It is generally believed that plumbing work, such as the installation of heating systems, water supply and sewer systems, requires the involvement of highly qualified specialists. However, practice shows that when doing work with your own hands, you can often achieve better quality of work than hired workers. The fastening of clamps can be rigid or free (floating). When installing heating, water supply and sewerage systems, the correct and reliable fastening of all elements of the system. Failure to comply with the requirements can lead to deformation and rupture of joints and, as a result, to the appearance of leaks.

Therefore, we will consider the technology for properly fastening pipes to the wall. The required set of elements for fastening sewer and heating pipes to the wall: pipes, fittings, transitions, couplings, etc.; clamps for fastening plastic pipes; supports; brackets; fasteners (screws, dowels, anchor bolts, etc.). Fastening of clamps can be rigid or free (floating).

Loose fastening prevents deformation during thermal expansion and compression. If installation is carried out in a heated room, rigid fastening of the clamps is allowed. When installing sewer pipes, special attention must be paid to the presence of a slope towards the drain point. The slope should be 2 cm per linear meter. The use of supports for pipes, as well as the use of wooden plugs instead of standard dowels, is not allowed . For hanging heavy elements, as well as when attaching to the ceiling, it is advisable to use anchor bolts. Sequence of operations Diagram of the fastening element. Marking of the pipeline axes.

A line is drawn on the walls along which the system will be mounted. Supports must be placed at all connections and at bends. The distances between supports in linear sections of the pipeline should not exceed 10 pipe diameters. If it is necessary to make an indentation from the wall, special brackets are used.

However, it must be borne in mind that the distance to the wall should be minimal. This is important both for the rigidity of the fasteners and for saving space in the room. When the fastenings are ready, you can install the pipes. Depending on the design of the clamps, the pipes are either snapped into the support or screwed with studs.

It is desirable that the clamps be equipped with rubber seals; this reduces vibration and compensates for thermal expansion. Sometimes pipelines are laid in special recesses in the wall - grooves or channels. This contributes to their more reliable fastening and insulation. Laying plastic pipelines in the thickness of walls and ceilings When laying pipes in the thickness of concrete, it is worth thinking in advance about removing obstacles to their thermal expansion. A channel is cut into a brick wall in such a way as to prevent overvoltages. If the channel will be sealed with plaster, the pipes should be wrapped in any soft material.

If high temperatures are possible, the pipeline in these places must be laid with insulating material. If the pipeline passes through the ceiling, it is necessary to ensure tightness and sound insulation. When laying pipes in the thickness of concrete, it is important to remove obstacles to their thermal expansion. Also, the pipeline must be well fixed to prevent it from moving when laying concrete. Features of fastening sewer and heating pipes When installing sewer pipes, a number of conditions must be met. First of all, they must run with the required slope along their entire length and not interfere with the laying of other pipelines. Further, plastic products are very sensitive to temperature changes.

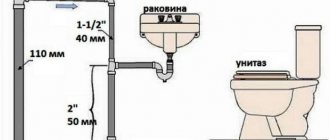

Therefore, it is important to select the correct diameters of the clamps to ensure freedom of movement in the fastening points. It is better to use pipes and fasteners of the same brand, which will make the pairing ideal. Layout of fastenings Fastenings should be installed exclusively on smooth parts of the pipe. The distance from bends should be at least 15 cm. The size of sewer pipes affects the method of their fastening. With a pipeline diameter of 50 mm, fastenings are made at a distance of 40 cm, but if the diameter is 100 mm, the distances are doubled.

If plastic pipes are connected using a special coupling, the coupling itself is attached. A special case is when the pipeline is filled with a cement screed. Then, to minimize wear, the pipe should be insulated from the cement with paper, cardboard or corrugated sleeve. Above the level of the screed, a special outlet is left, the so-called revision.

There are some other features of fastening sewer pipes. When installing risers, you must ensure that the distance to the wall is at least 5 mm. A clamp with rigid fixation must be placed next to the socket to prevent the pipe from moving after some time.

And the second fastening must be loosened in order to avoid internal deformations. Now regarding the fastening of heating system pipelines. Heating distribution in rooms should begin with the installation of radiators. It is advisable to mark the attachment points taking into account a slight deviation from the horizontal towards the highway. This will be almost invisible to the eye, but will help remove the air plug from the radiator.

