Septic tank pump

Fecal pump for septic tank

Having your own country plot is the ultimate dream of many city dwellers, capable of bringing just as much pleasure as it does trouble. Let's take sewerage, for example. It’s good if you have built a gravity system in which wastewater moves “by itself.” But if this is impossible for one reason or another, there is nothing else left except installing a fecal pump for the septic tank. Not everyone knows what it is. Therefore, if you plan to install such a device, you need to understand in advance the principle of its operation and the main types. Especially if you choose it yourself.

How are fecal pumps different?

In principle, this is the same pump for sewage. It differs in that it is capable of pumping only wastewater that does not contain solid particles. At this time, a conventional drainage pump easily operates in an environment where fine stones and other heavy impurities are found, due to which the impeller of the device can break. For this reason, drainage pumps are equipped with a special mesh filter at the inlet to trap particles that are too large.

You may be interested in information - submersible pumps for wells, how to choose

There are no filters in fecal pumps, and the maximum size of sewage effluents is limited only by the diameter of the inlet into which they enter (in most cases this is 3.5 cm or more).

Note! Most modern septic tank pumps are equipped with a float and a switch, thanks to which the operation of the device is fully automated.

Sewage pumps often do not have strainers.

We also note that this pump is often used to pump water out of basements.

You may be interested in information on how to pump out a sewer yourself

Drainage pump Sea-Land SA 150 M AUT (1100 W)

Photo: https://beru.ru

Sea Land is the best option today when you need water, but the water in the well is dirty. In addition to its build quality, this device can please you with its open-type impeller, designed for pumping water in any form. Whether it is clean or dirty, rain or dirt, it doesn’t matter. High efficiency and productivity are another couple of positive features of this model.

Drainage pump Sea-Land SA 150 M AUT (1100 W)

Advantages:

- high performance

- excellent build quality

- resistant body material

- long power cable

- The device makes almost no noise

Flaws:

- price

Types of fecal equipment

Such pumps are:

- superficial;

- submersible;

- semi-submersible.

Surface pumps

They are characterized by low cost and low technical characteristics. Pumps can be installed exactly where they are needed at the moment, and at a considerable distance from the tank (up to 9 m). These pumps can be used when the basement is flooded.

You may be interested in information - compressors for septic tanks

It is undesirable to install submersible devices permanently, since they, having weak waterproofing, can fail due to moisture: if the temperature drops below zero, the remaining liquid in the pump will freeze and destroy it.

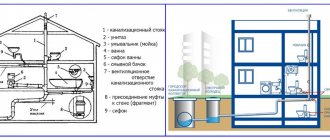

Surface pump and its installation diagram

Such devices are capable of pumping hot water (no more than 60°C). The pump itself can be installed not only remotely, but also, for example, on the edge of the tank, and only the suction pipe will be immersed in the drains. Surface circulation pumps are divided into two groups.

- Non-self-priming . They are capable of lifting water from a depth of up to 7 m, while the suction hose is completely filled.

- Self-priming . They are characterized by a higher lifting height - up to 8 m - and the fact that the suction hose is not filled with liquid.

Moreover, depending on the engine type, surface pumps can be:

- gasoline;

- diesel;

- electric.

Often such pumps operate on the principle of centrifugal force, but where their installation is not possible, vortex devices are used because they are more compact. Vortex pumps have great power, are almost silent, but are effective only at shallow depths.

You may be interested in information about a DIY peristaltic pump

Pros:

- portability;

- low cost.

Minuses:

- low productivity;

- frequent breakdowns under adverse weather conditions;

- pumping particles whose fraction does not exceed 5 mm .

Submersible pumps for septic tanks

Devices of this type are very productive, due to which they are used not only in private homes, but also in industrial facilities. Their work is also based on centrifugal force , with an electric motor interacting with the impeller and blades. When the engine rotates, a vacuum is formed in the suction line, which is why sewage is sucked in.

Note! Submersible models are quite powerful (up to 40 kilowatts) and are capable of pumping solid particles up to 4 cm in size without the use of a grinder (we’ll talk about what this is a little later).

The body of the device is made of materials resistant to aggressive environments, since it has to be in contact with it throughout its entire operational life. Often such materials are cast iron and stainless steel.

Submersible pump with float

pros:

- high performance;

- acceptable price.

Minuses:

- Do not use the device at temperatures above 40°C.

Submersible pump installation diagram

Comparative characteristics and prices of fecal submersible pumps from different manufacturers

Semi-submersible pumps for septic tanks

Such devices are very similar to conventional submersible pumps, but the size of solid particles that they are capable of pumping is smaller - no more than 1.5 cm. Semi-submersible pumps are used mainly for small pits, which is why they are not found in the industrial sector.

