One of the conditions for the proper operation of an autonomous sewer system is pumping out the septic tank. For this purpose, owners of private plots periodically use the services of vacuum cleaners who, using a special machine, remove liquid household waste. If it is not possible to provide convenient access for the vehicle to the treatment plant, an additional pipe is installed for pumping out from the septic tank, which allows dirty water to be collected from a considerable distance.

How often should a septic tank be pumped out?

The use of a septic tank is considered the optimal solution when arranging an autonomous sewage system for a country house. Such a treatment facility can easily cope with the collection and processing of liquid waste. At the same time, insoluble compounds gradually accumulate in the sedimentation tank, which have to be removed from time to time.

Independent removal of liquid waste is used quite rarely, given the complexity and danger of this activity, as well as the need to dispose of pumped out wastewater. Therefore, in this situation, it is more advisable to use the services of professional vacuum cleaners. On average, a car is called 1-2 times a year. In this case, the frequency of pumping depends on factors such as:

- volume and model of septic tank;

- number of permanent residents;

- intensity of sewerage operation;

- composition of household waste.

The septic tank must be pumped out in a timely manner, preventing the tank from overflowing.

Device for cleaning waste from barrels

The system for treating wastewater from barrels, like a similar structure made of reinforced concrete, can be two- or three-chamber. Sewage will flow into it by gravity, so it must be installed below the sewer pipes. The operating principle of this device is similar to the design of reinforced concrete rings.

Barrel selection

To set up an autonomous sewerage system based on the principle of a treatment system, you can use any containers. These could be old metal/plastic barrels. The main thing is that they are airtight.

If you decide to make a septic tank from metal barrels, then they should be pre-treated with an anti-corrosion agent.

Pipe supply

Plastic containers have a number of advantages over their metal counterparts:

- A wide range of plastic containers that can be used to equip a septic tank.

- The barrels are highly resistant to the aggressive effects of wastewater. Therefore, they last longer than their metal counterparts.

- The light weight of the containers simplifies their installation at a permanent location.

- Plastic does not require additional processing, unlike metal.

- The high tightness of the barrels eliminates the possibility of dirty water penetrating into the ground.

Plastic barrels must be securely fastened when installed in the ground, because due to spring floods or winter frosts they can be squeezed out of the ground. In view of this, plastic barrels are secured with cables to a concrete base (it must first be poured or a reinforced concrete slab must be installed). To avoid crushing plastic barrels, backfilling of soil should be done extremely carefully.

For seasonal use, sewerage from metal barrels is also suitable, but for stationary use this is not an option.

Metal barrels

The popularity of metal containers for sewerage installations is associated with their compactness and ease of installation. As a lid, you can use an appropriately sized piece of wood or one provided by the manufacturer. To install a metal septic tank, you need to dig a corresponding pit, which also needs to be concreted - the walls and bottom.

Metal containers do not have a long service life even after they are treated with anti-corrosion compounds. Therefore, installing them as a septic tank may be unprofitable. Buying stainless steel containers is not an option, as these products are very expensive.

Maybe you decide that in this case you can buy barrels with thin walls. However, this is also not the best solution, since during operation such a septic tank can be pushed out. And such barrels have a limited capacity - up to 250 liters, which is not suitable for a large family.

To install a reliable wastewater treatment system, it is better to use factory-made polymer barrels.

Materials and tools

To make a septic tank from 220 liter barrels, you will need the following materials:

- geotextiles – 80 m2;

- sewer pipe Ø110 m, length 5 m;

- crushed stone fraction 1.8–3.5 cm, approximately 9 m3;

- corner for sewerage at an angle of 45 and 90º – 4 pcs.;

- plastic barrel with a volume of 220 l – 2 pcs.;

- coupling, flange – 2 pcs.;

- wooden peg – 10 pcs.;

- Y-shaped sewer tee – 4 pcs.;

- building level;

- drainage perforated pipe in the filter 5 m – 2 pcs.;

- epoxy two-component sealant – 1 pc.;

- glue for PVC – 1 pc.;

- plumbing tape – 1 pc.

Tools you will need:

- Shovel.

- Electric jigsaw.

- Rake.

Features of installation of plastic containers

For a dacha/small country house, if used sparingly, standard plastic barrels are suitable. Installing such a cleaning system is not difficult. If you do not pour black waste into the sewer, the septic tank will be unpretentious in maintenance. If there is a toilet in the house, then the sewer will have to be cleaned regularly by calling a sewer service.

For private homes with permanent residence, barrels will not be enough. For sewerage, it is better to purchase plastic cubes/tanks/tanks. The process of installing them in the ground is no different from installing barrels.

