The pumping station does not pump

Why doesn't the pumping station pump water? This is a question that many owners of equipment ask themselves, which is often an integral part of the water supply system for a country house from a well or well. One of the reasons for unit malfunctions is that the pumping station pumps water with air. How to get rid of this phenomenon is suggested in the article.

Determining the cause of the malfunction

If the pump does not pump water, then most likely one of the most important components of its functionality is broken - this is:

- Sufficient quantity and level of water in the hydraulic structure.

- Power supply of pumping equipment in accordance with its specified characteristics - voltage, frequency, current.

- The design power and productivity of the unit corresponds to the parameters of the well - depth, volume.

- The filter system, pipeline, valves, fittings are in good condition.

As a rule, an autonomous source of water supply works not only to supply the house, but also the vegetable garden, garden, greenhouses, bathhouses, swimming pools, etc. In this case, the source of the breakdown may be located not only in the premises or consumption facility, but also in the pipeline or equipment and the well itself. The best quick way to find a breakdown is to use the elimination method:

- First, the caisson supply pipe is disconnected. If water comes out of it, it means there is a breakdown in the line or at the consumer.

- If water does not flow when the caisson hose is disconnected, the problem lies in the well itself or the pumping equipment.

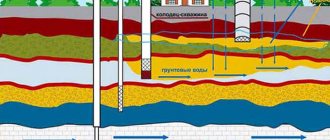

Construction of a water well Source oskada.ru

Note! Sometimes, outwardly, the pump may appear to be working properly and make operating noise when there is no water being pumped at all. There may be several reasons for this - errors were made in the installation of equipment or in the selection of its components, the natural water level has decreased, constant voltage drops in the network, a phase failure has occurred in the electric drive housing.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

NS Marina: secrets of success

In the field of pumping equipment production, Speroni is far from a newcomer.

With a half-century history behind it, it has managed to accumulate vast experience in engineering and production activities, which today is embodied in world-famous automatic pumping stations and other products.

At Speroni factories, every part is manufactured using the latest ultra-precise equipment, and modern technologies allow for assembly of the highest quality.

Each stage of production is controlled most carefully.

Thanks to this approach, the equipment produced by the company, including the NS Marina, has the highest characteristics and is considered the standard of quality, reliability and durability.

[wpmfc_short code="Block2"]

The main reason

If the pump hums but does not pump water, the reasons lie either in a clogged source or in technical problems with the equipment. Indirect signs indicating clogging with small particles are:

- Cloudiness of the water stream.

- Increasing reduction in pressure with fully functional operation of the unit.

- The presence of small particles, sand, silt and other impurities in the water.

Clogging of equipment with sand, silt or rock occurs as a result of the following series of processes in the well itself:

- The initial presence of small algae in the water.

- Collapse of the canal walls.

- The presence of rock or sand particles in a ground flow.

- Sludge stirring up from the bottom during pump operation.

The well produces muddy water Source oskada.ru

As sediment accumulates, the cross-section of the watercourse will narrow, the water entering the surface will become cloudy, and the pressure will weaken until the supply completely stops. However, the sensor installed to turn off the motor in this situation may not work, and therefore the equipment will continue to operate.

To resolve the problem, the following series of operations are performed:

- All equipment is de-energized.

- The pump is lifted and removed from the well.

- The remaining water in the canal is pumped out.

- The inside of the well is cleaned and disinfected.

- The fluid is pumped out again from the canal.

If all procedures were performed technically correctly and the equipment was not damaged, after the instruments are returned to their places and started, the well will start working with the same strength.

Step-by-step instructions on how to adjust it yourself

The setup is carried out with the power turned off. To check the result, the station is connected to the network.

Tools

The system is regulated by setting the relay. You will need a simple tool for the job:

- socket or open-end wrench;

- screwdriver.

Preparation

The principle of its operation is to close and open electrical contacts. Therefore, first:

- Turn off the power supply.

- Unscrew the screw located in the cap with a screwdriver.

- Remove the casing from the device.

Process

Under the relay cover there are two springs: large and small. The pressure in the water supply acts on them through a membrane. The 2 relay positions depend on the tension of the springs.

Adjustment steps:

- Tightening the nut on the large spring increases the release pressure. Select the direction of rotation of the nut. 1 turn of the nut changes the value of the lower pressure gauge reading by approximately 0.4 bar (1 atm. ≈ 1 bar). Having loosened or tightened the spring by eye, turn on the system and take readings from the monitoring device.

