If you are the owner of a private house or cottage, then you have probably appreciated the usefulness of pumping equipment, which allows you to solve many problems related to providing your home with water, installing a sewer system, and watering your garden. Even in a situation where wastewater cannot be removed by gravity, fecal pumps come to the rescue. However, high-tech, high-quality and durable models are not cheap. But don’t despair, because you can make a sewer pump with your own hands. Without a doubt, in terms of functionality it cannot be compared with factory models, but it can be used as an inexpensive alternative.

Features of drains

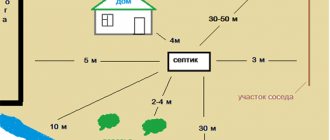

To collect wastewater from a country house or dacha, a cesspool is built on the site or a septic tank is installed.

In any case, it is necessary to periodically pump out silt deposits and solid impurities from this structure. Even when using a modern multi-chamber septic tank, in which bacteria are responsible for processing waste, periodic cleaning of sewage waste will be required. The best mobile application for experienced players has appeared and you can have a phone with all the latest updates and discover sports betting in a new way.

It’s good if there is free access for a sewage disposal truck to the treatment plant. Otherwise, you will have to use a factory-made or homemade fecal pump. In any case, the installation of such equipment must be carried out according to all the rules, so when doing the work yourself, it is worth familiarizing yourself with the nuances and sequence of installation.

If the septic tank or cesspool is not cleaned in a timely manner, this can lead to serious problems. As a result, the carrying capacity of the soil may deteriorate, which will lead to the accumulation of a large amount of wastewater in the container. The accumulated wastewater will spill onto the site and cause deterioration in the sanitary condition of your site.

All about silt suckers

A sludge sucker (SMD) is a technique designed to remove sludge from sewer wells. It copes with highly viscous waste. Thanks to the sludge sucker, you can clean ponds, creeks, technical and drinking wells. The sludge sucker is also used to clean cesspools, septic tanks, settling tanks and clogged pipes.

Purpose of the fecal pump

As we have already said, silt deposits and solid impurities accumulate on the walls of cesspools, which cannot be absorbed into the soil like water. As for septic tanks, bacteria cannot cope with all the waste and some of it settles on the bottom and walls of the container. To maintain the operation of the sewer system, as well as maintain a favorable sanitary situation, these structures need to be cleaned periodically.

A fecal pump is best suited for this task. This is a special pumping unit that grinds and pumps sewage from a sewage facility.

How to make a water pump with your own hands?

Attention: a conventional water pump is not suitable for such purposes, since its impeller will quickly become clogged with large waste particles, which will lead to overload of the electric motor and its failure. Only a special fecal pump or its homemade equivalent can process solid sewage waste.

Determining the degree of pollution of a reservoir

The first thing you need to pay attention to when cleaning a pond is the degree of contamination. The first stage is eutrophication, a decrease in oxygen in water. This happens if you do not remove debris, leaves and branches from the surface of the reservoir in time. At the second stage, duckweed begins to grow, insects, frogs and other inhabitants appear. The third stage is the appearance of silt, which covers the bottom of the pool and subsequently causes re-pollution. At the last, fourth stage, shallowing occurs: the pond is heavily covered with silt, duckweed, and various vegetation, and the reservoir may dry out completely.

Determining the degree of contamination helps to select the necessary cleaning method and effective means.

What do you need to assemble a pump yourself?

It is not difficult to make a fecal pump with your own hands, because its design is relatively simple. First you need to understand the main components and their purpose, as well as understand the principle of operation. The most important advantage of a homemade pump is its low price compared to similar factory-made products.

To assemble homemade pumping equipment for pumping out sewage, you will need the following parts:

- pumping unit of the “Baby” modification;

- fine mesh;

- metal slats;

- strong rope;

- welder.

Attention: to assemble a sewerage pump with your own hands, you do not need to disassemble the basic pumping device and change its technical characteristics. It is enough to install a filtration mesh at the inlet pipe, which will allow only wastewater with a particle size of solid impurities acceptable for this equipment to enter the unit.

Operating rules

A home-made pump for pumping out sewage with your own hands will serve for a long time, provided that the operating rules are followed:

- Regularly remove the mechanism, inspect it, identify malfunctions in the operation of components and connections. It is not recommended to lift the pump to the surface without first disconnecting it from the power supply.

- If there is a cutting mechanism, check its performance.

- To avoid the formation of grease deposits, regular washing of the internal parts is required. To do this, just hold it in a container with very hot water for a few minutes. For uninterrupted operation of the pump, it is advisable to consider the possibility of an additional power source, for example, a generator.

- After completing maintenance, be sure to check the operation of automatic devices and mechanisms.

- Before the next dive, you need to check the serviceability and correct operation of the mechanisms. The equipment is connected to the water supply network and pumps clean water.

Assembly, installation and maintenance

It is immediately worth noting that a homemade fecal unit is not suitable for multi-storey country houses and cottages. It is suitable for pumping out sewage from a small one-story house or cottage.