Plastic barrel

The distance of the septic tank from the house should not exceed 15 m. Too much distance will complicate the process of connecting the sewerage system to the house:

- there is a need for a large depth of the pipeline;

- On the way to the septic tank you will need to install an inspection well.

Features of installing metal barrels

A sewerage system made from metal barrels does not require large financial investments or complex installation work. To begin with, as in previous cases, you need to prepare a pit, and then install 2 barrels, each of which has a volume of at least 200 liters. Then pipes are installed to transfer liquid from one barrel to another and transfer to the filtration fields/drainage well.

Each subsequent container must be located below the previous one in level.

The joints must be sealed, and the barrels must be insulated using polystyrene foam. After this, the pit and septic tank are filled up. Since, as mentioned above, metal barrels do not last long, you need to be prepared for the fact that after 3-4 years they will need to be replaced.

After watching the video and completing all the work correctly, all that remains is to check the system and enjoy the benefits of civilization.

We recommend that you read:

- Do-it-yourself septic tank from a Eurocube (diagram).

- How to defrost a sewer pipe using chemicals.

Operating principle of a sewage disposal machine ↑

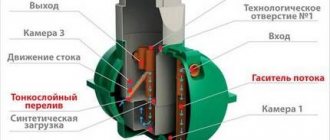

The main elements of any sewage disposal machine are: a reservoir (tank) for transporting liquid, a vacuum pump, a pipe for pumping water from septic tanks, sewer wells, drainage systems of car washes, natural reservoirs, etc. The operating principle of such equipment is as follows:

- One end of the pipe is connected to the machine, and the other is lowered directly into a container of liquid.

- Using a vacuum pump, water mixed with sludge is pumped into the tank. The process continues until the septic tank is completely empty or until the tank is full.

- Disposal of reinforced waste products is carried out in strictly designated areas, taking into account environmental standards.

Theoretically, the transport tank and pumping equipment can be installed on any vehicle chassis that meets the technical requirements. In Russia, as a rule, GAZ, KamAZ or ZIL are used for such purposes.

Machine for collecting and recycling wastewater based on GAZ 3309

The maximum distance within which water can be drawn depends on the length of the pipe (hose). The standard length, regulated by the manufacturer, usually varies between 6-15 m. By individual order, this parameter can be increased to 25 m. Some sewer trucks use additional hoses, which allow increasing the length by another 5-10 m. However, even this is sometimes not possible enough to clean a septic tank located at a great distance from the roadway. In this case, additional measures will be required from the owners of the site.

Methods for pumping out sewerage

The most popular environmental service, in the form of pumping out a drainage pit, uses three main methods:

- Contacting a special service (calling a sewer truck to your home).

- Independent use of fecal pumps.

- Manual pumping.

When ordering a car, you need to take into account that the owner of the house will incur material costs, but the positive aspects here will be: urgency of the call, speed of execution, guarantees, high-quality work of specialists and personal time savings (you won’t have to bother with it yourself).

The first method not only pumps out sewage, but also flushes the sewer pipes and well, and cleans the bottom of the pit from silty inclusions.

IMPORTANT! The sewer well must have convenient access. This must be taken into account when installing external sewerage.

The second way to remove sewage is to use a sewage pump with a grinder. Such special pumps have advantages over conventional water pumps. Water pumps do not have a filter, so if they are used to clean drains, they will quickly become clogged and break.

Sewage pumps are selected according to the type of engine cooling, the diameter of the outlet, the ability to achieve maximum pressure, the location of the pipes and the ability to carry out repairs without dismantling. Such products make it easier to pump out wastewater of any degree of contamination, are easy to use and have guaranteed durability.

The third option is the manual method of cleaning waste containers, which must be performed by 2 people. The disadvantages of this method include the heaviness and dirt of the work, which involves scooping sewage outwards using a shovel, rope and bucket. The wastewater will then need to be disposed of and carried off-site. Sewage waste is collected in a special container.

In addition to the above pumping methods, 3 types of pumping are used:

- hydrodynamic;

- vacuum;

- emergency.

Hydrodynamic pumping using special equipment involves removing all blockages and deposits using a hose through which water is supplied to the sewer pipes under high pressure. The pumped out wastewater is transported outside the territory for subsequent discharge.

Emergency pumping is used in case of unexpected accidents. It is also carried out using special equipment (vacuum trucks). Any powerful fecal pumps or hoses can help here.

Vacuum cleaning is carried out using a high-power vacuum pump. This cleaning removes all silt deposits well. This special equipment can always be rented when planning independent pumping of pits, wells and septic tanks. Waste is collected in a tank.

