Sewer wells are a mandatory attribute of external sewerage; without them, its installation is impossible. They must run along the entire length of the pipeline. Their design and quantity may vary slightly, depending on the type and purpose of the structure, complexity and length of the system.

The process of constructing such a device is not complicated, the main thing is to understand the difference in types of structures, because a homemade septic tank or cesspool is also a well, and to comply with the rules and requirements. After this, it will be easier to make an efficient and trouble-free sewage system for your home.

Types of sewer wells

A structure of this kind has its own purpose and method of construction. Sewage tanks differ in a number of ways.

By functional purpose

There are several types of wells:

- Cumulative. This is a more modern and environmentally friendly option for a waste pit. It carries out fractionation of wastewater and sewage. Liquid and light particles are directed into the filtering septic tank, and heavy particles fall to the bottom of the storage tank. The volume of the structure is 2-50 thousand liters and depends on the amount of water used. It must be installed at the lowest point of the site, which ensures the correct angle of inclination of the sewer pipes.

- Filtering. The structure is designed to discharge wastewater into the soil. The well design has no bottom. The installation of filter collectors is allowed only on sandy and sandy-clayey soils. As a rule, wells are made of reinforced concrete rings. Sand, crushed stone and special materials can serve as a filter.

- Lookout. Used for periodic inspection and convenient cleaning of the drainage system in small areas where the direction, slope or diameter of pipes changes, in connection areas. Unlike other types of treatment facilities, presented in the form of a pipe or collection tank, the inspection tank is an open container. It is mounted in a straight line in increments of 15 meters, while the initial well is placed at a distance from the house no closer than 3 meters and no further than 12 meters.

- Turning. The structure is intended for areas with a branched drainage pipeline, as well as in cases where the angle of rotation on the pipeline exceeds 90 degrees. This is due to the lack of possibility of constructing a continuous straight section from a residential building to a storage septic tank. Rotary collectors must be erected at each bend of the laid pipe. This design can be used as an inspection septic tank, which makes it quite easy to clean a certain section of the pipeline through it.

- Perepadny. Used in areas with large elevation differences. In this case, the inlet pipe is placed much higher than the outlet pipe. The design of the septic tank has a drop, which is a vertical pipe going into the well, which is connected to the inlet. The lowering is attached to the tank wall using clamps. The length of this element depends on the difference in the area. On the reverse side of the lowering, a 45 degree bend is installed.

By materials used

Collectors are made from various materials:

- Reinforced concrete. The structures are durable, resistant to the negative effects of chemical compounds, and fairly easy to install. In addition, they have a large weight and different ring diameters. The products are used for constructing septic tanks of filtering, storage and inspection types. Suitable for installation in any type of soil.

- Brick. For the construction of the collector, clay waterproof bricks are often used. Brick can be used to build structures of square, rectangular or round shape.

- Plastic. Structures made of polyethylene are characterized by high strength, tightness, wear resistance, as well as ease of installation and relatively low cost. They are used for installing rotary, differential and inspection septic tanks.

Reinforced concrete structures are durable, resistant to the negative effects of chemical compounds, and fairly easy to install

How to monitor the water quality of drinking wells

When the relevant authorities check the quality of water in drinking wells, the surrounding area is also subject to inspection. The main types of water quality control:

- Planned. It is carried out after a certain period of time. Includes a set of basic measures to determine the water quality of all water supply sources (wells, wells).

- Selective. Can be carried out in regions where problems with water supply systems were previously noticed.

- According to one-time applications. The initiator of such a check is the direct owner of the land plot. Performed to check the suitability of water.

Often, the first water intake may include too many harmful bacteria and microorganisms. Then a more in-depth examination of the water is carried out, which determines the cause of the deterioration of the water. All indicators are compared with the standards of the relevant instructions.

To improve the quality of water, the drinking well can be cleaned and subsequently disinfected. If after this the problem has not been eliminated, then the quality of the water is improved by using special preparations with a high chlorine content. If the pollution is of a chemical nature (especially pollution with aggressive substances), then a decision may be made to eliminate the source.

Rules and requirements

The process of planning and construction of sewer systems is carried out by Special Rules and Regulations (SNiP), regulating certain requirements, the main of which are:

- Structures should be located away from sources of drinking water and plumbing systems.

- Collectors should be installed at a distance from residential buildings and nearby areas.

- The volumes of the tanks must correspond to the number of people living in the house and the average volume of wastewater over a certain time period.

- The depth of the pit for the tank should not exceed 2.5 meters , and its diameter should be half a meter larger than the diameter of the structure.

- The need for waterproofing at high groundwater levels.

- The bottom of the pit must be covered with a sand cushion 10 cm high.