But this method is not suitable for heating systems with counter-movement of air and coolant. Here the air plug will be pulled back into the radiator. In this case, the radiator is placed horizontally and an air vent is used. The radiator is usually hung in a package to avoid contamination and damage. Share a useful article: Similar articles:

Polypropylene pipes are elements of a hot and cold water supply system.

Fastening for polypropylene pipes is made in various ways. There are two main types of installation: external and inside walls. Regardless of the method of installing pipes, before starting work you need to stock up on related consumables.

Fastening material - different shapes

Clips - their meaning and installation details

The clip is made from a special material - nylon.

It has such useful properties as high heat resistance and resistance to mechanical stress. Among the technical characteristics of the clip, you need to pay attention to the diameter; it must correspond to the size of the outer diameter of the polypropylene pipe. Installation of clips has its own rules, the implementation of which determines the service life of the finished communications system.

Single clips and double clip

The main issue that is important not to miss is the step size between the clips. If you install the clips too far apart, there is a risk of sagging at the support points.

When installing a communication system with two parallel pipes, use a double clip.

Correct pitch between clips

In what cases are clamps used?

It is recommended to fasten polypropylene pipes to the wall using clamps in cases where it is necessary to install large-diameter pipes with a fairly heavy weight. The clamps are a design with a screw tie and a rubber internal gasket, which is necessary to compensate for vibration. Thanks to this, they reliably hold the pipe even when strong vibrations occur.

The clamps are equipped with a dowel and a pin.

The mount can be made of metal or plastic. When laying polypropylene pipes, it is better to choose clamps from similar raw materials: this way you will ensure the same strength indicators for the entire structure. Installation of fastening material can be rigid or floating:

Rigid fastening is made by tightening the clamp extremely tightly around the pipes. A rigid coupling is required in areas below the bell.

Thanks to the rigid fixation, the possibility of displacement of the communication system is eliminated. A floating fastening indicates the presence of a gap between the pipes and the clamp. The fastening is tightened in such a way as to allow free movement of the pipe. The mobility of the fasteners allows the pipes to expand during temperature changes.

How to attach the clamp

How to connect

In addition to the main fasteners, you also need auxiliary ones that will serve to connect the entire structure into a single whole:

- You can drive nails into a wooden surface. Spacers or washers are also used to reinforce everything;

- Bolts, screw products - suitable for fastening if there is a screw thread. Any type of fastener can be fixed with them. They are easy to use and versatile;

- Self-tapping screws or self-tapping screws - the first option is universal, the second is more often screwed into wood;

- Dowels - used to secure a screw or self-tapping screw;

- Nuts or washers - Sometimes the design of the piping system is provided, so they must be used. Strengthens the reliability of the fastener and its tightness.

Pipe fastening technology - step-by-step instructions

Before installation work begins, the pipes are connected using butt welding, polyfusion welding or the electrofitting method. If you carefully familiarize yourself with the pipe laying technology, the process will not take you much time:

- The first step is to mark the path of the future pipeline along the perimeter. Please note that it should be installed with a slight slope - this way you will eliminate the possibility of water freezing in the pipeline even in an unheated room (for example, in a country house). Using a drill, you need to make holes for the dowel-nails. Pre-prepared mounting clips for polypropylene are inserted into the holes pipes. We insert the dowel into the hole using a hammer and screwdriver. The final stage of the work is installing the pipes into the clips.

Appearance of the finished fastener

Is it possible to install PP pipes in the wall?

Polypropylene is a material that has high resistance to chemicals and corrosion.

Therefore, installing pipes in the wall is quite acceptable. In order for the communication system to last for a long time, it is important when laying to leave the necessary space gap for the expansion of the hot water pipe. In addition, the system itself should be as monolithic as possible, with the least number of connections.

The pipe along its entire perimeter must be additionally protected with thermal insulation. This can be corrugated cardboard, glass wool, mineral wool or other insulation. This way you will protect the structure from fogging.

Laying PP pipes in the wall

We install pipes in the wall

Any installation work begins with marking. You can do it with a simple pencil. Next, proceed to the main work:

- Using a grinder (perforator), you need to make 2 parallel grooves in the wall strictly according to the markings - grooves. To work with an angle grinder, you should use a disk with diamond-cut teeth or a simple disk for cutting stone. Using a chisel or hammer drill, remove the material between 2 markings, connecting them into one. A polypropylene structure is inserted into the finished grooves. The polypropylene pipes in the groove are covered with cement mortar on top. The finishing is done with plaster or other building material.