IMPORTANT! The advantage of calling a sewer truck is that the specialists will do a good job of flushing out the sediment at the bottom of the collector.

Installation of a pipe for pumping water from a septic tank ↑

In order not to depend on the length of the sewage hose, a pipeline is laid from the treatment plant to allow the removal of wastewater. In this case, the pipe for pumping out of the septic tank must correspond to a certain type and technical parameters.

Why you can’t use pipes for internal sewage ↑

During the process of pumping out liquid, a negative pressure or, in other words, a vacuum is created inside the pipe. At high vacuum, the pipeline tends to compress, and in this situation, the reliability of the system will depend on the strength of the material used and its suitability for working in such conditions.

Conventional gray sewer pipes, which are used for indoor installation, have a wall thickness of 2.2 mm, which is insufficient to work under pressure or vacuum conditions. Therefore, such a pipeline is used exclusively for non-pressure systems.

So, what kind of pipe is needed for pumping out a septic tank? For such purposes, you should use special pressure pipes with increased wall thickness or an orange PVC pipeline, which is intended for outdoor placement.

Orange pipes have a multilayer structure, which increases their strength and reduces thermal conductivity

Correct pipe diameter for pumping concrete waste ↑

The diameter of the pipeline must correspond to the size of the suction pump hose. Theoretically, the size of the pipe for pumping water from the septic tank can be smaller. However, it should be borne in mind that in this case the pump will need more effort to create the required pressure, and it will work with increased load.

Since the diameter of the suction machine hose is usually 100-104 mm, it is advisable to use a 110 mm PVC pipe. The interpipe space can be covered with a wet rag or an adapter can be used to seal the pipeline and hose.

Installation technology ↑

Pipe laying must be carried out taking into account the following rules:

- The pipeline is laid at a shallow depth from the septic tank to the roadway. The slope is towards the septic tank.

- The pipe cuts into the septic tank at a depth of about 1 m and, using an angle, turns down, resting with an oblique cut (45°) on the bottom.

- Exit to the street is realized using a 90° corner, which is located in a small pit near the intended entrance of the sewer truck.

A pit with a pipe for pumping out a septic tank is usually located near the road

Such a system will make it possible to remove concrete waste even when the septic tank is significantly removed from the roadway. In this case, the pipeline does not need to be buried below the soil freezing level. Firstly, it is filled with liquid only during the pumping process, and secondly, pipes for external sewage can easily withstand low temperatures.

This article provides general recommendations for installing pipes for removing liquid waste. If there are specific operating conditions for an autonomous sewer system, it is better to additionally consult with specialists.

Pumping out cesspools - ways to clean a cesspool

Pumping out cesspools with your own hands

The classic cesspool will remain for a long time one of the most common options used in the construction of autonomous sewer systems. Its construction is a fairly economical undertaking, but the use of a cesspool as a container implies its regular pumping.

Drainage tunnels

Drainage tunnels or blocks are a newer and more modern system, which is intended for summer cottages and recreation areas in a larger format. The thing is that this replacement of filtering fields no longer requires a separate place with mandatory requirements.

Due to the characteristics of the prefabricated system, you can even install a gazebo over the drainage tunnels, a parking area in the country, or deploy an original landscape structure, the same rock garden.

But it is immediately worth noting that along with the advantages of the system in terms of quality of work, strength and durability, one must immediately consider its cost. It seems average and acceptable, but for many it can become a serious budget cut

Therefore, when exploring the possibility of installing filtration tunnels at your dacha, immediately pay attention to the price

There are also risks if such water is not discharged correctly and is not absorbed into the ground at a certain depth. Of course, one can object to this, because there are many cases where water is diverted into ditches and rivers

Advantages of a drainage tunnel system

- We can say that this is a fairly durable system that is installed once and for many years.

- The overall design has increased strength, due to which the area on top of the system can be used beneficially.

- Truly improved performance so you don't have to worry about the number of resets.

Drainage tunnels for a country septic tank: installation recommendations

Few people have worked with drainage tunnels, since this system is not suitable for everyone in terms of costs. More often, drainage wells or even just cesspools are installed instead of a septic tank. But if you want to install just such a system on your site, we will give you some advice:

- It is highly advisable to install drainage tunnels to greater depths. This often happens in the following way: a trench is dug the size of the module, plus 40-50 cm on each side. The depth of the pit is about 2 m. 50 cm of sand is placed at the bottom, then 30 cm of crushed stone, and only then the module is installed, preferably on an already compacted surface.

- The modules are installed on the finished pad and connected both to each other and to the leads from the septic tank.