You may be interested in information - vibration pump operating principle

During operation, the engine is located above the liquid thanks to special floats, and the mechanical pumping structure is immersed in water.

Semi-submersible pump

Note! Features of the engine installation allow the use of such pumps with very hot liquid – up to 90°C. There will be no overheating.

pros:

- the device is applicable in high temperature conditions;

- ease of repair, which is achieved thanks to the design features.

Minuses:

- small sizes of pumped solid particles.

Drainage pumps

This is a special type of pump for a septic tank. With their help, you can pump groundwater, precipitation and other slightly contaminated liquids. In our case, it will be used to pump purified water from the filtration well to the site .

You may be interested in information about the design of a circulation pump for heating

The main feature of this pump is a protective mesh that prevents large solid particles from entering the device.

Prices for fecal pumps

fecal pumps

Cost and popular models

Today's pumping equipment market is impressive with its large assortment. Russian and foreign manufacturers offer products that can satisfy any consumer.

Grundfos, WILO, Pedrollo, are deservedly popular among buyers

Grundfos drainage pumps

The model range of the manufacturer Grundfos is represented by several types of submersible and external pumping equipment with different technical characteristics, but consistently high European quality.

Advantages:

- High power levels.

- The filtered particle size is up to 50 mm for some models.

- Convenient handles for carrying.

- Light weight.

- High level of liquid pumping.

- Increased wear resistance due to the use of non-corrosion steel.

The only disadvantages include the relatively high cost.

The price range for units of this brand ranges from 9,500 rubles to 100,000 rubles.

Is it possible to do sewer installation work with your own hands? How to choose a septic tank and install it? https://klimatlab.com/kanalizaciya/septiki/dlya-chastnogo-doma-kak-vybrat.html Find out by following the link.

Pedrollo drainage pumps

The Italian company has been a leader in its niche for a long time. Since 1974, leading Pedrollo specialists have been inventing new and improving old pumping systems. To date, the Pedrollo model range includes more than 100 units.

Advantages:

- Intelligent control over all production cycles results in only a high-quality product.

- Submersible devices are capable of operating stably at immersion depths of 20 meters or more.

- Automatic start and stop mode.

- High-quality, highly wear-resistant materials.

- Long service life if all rules are followed.

Flaws:

- The pumping equipment of this company is represented only by submersible models.

- High but reasonable price.

The cost of devices varies significantly due to technical characteristics and ranges from 6,500 to 50,000 rubles.

WILO drainage pumps

This German company produces and sells modern pumping equipment for heating systems, water supply, ventilation and air conditioning. The scope of services of this brand also includes the production of fire extinguishing systems and equipment for water parks and swimming pools.

In all of these areas, WILO has established itself as a reliable partner providing first-class products.

Advantages:

- The units are produced in two types: submersible and surface.

- Affordable price for powerful models.

- Mobility of devices due to low weight and simple installation method.

- Full adaptation of production technologies for Russia, thanks to joint cooperation.

- High quality materials and long service life.

No shortcomings were found in the models.

The price for WILO drainage equipment is quite reasonable, considering the quality of the device and a service life of up to 10 years. Minimum – 5500 rubles.

Video example of the operation of a drainage pump for pumping out a cesspool:

Important! Purchase pumping equipment only from official representatives or a trusted shopping center. You should not chase a low price - there is a big chance of running into a fake.

Grinder in fecal equipment

There is another classification of pumps that divides them into two categories.

- Devices with a grinder capable of pumping cold/hot wastewater.

- Similar devices without a chopper.

Note! The grinder is a special device built into pumps for grinding particularly large solid particles.

Let's look at them in more detail.

Devices for cold liquid

Installing such a pump without a grinder involves parallel connection of several plumbing fixtures at once. This is very convenient, but do not forget about the temperature limit - no more than +40°C. Moreover, you need to carefully monitor everything that ends up in drains.

You may be interested in information - installing a drainage pump

Disintegrator devices often consist of a toilet pump located directly behind the plumbing fixture. It accumulates waste, crushes it and sends it to the sewer. To connect the device to the toilet, a special adapter coupling is required.

These pumps are characterized by a long service life, but provided that the fluid temperature does not exceed the above mark.

Note! In this case, a large pipeline diameter is not required, because the wastewater is thoroughly crushed.

Devices for hot liquid

Pumps that do not have a grinder are installed next to sinks, dishwashers, bathtubs and washing machines. The maximum wastewater temperature is 90°C.

Finally, fecal pumps equipped with a grinder . They can withstand higher temperatures (about 95°C), while crushing all solid waste. They are installed on any plumbing fixtures.

