The Eurobion septic tank was developed in 2005 by engineer-inventor Yu. O. Bobylev. In 2011-2014, the station was produced under license in St. Petersburg by the company Deka. In 2021, the design was changed and the septic tank was named Eurobion Art. Today Eurobion is produced by Moscow (NEP). The production is located in the Istra district of the Moscow region.

Eurobion is a full-fledged aeration station in which the wastewater is saturated with oxygen and purified by aerobic microorganisms. Compared to similar stations, it has a larger salvo discharge, a lower probability of blockages, and a simple electrical circuit with one compressor. But there are also disadvantages - the lack of averaging of flows and a long time to reach the regime.

Important questions that we will address in the article:

- Septic tank body.

- Models offered by the manufacturer.

- Septic tanks Eurobion and Round, main differences.

- Design and principle of operation of the Eurobion septic tank. Changes in Eurobion Art from 2021.

- Complete set and additional equipment.

- Turnkey installation of Eurobion septic tank.

- Maintenance of Eurobion wastewater treatment plant.

- Advantages and disadvantages of Eurobion.

- Frequently asked questions from customers.

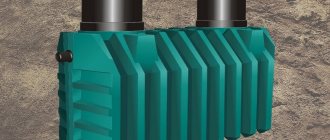

Eurobion septic tank body design

The body of the Eurobion Art septic tank is made in the shape of a cylinder. It was the first cylindrical polypropylene station on the market. The pressure is distributed evenly throughout the cylindrical body, so it better withstands loads. Integral foamed polypropylene, three-layer. Between the sheets of homogeneous polypropylene there is a porous layer. The advantages of this material are good thermal insulation and low weight.

The body has one weld across the entire thickness, and the strength of the seam reaches 80-90% of the strength of the material. The case is equipped with stiffening ribs along the entire length, this is additional protection against deformation. The bottom has protruding edges with lugs, so the septic tank is stable in high groundwater.

Main advantages of the installation

Advantages of using Eurobion units:

- environmental safety due to high quality cleaning;

- long service life ensured by the strength and corrosion resistance of the plastic case;

- possibility of use both constantly and periodically, which is very convenient for summer residences and summer cottages;

- increased volume of salvo discharge, allowing the installation of any plumbing fixtures in the house;

- ease of use: no odors or noise.

Eurobion septic tanks are an innovative solution to the problem of safe disposal of sewage. The use of modern polymer materials for the manufacture of parts has significantly increased the reliability of the installation and its service life. The stations are compact; you don’t have to allocate a large area to install them on your site.

Model range of septic tanks Eurobion

Initially, the model range began with the Eurobion 2 and Eurobion 3 rectangular models (dimensions, respectively, 1x0.7 m, 0.7x0.5 m). These were gravity stations. These models were then discontinued. Their release was economically unprofitable. Mostly forced cylindrical modifications were sold. More material was spent on a rectangular body and such a septic tank was more expensive.

Today, Eurobion 5, 8, 10, 15, 20 models are produced according to the number of conditional users. The index R (radius) in the name means that the station is cylindrical. Eurobion 5 has one caveat: based on the norm of 200 liters per person per day, it must process 1 cubic meter. meter of drainage, but in practice its productivity is 900 liters. This is not critical, since the real average water consumption is slightly less - within 150-175 l/day.

Typically, in suburban areas, models from Eurobion 5 to Eurobion 20 are installed. There are models with higher productivity - for 30, 40, 50 conditional users, but they are used much less frequently. Models over 20 have a rectangular body and are simply called Eurobion, without the addition Art.