- A gap of 60 cm must be provided between the bottom of the tank and the bottom of the pipe

Collectors should be installed at a distance from residential buildings and nearby areas

Network composition

Various sources can be used for water supply. There are social and autonomous types. Public ones have high power and are capable of providing water to large settlements. Autonomous are wells or wells designed to supply a certain, relatively small number of consumers.

The public complexes include:

- main lines or water intake;

- stationary treatment plant with a preparation complex;

- pumping station providing standard pressure in pipes;

- system of pipes, wells, shut-off valves, and other technological components.

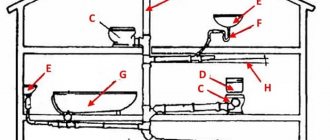

Sewage systems are also divided into public and autonomous. The first has a branched structure, largely replicating the water supply network. Installation of sewerage networks is carried out according to our own standards, of which sanitary requirements come first. The drainage systems include:

- pipeline complex;

- wells for one purpose or another (inspection, rotary, extinguishing, differential);

- pumping stations;

- open trays (for rain nets);

- filters, sand traps, settling tanks.

Treatment facilities are also part of the sewer system, but form a separate group of structures. In autonomous systems of private houses, waste disposal is carried out independently. There are structures that accumulate wastewater, but require periodic pumping. There are more modern installations that can process organics partially or completely. They are built according to their own rules, which cannot be ignored.

Construction of a sewer well

Preparatory work

Preparation for the construction of sewer septic tanks consists of several stages:

- drawing up a drawing of a sewerage diagram with marking of the installation location of the collector, layout of the site;

- cleaning the construction site;

- organization of a temporary road for equipment at the construction site;

- digging a pit and trench;

- cleaning and leveling the bottom of the pit.

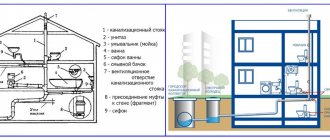

Sewage well design diagram

What standards regulate the location of objects on the site of a private house?

The main document according to which the construction of a house and the installation of communications is carried out is the project. It contains a work plan indicating all distances and dimensions. The distance from the house to the sewer drainage point is also indicated here. During design, we are guided by two standards:

- SNiP 2.04.01-85;

- SanPiN 2.2.1/2.1.1.1200-03 (or 2.1.5.980-00).

These documents detail all the requirements for sewerage and define the minimum permissible distances between objects and buildings. It must be taken into account that instead of SNiP, the updated version of SP 30.13330.2016 is used today. It is more in line with current realities, although there are no fundamental differences. Regardless of where and by whom the sewerage system is built, the rules and regulations must be strictly followed.

Some owners of private houses believe that the location of the sewer system is their own business. This is a wrong point of view. The rules and regulations specified in building and health directives must be followed by everyone without exception. If the system is being built on the site of a country house, the requirements are more relaxed. But, for a residential building, all existing requirements must be met.

It is noteworthy that the issue of the distance from the septic tank to the house is ambiguous. While the minimum value is clearly defined, the maximum value is not mentioned anywhere. Sanitary standards for sewerage for the private sector also do not mention a maximum. It is only noted that it is advisable to make the distance as large as possible. However, if the septic tank is too far away, blockages or defrosting of the pipes are inevitable. Under such conditions, the system will not be able to operate normally. Therefore, the location of the sewerage system on the site must meet not only sanitary, but also operational requirements.

Construction of a stone well

The construction of a septic tank from reinforced concrete rings is carried out as follows:

- After installing the first ring, holes are made in its walls for pipes, which should be inserted into the ring no more than 10 cm

Soil is excavated from the internal contour to level the structure horizontally. To eliminate errors in operation, this process should be controlled using a level.

- After installing the first ring, holes are made in its walls for pipes , which should be inserted into the ring no more than 10 cm. The hole is sealed around the circumference of the pipes with a solution.

- At the bottom of the tank there is a concrete trench located from the pipe inlet to the outlet. The cross-section of the gutter must be equal to the diameter of the pipes. To make it, you can take part of a sewer pipe.

- After installing the first ring, install the next one. At this stage, it is necessary to ensure that the locks on the inside of the rings are located at the same level.

- Upon completion of the installation of the last ring, the bottom of the collector is filled with concrete mortar , and the junctions of the rings are sealed with a sand-cement mixture. When constructing a filtering septic tank, its bottom is not concreted, but covered with 0.5 m thick crushed stone or crushed brick.

- Next, the structure is covered with a concrete slab with a hatch. You can also install a frame with a hole and fill it with concrete.

- After installing the well, they begin laying the pipeline at a depth of 60-70 cm with a slope of 2 cm through each meter of the pipeline.

