Previously, work on cleaning the well bottom was carried out exclusively by hand using buckets and ropes. Now pumping equipment helps to cope with this problem. Using technology, the cleaning procedure is much simpler and much faster. Do you agree?

We will tell you how to choose the ideal pump for cleaning wells, capable of pumping water containing sand and fine gravel. Here you will find out whether the borehole or drainage model will better rid the mine of silt and mineral deposits. You can choose the most efficient equipment.

The article we have proposed describes in detail the technologies for cleaning a well shaft using different types of pumps. For visual perception of information, diagrams, photo collections, and video instructions are attached to it.

Drainage pumps and their capabilities

During intensive use of a well, its bottom becomes silted, which leads to cloudiness of the water, a decrease in its flow, and the appearance of an unpleasant odor. In order for the water source to always remain in a usable condition, it is necessary to periodically clean its bottom from lapped sand, clay and other solid impurities.

It is recommended to clean wells once every three years. With the exception of structures excavated on fine sands, which require annual cleaning. Private hydraulic structures are cleaned using drainage pumps - devices endowed with great functionality.

Image gallery

Photo from

Drainer in cleaning a well

Well cleaning with two pumps

Pump float mechanism

Immersion of the drainage pipe into the well

Drainage pumps are capable of pumping clean and turbid water from wells, filled pits, swimming pools, cellars, and basements. The pump is also suitable for quickly eliminating the unpleasant consequences of utility accidents.

In addition, the drainer can be used to ensure constant circulation of water in garden fountains, ponds and other artificial reservoirs.

Household sump pumps can pump dirty water with solids up to 35mm in diameter

In order to select the device that is optimal in terms of technical parameters, you need to clearly understand what kind of water, dirty or clean, the pumping equipment will have to work with. By pure water we usually mean a liquid that has inclusions no larger than 5 mm in size.

Drainage pumps designed for pumping clean and dirty water differ:

- diameter of the outlet pipe;

- cross-sectional diameter of the suction hole;

- material taken for the manufacture of device parts.

Dirty water can contain solid particles up to 35mm across. Next, it is necessary to determine the total volume of pumped water.

It is also important to find out the depth from which water intake is supposed to be organized, as well as take into account the composition of the bottom filter - what size of gravel was used for its construction.

In addition to cleaning wells, drainage pumps can drain flooded basements and stimulate water circulation in artificial reservoirs

Video description

Video example of pumping water from a basement:

The pipes of the drainage system are laid at a slope so that the water from them accumulates in special wells. The latter are drained naturally, or with a high inflow debit - using a submersible pump.

- Automatic pumping.

When water enters the basement seasonally and abundantly, for example, with the arrival of a flood, it will not be possible to pump it out without a special pump. For its installation and efficient operation, a special pit is equipped. This is a small recess lined with brick from the inside. Its dimensions must allow for easy installation and maintenance of the device.

As water enters the basement, the pump, equipped with a float sensor, will automatically turn on. When the water stops flowing, it will turn off on its own. To carry wastewater to the drainage point, a pipeline will need to be installed.

Important! To protect the walls of the basement from the penetration of dampness from the ground, it is necessary to make high-quality waterproofing. A combination of layers of cement plaster and bitumen mastic is best suited for this purpose.

Selecting a pump based on performance and pressure

In addition to water quality, the most important parameters for selecting a drainage pump include its performance and pressure. Productivity refers to the volume of water that a pump is capable of pumping in a certain unit of time.

Typically, the performance of pumping equipment is measured in l/h or m3/h, which respectively means liters per hour or cubic meters per hour. This technical parameter shows how quickly the device can clean the well of contaminated water.

In order to choose a pump for cleaning a well, you need to know the depth of water intake and the composition of the bottom filter

Pressure is an indicator of the height of water rise, measured in atmospheres, bars and meters. This indicator of drainage pumps is usually small, since water is pumped out from a shallow depth. Do not forget about the ratio of vertical and horizontal pressure, which is 1:10.

For example, if you pump water from a well 8 m deep and move it 10 m along a hose lying on the ground to carry it beyond the boundaries of your property, then the pressure at the pump should be at least 9 meters.

It is also necessary to remember that pumps, depending on the lift height, will operate at different levels of performance. Graphs of the dependence of both of these quantities can be found in the instructions supplied with the device.

Search for the optimal unit: choose, compare, look for the best

The above units differ in both price and performance. As a result, it will be very difficult to choose any specific model without preliminary analysis. Therefore, below in the text we will analyze pump characteristics such as lifting depth, performance and price in order to choose the optimal unit option.