Characteristics of Eurobion 5R Art - the most popular model.

| Productivity, l/day | Salvo discharge, l | |

| Eurobion-5 R ART (Standard) itself. | 900 | 390 |

| Eurobion-5 R ART (Standard) prin. | 900 | 320 |

| Eurobion-5 R ART (Midi) itself. | 900 | 390 |

| Eurobion-5 R ART (Midi) prin. | 900 | 320 |

| Eurobion-5 R ART (Long) itself. | 900 | 390 |

| Eurobion-5 R ART (Long) prin. | 900 | 320 |

| Eurobion-5 R ART (Superlong) itself. | 900 | 390 |

| Eurobion-5 R ART (Superlong) prin | 900 | 320 |

Lengthening the septic tank body does not affect the working volume in any way. Increasing the depth of insertion of the supply pipe is limited by the fact that the longer the body, the stronger the soil will press on it. In addition, the larger the diameter of the septic tank, the less rigidity of the body becomes, and, accordingly, the less elongation of the body without loss of strength.

| Name | Number of persons | Salvo release, l. | Price, rub |

| Septic tank Eurobion Round-4 standard (600) universal. | 4 | 200 | RUB 104,500 |

| Septic tank Eurobion Round-4 midi (900) universal. | 4 | 200 | 111,000 rub. |

| Septic tank Eurobion Round-5 standard (600) universal. | 5 | 320 | 107,000 rub. |

| Septic tank Eurobion Round-5 midi (900) universal. | 5 | 320 | 112,000 rub. |

| Septic tank Eurobion Round-5 long (1200) universal. | 5 | 320 | 124,000 rub. |

| Septic tank Eurobion-5 ART standard (600) universal. | 5 | 390 | 108,000 rub. |

| Septic tank Eurobion-5 ART midi (900) universal. | 5 | 390 | 116,000 rub. |

| Septic tank Eurobion-5 ART long (1200) universal. | 5 | 390 | 135,000 rub. |

| Septic tank Eurobion-5 ART superlong (1600) universal. | 5 | 390 | 151,000 rub. |

| Septic tank Eurobion Round-8 standard (600) universal. | 8 | 630 | 151,000 rub. |

| Septic tank Eurobion Round-8 midi (900) universal. | 8 | 630 | 162,000 rub. |

| Septic tank Eurobion Round-8 long (1200) universal. | 8 | 630 | 178,000 rub. |

| Septic tank Eurobion-8 ART standard (600) universal. | 8 | 700 | 152,000 rub. |

| Septic tank Eurobion-8 ART midi (900) universal. | 8 | 700 | 165,000 rub. |

| Septic tank Eurobion-8 ART long (1200) universal. | 8 | 700 | 202,000 rub. |

| Septic tank Eurobion-8 ART superlong (1600) universal. | 8 | 700 | RUB 222,000 |

| Septic tank Eurobion-10 ART standard (600) universal. | 10 | 900 | 209,000 rub. |

| Septic tank Eurobion-10 ART midi (750) universal. | 10 | 900 | 219,000 rub. |

| Septic tank Eurobion-10 ART long (1200) universal. | 10 | 900 | RUB 232,000 |

| Septic tank Eurobion-15 ART standard (600) universal. | 15 | 1125 | RUB 232,000 |

show all

Where is the best place to install a septic tank?

During preparatory activities, it is necessary to read the installation instructions, which indicate that the station should be located on a site at a distance of at least 5 meters from a residential building. It makes no sense to install a septic tank beyond the specified value - this will increase the costs of a larger number of pipes and may cause blockages. When laying the pipeline, unnecessary turns and sharp corners should be avoided. The pipe is laid at a slope from the house to the station.

Comparison of septic tanks Round and Eurobion

In 2021, the Rusin station appeared. More recently, it was renamed Round. Today, 2 modifications are available, designed for 4 and 5 people, with gravity or forced drainage. The depth of insertion of the supply pipe from the zero ground level is up to 60 cm.

Round is an economical modification of Eurobion 5. The cost reduction is achieved by simplifying the design:

- There are no external stiffeners.

- The lid has no hinges (simply fits onto the body).

- There is no top edging (the lid protrudes 20 cm).

- Economical compressor.

At the Zagorod company you can buy a Eurobion Round septic tank from the official manufacturer.

| Productivity, l/day | Salvo discharge, l | |

| Eurobion Round-4 itself. | 800 | 250 |

| Eurobion Round-4 prin. | 800 | 200 |

| Eurobion Round-5 itself. (Standard) | 900 | 390 |

| Eurobion Round-5 prin. (Standard) | 900 | 320 |

| Eurobion Round-5 itself. (Midi) | 900 | 390 |

| Eurobion Round-5 prin. (Midi) | 900 | 320 |

The South Korean DongYang compressor is installed in Round. Eurobion Art used to be equipped only with Japanese Hiblow compressors, but today German Thomas compressors are also used. It is believed that Thomas is more reliable than Dong Yang, although the difference is not critical. Both compressors are efficient and durable. They serve, on average, 5-7 years.