The final action, an hour after installation, is to test the system. The pipes must be filled with water and checked for leaks, sagging and other malfunctions in the operation of the water supply system. If none are found, congratulations, you have correctly attached the PP pipes.

Leaky sewer pipes can instantly turn a house or apartment into a garbage dump with all the accompanying stench and dirt.

It’s unlikely that anyone enjoys leaks and disgusting odors. The pipelines need to be replaced immediately. But how can sewer pipes be secured so that they last as long as possible?

Rules for safe gas pipeline installation

Installation work is carried out only by specialists in accordance with the prepared and agreed upon project.

Safety precautions before starting work:

- remove any open flames;

- turn off electrical heating equipment;

- install a warning sign about gas repair work;

- block gas access to the work site;

- remove remaining gas from the pipes. Blowing into ventilation ducts, indoors is prohibited.

Flexible connections

The installation stages depend on the specifics of the project, but the main ones stand out:

- use a grinder to cut the system in the required places;

- plugs are installed in the cut-off gas inlets and outlets into the apartment;

- some sections are cut off and others are welded, as provided for in the project;

- if necessary, holes are made with a drill in the pipes into which individual elements of the system are welded;

- When installing taps, the connection point is sealed on the thread with tow, paronite gasket, and special tapes.

Only after the entire network has been formed can gas equipment be connected, plugs removed and connected to the building system.

Threaded connection

Safety measures after finishing work:

- ensure ventilation of the room;

- if fundamental changes were made to the gas system of the apartment (and not just a piece of pipe was replaced), the gas pipeline is purged. At the same time, all the air is blown out of it and gas samples are taken to determine the oxygen content in it. This is done until the oxygen content is equal to or below 1%;

- Check all joints for leaks, usually this is done with a soap solution, but professionals use special devices.

Important! A general safety requirement is that after installation, gas pipes are painted in a color so that it does not blend in with the color of the walls. Inconvenient from a design point of view, but practical in case of an accident.

Fastening material: plastic vs metal ↑

The vertical riser and horizontal pipelines of the intra-house sewerage system can be laid inside the walls in a closed installation or fixed to the walls and ceiling. The first option involves gating, which is accompanied by dust and is not applicable in all homes. Using special fasteners is more practical.

Various mounting options

For open installation, pipelines must be secured.

Otherwise, they may sag under their own weight and become depressurized. The quality of fasteners directly affects the durability of the sewerage system. Sewage pipe manufacturers produce a wide variety of fasteners for installation. All of them are divided according to the material of manufacture into two groups:

- Metal. Plastic.

Fastenings for sewer pipes made of metal are stronger than their plastic counterparts.

But this strength is in many cases excessive. Plastic products are now quite reliable. Plus, plastic fasteners are more aesthetically pleasing and presentable.

In addition, they will not rust in conditions of high humidity in the bathroom. The two main options for pipes for internal sewerage systems are cast iron and plastic. Often, galvanized fasteners are selected for cast iron, and polymer fasteners for plastic.

In many ways, the choice between metal and plastic depends on the preferences of the home owner. Both options allow you to securely fasten sewer pipes at the desired slope both on the walls and on the ceiling. However, metal fasteners do not look as elegant as plastic ones, so they are most often used for installation work in utility rooms and basements.

Types of fastening structures

Load-bearing fastening structures are divided into the following types:

- Fixed supports. When using this fastener, angular or linear movement of the fixed areas is not allowed.

- Guide supports. The use of this design allows displacement in only one direction. As a rule, only along the horizontal axis.

- Hard pendants. Movements are permissible, but only in the horizontal plane.

- Spring suspensions and supports. Movements are possible both in the vertical and horizontal planes.

Types of fastening pipelines to the wall

Requirements for supports and suspensions

If fixation occurs between two fixed supports, movements that may occur as a result of changes in temperature conditions, installation stretches or displacement of supports must be self-compensating. But such compensating ability, as calculations show, is sometimes not enough. In this case, special compensators must be installed.

The pipe clamp is equipped with a screw/bolt

They are made from pipes of the same type and diameter as the structure as a whole. Most often they are made in the form of the letters “P” or “G”.

If the structure is fixedly fixed, the fastenings must withstand the weight of the pipeline itself, the liquid that moves along it, as well as axial loads generated by thermal deformation, vibrations and hydraulic shocks. When installing polymer products, movable supports are most often used.