- To prevent the perforation from silting, the modules are covered with geotextiles.

- Next, the system is sprinkled with crushed stone, and ventilation outlets are installed in special holes.

- All that remains is to add the layer to the soil level. This is done with a mixture of earth and sand. Also, in many cases, to make the surface usable, a geogrid is laid, which we discussed in several articles on the site.

We would like to note the fact that this information is general and may partially change when choosing a particular system, as well as in combination with a septic tank installed at the dacha. It is very advisable to consult with specialists at the place of purchase of VOCs about the choice of drainage for a septic tank, because each treatment facility has its own characteristics.

Almost every one of us can do drainage for a septic tank with our own hands, we just have to approach the issue seriously and with all responsibility. All we can do is wish you success in your work and invite you to share your opinion about the material in the comments column.

https://dachadecor.ru

The need to pump out cesspools

The use of cesspools in autonomous sewer systems will allow you to significantly save money during the construction phase. But in the future, such a structure, unlike a septic tank, will require regular maintenance.

You might be interested in information about how long a tire drain pit will last

A cesspool is just a storage tank into which sewage flows. No cleaning takes place in such equipment; sewage is stored in a cesspool until it is emptied.

Cesspool with brick walls

There are certain sanitary rules for the construction and maintenance of cesspools on personal plots. So, pits should be located no closer than 15 meters from residential buildings. The drainage pit itself is a potential source of pollution of both the surrounding soil and the air in the area of its head. Untimely cleaning of cesspools can lead to adverse environmental consequences. In addition, an overflowing sewer pit is a source of strong unpleasant odors, which significantly reduces the comfort of living in your own home.

Which pump to choose for pumping waste out of a container?

Pumps used for pumping out drainage pits must have filters. A fecal pump is best suited for these purposes.

The device is available in a variety of models on the market. When choosing, you should pay attention to the following points:

- Material. It is best if the pump is made of stainless steel, cast iron or plastic.

- Power. Performance matters.

- Impeller. It is best to have knives that are preferred over edges.

- Control. The adjustment of the product should be located in an accessible place for convenience and ease of operation.

Any pump has a built-in round knife or a special edge with cutting elements, which is used to grind solid waste and feces. The device is connected through a hose system to a sewer truck. You can freely operate such a device up to 40* Celsius.

IMPORTANT! Powerful pumps (hydrodynamic, vacuum, emergency) are used in case of emergency. Such equipment can always be rented from a company that provides sewage cleaning services. You can pump it out yourself or call specialists for this purpose.

Where to place the toilet on the site

When designing a cesspool for a country toilet, you should carefully approach the issue of choosing a place for it in the garden. First of all, measurements are carried out in accordance with the requirements of SNiP 2.04.03-85 “Sewerage. External networks and structures" (in particular, you are interested in table No. 1; further we will provide figures based on it).

The cesspool must be located at a distance of at least 8 m from your own residential building and at least 10 m from neighboring ones. You need to retreat at least 20 m from the centralized water supply, and at least 5 m from the gas supply pipes. The distance from the fence with the neighboring plot should be at least 1 m, and from outbuildings and fruit trees - at least 5 m.

Before starting excavation work, a drawing of the site and neighboring buildings is drawn up. The location for the future pit is selected taking into account the above standards, after which the selected point from the diagram is marked on the territory.

In some cases (when the site is located next to an open reservoir), the placement of a cesspool should be coordinated with the State Sanitary and Epidemiological Supervision and environmental authorities.

Also, before digging a pit, you should find out the location of groundwater in the area. It is especially important to carry out this activity if you plan to install a container with natural filtration of waste into the soil. The lower part of such a well should not cross the groundwater level.

Properties of pipes and their purpose

The place where pipes are used directly depends on their physical properties. Polyvinyl chloride is one of the types of plastic that does not deform from high temperatures, is frost-resistant, and does not lose its properties when heated and frozen. The main purpose of PVC is to install them in water supply and drainage systems, and the place where they can be used depends on the thickness and density of the walls:

- sewerage;

- pressure system;

- gravity drain.

PVC sewerage Source nomitech.ru

Pipes are divided into these subtypes only after they have undergone certain processing. Plasticized PVC PVC-U is considered one of the best in terms of its parameters, which determine the location where such a pipe can be used. The following indicators are characteristic of PVC:

- Good strength against mechanical damage and three-layer production technology, as well as external corrugation, thanks to which it can be installed deep underground.

- Resistance to external factors.

- The highest wastewater temperature that such a pipe can withstand is +65 °C, the lowest is -10 °C.