The Round septic tank uses a Chinese UniPump Sub 2009 pump. The Eurobion uses a Dab Nova 180 MA pump (Italy, Hungary). In the Dub Nova pump, the float is mounted on a rigid rod (stage) and moves only in one plane. When turning the pump (when the station is turned on), the float may rest against the chamber wall and get stuck in this position. UniPump Sub 2009 is a standard design pump with a float attached to the end of the cable and moves freely.

Eurobion Round septic tank diagram. Until recently it was called Rusyn.

Price ↑

Today, the cost of these septic tanks remains one of the most affordable on the market. This is due to the simplicity of the design and the use of domestically produced components.

However, this fact does not affect the quality guaranteed by the manufacturer.

Price

| Model | Supply pipe depth | Performance | Salvo release | Dimensions L x W x H | Retail price |

| EUROBION - 2 (h=1.86 m) itself | up to 30 | 400 | 130 | 1140x530x1960 | 61500 |

| EUROBION - 3 (h=2.33 m) itself | up to 60 | 600 | 200 | 1140x530x2480 | 64800 |

| EUROBION - 4R (h=2.33 m) itself | up to 60 | 800 | 250 | 1000x1000x2330 | 66476 |

| EUROBION - 5R (h=2.34 m) itself | up to 60 | 900 | 390 | 1080x1080x2380 | 90790 |

| EUROBION - 5R (h=2.34 m) prin | up to 60 | 900 | 320 | 1080x1080x2380 | 72990 |

| EUROBION - 5R (h=2.60 m) | up to 85 | 900 | 320 | 1080x1080x2640 | 76000 |

| EUROBION - 5R (h=2.60 m) prin | up to 85 | 900 | 320 | 1080x1080x2640 | 78000 |

| EUROBION – 5R (h=3.00 m) | up to 120 | 900 | 390 | 1080x1080x3040 | 79030 |

| EUROBION - 5R (h=3.00 m) prin | up to 120 | 900 | 320 | 1080x1080x3040 | 81030 |

| EUROBION - 5R (h=3.30 m) | up to 150 | 900 | 390 | 1080x1080x3350 | 97750 |

| EUROBION - 5R (h=3.30) prin | up to 150 | 900 | 320 | 1080x1080x3350 | 99750 |

| EUROBION - 6 (h=2.50 m) | up to 70 | 1200 | 450 | 1040x1140x2650 | 93230 |

| EUROBION - 6 (h=2.50) prin | up to 70 | 1200 | 380 | 1040x1140x2650 | 95230 |

| EUROBION - 8R (h=2.34 m) | up to 60 | 1600 | 700 | 1050x1050x2390 | 95230 |

| EUROBION - 8R (h=2.34) prin | up to 60 | 1600 | 630 | 1350x1350x2690 | 100600 |

| EUROBION - 8R (h=2.60 m) | up to 85 | 1600 | 700 | 1350x1350x2640 | 99850 |

| EUROBION - 8R (h=2.60 m) prin | up to 85 | 1600 | 630 | 1350x1350x2640 | 99850 |

| EUROBION - 8R (h=3.00 m) | up to 120 | 1600 | 700 | 1350x1350x3040 | 109000 |

| EUROBION - 8R (h=3.00) prin | up to 120 | 1600 | 630 | 1350x1350x3040 | 111000 |

| EUROBION - 8R (h=3.00) prin | up to 150 | 1600 | 700 | 1350x1350x3360 | 124330 |

| EUROBION - 8R (h=3.00 m) prin | up to 150 | 1600 | 630 | 1350x1350x3360 | 126330 |

Changes that have been made to the Eurobion ART station (since 2016)

A removable hair catcher has been added. This is important because hair clogs the station a lot. It is a tube with a soldered polypropylene rod. Installed in the receiving chamber. During service, the hair trap is removed and washed.