- The next step is to test the design for 24 hours. To do this, the collector is filled with water, and the ends of the pipes are closed with plugs.

- After testing, the outer walls of the tank are covered with earth and thoroughly compacted.

- The final stage is to make a concrete blind area around the neck 1.5 meters wide.

Let's consider the technology of building a brick collector:

- A pit is dug, at the bottom of which formwork is installed and filled with a solution of cement, sand and crushed stone 20 cm high.

- Allow the solution to harden for 7 days , while periodically sprinkling with water.

- After the mortar has hardened, they begin laying brick walls using a cement mixture.

- The erected walls are plastered with sand-cement mortar.

- Without waiting for the solution to completely harden , iron the surface by rubbing a thin layer of dry cement into the plaster.

- The bottom of the collector is formed depending on its purpose.

- Waterproofing of the plastered layer is carried out.

- Cover the internal walls of the septic tank with mastic or bitumen.

- Form holes for pipes.

- The pipes are installed, and the resulting gaps are sealed with sealant.

- Fill the space between the pit and the walls of the well with soil and compact it thoroughly.

- Cover the collector with a hatch.

The construction of a well from natural stone is carried out according to a similar scheme. Difficulties in the process of its construction arise due to the unequal size and shape of the stones. Therefore, arranging the collector requires much more time and solution consumption.

Construction of an inspection drainage well

Material of manufacture

The sewer well shaft can be made of various materials. The most common:

- brick;

- concrete;

- plastic.

| Brickwork | High strength; if you know how to use a trowel, installation will not require much time. Holes in the walls are made during the construction phase. |

| Concrete | Installation - using formwork or installing ready-made rings. Holes for pipes in poured structures are made during pouring, in rings - with a hammer drill or other tool. |

| Plastic | Made from Eurocubes or barrels. There are also factory containers that include trays with various types of wiring. May require anchoring to concrete base. |

For brick and concrete wells, waterproofing of the walls, outside and inside, and the bottom is necessary.

Features of well construction

When building a septic tank, it is important to take into account the installation features of each, depending on their purpose and material of manufacture.

The peculiarity of a filter well is that its main task is to clean wastewater from harmful impurities. To accomplish this task, the bottom of the collector is covered with crushed stone about 1 meter high. In this case, the bottom is not completely filled with concrete solution, but only along the perimeter. This prevents the destruction of the base and the release of water through the center of the circle in which drainage and cleaning occur.

For the construction of an inspection well, it is customary to use a pipe with a diameter of 46 cm. This pipe size makes it possible, if necessary, to clean the structure with water using a hose. If you need to go down into the tank, the diameter of the pipe must exceed 92.5 cm.

When constructing an inspection collector on an area without a road surface, an additional blind area is required, which facilitates the drainage of wastewater. If the road surface is of high quality, installation is carried out 7 cm above the ground surface.

Storage tanks are installed in the lowlands of the site to ensure water flows into the well. The structure is placed at a depth of 3-6.5 meters, no more than 7 rings are used during construction. At the bottom, special depressions are made, which are filled with sand or crushed stone. Water from the reservoir can be used for domestic needs.

Locations depending on destination

The installation of inspection cameras is regulated by construction documents. According to SNiP, inspection points are installed in places of turns, as well as slopes when changing the linear pipeline. And at the junction of the central line of additional branches.

The removal of sewer systems for residents of the private sector is possible with the installation of inspection cameras. The diameter of the installed pipe is directly affected by the distance of its installation (linear section).

For pipeline lengths up to 35 meters, elements with a diameter of 150 mm are used. There is an inverse relationship. For example, if the diameter of the pipes included in the overall pipeline system is 150 meters, then, according to the installation conditions, there must be an inspection well after 35 meters. An industrial control system may be fundamentally different from its counterparts installed in the private sector.

Blitz tips

- It is not recommended to make the trench depth too large , because you will need to add soil, which will subside over time. As a result, the highway may change the correct slope.

- To avoid damage to the pipeline, it is prohibited to place solid objects under the pipes during their installation .

- When choosing a site for the construction of a filtration or storage collector, it is necessary to provide for the possibility of equipment access to clean the structure.

- Despite the fact that a sewer septic tank is a wet type of well, its tightness must be ensured. This is necessary in order to minimize the penetration of wastewater into the environment. To waterproof the ring joint areas, special waterproof compounds are used.

- During the period of providing a waterproofing layer for 3 days, it is necessary to exclude the impact of mechanical loads and low temperatures on the surface. During this time, the treated areas should be regularly moistened using a regular sprayer. You can also cover the surface with a film, which helps reduce moisture evaporation.