Submersible pump for dirty water AL-KO Drain 11001

According to the first criterion - lifting depth - the leader is the AL-KO Drain 11001 model, which retrieves water from 9.5 meters. But she is an outsider of the third criterion - the price of the unit. Therefore, we should take a closer look at the domestic model Whirlwind DN-400, which pumps water from an 8-meter depth.

According to the second criterion - performance - the leader is the most expensive pump Drain 11001 from AL-KO and the cheaper option - DN-400 from Vikhr. Other models are 1.5-2 times inferior to these units, but at shallow depths the “Italian” Ergus Drenaggio 400F demonstrates the greatest performance.

According to the third criterion - price - the advantage is on the side of the domestic manufacturer, which has produced both the low-power unit Gilex Drainage 110/6 and the fairly productive DN-400 from the Vikhr brand.

And if you take a closer look at these data, you can draw the following conclusions:

If you have a large budget and a deep well, it is better to buy a pump from AL-KO, since the “Vikhr” pumps only slightly dirty water (the caliber of Drain 11001 is 30 millimeters, and that of DN-400 is 5 millimeters).

- With a small budget, the owner of a deep well will have to do the opposite and buy a DN-400 pump from the Vikhr brand, resigning himself to the possibility of sucking only small-caliber particles.

- Owners of shallow wells are better off purchasing an “Italian” from Ergus Drenaggio: after all, 400F pumps better, allows larger particles to pass through, and is not much more expensive than the Gilex product.

- If you are on a very tight budget, you will still have to buy a pump Drainazhnik 110/6 from the Russian-Chinese manufacturer Gilex. Yes, it comes out on top only in the “price” category, but it is a quite decent drainage unit, which lost “prizing places” to very “strong” competitors, with clearly greater performance or clearly better “pedigree.”

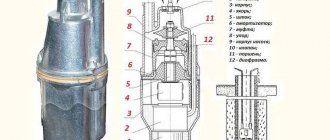

Types of submersible pumps

To pump out water, owners of suburban land plots use submersible pumps, which can be vibrating or centrifugal. Models differ in the way they absorb water, so the quality of the latter plays an important role when choosing pumping equipment.

The fact that the water in the well has been pumped out is indicated by a float, thanks to which the equipment does not run dry.

Submersible pumps with centrifugal mechanism

Models that use a wheel with blades as a suction device are called centrifugal. This design feature increases the pump’s performance and also prevents abrasive particles found in the pumped well water from entering it.

Depending on the model, water chambers and centrifugal wheels can be manufactured:

- of steel;

- made from high quality polymer.

Also, a distinctive feature of submersible drainers is the presence in their design of a float or electronic switch. Devices with a float switch are more widespread because they are simpler, cheaper, and most importantly, more reliable. The switch is needed to automate the process of pumping water.

Some models of drainage pumps use a centrifugal mechanism. Before purchasing them, you should find out whether the pump can pump abrasive particles

A float is a small sealed container with a contact block inside. As the water level decreases, the float mechanism gradually lowers until it reaches acceptable limits. At the maximum depth, it turns off the engine, preventing it from running dry. Dry operation leads to failure of the pumping device.

The drainage pump housing should always be immersed in liquid, as water helps cool the operating mechanism. Water also acts as a lubricant for rotating parts.

Installing a drainage pump: step-by-step instructions

Before starting work to install the pump, determine or arrange a level area so that it operates in a strictly vertical position, then:

- A hose is connected to the pressure pipe using connecting elements for fastening.

- If the model has a float switch, install a check valve on the pressure line.

- A device equipped with a three-phase electric motor must be checked for correct rotation of the centrifugal wheel.

- Turn on the equipment and immediately turn it off, paying attention to the direction of rotation of the pump shaft: clockwise - everything is connected correctly, if not, swap the phases.

- The pump is connected using a carabiner to the electric winch cable or to a rope, making sure that the pressure pipe remains directed upward.

- The unit is slowly lowered to the bottom of the silted well.

- When operating pumping equipment, comply with safety requirements.

If there are signs of equipment malfunction, you must immediately turn off the power supply and stop pumping.

Vibrating Submersible Pumps

Vibration-type pumping equipment operates by changing the internal pressure, causing oscillations of the diaphragm. The difference in pressure appears as a result of the magnetic field generated when an electric current passes through the coil.

Parts set in alternating motion under the influence of a magnetic field raise the water flow upward. Vibration pumps are powered by a 220V power supply and consume approximately 270 W per hour (the figure depends on the power of the model).