It can also be noted that the weight of 1 m of plastic pipe is only 2 kg, and the greatest strength is 50 MPa.

Laying underground Source experttrub.ru

Cesspool options

There are two main options for sump design:

When constructing a cesspool with your own hands without pumping, it means that waste is absorbed through the open bottom into the soil. To assemble such a cesspool, concrete rings, old tires, metal barrels, bricks, monolithic concrete or concrete blocks can be used. In the case of a cesspool that needs to be pumped out periodically, ready-made plastic containers are used.

To choose the appropriate option for the site, you need to understand the features and key differences between the two systems.

Sump with natural filtration

Most often, cesspools without a bottom are assembled from reinforced concrete rings. This material is durable, not afraid of aggressive environments, and is easy to install.

This system is suitable for both seasonal and permanent residence. The rings are installed on a sand and gravel bed, which filters wastewater, passing it through itself into the soil. To improve the quality of cleaning, it is recommended to pour solutions with anaerobic microorganisms into such cesspools.

A pit with an open bottom is placed at a distance of at least 5 m from the foundation of the building and 20 m from the water supply. The depth of the pit depends on the groundwater level; the lower part must be at least 0.5 m below the groundwater level.

Sewage system made of concrete rings

If you are not satisfied with a ready-made plastic autonomous system for wastewater treatment, due to its size or cost, then you can make a septic tank from several compartments yourself. An excellent inexpensive material for realizing your plans is concrete rings. You can do all the work yourself.

Advantages and disadvantages of the system

Among the advantages of a septic tank made of reinforced concrete rings, we note the following:

- Affordable price.

- Unpretentiousness during operation.

- Possibility of performing work without the help of specialists.

The following disadvantages deserve attention:

- The presence of an unpleasant odor. It is impossible to make the structure completely airtight, and therefore the formation of an unpleasant odor near the septic tank cannot be avoided.

- The need to clean the chambers of solid waste using sewage disposal equipment.

You can reduce the frequency of the need to pump out the septic tank if you use bioactivators. They reduce the amount of solid fractions by accelerating the process of their decomposition.

If the installation of the rings is carried out incorrectly, the septic tank will not be airtight, which will increase the risk of untreated wastewater penetrating into the ground. But, with proper installation, the septic tank will be sealed, so this disadvantage of the system is rightly called conditional.

Scheme and calculations

The design of a septic tank, as a rule, includes 1–2 chambers designed for settling and purifying wastewater and a filtration field/filter well.

If there are few people living in your house and a minimum of plumbing fixtures are connected to the sewer system, then you can easily get by with a septic tank consisting of one septic tank and a filter well. And vice versa, if you have a lot of household members and many devices are connected to the sewer system, then it is better to make a septic tank from two chambers and a filtration well.

Rings for a septic tank

How to calculate the required volume for a septic tank has already been described above. According to building codes, the septic tank chamber must accommodate a three-day volume of wastewater. The volume of the reinforced concrete ring is 0.62 m3, which means that to build a septic tank for 5 people you will need a septic tank of five rings. Where did this amount come from? For 5 people you need a septic tank with a volume of 3 m3. This figure must be divided by the ring volume equal to 0.62 m3. You will get a value of 4.83. It needs to be rounded up, which means that to install a septic tank in this particular case you will need 5 rings.

Preparatory processes

The pit must be of such a size that it can accommodate septic tank chambers and a filter well. This work, of course, can be done manually, but it takes a long time and is very difficult, so it is more cost-effective to order digging a pit from a company with earth-moving equipment.

The bottom of the pit at the site where the settling chambers are installed must be concreted in order to avoid the possibility of untreated wastewater penetrating into the ground. Before starting concrete work, part of the bottom of the pit should be drained to install settling tanks by laying a sand cushion on it in a layer of 30–50 cm.

If you do not want to concrete the bottom, then you can purchase reinforced concrete rings with a solid bottom. They will need to be installed first in a vertical row.

The place for the filter well also requires preparation of the base. Under it you need to make a cushion of sand, crushed stone and gravel at least 50 cm thick.

Installation of rings

To install the rings, you will have to order the services of lifting equipment. Performing these tasks manually is very difficult. You can, of course, install the rings by digging under the bottom ring. But this method is labor-intensive. And the bottom will have to be filled after installing the last ring, which will entail a number of inconveniences. In view of this, it is better not to save on ordering lifting equipment.

Usually the rings are fastened together with mortar, but for greater structural reliability they can be fastened with metal plates or staples. In this case, your septic tank will not be damaged due to soil movement.