If the installation is carried out in fixed supports, restrictive rings or segments 10-20 mm wide, which are made from pieces of pipes of the same plastic, are welded to the pipes. These segments or rings should be located on both sides of the support.

Selection of fastening elements

Suitable fastenings are selected taking into account many factors. The choice depends on the location of the installation site, the purpose of the specific system, and so on.

Fastening a plastic pipe

Sometimes the pipe must be insulated from the source of cold or heat. If you use a simple clamp that fixes the area, then it will not provide the gap from the adjacent surface necessary to solve the problem. But, for example, a ring support, which has a threaded extension and a plate for fastening to the supporting surface, will completely eliminate the problem.

If you have to fasten heavy cast iron pipes, then use special fasteners that can withstand heavy loads. For vertically located systems it is installed on the floors. Horizontally oriented systems are fixed not even one at a time, but in groups of pipes laid on a console.

A competent approach to the selection and placement of fasteners allows you to operate the pipeline for a long time and efficiently, without fear of emergency situations. But we should not forget about the economic component of this problem. After all, exceeding the required and sufficient number of elements can lead to an unjustified increase in the cost of the structure and complication of installation work.

Types of fasteners for sewer pipes ↑

When choosing the method and type of fastening, it is necessary to take into account the material of manufacture and the diameter of the sewerage pipelines, as well as the length of the secured segment. The weight that the fasteners must withstand depends on these parameters.

Types of fasteners for fixing drains

Sewer pipes can be secured using:

- hangers-hooks; brackets; clips; clamps.

The first option is intended for attaching pipelines exclusively to the ceiling, the second - only to the wall, and the third and fourth can be used in both cases. The choice of holders is quite varied, but the most popular and reliable are all kinds of clamps.

Types of clamps ↑

A standard clamp fastener consists of an installation unit and a clamp bracket in which the waste pipe is fixed. It is attached to supporting structures using dowels, self-tapping screws, studs and anchors. The clamping bracket is tightened with latches or screw ties.

Clamp diagram for fastening pipes

Depending on their purpose, pipe clamps are divided into:

- Support. Crimping. Guides.

The first ones are designed for attaching vertical risers and hanging sewer pipes from the ceiling. The latter are used when compressing the joints of drains and their connections with fittings.

And still others help fix the pipes at the required angle and keep them in this state. Most clamp products have a rubber insert that securely grips the pipe on one side and allows it to move slightly on the other. But there are options without rubber gaskets. The choice here depends on the method and technology of installing the sewer network.

Required space between support points according to SNIP

A suitable distance between pipe support points is an important characteristic for the operation of the system. The points where the fastenings are installed make it possible to evenly distribute the existing load and reduce possible stress as much as possible. When laying heating mains, it is necessary to successfully distribute the temperature load.

The characteristics given in the SNiP tables contain requirements for the permissible free space between fixed supports, taking into account the purpose of the system. This data is necessarily included in tables, which significantly simplify the calculation of the system. Do not forget that the table does not contain recommended data, but a specific distance corresponding to SNiP, at what distance, what kind of fastenings and how many should be installed.

SNIP data

The choice of suitable holders directly depends on the characteristics of the mounted system and the level of future load on the elements used. Free placement of the pipeline is required where expansion effects due to high temperature are possible. Suitable fastenings allow the expanding elements to move freely when heated, but keep the system well on the wall surface.

Rigid and floating mounting schemes ↑

Sewer pipes can be fastened with the same clamp firmly, tightening the clamps all the way so that the drains cannot be moved from their place. Alternatively, the bolts can be left slightly loose so that the riser can “float” in the fastener.

Clamps are needed to fix both horizontal and vertical pipes

When heated and cooled, plastic tubular products slightly change their geometry. To ensure their integrity, a floating fastening method is used. In this case, during linear expansion, the pipelines will not be damaged or depressurized.

Advice! The rigid version of fixing waste pipes is recommended to be used only in heated rooms with minimal changes in air temperature.

If the sewerage system is laid in a room without heating, then the pipes should be attached to the walls and ceiling using floating technology. The temperature inside will vary widely, heating and cooling the pipes. And they should not be damaged.

Pipeline attachment points

There are several options for piping placement:

- to Wall;

- semi;

- to the ceiling.