A special brush has appeared that is inserted into the channel sump. It also collects hair and other dirt. In addition, activated sludge settles on the channel settling tank. The removal of silt during volley discharges is less.

An inclined partition appeared under the false bottom between the aeration tank and the secondary settling tank. Before this, there was a partition between them to the bottom with a 50 mm hole. If there was no service for a long time, this hole became clogged. Now the cameras communicate through a wide gap and blockages are impossible.

A service airlift has been added for pumping out the septic tank with your own hands. This airlift is equipped with a special plug. To start pumping out the sludge, you need to remove the plug. There is a trick: you need to unscrew the tube from the compressor distributor that goes to the aerator, and put a plug from the airlift in its place. This will shut off the air supply, and pumping sludge through the airlift will go faster.

Scheme of operation of the Eurobion ART septic tank with improvements after 2021. An inclined partition appeared, the airlift between the secondary settling tank and the aeration tank disappeared, and a service airlift appeared.

Expected quality of cleaning

The quality of wastewater treatment directly depends on the state of the microflora. Immediately after connecting the septic system, the water coming out has a cloudy appearance. The installation needs to be operated for several weeks to reach full capacity. During this period, the percentage of purification does not exceed 70%.

To prevent environmental pollution, the active microbiological mass can be colonized immediately after installation. The system does not provide for the use of aeration fields, so the final quality of the effluent can be checked by taking a sample from the tertiary settling tank.

If the number of people living is less than the septic system is designed for, reaching full capacity will take much longer. The process can last from 6 to 12 months.

Cloudy residue in samples taken from the tertiary settling tank indicates problems with the system. Typically, this can be caused by leaching of activated sludge or low concentrations of it. Most often, such consequences occur during salvo discharges.

Sometimes this is a consequence of a clogged one of the system pipes. After the installation reaches full capacity, the water should not contain fine suspended matter.

But even clear drains contain large amounts of phosphates and other surfactants found in detergents. The design of a standard septic system does not provide a mechanism for neutralizing chemical impurities.

This is what water samples from a septic tank should look like. The first sample with a small amount of finely dispersed sludge was taken from the primary settling tank. The second sample was taken from the tertiary settling tank. Water quality must be checked periodically

Treated domestic wastewater does not have an unpleasant odor and can be discharged into a drain or swamp. Discharge into rivers or other bodies of water is prohibited, as this leads to phosphate poisoning of local biological flora and fauna.

The company allows you to separately purchase a dispenser for wastewater disinfection, but it cannot be installed in the device’s container itself. Since the water in the station constantly circulates between the compartments. For this you need a drainage well.

The diagram shows an option for installing a filter well for post-treatment of wastewater processed by the station. The clarified and disinfected liquid drains through the soil filter and is disposed of in the underlying layers (+)

An alternative method of purification is the installation of ultraviolet radiation. The plastic from which the body is made is resistant to UV rays. If the station is installed in an environmental zone, then it needs additional modernization. The equipment can be ordered on the manufacturer's website.

Complete set and additional equipment of Eurobion stations

The standard septic tank package includes:

- Frame

- Technological equipment: aerator, recirculation airlift, etc.

- Compressor.

- Polypropylene elbow 110x15°.

I must say that the equipment is one of the weakest among other stations. There is no pipe for inserting the supply pipeline and there is no polypropylene rod for welding the pipe. Also, the Eurobion does not come with a hazard warning lamp.

Optional equipment. Not included in the standard package and must be purchased separately:

- Ultraviolet lamps (UV) for waste disinfection. They are installed only in elongated models with forced drainage (the drain is pumped through the lamp).

- You can also install the Bioguard system in Eurobion. This is an alarm that is triggered when there is a break in the electrical circuit and signals that the compressor has stopped working, including if it is stolen.

Installation

Since the Eurobion biological treatment station is a rather complex technical device, during its installation it is necessary to take into account and comply with many special conditions and regulatory requirements. In addition, certain skills will be required when installing and connecting pipelines, electrical equipment, etc.

Attention! In order to avoid mistakes and miscalculations that could lead to improper operation of the septic tank, the manufacturer recommends that the installation be installed by a specialized organization.

If the user, having the required amount of knowledge and skills, decides to carry out the installation himself, then when carrying out the installation it is recommended to use the diagram from the manufacturer.

