It is impossible to imagine individual water supply for a private home without pumping equipment that delivers water to the consumer; for this purpose, several modifications of electric pumps with different operating principles are used. One of the popular types is a screw pump for a well, mainly used for drawing water from sources whose water basins are located on sand.

Screw (screw) electric pumps, presented on the market as submersible models, are produced by many leading domestic and foreign manufacturers of pumping equipment; their cost does not exceed the average price range for this category of units. To choose the right electric pump, several classes with different principles of operation are considered, while a screw well pump, under certain conditions, has some advantages over other varieties.

Rice. 1 Popular models of screw pumps

Submersible well pumps - varieties

Pumps installed for pumping water, depending on their location relative to the water source, are divided into two groups: surface and submersible.

The first ones are installed on the ground next to the well; a pipe or pressure hose is lowered into the shaft for water intake, while the maximum suction depth (the location of the water mirror from the surface layer of soil) does not exceed 9 m. The overwhelming number of household water-suction outdoor units operate on the centrifugal principle and have average technical characteristics with a maximum volume of pumped liquid of 5 m3/h and a pressure of about 50 m, the efficiency of the devices is not more than 50%. Typically, surface units are included in pumping stations, which are a single unit in which, in addition to the electric pump, a hydraulic accumulator, a pressure switch and a pressure gauge are installed.

Submersible pumps are presented on the market in several varieties with different operating principles, depending on the design, cost and quality of well water; they are used in households for a variety of purposes.

Rice. 2 Operating principle and design of a centrifugal electric pump

Centrifugal

Centrifugal electric pumps occupy a leading position among other types due to the following design feature arising from their principle of operation - the inlet water flow enters the axis of the impeller and is displaced by its blades through a pipe on the side of the housing. Thus, it became possible to connect any number of centrifugal wheels with chambers (stages) in series with increasing pressure at each stage.

The pressure in household versions reaches 200 m or more, the throughput capacity is up to 20 m3/h, the efficiency increases with increasing dimensions of the pump unit and reaches 65% for household high-quality models of Danish and Italian production.

High-quality centrifugal electric pumps from world-famous European concerns are equipped with internal protection against winding overheating in the absence of coolant, have a built-in check valve, expensive models are equipped with an electronic unit for controlling the shaft rotation speed depending on the volume of water consumption using pulse-width modulation. This solution allows you to reduce the size of pumping equipment, practically eliminating the hydraulic accumulator from the connection diagram, and also save electricity, reducing its consumption by 40%.

Centrifugal pumps from the world's best manufacturers of pumping equipment are in high demand among consumers: Grundfos (Denmark), Pedrollo, Speroni (Italy), Wilo (Germany), Russian brands Belamos, Aquarius, Unipump (manufactured in China). It should be noted that the difference in prices between the products of leading foreign companies and products made in Russia or China is quite significant; a high-quality electric pump from Grundfos costs about 1000 USD, while a domestic or Chinese pump with similar characteristics can be purchased for 200 USD. e.

Rice. 3 Vibrating electric pump - device

Vibrating

The manufacturing technology of vibration electric pumps has not undergone significant changes since Soviet times, therefore there are many Russian brands on the market, there are products made in Ukraine and Belarus, and there are sufficient quantities of Chinese models.

The difference between vibration electric pumps and other types is the absence of rotating parts and, accordingly, bearings; the operating principle is based on the reciprocating movement of the coil armature when alternating current is supplied to its winding. A rod with a piston that draws in water is welded to the armature of the electromagnet; to prevent the outflow of liquid into the source, a check valve is installed near the inlet holes.

Vibration models have a rather low efficiency of about 35%, the maximum volume of pumped liquid does not exceed 1.5 m3/h, and the pressure does not exceed 80 m.

These characteristics are considered not too high to provide water to a private house with even one person living in it, so vibrating pumps are mainly used for economic purposes: for irrigating garden beds, filling swimming pools, ponds, various types of containers with water, and carrying out drainage work.

Since vibration types are not too sensitive to the high content of suspended particles in water, they are often used for pumping wells and wells, extracting from them turbid water with clay-sand fractions.

Vibration pumps are classified as products in the budget price category, their minimum cost is about 20 USD, the average price of a typical high-quality unit is 30 USD. Vibration pumps on the market are represented by a large number of domestic (Rucheek, Malysh, Dachnik, Aquarius, Vikhr, Zubr) and Chinese (Oasis, Patriot) brands.

Manufacturing companies

The list of companies, as well as the range they offer, is quite large. The Russian market presents mainly products from domestic, European and Chinese manufacturers. Screw pumps come in different brands.

Highest price segment:

- Grundfos. Excellent quality at a high price, very wide range. Large, world famous manufacturer.

- Gardena. European manufacturer. Prices are above average. The number of models for wells is small.