The most commonly used method is to attach pipes to the wall. This way, less material is wasted and unnecessary bends are eliminated. Reduces the risk of blockages. However, in older houses, pipes are often recessed into the floor. This option is even more effective, since the level of placement of the system is guaranteed to be lower than the plumbing drain sets. Sometimes sewerage is attached to the ceiling. This is a convenient option if the riser goes into the basement of a private house. The pipes do not get in the way underfoot and do not take up space along the walls. In addition, the pipes can be fixed under a suspended ceiling. To do this, they must be lowered to the floor below, or a pump for waste liquids must be used.

Installation of sewer pipes to the ceiling and walls ↑

The sewer network consists of a variety of elements that are subject to vibration, temperature influences and mechanical loads during operation. There is a whole set of rules, compliance with which during installation ensures reliable operation of the entire system.

Wall and ceiling mounting diagram

When installing sewer pipes you should:

- Make markings on the walls indicating the fastening points and the slope axis. Fix the fasteners on the walls and ceiling. Place the pipelines in the holders.

Fastening sewer pipes using clamps requires a minimum clearance between the drain and the wall. If you need to leave a larger gap there, it is better to choose brackets or hooks.

Important! Only with the help of fasteners can you accurately set the slope of the collector to the two to three degrees recommended by building codes and protect the sewer from blockages.

The distance between the fasteners depends on the diameter of the drain and the material from which it is made. Plastic pipelines are quite lightweight; for them, fasteners in horizontal sections can be spaced 1.5–2 meters apart. And to fasten cast iron sewer pipes, holders will have to be installed every half a meter.

Fasteners are installed on bends and branches of pipelines

However, in practice, fastening is carried out in places of branches, connections and bends, where communications are subject to the heaviest loads. You should not attach sewer pipes where it is most convenient for the technician. The placement of the holders should maximize the reliability of the entire system.

Recommendations and common mistakes

If the walls are well leveled, it is more convenient to use clips to fix the plastic outlets. It is better to attach adjustable clamps to walls with uneven surfaces.

When choosing between plastic and metal clamps, take into account the appearance of the future wiring.

For floating fastenings, clamps with an internal cross-section that exceeds the outer diameter of the channels being laid by 1-2 mm are used.

The most common errors are related to failure to maintain the proper slope of the horizontal parts of the highway. Let us remind you that it must be at least 20 mm for each meter of bends.

It should also be noted that the slope needs to be constant all the time, it cannot be interrupted. Otherwise, a counter-slope will form, where dirt will begin to accumulate and a blockage will appear.

Laying communications in channels ↑

To make it possible to cover the sewer with decor, grooves are punched into the walls. Inside them, the pipelines are secured using the technology described above using clamps. It should be taken into account that there should be no interference with the linear expansion of the collectors.

In the grooves, the drain should also be secured with clamps

Grooving is quite a troublesome task, but with this installation method, the fastening of communications is more reliable. In this case, the pipes are held not only by fasteners, but also by the edges of the groove in the wall.

Which way is better?

The choice of the best method is influenced by the quality of fastening and the price of the issue. For professional craftsmen who perform large volumes, convenience and speed of installation play an important role.

Fastening to reinforcing mesh has been used for a long time, its advantages are ease of installation and minimal costs. However, it is difficult to call the method convenient: you have to work all the time bent over, tying nylon ties with your hands. And the use of a grid does not cause unanimous approval. There is an opinion that it gradually cuts the plastic and over time the pipes begin to leak.

More and more craftsmen are resorting to working with a tucker, which allows them to produce large volumes of work in a short time. At the same time, the quality does not suffer compared to other methods.

The same can be said about the use of polystyrene foam mats with fixation. Time will tell which method will become the most common.

This video shows common installation methods

Video: device of a universal clamp for fixing pipes ↑

To secure cast iron and plastic sewer pipes, it is enough to use special clamps with rubber gaskets. Their installation is extremely simple and does not require special tools. You just need to correctly prepare a plan for laying out sewer pipelines and mark on it all the installation locations of fasteners.

Content:

Sometimes, when performing repair work, it is necessary to attach polypropylene pipes or other means of communication to the wall, for example, to set up a pipeline. The task, at first glance, looks quite simple, but it is not. How and with what to attach the pipe to the wall will be discussed in this article.

