For many owners of private houses, cottages and summer cottages, the issue of water supply is very acute. In some places it is possible to use a central water supply, but in others it is not, so the problem is solved by drilling a well and installing pumping equipment that will pump water into the house’s pipeline system. Some build wells on their property simply to avoid paying large sums of money for what is already under their feet. Today we will tell you what is good or bad about a surface pump for a well, compare it with a submersible one and consider different solutions.

Surface pump for well

TOP 6 best surface water pumps

| Photo | Name | Rating | Price | |

| #1 | UNIPUMP MH 500C | ⭐ 5 / 5 4 - votes | Find out the price | |

| #2 | UNIPUMP QB 60 | ⭐ 4.95 / 5 2 - votes | Find out the price | |

| #3 | GRUNDFOS MQ 3-35 | ⭐ 4.9 / 5 4 - votes | Find out the price | |

| #4 | KRATON PWP-370 | ⭐ 4.85 / 5 1 - voice | Find out the price | |

| #5 | GILEX JUMBO 60/35 N-K | ⭐ 4.8 / 5 | Find out the price | |

| #6 | SPERONI KPM 50 | ⭐ 4.75 / 5 1 - voice | Find out the price |

Which surface water pump would you choose or recommend?

Take the survey

Review of popular models

Before choosing a suitable device, you should familiarize yourself with the most popular pumps for wells:

- WILO SUB TWU 4 such a device is designed for the most practical homeowners. If we consider the technical characteristics of this device, we can come to the conclusion that its high cost is absolutely justified. This brand produces many high-quality devices. WILO brand pumps can perform almost any functional task assigned to them;

- Grundfos SQ are distinguished by their high cost and reliability. Such devices are endowed with the highest technical characteristics, but their cost is still a little overpriced. A significant argument for the manufacturer in the matter of pricing can be the additional options integrated into this well pump;

- Divertron (DAB) with integrated flow and pressure sensors, can operate in automatic mode. High-quality durable materials are used for the manufacture of devices, so the duration of their operational period remains quite high;

- "Belamos". Such devices are great for arranging garden plots. All its structural elements are made of stainless steel. The pump can draw water from a depth of up to 30 meters. Depending on the specific model, the power rating of the device can vary from 3 to 7.5 kW.

Surface pumps - what are they?

There are two types of pumps – submersible and surface pumps. You can guess their differences from the name, but to better understand the difference between these devices, you need to know their important characteristics. We will not understand the design, but will only discuss the most important differences.

Pumping station – pump and hydraulic accumulator

A surface pump is a device that belongs to the category of self-priming equipment. The maximum height to which it is capable of lifting water from the bottom of the well is 10.3 meters - this is a calculated value derived as the maximum possible at normal atmospheric pressure. In fact, this value is at an even lower level - about 8 meters, since the operation of the equipment is influenced by various factors that cause power losses.

Pump and external ejector

8 meters is, of course, not enough to extract high-quality water suitable for drinking, so this equipment is supplemented with remote ejectors - devices that help increase the lifting depth to 40 meters.

Ejector

The average productivity of a surface pump is not at a very high level - from 1 to 4 cubic meters per hour , but this is absolutely enough to meet all the household needs of even a large family.

A surface pump sucks water from a well through a pipe

The operating pressure that the equipment creates also varies greatly from model to model. Simple devices have a reading of about 2 Bar, while more powerful ones can reach up to 5, which is equal to 20 and 50 meters of water column, respectively.

Submersible pumps are lowered directly to the bottom of the well and controlled by a remote unit. They do not draw in water, but push it into the pipeline system, which makes it possible to use such equipment even in very deep wells. 200 meters is not the limit for them, but this applies to industrial equipment. For domestic use, you simply select a model of the required power for the depth of your well.

Submersible pump

Such equipment can provide very high water consumption - an average productivity of about 10-15 cubic meters.

What types of submersible pumps for wells are there, their technical characteristics, prices and, of course, the main criteria for choosing such equipment. We will try to fully answer these important questions in a special article.