Middle price segment:

- Speroni. European manufacturer. Quite high quality and reliability.

- Pedrollo. Wide range of models. International company. High level of product reliability.

- Aquario. A large number of models, there are options for narrow wells. Relatively high reliability.

Lower price segment:

- Aquarius. Several dozen models for wells. Well-known Ukrainian manufacturer. Insufficient reliability of pumps.

- Gilex. Products are manufactured in Russia. Popular brand. Conflicting reviews about product quality.

- Belamos. Production is located in China. Reliability is in class.

Operating principle and design of a screw pump

In a standard screw household electric pump, the working screw is made in the form of a spiral pin made of corrosion-resistant material, which is chrome-plated steel, stainless steel or high-strength plastic. The liquid sucked in by the rotating screw enters a technical polymer holder and is then pushed out into the upper outlet of the electric pump.

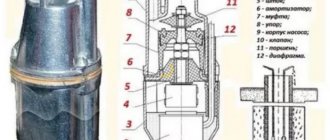

The screw electric pump used in everyday life consists of the following main components (Fig. 7):

1 — Electrical part with a vertically mounted single-phase electric motor with a dry rotor and an oil-filled chamber separating the engine compartment from the hydraulic part; a starting capacitor is located inside the lower part of the housing.

2 — The hydraulic part consists of a housing, a water intake filter and a working auger rotating in a cage made of elastic polymer (rubber) - an assembly of a screw and a rubber coupling pushes the liquid entering the housing through perforated holes 3 to the outlet pipe.

3 — The water intake part is a stainless steel cylinder with holes made in the side walls to draw in water.

4 — On the top cover of the pump, made of brass or stainless steel, there is an outlet pipe and lugs.

5 — The outlet pipe is made with an internal thread with a standard diameter of 1 inch, a check valve and a water-lifting hose are attached to it.

6 – A nylon or metal cable in synthetic protective insulation is tied to the eyes.

Rice. 7 Design of a screw pump

Manufacturing methods

If you need to reduce your own costs, you can create a screw yourself. For production you will need the following:

- Sheet steel, which has a thickness of 3 mm.

- A shaft through which force is transmitted.

- Fastening connections that ensure the fixation of the part.

- Two-stage gearbox. To select, the screw is calculated; the purpose of the gearbox is to reduce the number of revolutions and increase the force.

- An electric asynchronous motor transmits the main rotation. Today, in most cases, a 220V model is installed, as it is characterized by high efficiency and low energy consumption.

The auger drive is characterized by its small size in the case where it is not necessary to significantly change the output parameters of the electric motor. The standard housing is made in the form of a pipeline, which is divided into several sections. In this case, the sections are connected with bolts. There are also two sections: one is for loading, the second is for unloading the transported material.

You can often encounter a situation where self-manufacturing of a mechanism involves remaking an old one. Many experts note that such an approach is impractical. You can calculate productivity by applying certain formulas.

To produce a screw device, a certain set of tools is also required:

- Welding machine.

- Bulgarian.

- Hacksaw for metal.

- Various measuring instruments.

To increase the efficiency of the device, you should monitor the shape of the coil. Even minor defects can cause a significant decrease in equipment performance.

Distinctive features and parameters of screw electric pumps

A typical screw pump for wells used in individual water supply has the following technical parameters:

- Power supply voltage: AC 220V ± 10%, frequency 50 Hz.

- Temperature range of the pumped liquid: from 0 to 35 °C.

- pH of pumped water: 6.5 - 8.5.

- Operating ambient temperature range: from 0 to +40 °C.

- Minimum depth of immersion under the water surface: 0.5 m.

- Permissible volume of mechanical particles in pumped water: - no more than 500 g/m3, the content of fibrous materials in the liquid is not allowed.

- Permissible diameter of mechanical fractions: - 1 mm.

- Maximum pressure: 3 m3/h, for most models it does not exceed the threshold of 1.5 m3/h.

- Maximum pressure: up to 200 m, this indicator is a rare exception; most modifications create a pressure pressure of no more than 100 m.

Rice.

8 Main characteristics of Chinese Oasis Main advantages of screw electric pumps:

- Low cost, the price of the cheapest models is about 80 USD, in general all models are cheaper than centrifugal types.

- Simplicity of design. The working part consists of a screw and a rubber cage; they are easy to maintain and, if necessary, simply replaced, which makes repairing screw units very simple.

- Due to its operating principle, a screw pump for a well can transport liquid with large fractions of sand and clay deposits - this is its main advantage. A submersible screw pump is preferable to use for water intake from well sources on sand, which often have a high content of suspended particles of clay and sand. Although their parts are subject to mechanical stress from solid particles, the service life of a screw pump in turbid sources will be longer than that of centrifugal models.