Vibration pumps with upper and lower water intake are installed at different heights from the well bottom

Submersible vibration pumps can be produced with upper or lower water intake from the well:

- Devices with upper water intake operate without overloads, since they do not heat up during operation due to the cooling of the entire system. Also, such pumps do not suck in silt that has settled at the bottom of the well and do not contribute to cloudiness of the water during intake. Therefore, it is not advisable to use them to clean a well.

- Devices with bottom water suction, not equipped with automation and a thermal protection system, since the devices can overheat even during short-term dry operation. To protect mechanisms from sand and silt suction, a mechanical filter is used. Craftsmen replace the filter with an ordinary iron bucket in which the pump is placed. Lower the bucket with the apparatus into a low-flow well and pump water.

Vibration pumps are durable in operation, since their design does not contain rotating elements or bearings, and therefore the parts do not fail without being subject to friction.

When cleaning wells, vibration-type pumping equipment can only be used to pump out turbid water, and sand and silt deposits can be scooped out manually using buckets, homemade scoops, buckets, grabs and other devices.

Image gallery

Photo from

Low Cost Vibration Pump

Vibration pump care

System of two vibration pumps

Immersion of the pump in a bucket

Selecting a hose for pumping water

Hoses or tubes for pumps must be selected depending on the pressure force, as well as the cross-sectional diameter of the outlet pipe. The main requirement is that the diameter of the hose must match the diameter of the outlet pipe.

Compliance with this requirement will greatly extend the service life of the purchased pump and will have a beneficial effect on its performance.

A fire hose can be used as a flexible hose, which is attached to the outlet pipe using a clamp. At the edge of the well ring, the sleeve is pinched and the pump cannot push through the pumped out water. This problem can be eliminated using a plastic corner, to which fire hoses are connected on both sides.

After pumping dirty water from the well with a pump, the bottom sludge must be collected with a bucket and brought to the surface

Features of connecting submersible pumps

Before lowering the pump into the well, a number of preparatory measures are carried out, namely:

- determine the depth of the apparatus in the source;

- secure the hose to the pipe using a plastic clamp;

- thread a nylon cord or a small-diameter steel cable into special eyes located on the pump body;

- a special rubber ring is pulled onto the body, which will protect the vibration pump from mechanical damage if it touches the concrete walls of the well shaft;

- Elastic rubber 0.5 meters long is tied to the upper end of the cord so that it dampens vibrations.

The pump with the lower water intake is placed at a distance of 1.0 m from the bottom of the well, and with the upper one slightly lower - 0.5 m. The cable to which the pump is attached is secured to the crossbar installed on the upper well ring. After completing the installation of the equipment, connect the pump to electricity.

If the cord is not long enough, it is extended with an additional cable, and the connection must be located outside the well shaft. While pumping out water, monitor its pressure, preventing the motor from running dry. After two hours of continuous operation, turn off the pump for 15 minutes to avoid overheating of the electric motor.

Image gallery

Photo from

Borehole pumps in well cleaning

Unsuitable medium for pumping

Submersible pump after cleaning the well

Pumping out disinfected water

Why do they order sewage disposal equipment from us?

Own fleet of imported vehicles

Prompt and high-quality provision of services

Guarantee of cleanliness of the area after completion of work

All equipment is equipped with long hoses (50 m)

We work around the clock without breaks or weekends

Favorable terms of cooperation for regular customers

Experts recommend performing routine well maintenance at least once a year. The service includes:

- removal of silt deposits;

- sealing cracks;

- washing the walls;

- replacing pebbles at the bottom;

- disinfection.

Cleaning a heavily silted well

If the well is heavily silted, the efficiency of using the drainage pump is sharply reduced. The equipment quickly becomes clogged with sand, and therefore cannot cope with the tasks assigned to it.

In this case, some summer residents advise using another surface pump, which under pressure discharges sand-free water back into the well shaft, thereby facilitating the erosion of bottom sediments.

The method is as follows:

- a barrel or other container is installed near the well, the volume of which is 200-300 liters;

- a drainage pump is lowered into the well shaft, which pumps muddy water from the well into a prepared container;

- the clean water that has settled in the barrel is directed by the second pump back to the well, and the sand from the bottom of the tank is removed;

- a stream of water released under pressure erodes the bottom sand, which, together with the water, is lifted up into the barrel by a drainage pump, and everything is repeated all over again.

This method of cleaning a well has opponents who consider it economically unfeasible. In their opinion, it is more profitable to hire a team of workers who can go down and scoop out the silt with buckets, raising it to the surface. If this is not possible, why not try the option with two pumps.

Vibration pumps are used for pumping dirty water without solids

With the help of pumping equipment, a silted well can be easily and quickly cleaned. After pumping out the muddy water, the well is filled with crystal clear life-giving moisture and begins to delight its owners with delicious, cold water.