Comparison of surface and submersible pump

Which option should you give preference to on your site if the well depth is suitable for both types? Let's try to understand this issue. We need to know the following.

- In terms of reliability, it is impossible to talk about any difference, since both can be of high quality or downright bad. The most important thing here is to look at the manufacturer, equipment components, service, and so on.

- The main weak point of the two types of pumps is the electric motor, which can suffer due to overheating, bearing wear, short circuits and other things. Interesting to know! The liquid in which it is immersed is responsible for cooling the submersible pump. The surface one is cooled by an impeller mounted on a shaft and driven by the same motor.

- It is much more important to find out the consumed and output power of the equipment, and correlate them with the maximum possible water consumption in your home. For example, in the summer you will want to constantly water the garden.

- Here submersible equipment comes forward, since it spends less effort to lift water than surface equipment, and the greater the depth, the greater the difference. For a well 15 m deep, the difference in consumption will be about 25-30%.

Compact pumping station for a small house and irrigation organization - The next important point is station maintenance. Here surface equipment takes the lead, since in order to get to it, you just need to open the hatch and go down inside the caisson in which everything is installed. The simpler design of the ground pump also affects this factor. It is very difficult to disassemble a submersible pump without knowledge of the device and the availability of specialized tools. It is also difficult to put it back together, since this device has very high requirements for the tightness of the housing - they made a mistake, suffered an instant failure of the equipment, and were left without water at all.

- In terms of price, of course, it is more profitable to take surface stations, but if you have a constantly high water consumption, then the difference in the initial cost is leveled out over time due to savings on electricity.

In general, you will decide for yourself what to buy, and we continue to introduce you to surface equipment.

Types of surface pumps

We have already mentioned in passing that the surface pump is a self-priming equipment. This means that it can independently remove air from the pipes, which is not possible for submersible and circulation pumps, which together are called normal suction pumps.

Pumping station and various types of plumbing connections

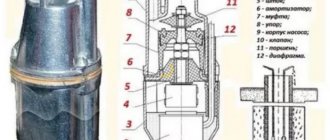

A standard surface station includes not only a pump, but also other elements:

- A hydraulic accumulator or membrane tank in which a certain volume of water is stored to maintain normal pressure in the pipeline.

- Suction pipe.

- Outlet pipe.

- Shut-off valves for control and measurements.

- Filter system.

Supplying water to the house with a surface pump

All surface pumps are vane pumps, but the liquid can move in different ways in the working chamber. According to this parameter, pumps are divided into vortex and centrifugal. What is the fundamental difference?

Centrifugal pump

A centrifugal pump has a constantly rotating impeller consisting of two disks installed in parallel. There are blades between them. The parts rotate in different directions.

Centrifugal pump Pedrollo

Several such wheels can be installed in the system, which determines the power of the device and its purpose. In appliances used in everyday life, the wheels and motor have a common shaft and are located in the same housing. In industrial equipment, a separate layout is more often used, but all parts are always installed on the same frame. The engine is connected to the working shaft through a belt or transmission drive.

In principle, this is all that the user needs to know about such pumps, since the rest of their capabilities relate to industrial equipment.

Vortex pump

In a vortex pump, despite the presence of blades, water moves in a different direction and according to a different principle. The working chamber has a ring shape; the discharge and pressure pipes are connected to the channel, separated by a seal. As water passes through, it twists into a double screw, like a chain of DNA. Due to the centrifugal force from the action of the screw, it enters the outlet pipe, in which the acceleration force of the water is converted into a pressure force.

Vortex pump called “Vortex”

In a centrifugal pump, water moves along the shaft, and after passing the wheel, it can immediately change directions to axial, radial or perpendicular, which depends on the design of the unit.

Vortex pumps are capable of creating very high pressure, but they are characterized by large energy losses, and as a result, the efficiency drops significantly compared to centrifugal pumps. Therefore, they are given preference only when there is no other choice, or when a really powerful pressure is needed.

