a mechanism inside a pump that operates using differential pressure. Due to the narrowing of the shape, a change in atmosphere occurs and, as a result, the working medium is forced to be sucked into the pipe. It is connected according to this scheme:

Details

How to choose a device

If the station is manufactured at a factory, then it is equipped with a surface-type pump, which has an ejector inside or outside the housing. There are stations with a submersible pump type, but they are called a pumping system.

If a membrane tank is installed as part of a station, then they may have a smaller volume than a water tank in systems with a submersible pump. This parameter depends on the fact that submersible devices have a smaller number of pump activations per hour than surface-type pumps.

If there is an ejector inside the surface pump, there is a limitation regarding the depth of water intake. The maximum dive is eight meters. When leaving the system, a strong liquid pressure is created, with a column of up to 60 meters, under a pressure of up to six bar.

Air plugs will not interrupt the operation of the internal ejector. First, the device pumps air, then pumps water into the pipeline from the source. The disadvantage of a station that has an internal ejector is considered to be loud noise during pump operation. If you plan to install a pump in the house, then it is better to prepare a utility room for this that is soundproofed.

When installing a remote-type ejector, you can lower the pump into the well to a depth of up to fifty meters. The operation of the pump is economical, but not so productive, the efficiency does not exceed forty percent. Their quiet operation is considered a plus.

How to choose a location for installing a station

The location of the equipment depends on the characteristics of the pump. The suction capacity of the pump decreases by a meter with each extension of the horizontal pipeline that is laid between the pumping device and the well.

When the pump is more than 10 meters away from the well, a unit with a high suction depth should be installed. The station can be located:

1.in a special caisson located outside near the well.

2.in a special warm room built for the pump.

3.in the basement.

When arranging a stationary option, a caisson should be installed outside the building, a pressure pipe should be laid from it to the house, which is buried in a trench to a depth below the soil freezing layer.

Attention! If the pipeline is planned to be operated all year round, then the pipe rolls should be laid in the ground, lower than the soil freezing limit.

If the pipeline is used in the summer, then it can be laid on the surface of the ground, or without being buried below sixty meters.

When installing a pumping station in the basement or ground floor, care should be taken to insulate the device. The suction pipe must pass below the freezing level of the ground.

Sometimes the well is located inside the house, and the pipeline is short. Not every cottage allows you to install the pump in this way.

Pumping units can be installed in a separate building when used in the warm season. Otherwise, the room should be heated; the best option is to install the station in an already heated house.

Attention! The instructions for the pumping station indicate the maximum temperature values at which the station operates uninterruptedly. They must be taken into account when choosing an installation location.

Advantages of a station with a hydraulic tank

In an autonomous water supply system, the pump is considered the main part of the structure.

With the help of it, liquid is supplied from a well or borehole. Water is distributed through the operation of a pumping unit, either using a hydraulic tank or using a hydraulic accumulator. If you use one pump to distribute liquid, problems may arise. This design will work constantly, which reduces the service life of the device. If there is a power outage, there will be no water in the house at all.

To reduce the level of wear and tear and ensure that the house is constantly supplied with water, a storage tank is used. It can be a water pressure tank, which is located in the attic, from which water flows by gravity to the plumbing. The pressure can be maintained by a hydraulic accumulator in the form of a membrane tank, or hydraulic tank.

The pump runs when the water in the tank needs to be replenished. If the station has a hydraulic tank, then the control system is activated based on pressure indicators.

Attention! The station, which has a water storage tank, creates a liquid reserve if the electricity is turned off. While equipment with a hydraulic tank will stop working completely without power supply.

The water container is quite heavy; if you place it in the attic, you will need to additionally strengthen the ceilings and also insulate the room. If the tank is of membrane type, then this design is more convenient and practical to use. The operating principle of such a station is based on the artificial maintenance of liquid pressure in the pipeline. The water pump starts working only to fill the tank. Compressed air helps move water into the system.

The option with an expansion tank differs from the hydropneumatic installation in being more bulky in size. When operating a membrane accumulator, water hammers on the network are eliminated, a stable pressure in the pipeline is maintained, and maintenance of this type of device is easier. These qualities can be attributed to the positive characteristics of the hydraulic tank.

The disadvantages of a pumped accumulator station include dependence on electricity. The storage tank has standard volumes from 25 to 30 liters. The pump runs frequently to fill it; in the absence of electricity, there is not enough liquid for a long time. Therefore, an autonomous energy generator should be installed.

Frequent station problems

If there are interruptions in the operation of the station associated with frequent switching on of the unit, and it immediately turns off, you need to inspect the hydraulic accumulator for air pressure. If it is lowered, then it is pumped up. If the membrane with the tank body is intact, the problem can be easily fixed. If the integrity of the parts is damaged, you will have to contact the service for repair.

If drops of water appear on the nipple located on the air valve, you should immediately disconnect the accumulator from the water supply. This sign indicates a problem in the membrane. It will have to be replaced. Do not allow air to enter the water supply of your home.

If the equipment does not turn on, inspect the pressure control lever. In some situations, the pressure on the relay is higher than the operating pressure. Sometimes air enters the suction hose, which triggers the dry-running protection system.