Installation diagram of Eurobion septic tanks. Source – official dealer website https://www.e-bion.ru

Turnkey installation of autonomous sewage system Eurobion

Pre-installation measurements and cost estimates

Before installation, a survey engineer is scheduled to visit the site. He arrives on the agreed day and determines:

- A place for a septic tank, taking into account the permissible distances to the road, house, trees (up to 3-5 meters) and sources of drinking water (up to 50 m).

- Soil type and groundwater level. Taking this into account, the specialist chooses a method of drainage. In sandy or sandy loam soil with low groundwater, Eurobion is installed with gravity drainage into a filter well. For clay and/or high ground, a forced modification with a drainage pump is chosen, with pumping into a ditch.

- The depth of the drain pipe from the house. This affects the selection of modifications according to the insertion depth. The pipe must be led to the septic tank with a slope of 2 cm per meter of route. The distance to home is taken into account. If the drain pipe is located deep, then choose Eurobion Midi, Long or Superlong septic tanks with an elongated body. With such models you can cut the pipe deeper.

The measurer also discusses additional work with the customer. It happens that you need to cut down bushes for a septic tank. Sometimes you can raise the outlet of the fan pipe so as not to install a more expensive extended station. This work is also performed during installation.

After measurements and discussion with the customer of all the nuances, an installation diagram is drawn and an estimate is drawn up. The Zagorod company calculates estimates directly on site, within 45 minutes after measurements. Our company includes every last detail in the estimate. The total cost of installation is immediately clear. We carry out delivery strictly according to the estimate, that is, we bring everything that is needed for installation.

Installation of housing and pipelines

The pit is dug 50-60 cm longer than the length and width of the septic tank, so that there is 25-30 cm left on each side for sprinkling with sand. A sand cushion 10 cm thick is poured at the bottom of the pit.

During installation, the septic tank is leveled. The permissible slope is up to 5 mm per 1 m. The supply pipeline is cut into the receiving chamber, in which a movable false bottom is located.

Then I sprinkle the septic tank with sand and spill it with water. All chambers communicate with each other, so water can be poured into any compartment without the risk of damaging the structure. Backfilling and filling are carried out in stages. First, pour water to a depth of 30 cm, then sprinkle the septic tank with sand and compact it, then fill it again, sprinkle it, and so on until the outlet of the aerodrain system. This water level is called working.

Sanding and watering

The height of the insert from the bottom is 1.6 m from the bottom for any model. The recommended insertion depth for a standard station is 30 cm. In this case, during volley discharges, the supply pipe will not be flooded. The insertion is made using a crown and a hot air gun. A hole is cut out using a crown, and the pipe is sealed with a polypropylene rod using a hairdryer. The input is sealed.

Correct insertion of the pipe

Installation of a compressor and pump in Eurobion forced septic tanks

The compressor is installed in the electrical compartment and plugged into a power outlet. The pump in forced modifications is installed in a chamber for purified water. The pump cable is inserted into the compressor compartment and the plug is plugged into the second socket.

Connecting the compressor and pump

If desired, the compressor can be installed outside the septic tank. This is not difficult to do, but there is no point in such a setup. It is generally not recommended to install a compressor in a living room - there is not enough oxygen in it, in winter warm air enters the pipe and condensation forms on it. Installing a compressor in a heated room is only possible with constantly running supply ventilation.

The compressor is connected through a HDPE pipe 25. Plastic cone nozzles are provided for this purpose. The remote compressor is plugged into an outlet in the room where it is installed. When placing the compressor inside the septic tank, the cable is laid in a corrugation, inserted into the compressor compartment and connected to the receiving block. Together with the compressor, an alarm is installed, a lamp and a float are hung in the receiving chamber.

In the technical data sheet, the manufacturer strongly recommends venting exhaust air through the supply pipeline. It is best if the air is removed through a vent pipe leading to the roof of the house. This will avoid the breakdown of water seals, although a septic tank can operate effectively without such ventilation. The exhaust air exits normally through the holes in the cover.