Types of fasteners

The standard fastening for sewer pipes to a wall or other support is a special clamp. This is a universal element capable of holding any round pipelines. There are different types of fasteners:

- crimping Capable of simultaneously performing two functions - holding the pipeline and sealing the connection;

- guides. Used only to indicate the position of the pipe relative to the supporting structure;

- supporting They can fix pipes to vertical and horizontal planes - to walls, floors or ceiling slabs;

- safety. These elements are installed as additional support for complex system components.

To assemble PVC sewer systems, fasteners for sewer pipes of 110 or 50 mm are used. These are the most common sizes for vertical and horizontal pipelines.

Two types of installation are used:

- hard. The pipeline is tightly clamped with a clamp and fixed in a stationary state. This method is used for vertical pipelines (risers) that require complete immobility;

- mobile. The pipeline has the ability to move inside the clamp. This method is used for horizontal pipelines (beds), which do not need to be rigidly attached to supports. Mobility allows you to compensate for thermal expansion of the plastic.

In order to ensure free movement of the pipe, fasteners of a larger diameter are chosen. Any sewer clamp is manufactured in accordance with pipeline standards. Before starting assembly, you need to count the number of clamps

It is important to consider which areas will be rigidly fixed and which will be movable

Plastic clamps

These are fasteners made of PVC of the same brand as the pipelines. There are clamps for all available diameters of system parts. The design of fasteners varies according to the assembly method:

- an element of two halves connected with screws. It is attached to the supporting planes using a pin screwed into a dowel. Provides a strong and rigid connection;

- clamp equipped with a movable latch. The pipe is inserted into the bracket, and the latch wraps around it from above and is fixed on a special protruding tooth.

The first type of clamps allows you to adjust the distance from the wall to the pipe. This is provided by a pin, which can be immersed deeper into the wall or slightly unscrewed from the fastener itself. The second type is convenient for assembly, as it does not require the use of additional tools. In this case, clamps with a latch are tightly attached to the support at a fixed distance from it.

Metal clamps

Metal fasteners are load-resistant. They usually consist of two halves that are connected with screws. Both parts have rubber gaskets that seal the connection and cut off the metal from the pipeline. Before fixing the sewer pipe to the wall, you only need to mark the axis and place the clamp installation points on it

It is important to remember the need to create a slope, for which the axis is immediately placed at an angle. For a diameter of 50 mm it is 30 mm for each meter of length

Let's look at how to attach sewer pipes to the wall using metal clamps. The studs for such fasteners have two types of cutting. At one end there is a thread for attaching the lower half of the clamp, at the other there is a standard thread, like a screw. When installing, first drill a hole for the dowel. Then install the stud using a wrench or pliers. The gap between the two types of cutting is shaped like a hexagon. This section is used to install the element into the dowel. The last step is to screw the clamp half onto the stud. Then all that remains is to install part of the system and screw the upper part of the fastener.

Tools and materials required for pipe fastening

To attach pipes to the wall, various tools and accessories are required. Their choice depends on the materials from which the communication system is made. In this case, it is necessary to take into account the length, diameter and weight of the line.

Used fasteners for pipes in the wall:

Clamps. Their internal diameter must be larger than the external diameter of the pipe. For a more reliable grip, there should be a rubber liner on the clamp.

Its popularity is due to the fact that the diameter is easy to adjust. Clamps can be metal or plastic. It is advisable to purchase a product made from the same material from which the pipe is made.

Clamps are divided into four types: fixing, supporting, guides and for protection. Brackets. They are used for installation of steel products. However, instead you can use special brackets, as well as metal clamps with gaskets.

If it is necessary to place the pipe at a certain distance from the wall, then brackets and clips are used. These fasteners are most often plastic. Therefore, they are often used to secure pipes made of the same material.

But they are also used for water pipes or areas of hot water heating systems. For these purposes, experts advise choosing double clips. But they are not suitable if the diameter of the corrugated pipe or other element exceeds 50 mm.

Any of these things can be easily bought at the market or at a hardware store. Anchor bolts are well suited for securing pipes to the ceiling. The type of communication depends on which fasteners will be used.

Do not forget about the purpose of the installed products. This could be a water supply system, sewerage system or heating system. It is important to choose the right fastening tools and also read the instructions for their use. In this case, you will get a reliable design with a long service life.

Types of pipe clamps

The choice of fasteners depends on the material of the pipe, the intended purpose, the diameter, and the type of surface to which the fasteners are made.

bracket

Metal bracket

This type of wall mounting is used in the installation of heating and hot water systems, where, due to possible linear thermal expansion, there is a risk of horizontal axial displacement of the pipework. Pipe brackets provide free fixation of the mounted pipeline due to the small space between the wall and the clamp.