Now it’s time to organize an overflow, and for this you need to connect pipes to the rings. It is better that they work on the principle of a water seal, that is, they need to be installed with a bend.

Sealing

To seal the joints you need to use a solution with an aqua barrier. The outside of the tanks must be treated with coating or weld-on waterproofing.

Another option is to purchase plastic cylinders that are installed inside the well. In this case, the likelihood of dirty water entering will be minimized.

Installation of ceilings/backfill

Installation of floors and backfilling

Finished wells must be covered with special concrete slabs, which have holes for installing sewer hatches. Ideally, backfilling of the pit should be done with soil containing a high percentage of sand. But if this is not possible, the pit can be filled with soil previously removed from it.

Now the septic tank can be put into operation.

Required materials and tools

To independently install a country toilet with an odorless pit cesspool, you will need the following tools:

- angle grinder;

- shovel;

- building level;

- buckets;

- perforator;

- drill with a set of drills.

- container for accumulating waste (metal barrels, bricks, concrete rings, tires);

- sewer pipes, diameter 100-110 mm;

- a set of pipes and couplings;

- geotextiles;

- sealant;

- slate;

- sand;

- fine gravel;

- cement;

- waterproofing mastic.

Preventive measures or how to increase the effectiveness of Shambo

If you value your work or simply want your sewer system to work as it should for many years, you need to follow some rules. Let's take a closer look at what to do to prevent pipes from becoming clogged and to make cleaning drainage wells and septic tanks easy and simple.

- Install catchers on sinks. They cost 2-3 rubles each, but will bring a lot of benefits. These nets will protect you from things that are terrible for the sewer system, such as threads, large food waste, bones, etc. All this can cling to the walls of the pipes, especially if there is a bend somewhere on one line or simply a change in the degree of slope. Then it clogs the canal and creates a lot of headaches for the owner of the house.

- Once every 2 weeks, pour a specially prepared mixture into the sink, bathtub, and toilet to remove grease and organic matter in the pipes. Vinegar, water, soda in a ratio of 1:3:2. 3-4 glasses will be enough. This will significantly improve not only the throughput of the pipes, but will also dilute the mixture in the sewer tank.

- Once a month, throw in a few tablets of chemicals to dilute it. This will almost completely eliminate the problem of sedimentation.

- If possible, you should make a container for the sewage drain with a cone-shaped bottom so that the pump that you then place there can completely remove everything. It will also be convenient when operating a vacuum cleaner.

If you adhere to these rules, then you will not spend a lot of effort and time on subsequent sewer maintenance. 30 minutes is enough to pump everything out with a fecal pump.

Calculation of the cesspool

Before starting work, it is necessary to calculate the volume of the container into which the family’s waste will fall.

When calculating, the following standards should be taken into account:

- Almost 200 liters of waste water per person per day. Thus, the monthly volume of wastewater in a family of four will be at least 20 m3 (the indicator is important when calculating the volume of a sealed container);

- when constructing pits with an open bottom, it should be taken into account that the filtration of wastewater in sandy soils is 15% faster than in loams;

- a one-time volume of sewage removal does not exceed 10 m3, which is equal to the volume of approximately four concrete rings with a diameter of 2000 mm;

- When calculating the volume of a container, you should take a safety margin of at least 10%, since it is not always possible to quickly call a sewer truck.

Entrust the choice to specialists

offers a large selection of sewer pipes, the range of which can be found on the online store website. Each client, before deciding which pipes to use for connecting a septic tank and laying external sewerage, can take advantage of professional advice from our specialists. They are always ready to provide assistance in choosing products and make the necessary calculations, including taking into account operating conditions - to do this, you can call any branch of the company or use the feedback service directly on the website of our online store.

You can place an order and delivery of goods to the specified facility, in addition, order the service of professional installation of a sewer system of a country house and connection of a septic tank - our craftsmen are ready to perform this work quickly and efficiently.

Marking and excavation work

When preparing a pit for a cesspool, the following rules and recommendations must be observed and taken into account:

- The marking is carried out according to the plan for linking the cesspool to the buildings on the site.

- The diameter of the pit should exceed the diameter of the concrete rings, tires or barrels by 300-400 mm, so that the walls do not interfere with installation.

- The depth of the pit should exceed the height of the rings by 200-300 mm, which will be required to create a sand and gravel cushion.

- If a non-filtering well made of concrete rings is being installed, a monolithic slab is poured at the bottom or ready-made slabs are laid, after which the joints between them are carefully sealed. You can put rings in the well after the concrete base has fully gained strength.

Varieties and characteristics

Several varieties are distinguished in the group of sewage pumps. The most common models include:

Models without shredders, with maintained temperatures up to 40 degrees.