Fully installed and connected septic tank

Advantages and disadvantages of Leader brand structures

One of the advantages that Leader brand devices have concerns the location of the structure relative to a residential building. Due to the absence of an unpleasant odor and the quiet operation of the equipment, the septic tank can be placed at a minimum permissible distance of 5 m (SNiP). Other standards should be taken into account, for example, to the nearest well - 25-30 m for sandy (sandy loam) soils, 45-50 m for clay soil.

Residents of cottages who have been using septic tanks for several years note the following advantages:

- high efficiency of sewage treatment - several processing chambers are capable of purifying liquid by 95%;

- the ability to work without biologically active additives, which experts from some companies recommend adding to septic tanks;

- stable operation even with regular long interruptions in the supply of wastewater, which does not require conservation;

- easy tolerability of power outages - in the event of force majeure, the system is able to operate as usual for 2 weeks, without changing the properties of purified water;

- the possibility of using one of the drainage schemes with a focus on the type of reservoir or the presence of a structure for discharging purified liquid;

- compactness of the structure, allowing for economical distribution of the free territory of the site;

- the possibility of installation in clayey soil or in an area with high groundwater without a specially designed concrete foundation (the presence of a stable concrete slab at the bottom of the pit is one of the conditions for installing septic tanks from competitors).

The manufacturer recommends selecting a structure so that the useful volume of the device is approximately 3 times greater than the daily amount of sewage. Many consider this a disadvantage; in fact, this ratio helps to easily withstand salvo discharges and clean the liquid by at least 95%.

The possibility of neck extensions is also an advantage. It is necessary to bury the septic tank below the normal level. This need arises in northern regions with deep soil freezing

Another advantage can be found by purchasing the Leader cleaning system directly from the manufacturer. Without markups, the cost of equipment that belongs to the middle price segment is much lower.

One of the disadvantages is the poor functioning of the installation at low temperatures and the need for additional insulation, but this problem applies to any VOCs.

Some users report a bad odor, but this is most likely due to incorrect installation or untimely removal of sediment or sludge. Based on reviews, one can judge that the advantages of the Leader septic tank outweigh its disadvantages.

Eurobion septic tank service

Maintenance is not just pumping out sludge every 6 months, but also regularly monitoring the operation of the station. Many users do not call a service engineer until they have problems cleaning their drains and there is an odor. This attitude leads to high costs for station repairs. But even after several years without maintenance, both a service specialist and a vacuum cleaner are often needed. The channel settling tank, airlifts, film degasser, and air drain tube become heavily clogged.

The septic tank is pumped out in several stages so that it is not pushed out by groundwater. All working elements are sorted and washed. In the old version, it can be difficult to clean the overflow between the settling chamber and the secondary settling tank. In this case, intense movements of the false bottom up and down help. But it helps with minor blockages. If it is strong, then you can break the hinges for attaching the false bottom.

You can service the Eurobion septic tank yourself:

Once a day, check that the hazard warning light is not on. This means that everything is in order with the sewer.

Once a month you need to open the lid of the septic tank and carry out a visual inspection, catch floating debris from the aeration tank and also check whether the alarm system is working (to do this, simply lift the float). When inspecting, you need to pay attention to the condition of the water at the outlet. It should be light and odorless.

Signs of normal septic tank operation:

- The main airlift drains water into the receiving chamber (this can be seen when the water level in the receiver is normal).

- Aeration elements saturate the water with oxygen (rising air bubbles are visible).

- There are no whistling sounds (if there is, then this is a sign of poor fixation of the injectors; they need to be tightened).

- There is a flow of water towards the film degasser.

- The aero drain works normally (if not, then you need to clean it).

Once every 6 months, maintenance is carried out with sludge pumping out. It is necessary to remove and wash the brush and hair catcher, blow out the main airlift, clean and rinse the filters on the compressor.

It is recommended to replace worn compressor membranes once every 3 years. The aeration element is replaced once every 10 years. A full service with pumping out sludge and garbage is performed once every 5 years.

Operating principle and design features

Septic tank Topas 10 Long

The Yubas treatment plant operates as follows:

- Through the sewer pipe, wastewater enters the receiving aeration tank and then into the aerobic settling tank. In both compartments, the liquid is enriched with air using aerators, which promotes the full functioning of bacteria.