- If the previous actions did not lead to the desired result, continue adjusting the large spring. After a successful attempt, they move on to setting up a small spring.

- This spring sets the difference between the lower and upper readings of the pressure gauge of working equipment. Changing the characteristic it regulates requires approximately 2 times less revolutions than adjusting a large spring to the same value. Compressing the small spring increases the operating range of the system when the engine is off. The control results are checked similarly to the previous case, under real plant operating conditions. Now you can immediately check the lower and upper values of the pressure gauge.

After setting the pressure gauge control values, it is recommended to ensure that the pump starts no more than 30 times per hour.

Algorithm for further actions

Sometimes, even after completely cleaning the borehole channel, the watercourse is not restored. In this case, there are several reasons why the pump does not pump water:

- The mechanics of the equipment were damaged.

- There have been disturbances in the electrical circuit.

- There was a depressurization of the central pipeline.

- The control system has broken down.

Checking the pumping station Source sovet-ingenera.com

To identify the malfunction, the pump is again removed from the well channel and immersed in a barrel filled to the brim. Next, the engine is started and diagnostics are carried out. There are three possible scenarios:

- The motor has started and is working properly - therefore, there are no breakdowns in the electrical circuit.

- The engine does not turn on - disassembly and electrical repair is required.

- The pump is operating, but the outlet pressure does not reach operating levels.

Low pressure when the unit is running may indicate breakdowns in the line. If it is not possible to visually establish their location, then plugging the flow outlet, for example, with the hand of a hose, will provoke a sharp increase in pressure in the pipe and the formation of water streams in places of leakage.

Advice! Repairing a broken hose operating under pressure is unreliable. Because under the influence of pressure, both the patches and the glued areas will constantly break through and lead to even greater leakage. It is better to immediately replace it with a new one.

Replacing the main hose Source ytimg.com

Reckless often turns on

Possible causes and solutions:

- The pumping station often turns on if the air pressure in its hydraulic storage tank is very low or absent at all. In this case, the pumping station will turn on at every, even small, flow of water from the water supply system. Since the liquid is practically not compressible, the lack of air pressure in the tank will lead to the fact that immediately, with any opening of the tap or mixer, the pressure in the system will rapidly drop, which will immediately entail turning on the pumping station. When you close the tap, on the contrary, the pressure instantly rises and the pump immediately turns off. Measure the air pressure in the hydraulic storage tank and, if necessary, add to the required level: it should be 10% less than the lower pressure (pump activation).

- Another reason why the turretless engine often turns on may be the destruction of the membrane of the hydraulic storage tank . In this case, water will come out of the air injection fitting when you press on its core. The membrane chamber can be replaced by first disconnecting the front flange of the tank, which is secured with bolts. When installing a new membrane, it is advisable to cover the points of its contact with the tank and flange with silicone sealant.

- The third possible reason for frequent switching on, if the membrane is intact and the air pressure in the tank is normal, may be that the adjustment of the pressure switch is broken - the difference between the pump switch-on and switch-off pressures (ΔP) is too small. In order to increase the difference, you need to tighten the nut on the smaller of the two regulators clockwise.

The pump works without pumping

The reasons why the pump does not pump water from the well, even if the electrics are working properly and the main line is intact, may be the following:

- Filter and check valve clogged. The knots may become clogged with sand, silt, rock particles, or algae. To restore operation, the devices are cleaned or replaced with new ones.

- Dry running sensor malfunction. The burnt out sensor is replaced. Otherwise, the motor may overheat when the water level drops, with corresponding consequences.

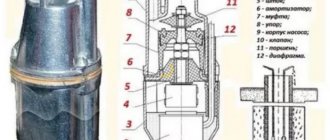

Good to know! Submersible vibration pumps often fail when overloaded. The reason is failure of the piston or destruction of the rod. Damage can be avoided by constantly monitoring operating parameters.

Independent work or professional help?

The following malfunctions of the submersible pump allow you to cope with the problems yourself, without the involvement of a specialist. However, even in these cases, you must understand well that without knowledge of the technology, the problem that has arisen and minimal skills, it is quite difficult to cope with the repair.

Before searching for any fault, you need to get acquainted with the design. First of all, you need to carefully study the instructions for the unit and its diagram. In order not to end up with unnecessary parts later, you need to remember the sequence of actions during disassembly. When working with any unknown device, it is recommended to photograph each step.