The vortex pump has a compact body

Another advantage of a vortex-type station is its ability to better pump liquids with a high content of water-insoluble impurities, such as sand or clay. So, if you need water not for drinking, but, for example, for irrigation, and you do not intend to install a filter system, vortex units are what you need.

Basic parameters for choosing a pump

So, we have already written about the height to which the water needs to be raised. What else should you pay attention to when choosing? We need to know exactly the distance of the well from the house, and the volume of pumped liquid, which will depend on the total volume of the water supply network and the maximum possible water consumption at any given time. A trivial example: we open the tap closest to the point of entry into the building - we get good pressure, open the second one - the pressure drops, and at a remote point the water flow will be the smallest.

Pump inside a wooden frame structure

The calculations here are, in principle, not complicated; you can do them yourself by using an online calculator, or simply by studying the instructions from the manufacturer.

Advice! Household appliances that work with water need to constantly maintain the pressure in the pipeline at a level of at least 0.3 Bar. Consider this point also when choosing a pumping station.

What does the pressure in the system depend on? It depends on the power of the pump and the volume of the hydraulic accumulator - the larger it is, the more stable the average pressure in the water supply. The fact is that when turned on, the pump does not work constantly, since it requires cooling, and when the operating pressure is reached, it should not continue to increase it. The system is designed in such a way that it pumps water into a hydraulic accumulator, in which a check valve is installed, which prevents water from flowing back when the pump is turned off. When the pressure in the tank reaches the set threshold, the pump stops. If water withdrawal continues, it will gradually drop, reaching a minimum level, which is a signal to turn on the pump again.

Diaphragm tank - the stability of the pressure in the tap depends on it

That is, the smaller the accumulator, the more often the pump is forced to turn on and off, the more often the pressure will rise and fall. This leads to accelerated wear of the engine starting equipment - in this mode the pumps do not last long. Therefore, if you plan to use water from a well constantly, buy a tank with a larger capacity for the pumping station.

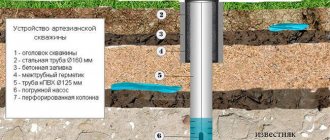

Water supply to the house from a well

When constructing a well, a casing pipe is installed into it, through which water rises. This pipe can be of different diameters, that is, it may have different throughput. Based on the cross-section of the casing pipe, you can also choose the right equipment for your home.

Interesting to know! The most popular casing pipe size today is 100 mm.

All the necessary information will be in the instructions for the purchased pump. You can also get recommendations from the specialists who are drilling your well. They will know exactly the optimal operating parameters. It will also not be superfluous to make some reserve in the power of the unit so that the pressure in the system rises faster to a comfortable threshold, otherwise water will constantly flow sluggishly from the tap.

Calculation of required functional characteristics

It must be understood that in the process of selecting a suitable pumping installation, many control parameters must be taken into account. The external characteristics of a device may not always matter, but this data should not be neglected either. First of all, you need to determine the appropriate pressure. For this purpose, it is necessary to summarize the sufficient height of rising liquid, as well as the distance from the well to the living space.

To be on the safe side, another 20 meters are added to the resulting coefficient. As a result, you can get a number corresponding to the required pressure indicator pumped by the well pump. You should not worry if you end up with a number of about 50-70 m. This figure is considered the minimum for a conventional borehole centrifugal pump.

The performance of the device must be taken into account. This indicator depends on the number of people living in the house, as well as the planned water consumption. For a family of 3 people and a small garden, it is enough to install a submersible pump that takes about 3 cubic meters of water per hour. This figure will have to be increased if more water needs to be extracted. Pressure and performance level are the main functional characteristics that must be taken into account when selecting centrifugal well units. Other indicators are determined on a residual basis.

Device operation and maintenance

Before purchasing, you need to familiarize yourself with the basic rules for using and maintaining the equipment:

- The unit should not be allowed to stand idle. If the pump is immersed in a working environment, it must function continuously;

- Monitoring the condition of the unit;

- Always follow the rules outlined in the installation instructions. The permissible lowering depth and operating rules for additional equipment must be observed.