The disadvantages of screw units include the mediocre quality of many products (chrome-plated screw, quickly abraded holder) and not very high technical characteristics, noticeably inferior to centrifugal types, as well as low efficiency, not exceeding 45%.

Where is it used?

Screw pumps are capable of pumping not only water, but also gas, steam, and liquids containing viscous impurities.

Water pumped from a deep well serves different purposes:

- as drinking water or for technical needs around the house;

- filling a fountain or pool;

- to fill the storage tank;

- for drip or irrigation irrigation system of the site.

The main areas of operation of a screw pump are:

- Water supply for the entire suburban area;

- Functioning as a water purification system;

- Providing water from a well. Screw pumps are used as a pressure generator for autonomous heating systems; they work even in wells clogged with sand. Water is supplied from both a meter-long and deep well;

- Use of liquid media in a pumping system during construction, for example, ground or industrial water. This also includes dosing difficult-to-pump suspensions or liquids, such as silicones, paints, and anti-corrosion agents.

Screw screw pumps for water are popular due to their multi-purpose use, long service life and trouble-free operation. In addition to the fact that they pump water from reservoirs and rivers, they are used to transport demineralized water in industrial workshops or for pumping honey or fats in the food industry.

Application area

We can say that a screw pump for a well, due to its ability to pump out dirty water, is a leader in the number of areas in which it is used in household management. A screw well pump is purchased for:

- arrangement of water supply for cottages, dachas with water supply from wells and boreholes;

- filling artificial ponds, swimming pools, tanks for heating and drip irrigation;

- irrigation of vegetable gardens, orchards and any areas with plants on a personal plot;

- carrying out drainage in case of flooding of basements, cellars and basement rooms in the house;

- pumping wells after drilling operations, some professional drilling companies specifically purchase screw pumps for this purpose;

- cleaning wells and wells from silt deposits.

Read a separate article about choosing a drainage pump for dirty water.

Rice. 10 Parameters of Unipump Eco Vint series screw pumps

Well installation rules

To immerse an electric screw pump into a well, use a head or adapter, to which a cable is tied and a water supply pipeline coming from the unit is attached. Usually, before diving, the pressure hose, power supply cable and holding cable are tied together with insulating tape or plastic ties, and the following rules are observed during installation:

- Water-lifting pipes can be selected from low-pressure polyethylene (HDPE), steel or flexible elastic polymers, the main condition is the ability to withstand the maximum pressure in the system and the internal bore diameter is not lower than the thread size inside the outlet pipe.

- When using a flexible hose, make sure there are no kinks or twists.

- For lowering and lifting, use only a nylon or metal (stainless) cable; it is forbidden to hang the unit by the electrical cable.

- Before diving, you should make sure that the internal diameter of the casing is higher than the external dimensions of the pump housing together with the electrical cable, and that the pipes do not have any bends or narrowed areas.

- It is not recommended to place the power cable in a coiled coil - this leads to overheating and melting of the insulation.

- The minimum distance of the pump from the bottom of the well is 0.5 meters, the optimal is 1 m.

- It is prohibited to operate the pump with the tap closed - this will lead to its failure.

- It is mandatory to install a dry-running protective relay in the control system, even if there is internal automatic protection against winding overheating.

- When installing modifications that do not have a built-in check valve, it is installed on the outlet pipe in front of the water-lifting pipeline.

Rice.

10 Installation and connection diagram for a screw unit When comparing which well pump is better: centrifugal or screw, there is no clear answer, since the scope of application of these pumping units is slightly different. Screw electric pumps are usually used in situations where it is necessary to work with contaminated water, and due to their relatively low technical characteristics, the well should have a shallow depth or be located closer to an individual house. It is impossible to find European-made screw pumps on the domestic market; all goods are supplied to the retail chain by domestic and Chinese companies, so user reviews regarding the quality and materials of manufacture of screw units are contradictory.

Types of screw pumping equipment

Since screw devices are used in many fields of application, they differ from each other in their design features. According to their design, the units are divided into the following types:

- Screw pumps - these units are designed for pumping large volumes of aggressive chemicals and abrasives. The screw device works effectively in both vertical and horizontal positions. Often such equipment is used for water from wells and deep wells. Screw units have a simple design and relatively low cost;

- Rod pumps - these types of devices are used for highly viscous media in oil production and refining enterprises. The rod pump design includes a wellhead gland, a rotary column and a surface drive. Units of this type are characterized by high productivity and fairly high cost;

- Vacuum pumps - these units are equipped with two screw rotors rotating in opposite directions. Thanks to this design of the vacuum pump, the liquid first enters the area between the screw chambers and the cylinder, and then enters the exhaust port.

A screw pump for viscous liquids shows high performance, but the efficiency of the device largely depends on the correct use of it. In this regard, before purchasing a device for domestic or industrial purposes, you need to make sure that it is suitable for the chosen area of application.