The price of a submersible pump plays a big role. Small “liberties” are allowed when repairing simple, inexpensive models, since in this case it will be more or less simple to assemble and disassemble the structure. Expensive imported (European) models have a longer warranty period, so the best solution in this case is to contact a service center.

Common breakdowns

There are several other common reasons why the pump works but does not pump water - these are:

- A decrease in the natural water level due to seasonal changes or improper well construction.

- Increased pump performance.

- Insufficient power of the unit in terms of head height.

- Voltage drop in the network.

- Clogging of pipelines, filter units and fittings.

- Depressurization of the main line.

- Breakdown of pumping mechanisms.

If the pump works but does not pump water, the reasons may also be hidden in the breakdown of its critical mechanical parts. The situation can be corrected either by repair or installation of a new unit.

Important! To ensure uninterrupted operation of an autonomous source, pumping equipment must be correctly selected according to the height of the flow being lifted. In this case, the calculation takes into account not only vertical, but also horizontal sections. As a rule, a lying section of pipe of 5 meters is equivalent to a 1-meter segment located standing.

Pumping station "Marina" CAM 40/22

This option is perfect for summer residents and owners of private houses whose pipeline pressure does not satisfy all user needs. The delivery set is thought out to the smallest detail - immediately after purchase you can begin installation and commissioning of the equipment.

Peculiarities:

- complete automation of all processes;

- adaptability for long-term work without technical breaks;

- cast iron body;

- waterproof motor with built-in thermal protection;

- everything is small - the unit can be easily moved in space, mounted on 4 stable legs, through which it can be screwed to a stand or workbench.

Technical parameters of CAM 40/22:

- Power – 0.8 kW;

- Throughput – 0.06 m3/min;

- Head – 28 m;

- Suction – 25 m;

- Receiver – 22 l;

- Weight – 14 kg.

Briefly about the main thing

There may be two main reasons why a water pump does not pump water - clogging with sand or mechanical failure of the equipment. In addition, malfunctions can occur in the following cases:

- Insufficient water level in the well.

- The operating parameters of the equipment are incorrectly selected.

- Failure of the mechanical parts of the unit.

- Clogging of the borehole channel, filters, pipelines, fittings with sand, silt, rock.

- Depressurization of the main line.

- A drop in the characteristics of the electric current in the network.

- Dry running sensor failure.

The easiest way to check and restore the operation of the well is to remove the pump and clean the water source channel. If this does not help, the equipment, electrical circuits and the integrity of the highway are successively checked for serviceability.

Ratings 0

The crazy guy can't hold the pressure

a water leak somewhere in the system .

First of all, you need to check the check valve to see if it is letting water back into the well or borehole. Solids may become lodged in the valve, preventing it from closing completely, or the spring may weaken.

If you are convinced that the check valve is working properly, it means that the leak is occurring in the system itself. It is necessary to check the integrity of the pipes and their connections , as well as the connection points of shut-off valves and plumbing fixtures.

the plumbing fixtures themselves can let water through : taps, mixers, toilet flush, etc.

The lineup

The line of pumping units of this brand has the following classification:

- Pumping station Marina-Speroni RSM 5/25

- APM series units are designed to lift water from deep sources located at a level of up to 30 meters;

- pumping stations of the HC Marina Speroni series have characteristics such as increased power and increased productivity;

- the CAM series of pumping devices represents the most budget-friendly and economical units that can draw water from a depth of up to 9 meters;

- A special feature of Indromat pumping stations is the presence in the design of the units of an electronic control device, which turns off the operation of the unit during a “dry” start.

Pumping station CAM 198/25 Having reviewed all the characteristics of Marina pumping stations, we can say that they have the following advantages:

- low power consumption;

- long period of operation;

- ease of installation and maintenance;

- stability of operation.

What is the Marina pumping station?

This is a complex installation designed for automatic water supply, which allows for proper production and distribution of water in almost any area. The design of the device is made in such a way that water can be pumped both from small reservoirs and from deep wells , tanks and wells. The production of such pumping stations has been going on for more than 60 years; during this period of time, the device has gained popularity among many consumers, including large enterprises and organizations.

The pumping station contributes to the uninterrupted supply of water to country cottages and summer cottages, and also allows you to increase the pressure in the main water pipelines.

In addition, the station can be used to irrigate summer cottages - the principle of operation is quite simple and does not require any special skills.