It should also be taken into account that installation of such equipment is carried out independently only if you have the appropriate skills. Otherwise, it is better to trust the installation of equipment to sufficiently qualified specialists so that subsequent operation of the pump does not involve many problems.

You may also like

Diagram and design of a cantilever centrifugal pump

What are the types of water centrifugal pumps?

How to make an order

Our catalog contains a fairly rich assortment, which allows you to select equipment taking into account the upcoming operating conditions. We have a considerable amount of goods in stock, so customers do not need to wait a long time for the delivery of the necessary products from another city.

Among our advantages is prompt delivery of ordered goods to the client’s address. We set prices for the products presented in our catalog lower than those of our competitors. Buyers can independently find the desired types of goods in the catalog and submit a delivery request. If you have difficulty making a choice, you can ask our consultants for help. There are different forms of payment for ordered goods, from which customers can choose the most convenient one.

Scope of application

Due to their specificity, diaphragm pumps are used in the following industries:

- Food – due to the high tightness of the pump itself, high purity of the pumped product is achieved, the ability of such pumps to pump thick substances also plays a role, this is especially widely used in the confectionery industry;

- Pharmaceuticals, the same reason as the food industry. In this type of production, increased purity of the pumped compounds is often required; a diaphragm pump copes with this task;

- Chemical industry, for pumping aggressive liquids, it is clear that in this case special requirements are placed on the material of the pump body and membrane;

- Ceramic, mining and mineral processing industries use diaphragm pumps due to their ability to pump abrasive substances.

Diaphragm pumps are also used in other areas of industry that require the movement of thick, aggressive and abrasive liquids and compounds.

Additional items

In order for the pump, which pumps water from wells of various depths, to function normally for a long time, it must be equipped with additional technical devices. In particular, if the water pumped out using such a pump contains a large amount of sand and other foreign matter, it is not recommended to avoid using filters. The use of filters allows you to protect the internal parts of pumping equipment from mechanical damage and premature wear.

In addition to coarse filters, an external or surface pump requires other elements of additional equipment, which, in particular, include:

- a flexible hose or metal pipe through which the pumped liquid medium will rise to the surface;

- electrical machines with which pumping equipment will be connected to the power supply network;

- a check valve that will prevent the pumped liquid from returning back into the well, which will protect the pump from such a negative phenomenon as idling.

Complete wiring diagram for connecting a surface pump

List of equipment and components

In addition, surface pumps for wells are equipped with float-type switches, with the help of which the operation of such equipment can be made automatic. The use of float switches allows the submersible pump to turn on without your participation at the moment when the water level in the well reaches the maximum permissible value, and turn off independently when the water in the underground source becomes too low.

Due to the peculiarities of its design, surface-type pumping equipment should be operated in a place well protected from high humidity. In particular, a specially prepared site or pit located in the immediate vicinity of the well shaft can be used as such a place.

Advantages of devices: which one to choose?

| Kinds | Advantages |

| Submersible |

|

| Superficial |

|

Customer Reviews

Well pump BELAMOS TF3-40 (550 W) is almost silent. Compared to vibration, it is much quieter. Has a relatively small size. Great design. Good steel. It really doesn't rust. Sometimes clay gets in. But the pressure holds.

The borehole pump GILEKS Vodomet PROF 55/50 (600 W) is easily installed on wells and shallow boreholes. The body is made of high-quality stainless steel, inside there are impellers made of high-strength plastic. Low vibration level, quiet operation. The weight allows the use of a plastic head for wells.

A borehole pump VORTEX CH-50 (750 W) was installed on a summer cottage for a well. There are special rings for attaching the cable, for lowering and lifting. There is a thermostat for overheating. We got clogged with sand a couple of times, the safety device worked, we cleaned it and it works again.

Installation of equipment

Installation of a pump in a well should only be carried out by qualified craftsmen. You need to contact a qualified company that offers turnkey services. Here you will not only equip the well, but will also be advised on the optimal characteristics for the pump. The fact is that the construction of a well itself is a technologically complex process in which special equipment is used. First of all, it is necessary not only to allocate a place for the future water supply system, but also to select the area where this will be done most correctly.