They are distinguished by an affordable price, as well as wide flow channels. An excellent option for pumping out groundwater containing lumpy particles. This is especially true for water that floods premises in the fall or spring.

From 90°C, without grinders. Scope of application: baths with laundries.

For pumping out hot water

Rarely found among representatives of the private sector. Designed for use on the territory of large complexes.

In addition, there are several types of devices depending on the methods of operation:

Submersible. Immersion in wastewater requiring treatment is complete. The bend in the form of an angle and special guides facilitate fixation at the bottom of the pit. The main thing is to remember that each manufacturer sets its own immersion depth for a specific model. A depth of 100 meters is optimal for using horizontal pumps.

For vertical ones, a dive of no more than seven meters is permissible.

Semi-submersible. Half immersion in sewage water is assumed. The pumping part must be located underground. The engine maintains its position on the surface. It is important to use floats or special devices that help keep the engine at the top. The device is not used with fecal waste due to the lack of a grinding device.

Surface varieties

External-type models are mounted near the location of sewage pumps. The intake hose must be lowered into the wastewater. The installation method is called “dry”.

Video tips for choosing the right pumping equipment:

Instructions for constructing a cesspool

Let's consider the procedure for constructing cesspools made of various materials.

Concrete rings

The design of this structure resembles an ordinary well.

How to dig a pit for concrete rings? To a given depth (at least 0.5 m below the ground level), with a width slightly larger than the size of the ring. Depending on the type of pit, the bottom can act as a filter or be completely monolithic.

To connect the pit to the toilet, a trench is dug into which sewer pipes are laid. In the summer, the pipes will work without interference, but in order to prevent the drains from freezing in winter, the pipes are insulated.

The well is closed with a concrete lid with a hatch for pumping out sewage.

Car tires

The pit is dug with a width exceeding the diameter of the tires by 300-400 mm. A sand and gravel cushion 200 mm thick is placed at the bottom. The tires are laid one on top of the other with the joints sealed with plumbing sealant. The lid is made of boards or plywood with mandatory treatment with antiseptic agents.

Monolithic concrete

The pit is made with a margin of 500 mm in width. The formwork is being prepared, inside which the reinforcing mesh is laid. Cement-sand mortar for pouring is prepared from M300 cement in a 1:2 ratio with sand.

After pouring concrete, you need to wait at least 10 days for sufficient strength to develop. The finished concrete ring is coated with waterproofing mastic. A sand and gravel cushion 200 mm thick is placed at the bottom of the pit. The cesspool cover with a hole for pumping can also be cast from concrete.

Metal barrel

This option is suitable for houses with no more than 2 inhabitants and for sandy soils with low groundwater levels.

Holes with a diameter of 10-15 mm are made in the walls of a metal barrel with a volume of 200 liters in increments of 200 mm, and the outside is wrapped in geotextile along the height, securing it with wire.

The lid is hermetically secured along the diameter and a hole is cut for the inlet sewer pipe.

The pit is dug to a depth exceeding the height of the barrel by 300 mm; the bottom of the pit should be filled 200 mm with fine gravel. The side voids are also filled with gravel.

Brick

Let's look at the step-by-step organization of a brick pit:

- a pit is dug to the size of the future cesspool;

- a sand and gravel cushion 200 mm thick is made at the bottom of the pit;

- along the perimeter of the pit, according to the size of the masonry, formwork is arranged and a monolithic concrete slab is poured;

- After the foundation has gained strength, they begin laying brick walls. The easiest way is to make a well in a square or rectangular shape. The thickness of the wall is one brick;

- the outside and inside of the walls are plastered with clay mortar;

- a sewer pipe is laid in the trench connecting the pit and the toilet in the house;

- the cesspool cover is made of boards or cast from concrete, providing a hole for a hatch with a diameter of 500 mm.

Laying the external main

The pipe is laid with a certain slope

It is necessary to lay a pipeline from the point where the sewer pipe exits the house to the septic tank. The main must lie at a slope that ensures the drainage of contaminated water. The larger the diameter of the pipes you use, the smaller the angle of inclination required for their operation, on average it is 2 degrees. The depth of the trench for laying pipes must be greater than the amount of winter freezing of the soil. If the depth of the trench is small, provide thermal insulation of the line.

The average depth for laying a sewer system is 1 meter; in warm regions it is enough to go down to 70 cm, and in cold regions you will need to dig a pit up to 1.5 meters. The bottom of the dug hole is covered with a dense cushion of compacted sand. This procedure will protect the pipes from soil displacement.