The standard model of the bracket is made of high-strength polypropylene with a fixing element located on top. According to their design, mounting brackets can be composite (with connectors) or one-piece, one-piece. Fasteners are ideal for fastening PVC plastic pipes of various diameters from 20 mm to 50 mm.

Installation using clamps

Plastic clamps

The most accessible and inexpensive option for securing pipes to the supporting structure is carried out using fasteners - clamps. The main advantages of this type of fasteners are their versatility, low cost of the product, ease of installation and reliable fixation. However, due to the low aesthetics of appearance, there are restrictions on the use of clamps in open engineering systems in public and residential premises.

When transmitting mechanical forces to a support or wall, installing pipes with clamps provides the necessary strength to pipe connections. Universal fasteners made of metal or durable plastic can cope with this task:

- Steel fastening clamps are used for fastening pipe connections of any material and diameter. The main feature of metal fasteners is to create a reliable free “floating” fastener and reduce vibration forces affecting the linear pipe structure.

- The clamp for polypropylene pipes is designed for fixing polymer pipe products of small diameter. To reduce the risk of damage to the surfaces of hollow plastic pipes, a rubber seal made of elastic cellular material is placed on the inside of the fastener. The corrugated seal fits tightly around the linear elements of plumbing systems and does not interfere with their thermal expansion. Propylene clamps are used not only for hot water supply, but also for laying sewerage systems. In residential apartments, an example would be plastic drainage risers rigidly attached to the walls.

Do-it-yourself flaring of copper tubes at home: types and tools Copper tubes in accordance with GOST 21646-2003, due to their high heat capacity and ductility, are often used in cooling systems and air conditioners. For the formation of complex bends and connections at home, products...

The principle of attaching pipes to the wall

Now let's look at how to attach heating pipes to the wall. There are two ways to accomplish this task: hard and floating.

The first is intended for sewers, heating systems and other pipelines through which hot or cold water will be transported. In this case, the fastenings completely fix the movement of communication elements. The fitting here is a rigid support.

Floating mounts most often use clamps that are not tightened all the way.

In this case, slight mobility of the system elements is maintained. This fastening option is only possible if the inner diameter of the clamp is larger than the outer diameter of the pipe. When installing a pipeline, one should never forget about the influence of temperature changes. If the room is heated, then this phenomenon will not occur, then the fastening is best done in a rigid way (about

Using clamps

Fastening pipelines using clamps is very similar to the previous installation option, however, such fastening also has some features that are worth paying attention to:

- The main difference between clamps and clips is that the former have a closed design. Thus, when securing a pipe, you first need to open the clamp, and only after that the pipe snaps into it. The assembled structure is more reliable and durable. This type of pipe fastener is ideal if you need to fix a section of communication located in a vertical plane to the wall;

- Today on the construction market you can find two types of such devices. The first type includes products in which the self-tapping screw is connected directly to the dowel and pipe fastening. In the second case, the part that clamps the pipe does not fit with the screw, which allows you to easily remove the pipe from the clamp;

The clamp is a closed version of the clip; in order to insert a pipe into it, you need to open the upper part - the clamp

Note! When purchasing a pipe clamp, it is recommended to pay attention to the quality of the latches.

- There is a separate type of clamps, which differs in that it does not have a dowel. For such products, you must purchase a dowel separately. The main advantage of these clamps is their low cost, so purchasing such devices will save on pipeline installation.

Most often, clamps are used for fastening metal-plastic communications that require reliable fixation on the working surface. The installation of these fasteners is practically no different from the installation of clips; however, differences in the design of the fastener require its preliminary opening.

Sewer pipe fastening

To fix plastic pipes, all kinds of fittings are used (splitters, corners, etc.).

You may also need various terminal devices to complete a task. This is what taps and drain valves are called. Their choice will be based on the purpose of the communication system.

If you plan to install a serious engineering system, you will need hydraulic accumulators, valves and similar devices. It is also possible to attach a clip for polypropylene pipes (pro

Anchor shackle

The new product, which allows fixing two adjacent pipes, has greatly simplified the task for craftsmen and owners of new houses.

The bracket consists of a dowel and two plastic brackets, shaped like an anchor. This part is designed to hold only pipes under a warm water floor.