To provide a dacha or private estate with high-quality drinking water, you can make a well from concrete rings with your own hands. This structure can be equipped with a pumping station, which will allow organizing a centralized supply of water to the entire household - from the bathroom to watering the garden, and in the absence of electricity, the liquid can simply be collected with a bucket.

Preparing for well installation

The work project (WPP) for the construction of wells made of reinforced concrete rings involves not only digging up the earth and the initial preparation of the structure for operation. The PPR must include the cost of installing the pumping system. So, a dug well with sufficient flow is the starting condition for further arrangement of the water supply system.

To avoid having to carry water into the house in buckets, the PPR involves the following main types of well installation work:

- waterproofing the structure (if necessary, using a “glass”);

- well insulation;

- pipeline installation;

- pumping system design;

- making concrete platforms and trays;

- installation of a water filtration and purification system.

A shovel is the main tool needed when performing well construction work. You will also need a hose and bucket. Construction of a well may require a special device for lifting soil from the shaft. The use of a fire hydrant in a well is suitable if the structure is thermally insulated. However, you will need the following types of tools:

- hammer;

- rope-ladder;

- hacksaw;

- cable;

- chain;

- deep well pump.

A building level will be required to check the horizontalness of the installed reinforced concrete rings. To fill the bottom of the well, crushed stone of fine and coarse fractions should be prepared. To obtain a durable structure, it is necessary to select high-quality reinforced concrete products.

Material for mine wells

A well shaft can be made from many materials. Previously, it was stone or wood, later brick appeared, and recently the most popular is a well made of concrete rings. The disadvantage of stones is that they are inconvenient to work with; in addition, their cost leaves much to be desired, as is the case with natural wood.

Concrete rings for well construction

Brickwork is a rather labor-intensive process, and the material itself must be of high quality and have good water resistance. In the case of brickwork, it is very difficult to achieve good waterproofing that will not let water into the shaft. Concrete rings make it possible to simply and much faster build a well that will meet all the requirements for technical, sanitary and hygienic standards.

Characteristics of reinforced concrete rings

Reinforced concrete rings from which water wells are installed are manufactured in accordance with GOST 8020-90. It establishes a list of technical characteristics of prefabricated reinforced concrete rings for wells. These types of workpieces have a number of differences from each other, for example, in diameter, which can be 750-2000 mm in increments of 250 mm. If we take into account the height of the rings, the standard parameter is 800-900 mm. Reinforced concrete products, namely rings, are divided into 2 subgroups:

- with a lock at the end;

- without a lock.

The lock ensures the creation of a more airtight connection of reinforced concrete rings with each other. The structure is durable and airtight. Products without a lock are secured with metal staples. In general, reinforced concrete rings have the following advantages:

- strength and reliability of elements;

- short duration and ease of installation.

The service life of prefabricated reinforced concrete rings for the construction of wells is calculated in decades in any climatic conditions, if they are manufactured in accordance with GOST. This characteristic depends on the properties of the reinforced concrete used. The disadvantage of the products is their significant weight, although this characteristic is not considered critical. The estimator, when determining the number of blocks required for construction, first calculates the volume of reinforced concrete rings for wells. To do this, you can use the following formula:

V = Lx3.14xR (where V is the volume of the well, L is the height of the structure, R is the radius).

The exact price for reinforced concrete rings is set depending on their volume. Usually the norm is 0.16-0.54 m. And the volume of the future structure depends on the size of the rings.

Selection of reinforced concrete rings

The issue related to the choice of reinforced concrete rings should be resolved responsibly. It is recommended to purchase material after carefully studying all the characteristics of these products and making the necessary calculations. It is important that there is no damage to their surface, including cracks or holes. Otherwise, the rings will be subject to rapid destruction during operation.

Rust on mounting loops protruding on the surface of concrete products is unacceptable. If it is present, then this is evidence of a corrosion process. As a result, lifting the product without breaking the loop will be impossible. When purchasing a high-quality workpiece, you need to check the availability of a passport containing information about the constituent materials.

The lining of reinforced concrete rings provides reliable protection of products from rust. It allows for high-quality reconstruction of reinforced concrete wells from the inside. If the sewer begins to collapse, starting from the tank, then this process can only be prevented with the help of a lining. It is a modern polymer protection that ensures the long service life of concrete rings.

The use of polyethylene sheets for lining helps prevent the formation of all kinds of growths on the walls of the well from the inside. The sealed surface can be easily cleaned if necessary. This helps to improve the operational characteristics of structures.

Requirements for installation of a stationary country well

Before installing a well made of reinforced concrete rings, the owner of a summer cottage needs to decide in what period the structure will be used. It is possible that water is supplied only in the summer, and the owner plans to permanently reside in the country house. In this case, the installation of the sewer well will be different, taking into account the operation of the structure throughout the year.