After cleaning, the pump can always be used for other tasks. Inexpensive vibration models are used in cleaning wells after drilling. During floods and rising groundwater, flooded basements are quickly cleared of gushing water.

An inexpensive vibration pump, such as the “Springer”, can be used to pump out a pond, clearing its bottom of silt accumulations. A prudent owner will always find a way to increase the efficiency of the purchased equipment.

When pumping water from a well is not recommended

Different situations need to be taken into account. As practice shows, they often encounter two problems:

- The well, which was dug recently, did not have time to cover it with a roof or a canopy or decorate the head. The recent downpour filled the structure with water, mixing it with mud. In this case, you should not pump out, because the fragile walls of the structure, saturated with water, will begin to collapse (partially or completely). It is recommended to wait until the walls of the well shrink completely.

- It is impossible to pump out water during active snow melting. The liquefied soil presses on the bottom from below, raising the water level. The latter, in turn, puts pressure on the ground, preventing it from rising. If the liquid is pumped out at this time, the bottom will quickly rise, increasing its level inside the well. On the one hand, this is not bad, but in this way you can lose access to the aquifer. You will have to deepen the bottom, selecting the risen layer. And these are additional, quite serious financial expenses.

It is necessary to determine the exact time for pumping and cleaning. It is better to do this in the summer, when the water level inside the well is lowest. There is not much liquid in the structure, it can be pumped out easily and quickly. The process will take a little time.

Rules for operating the pump when cleaning a well

When choosing the necessary model for cleaning a well, carefully read the instructions. After all, some drainage pumps are initially designed to lift and pump only clean water that does not contain impurities. The manufacturer warns about this in the description of the technical characteristics of the equipment.

If such devices begin to pump out contaminated water, they will quickly fail. Remember that cleaning a silted well must be done with a drainage pump that can handle the intake of contaminated liquid that contains impurities and even small fibers.

If persistent deposits appear on the walls and bottom of the well shaft, before using the pump, you need to clean the well manually in order to quickly get rid of contaminants and prevent clogging of the working parts of the pump.

Selecting a hose for pumping water

The dimensions of the outlet pipe are important, but not the only criterion that influences the choice. Strength is taken into account, expressed in the amount of internal pressure that the walls can withstand. Compliance with these parameters ensures long service life and operating efficiency of pump cleaning equipment.

If you use a fire hose, you need to make sure that there are clamps to securely attach the hose to the nozzle. During the work, you need to make sure that the hose thrown over the wall of the well is not pinched. This can lead to overloading of the equipment, even leading to pump failure.

Review of popular models

Models from Russian and foreign manufacturers are represented on the pumping equipment market. Every brand has its fans.

Budget pumps from Russian companies Vikhr and Malysh attract with their affordable prices and good performance. German pumps of the brands Wilo Drain, Grundfos, Karcher, like Japanese Makita, do not need advertising.

These devices have high performance and reliability throughout their entire service life. When purchasing pumping equipment, be sure to check the availability of all components specified in the attached instructions.

Pay attention to the restrictions on use specified by the manufacturer. Remember that the technical characteristics of different pump models may differ significantly, which also affects the way they are used.

How to upgrade a structure on quicksand

Quicksand is a mobile sandy soil supersaturated with liquid. It creates many problems when constructing and operating a well, including displacement of the lower rings. It is impossible to carry out rocking according to the standard scheme - the water may completely disappear and the bottom will be covered with sand. Pumping is carried out carefully, no more than 20% of the volume.

If you don’t have experience in this kind of work, then it’s better to invite a specialist to clean the well on quicksand.

One solution to the problem is to install a bottom panel made of aspen, juniper or bog oak. It is fixed on holders and covered with washed stones - pebbles, gravel, shungite, jadeite. Large stones are placed first, followed by a layer of medium or fine stones. Then you can start pumping.

What immersion depth should I take the device?

Please note that each model has an immersion depth indicator. This is not the same as pressure, which shows the height of the water rising and, to a greater extent, the pressure that will be in the pipes. Immersion depth is the maximum depth to which the unit can be lowered into the well. To understand what parameter the model should have, it is important to know the distance from the well mirror (water level) to its bottom.

Calculating the depth of a well is not difficult. It is enough to tie a weight to a rope and gently lower it into the water. When the weight sinks to the bottom, the rope will lose tension, and you will realize that you have reached the bottom. Now simply count the “wet” length of the rope, that is, the distance from the weight to the end of the wet part of the rope. This will be the maximum depth to which you can immerse the device. Now you just select the appropriate device in the store.