Water protection

The control well on the sewer must be impermeable to water to prevent contamination of the soil and the environment by runoff. For this purpose, water protection is carried out using special means. It can be:

- rolled materials (roofing felt, waterproofing, PVC film);

- cement mortars;

- mastics;

- coating mixtures;

- membrane materials.

Waterproofing is carried out as follows. First, prepare the surface, clean it, and level it. Then the joints and joints are filled, only then the entire inner surface is covered.

Sewerage service control points can be divided into two types:

- serviced;

- managed.

The first type of device has a hatch; it is opened for periodic inspection of the condition of the system. In controlled points, control occurs using a special control cabinet. There is no need to go inside when the measurement occurs automatically. Equipment inside the monitoring well measures environmental indicators and shuts off the water if the measurement results differ from the norm.

The sewer system includes control wells for monitoring communications, periodic inspection, cleaning and maintenance. Solving all problems related to testing the quality of wastewater and the functionality of the entire system is impossible without control points.

Determining the location of the cleaning system

Any construction, including those that involve the installation of cleaning equipment, requires the need to carry out preliminary engineering calculations. If you have not yet started building a house, then this should be done in parallel with the layout of the main building. This will avoid problems, because sewerage in a dacha with your own hands can only be installed at a distance equal to or greater than 5 m from the house. If there is a well or other source of water on the site, then the distance from it should not be less than 30 m.

Before you make a sewer system in your dacha with your own hands, you should choose a hill, which is required to eliminate the possibility of natural water runoff. Installation of sewerage system elements must be done with a certain slope. But it is not recommended to use pipes that have bends, as this will certainly, sooner or later, cause a blockage.

Distance from underground utilities to foundations

SNiP 2.07.01-89 allows for the laying of underground communications within the boundaries of support foundations and pipeline overpasses, subject to the provision of protective measures in the event of settlement of the foundation base and accidents in the line.

Construction acts SNiP 2.07.01-89 establish the following distance limits to the supporting foundations of houses:

- water supply – 5 m;

- individual and storm (rain) gravity sewerage – 3 m;

- pressure sewer – 5 m;

- drainage pipeline – 3 m, accompanying drainage – 0.4 m;

- gas pipelines of low, medium and high pressure - 2, 4, 7 or 10 m, respectively;

- heating networks - from the tunnel wall 2 m, from the protective shell of pipes for channelless installation - 5 m;

- electrical cable lines and communication cables – 0.6 m;

- switching channels and tunnels – 2 m.

Fig. 4 Construction standards for distances between communications and underground networks

How does a sewerage scheme work?

Regardless of the number of containers, septic tanks work the same. Once in the first chamber, the wastewater is divided into heavy fractions, which settle to the bottom, and light fractions, which remain on top. Mechanical cleaning is complemented by the activity of anaerobes, which convert organic matter into gases. They escape into the atmosphere through the drain pipe of the internal sewage system or the ventilation riser in the septic tank.

A fatty film forms on top. To prevent it from getting into the next chamber, a tee is installed on the overflow, which is lowered into the drains below the film. There may not be a second tank, then the wastewater purified by gravity and anaerobic methods is discharged to filtration facilities, where post-treatment occurs. Such structures are common among summer residents who come only on weekends. But it should be borne in mind that a single-chamber septic tank quickly silts up and needs to be cleaned more often.

The processes in the second chamber do not differ from those that occurred in the storage chamber. Here, the pre-treated wastewater becomes even lighter. Silt falls to the bottom, and the remaining organic matter is processed by anaerobes. Then the water is sent by gravity for additional filtration or goes into an aerobic septic tank. This is where the final cleaning takes place.

What types of concrete rings are there?

It must be said that the rings are made at factories from fine-grained concrete, which, of course, gives them strength. In addition, reinforcement is often used for even greater reliability. Therefore, there is no doubt that the sewer well will last for many years.

When choosing concrete rings, pay special attention to the diameter. It can be different. And the volume of the future well will depend on which one you choose. In general, experts advise calculating all the necessary data at the design stage. To correctly determine the volume of a well, take as a basis the fact that about 200 liters of waste water per person per day.

If the sewer wells are small in volume, they will have to be emptied very often. And this, as they say, is money down the drain. Therefore, it is worth taking the design of the structure very seriously.

Having found out the required volume of the well, calculate the number of concrete rings that will be required for construction (read also: “Installing sewer rings - what to do and in what order”).

Concrete rings are produced in two types:

- Concrete rings of normal permeability

. Suitable for use in non-aggressive, soft soils. And in aggressive, clayey soils they are used only for closed pipelines. When planning a septic tank in clay soil, you need to study the features of such a device. - Concrete rings of low permeability

. Can be used in soils of any composition. They are also ideal for collectors, septic tanks and inspection wells.