A scheme that allows the installation of a water supply system assumes the presence of a source of electricity on the site. This is due to the fact that it will be necessary to install a pump in the well to supply water. Installing an electric pumping station to supply water to a well requires the development of all the necessary drawings. Using this traditional method, you can install sewer wells with water supply yourself.

The summer source of drinking water is a temporary structure, so its design can be stationary or collapsible. Usually it is used for 2-3 months. In order not to spend too much physical effort and material resources on the installation of such a structure, you must follow the recommendations below:

- select a submersible or surface pump in advance;

- take into account the depth of the pipeline (0.5-0.8 m);

- select a special area where the device will be placed;

- provide a drainage system for the stationary option.

You can install a permanent water supply using a manifold connection. The system must function due to such design elements as:

- pumping station;

- storage tank;

- water heater.

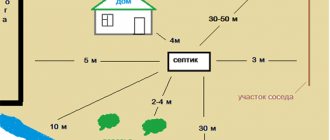

Before installing the rings taking into account the requirements of the PPR, it is necessary to understand the place where the water source is located. First, you will need to investigate the level of underground groundwater. To ensure a successful search, you can use different methods.

For example, these could be glass jars of the same size. They should be placed throughout the entire plot of land. In this case, the bottom of each of them should be at the top. After some time, you need to check all the jars: whether condensation has formed in them or not. The larger it is, the closer the location of the aquifer is considered.

A little about accessible aquifers

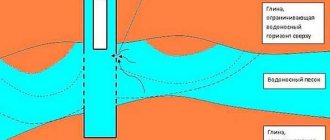

Diagram: occurrence of aquifers

- Verkhovodka. It is located closest to the surface and is replenished due to precipitation, which is why its fullness is constantly changing, and during dry periods and in winter it can disappear completely. In addition, it is susceptible to pollution by wastewater treatment plants.

- Ground. They lie at a depth of 6-20 m and are located between two waterproof layers, but do not have excess pressure, so the water level in the well shaft remains practically unchanged. Only minor changes are observed at different times of the year.

- Artesian waters are located at a considerable depth, are strongly squeezed between two waterproof layers, which is why they are under pressure, and when the formation is pierced, they gush out to the surface. The quality of the water is beyond doubt, but the construction and maintenance of a well of a special design is usually not cost-effective.

Do-it-yourself excavation work

After selecting the most suitable site, you can begin to dig up the soil, taking into account the size of the rings. It is better to carry out this type of work with an assistant, so that the partner supports the other person from above. First, you need to prepare a hole 1 m deep, which will allow you to roll a ring of reinforced concrete onto it. It should be lowered down only after checking the vertical draft using a plumb line.

If you find a deviation, you can use a shovel to correct it. When carrying out excavation work, you should take into account the rule: the greater the depth of the dug hole, the slower the installation will be. It takes time to dig out each subsequent meter. Typically this will take half a day. Then you need to make sure that each ring in the hole sinks down, as the video below describes.

When installing each subsequent product, you need to use a sledgehammer to drive the ring into the hole. If it is not located exactly on the previous product, you can correct the resulting deviation using a crowbar. One of the partners will need to tie himself with a rope to his belt, strengthening its other end on the surface in order to go down into the well when it is dug to a depth of 3 m.

After completing the excavation work in the wells, it is necessary to carry out the arrangement of the bottom. A “cushion” of crushed stone is made in a layer of 10 cm. This will prevent muddy water from entering the filled bucket. If you do not follow the rules for installing the rings, large gaps may appear between them. In this case, it will be almost impossible to repair the structure. Clay is suitable for sealing small cracks between the rings in sewer wells.

On the surface of the earth around the well at a distance of 50 cm, it is necessary to clear the area of excess soil. Then it is coated with clay and compacted. This allows excess water to be retained on the surface.

Alternate installation

Construction of a well using the method of alternate installation of rings.

With the second installation method, it is possible to dig the pit gradually. Initially, a pit is dug along the height of one structure. This concrete structure is lowered into the pit. Afterwards, the pit continues to be dug in the ring to the height of the other. When the pit reaches the required depth, they begin to carefully dig out the ground under the device. Thanks to this, it gradually drops lower. Next, the next ring is immersed and, by its own weight, it sinks down the pit. The operation of digging a pit is carried out until water is seen at the bottom.

When digging a hole for a future well, it is important to filter the water. Such filtration is performed using stones, crushed stone and gravel. The height of the filter should not be less than 30 centimeters. It is worth placing a special geological lining between all layers; it helps much better with water filtration. However, if after these manipulations the water begins to flow more slowly, then the filtration layer can be reduced in height.

The space that remains between the well and the ground must be sprinkled with a mixture of gravel and sand. To improve the waterproofing of the structure, a good solution would be to add some clay to this space.

Return to contents