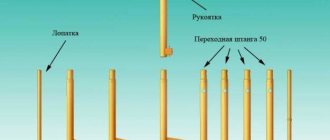

Work on assembling the unit is carried out in the following order:

- First you need to make a cage for the future fecal pumping device. To do this, a steel frame is made from metal slats, onto which a mesh with small cells is stretched. There is no need to take a very fine mesh; it is enough that the cell sizes are no more than 1x1 cm. Such a mesh will prevent large particles from clogging the pumping equipment, and the unit can easily handle impurities less than 10 mm on its own.

- A strong rope or cable is tied to the top of the cage. The pump itself is installed inside this cage.

- The unit is installed exactly in the central part of the septic tank (at the bottom). In this place, pumping equipment will not be able to pump silty layers, but will simply destroy them. Also, this arrangement will protect the unit from clogging with fatty substances floating on the surface.

- To prevent breakdowns of a homemade unit, you need to clean it and change the filter once a month.

Tip: you can use hot water to clean the fecal pump from grease. To do this, the pumping device is removed from the pit and placed in a container with boiling water for 5-10 minutes. During this time, the fatty deposit dissolves.

Cleaning methods

Many people wonder how many times a year they should do it. It all depends on its size, the volume of water used, this must be done at least once a year. You cannot completely pump out all the sludge; you must leave it at about 20% of the total mass. This is done in order to initially infect the chamber with bacteria.

The length of the pumping pipeline has a great influence on the quality of cleaning. If the length is large, then it is necessary to install an intermediate well. Thus, it will be possible to carry out cleaning in two stages using a standard corrugated hose.

Greater results are achieved when the septic tank is cleaned more often; this can be done by both specialists and the owner himself.

Self-installation of a factory unit

Installing a sewer pump is a simple and not labor-intensive task that can be completed by the owner of a country house. After completion of the well arrangement, pumping equipment is installed at the bottom of the structure. To ensure a minimum gap between the bottom of the structure and the intake hole, special metal supports are used on the pump body. To ensure more reliable operation, the unit can be suspended on a strong steel cable or a special support structure can be used.

DIY ejector pump for the station

Attention: experts do not recommend using a flexible hose as a discharge pipe. If you use this product for a long time, the pipe may become clogged. The best solution would be to use PVC pipes with a diameter of 6.3-7.5 cm. This pipe is connected to the pumping unit without sealing the connections.

To prevent the backflow of wastewater after the device is turned off, a check valve is installed. He crashes into a pipeline. If you are going to preserve the sewerage system, for example, for the winter in a country house, then you need to install a shut-off valve. It is installed in the pipeline behind the check valve. If you will be leaving for a long time, then this valve must be closed, thereby ensuring that the fecal pump is cut off from external drains.

It is important to know: for reliable operation in winter, the outlet pipeline must be carefully insulated.

The pumping unit is connected through an electrical panel equipped with protective devices. This panel must be grounded, equipped with a circuit breaker, a control panel and a protective device for forcibly turning on and off the pumping equipment.

Advice: if emergency power outages occur in your home, then for uninterrupted operation of the pumping equipment it is better to install and connect a gasoline or diesel generator of suitable power.

Overview of species

Functional differences divide this special equipment into groups. These are standard suction pumps with built-in waste regeneration, as well as devices with extended functionality.

It is worth separately describing this division of machines into types.

On resources that sell suction pumps or offer the services of this equipment, you can choose the option that is optimal for a particular case. In one situation, a sludge pump with a tank volume of 6000 liters will be required. But to clean a small pond, such a technique is not a targeted request, you need to take something smaller, sometimes 10 cubic meters is enough. Details can be discussed on the websites of these services. There you can also get advice from a specialist on choosing a suitable machine.

First start-up and setup of the unit

After installing the pumping sewage equipment and connecting the power supply, the pipeline is installed. Then it is necessary to test the installed system, and also adjust the level at which the float circuit breaker will turn off the unit, protecting it from running dry.

To do this, the septic tank is filled with water. In this case, the liquid level must be at the minimum acceptable level for this equipment. After this, we continue filling the tank until the mark at which the sensor is triggered and the pumping equipment starts.

Testing the device allows you to check its performance and the correct installation of the entire sewerage system. If the slightest problems are detected, they can be quickly and painlessly eliminated at this stage. After successful testing, the receiving well is hermetically sealed. Now you can safely operate the sewer system and be confident in the uninterrupted and reliable operation of the pumping equipment.

Fecal pumping device

In addition to its main purpose, this sewer pumping unit is also used on the farm for other purposes. For example, in case of flooding of the basement with groundwater. Using a fecal container, the pumping of water in the collection tank is organized. If it is used for pumping out thick masses, its operation can be fully automated by installing a float switch.

Also, fecal pumps make it possible to neutralize all the consequences of natural flooding from rain, melting snow and other natural phenomena in a country house or in a private house. The pump has a shredder in its design, so if minor debris or dirt comes across, there will be no negative consequences for it.

If you have organized a storm drain on your site, then a drainage-fecal apparatus is used to pump liquid from the collector sites. This is especially effective during seasonal heavy rains. Thanks to this, there will be no problems in these engineering networks.