Video - Sewage pumps with cutting mechanism

Scope of application

Based on the functionality, it can be understood that the drainage pump is not suitable for transporting wastewater directly after the toilet. Feces and toilet paper can cause the mechanism to jam, causing serious damage and costly repairs. In septic tanks, as a result of the activity of anaerobic bacteria, large inclusions turn into sludge and water, that is, they change not only their composition, but also their size and consistency. A drainage pump can be used to pump such treated wastewater.

A drainage sewer pump for a private home can be used for pumping clarified water after a septic tank

Features of choosing a pump for a septic tank

So we come to the main issue - choosing a suitable pump . Below are the main parameters that you should pay attention to when purchasing.

- Immersion depth.

- The diameter of the pipeline that supplies wastewater to the septic tank.

- Distance from the point of collection to the intended installation location of the pump.

- The maximum size of solid particles that can enter the sewer.

- Required productivity, m³/hour. It determines at what speed the liquid needs to be pumped.

To determine the height to which the drains will rise, add to the immersion depth the length of the hose from the septic tank to the place where the water will be transported (the latter value should be divided by ten, since 10 m horizontally is equal to 1 m vertically).

Example: the pump is immersed to a depth of 6 m, the length to the waste disposal site is 15 m. We use the formula: 6 + m.

It turns out that in this case it is necessary to select a pump that can lift water by 7.5 m.

Fecal scraper with cutting mechanism

To pump out viscous masses with solid inclusions, the installation must have a grinder. There are several variations of them that are found in different installations.

- Impeller with knives. The cutting element is fixed to the screw itself. Some may have a cast iron chopper.

- Cylindrical scissors-knives.

- Cross cleaver.

- Cutter. The operating principle is reminiscent of a household kitchen meat grinder.

- Lamellar cutters.

Each of these shredders has its own operating principle. But efficiency largely depends on the grade of steel used.

Therefore, when choosing a unit, pay attention to the cutting mechanism.

Installation of a fecal pump

Stage 1. First you need to install an automatic connecting system. This is a kind of coupling; one end of it needs to be fixed to the bottom of the container, and the other should be connected to the pump for the septic tank.

Stage 2. Next comes the installation of guide pipes. From the coupling you need to lay pipes equipped with a check valve and gate valve.

Stage 3. Then you need to work with electricity. First, the float sensors are adjusted and then connected to the control panel. The pump itself is connected there. After this, electricity should be supplied to the panel.

Note! At this stage of installation, it is advisable to take care of a voltage stabilizer, which will protect you from the unpleasant consequences of power surges.

Installation of a fecal pump

Stage 4 . Draining the pump. You need to put special drain chains on the device and lower it to the bottom of the container along pre-installed guides. Due to the automatic connection and the significant weight of the pump, you will achieve maximum tightness of the joints.

Step-by-step instruction

- First of all, it is necessary to find a pressure pipe at the pumping unit, to which the pipeline is connected, through which the wastewater will be pumped out. The clamp is carefully tightened at the connection point using a screwdriver or pliers.

- Most models are equipped with a float switch. If it is present in the model you choose, then a check valve should be installed on the connected pressure hose, which will prevent water from flowing back into the tank.

- Immediately before installation, you need to check the operation of the unit. Carefully read the instructions for it, manufacturers' recommendations and certificates. Another important point is determining the direction of the shaft. To do this, a household drainage pump is installed on a table or floor and connected to the network. If the movement is to the right, it means the equipment is working correctly.

- The pump unit must be installed exclusively in a vertical position. Make sure that the pressure hose is also directed vertically. Its end is directed into a container where the liquid will subsequently be pumped.

- Finally, the pump is sunk to the bottom of the tank and connected to the power supply.

Features of operation of fecal pumps

- Before use, rinse the device thoroughly with clean water.

- A preventive inspection should be carried out at least once a year.

- You need to carefully monitor the condition and level of the oil. The first inspection is carried out a week after purchase. If the oil has a grayish tint, it means water has got into it; most likely due to a defect in the shaft seal.

- The cable entry must be sealed, without clamps or kinks.

- If the pump clogs quickly, the chopper is worn out. This can be determined by the roundness of the cutting parts.

- Compliance with all manufacturers' requirements, such as permissible waste temperature and others, is a prerequisite for operating a fecal pump !

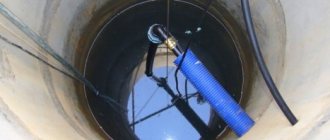

Submersible pump in operation

Well cleaning

To make the process of cleaning the well as simple as possible, it is recommended to purchase a special float with which the water level will be determined. Despite the fact that this type of device operates in automatic mode, it is advisable to monitor the process of its operation. It consists of the following steps:

- Effluent pumping.

- Destruction of growths of moss, silt and other contaminants present at the bottom of the tank.

- Cleaning the filter.

On average, cleaning a well takes 1-2 weeks.