- Heavy particles settle in the first settling tank, and water is mixed with activated sludge and flows into the second, where a biological film is removed from the surface of the liquid using a special device.

- In the case of intensive work and the receipt of a large volume of wastewater, the outlet dispenser “Aerosliv” does not allow insufficiently purified water to be discharged outside the installation and prevents the leakage of activated sludge.

- When the liquid level drops below the outlet, the airlift ensures the circulation of wastewater inside the device, maintaining the system in working order.

Considering that when using anaerobic bacteria in the process of wastewater treatment, the release of gases is accompanied by the appearance of unpleasant odors, the Yubas company has completely abandoned their use.

Customer reviews ↑

The best way to objectively evaluate a product is the reviews of people who use it.

Based on these materials, you can find out future problems in the operation of the septic tank, the specifics of its operation and repair:

Igor We installed a Eurobion 5 septic tank for a family of 4 people. So far we are happy with the work, no complaints. Our only regret is that we had to install an additional drainage pump to drain water into the storage well.

Vik1977 At first, when I first started choosing a septic tank model, I didn’t really trust Eurobion - the low price clearly indicated a loss of quality. But greed won - I bought it and installed it. So far it’s working fine, the season has finished without any problems. The only thing is that at the beginning of work the silt began to wash out. But the adjusters arrived and fixed everything.

Lyubov Andreevna After installing the septic tank, the installers advised us to immediately purchase an uninterruptible power supply for emergency power supply to the compressor. Thanks for the advice - after 2 months the electricity was cut off throughout the entire area. The instructions say that without it, the septic tank works normally only for 4 hours - and then a smell appears and poor cleaning. Our assistant lasted 2 days on 4 batteries, so they survived the disaster without noticing.

Recycled waste disposal options

Autonomous sewage systems achieve maximum efficiency when wastewater is discharged correctly. Potential consumers are offered three options for drainage arrangement:

Out into the ravine. Outgoing pipes are laid with a slope into the ditch. As it enters, sewage water is transported out by gravity. The method is effective for soil with a high level of water permeability.

Discharge of liquid into a drainage well. The peculiarity of the container is the absence of a bottom. The well is installed on a gravel/sand bed, and the waste flows into the soil, undergoing additional filtration through a layer of sand.

Discharge of purified water into a drainage ditch or stream. The choice of scheme provides for an additional process of water purification in the sewer pipe; wastewater is transported by a drainage pump. When using a drainage ditch in soils with a low filtration coefficient, the slope of the pipe should be 4-6 cm per 1 meter.

Important! In order to achieve the most efficient level of operation of the septic tank, it is preferable to collect the treated wastewater in a special container and force it upward through pipelines for irrigation of vegetation.

Go back to Eurobion 5

Installation and commissioning can be carried out, if desired, by the user himself, who has the necessary knowledge and skills in installing utilities and equipment. In this case, the location of the installation is determined by the flow rate (generation and disposal) and the conditions for the discharge/discharge of purified waste water, limited by the sanitary protection zone of drinking water supply sources, hydrological and climatic conditions of reference in a specific area of the area. The conditions for the disposal of treated wastewater from public installations for each specific facility are agreed upon and carried out by the Customer with the local authorities of the State Sanitary and Epidemiological Supervision.

The units are installed underground, with the lid located 15-20 cm above the ground surface to prevent rain and melt water from penetrating into the tank. To improve thermal insulation, the top meter of the installation is insulated with slatted insulation, such as Penoplex, or a layer of foamed polyethylene, such as “ENERGOFLEX”, with a total thickness of at least 20 mm.

Preventive maintenance and repair of electrical equipment installed in the EUROBION station must be carried out in accordance with the “Rules for the operation of electrical installations by the consumer” and by specially trained personnel. Insulation resistance measurements can only be carried out on installations that are disconnected on all sides by switching devices. Before taking measurements, you must make sure that there are no people in the part of the installation where the measurements will be taken. Before measuring insulation resistance, i.e. Before connecting the device and after measurement, the charge must be removed from the conductors. The insulation resistance of the current-carrying parts of the installation relative to the ground is measured with a megohmmeter for a voltage of 2000 V.