Such units are successfully used when servicing artificial small reservoirs; then it is better to use a submersible pump for sewage. If there is a natural reservoir nearby, then summer residents use such a pump to irrigate their plots.

Differences between a household submersible apparatus and a fecal drainage apparatus

Drainage pumps are primarily used for pumping contaminated liquids containing small particles. To prevent the penetration of solid and large elements, a mesh must be installed.

When pumping out a thick mass (for example, it could be a sewage pit), a fecal apparatus is needed. A submersible unit with cutting mechanisms will fulfill its purpose, but this requires a sufficiently powerful pump that can cope with high loads.

Important points

- It is not advisable to use chemicals to liquefy feces. They have low efficiency and pollute the environment.

- The pump must not be lowered to the bottom. For models without legs, a special stand is mounted manually.

- After pumping out the feces, the pit is washed with clean water from a hose, after which the dirty liquid is pumped out again.

- After operation, the pump is also thoroughly washed with running clean water and cleaned of all external contaminants.

Fecal scraper with cutting mechanism

To pump out viscous masses with solid inclusions, the installation must have a grinder. There are several variations of them that are found in different installations.

- Impeller with knives. The cutting element is fixed to the screw itself. Some may have a cast iron chopper.

- Cylindrical scissors-knives.

- Cross cleaver.

- Cutter. The operating principle is reminiscent of a household kitchen meat grinder.

- Lamellar cutters.

Each of these shredders has its own operating principle. But efficiency largely depends on the grade of steel used.

Therefore, when choosing a unit, pay attention to the cutting mechanism.

Materials

It is important to understand that the pump for pumping out fecal matter faces an aggressive environment. Therefore, the housing elements and its parts must be reliable. Depending on the manufacturer, the sewer apparatus is made of the following materials:

Plastic is used on budget installations. A drainage pump for sewerage made of plastic is relatively fragile and does not have high power. The most expensive device is made of stainless steel. But the high price is fully compensated by the quality and long service life. Cast iron is in the middle price category.

Of the listed materials, the best is stainless steel.

How to choose the right fecal agent?

Important technical information should be studied. characteristics of the device for pumping fecal and other masses.

| OPTIONS | DESCRIPTION |

| Power | The ability to pump out fecal matter at a certain speed. For constant pumping, preference is given to a 1.5 kW motor. If periodic cleaning is expected, then it is better to choose a power of 0.5 kW |

| Performance | The ability of the installation to pump out liquid at a certain speed per minute. For example, a device for arranging drainage and sewerage with a power of 1500 W is capable of creating a speed of up to 650 liters per minute. The choice of this parameter depends on the intensity of wastewater accumulation. If it is low, then a heavy-duty sump pump is not needed |

| Pressure | An important parameter indicating the ability of the device to lift liquid from a certain height. For example, a self-made pump mainly has a low pressure. It is important to consider not only the vertical, but also the horizontal pumping section. As a result, the pressure depends on the previous pump performance |

| Housing material | It is preferable to purchase a device for cesspools made of steel (stainless). Especially if we are talking about its constant operation in a difficult environment |

| Cutting material | The pump used with a grinder for the garden or home allows you to pump out masses with solid and thick inclusions. Taking this into account, the cutting element must be made of good quality steel |

| Automation | Units with cutting mechanisms can be equipped with automation. For example, a submersible pump with a float. Additionally, a water sensor is installed, which sends a signal to the motor to turn it on/off |

| Brand awareness | When choosing a sewerage device for a private home, preference should be given to well-known manufacturers. The selected model must have service in your area |

Operating principle

Submersible

The body of the device is made of reliable, durable material that is resistant to the negative effects of aggressive wastewater.

This pump can be used both permanently and periodically, connecting as needed.

In the first case, a platform for mounting the device is made at the bottom of the container with wastewater. Pipes for pumping out fecal matter are connected to the outlet pipes.

Good to know! The disadvantage of this solution is that to service the pump attached to the bottom of the septic tank, you will have to completely pump out the pit. Moreover, taking out the installation will not be entirely pleasant.

For possible maintenance, the fecal tank can be hung on a steel cable. It will be easy to remove and repair. The submersible unit can operate without human intervention. For this purpose, the equipment is equipped with automation and a float switch.

Submersible feces have positive aspects:

- The ability to lift liquid from a fairly large depth.

- The work process is automated.

- The motor cools itself.

- There is absolutely no noise during operation.

Surface

Such sewerage devices are installed in a place inaccessible to moisture, dampness and other atmospheric phenomena. These models have pumps that are less powerful, but their important advantage is mobility. Surface installations are easy to use for other purposes - for example, when pumping groundwater, cleaning an artificial reservoir, etc. The basic package includes a grinder for small particles.

The main inconvenience of using such a device is the need for installation in a separate room. You also need to choose a place from where the noise of the pump will not be heard.

Mainly used for periodic pumping of fecal matter. Not all models are capable of pumping viscous masses. Therefore, when choosing, you should pay attention to this parameter in the passport.

Semi-submersible

Only part of the unit is immersed in the pumped-out medium. The electric motor itself is located on the float. If periodic pumping is necessary, then this option is ideal; such installations do not have a grinder.