Pit for a septic tank near the fence

The best option would be to lay a direct pipeline to the collector. If it is necessary to make a turn, this place will be equipped with an inspection well. For the main line, you can use plastic and cast iron pipes with a diameter of 110 mm; their connection must be airtight. After installation, the pipeline is covered with sand and then with soil.

Recommendations for cleaning a cesspool

After installing a country toilet with a cesspool, you should consider a sewage pumping system, even if natural filtration into the soil is assumed.

When using anaerobic microorganisms, feces are processed directly inside the container, but it will not be possible to filter and process waste in a filtration well without residue. From time to time, such systems need to be completely pumped out to clean the walls and replace the drainage.

If a pit with a bottom is installed in a private house, pumping will have to be done much more often. A sewer truck is ordered as the pit is filled with sewage, since there is simply nowhere for the liquid to go. Therefore, when owners plan to install a cesspool for a toilet in a country house, they need to provide convenient access for the machine to the well, taking into account that the length of the sewer hose is usually from 10 to 20 m.

Advantages and disadvantages of PVC

PVC has a number of advantages, thanks to which they have proven themselves well in the market:

- Resistant to corrosion.

- Immune to damage by microorganisms.

- A large assortment.

- Availability of various diameters.

- Resistant to temperature differences and pressure changes, as well as chemicals.

- Can handle heavy loads.

- Do not deteriorate after prolonged use.

- Simply mounted to any sewer.

- They do not emit harmful fumes.

- Due to the fact that PVC pipes have a smooth surface, they are less susceptible to the formation of build-up or sediment.

- Do not allow electric current to pass through.

- Light enough.

- Inexpensive compared to other materials.

The main difference between plastic pipes and metal ones is that the former have a larger range, and the latter are most often made of cast iron. One of the disadvantages is that PVC is not as durable as its competitor, but will last at least 50 years.

See also: Catalog of house projects with 2 or 3 bathrooms.

Model specifications

Vacuum trucks have different performance characteristics. The size of the car depends on its performance. The most effective technology is the one that suits the user's needs. The table shows the main parameters of standard machines:

| Brand | Specifications | |||

| Tank capacity(m 3 ) | Pump capacity (m 3 /hour) | Dimensions(mm) | Stop pumping when the tank is full | |

| GAZ 3307 | 4 | 240 | 7000*2500*2500 | Automatic engine stop |

| GAZ 3309 | 3,75 | 240 | 7000*2200*2600 | Electromechanical valve |

| GAZ 53 | 5 | 260 | 7600*2500*30000 | Mechanical shutdown |

| KAMAZ 65115 | 10 | 310 | 8300*2550*3180 | Mechanical shutdown |

Tips for installation and use

It is imperative to take into account the subtleties of using a flexible pipe when installing a waste system. Corrugated hoses of intra-house networks are connected using a special coupling, which ensures maximum reliability of fixation.

Plastic hoses with a diameter of up to 300 mm in external systems are mounted through a connector - a sealing rubber band and a socket. When laying routes of larger diameter, HDPE is connected using special welding through heating the material.

For smooth hoses, use a connection to the pump nozzle through worm-drive clamps. Rubber sewage disposal hoses with a corrugated structure are used when connected to the pumping system of a tanker truck using a specialized fastener. The tightness of the outlet is ensured by full compliance with the product manufacturer's recommendations.

Having correctly selected the appropriate hoses for the sewer system, you can easily carry out maintenance of autonomous sewage systems, remove moisture that falls with precipitation, and dump accumulated feces into a common sewer or main city network.

To learn how to clean a drain with a hose, watch the following video.

If you plan to install a septic tank or make it yourself, then purchasing the necessary pipes will be required. A local sewer system involves the installation of special pipes, which will be needed not only to bring wastewater to the installation, but also to ensure proper drainage of water (already purified) and, if necessary, its distribution over the entire filter area. Pipes will also be needed to arrange an overflow between containers (chambers), since proper organization of a septic tank without this is simply impossible. Read how not to spoil your site with unsightly septic tank outlets and the range of septic tank covers available.

The photo shows PVC pipes for external sewerage

Drainage pipe for septic tank

When installing a septic tank, you will definitely need to install filtration fields. Many people use an infiltrator for these purposes, since the greatest preference is given to the most thoughtful solutions, since this device will be needed precisely for the formation of filtration fields. To properly arrange the above-mentioned fields, in other words, organize post-treatment of the soil, it is better to use drainage pipes:

- It is more advisable to take the diameter 50 or 110 mm. The diameter must be selected based on:

- soil filtering capacity;

- overall performance of the septic tank;

- filtration areas;

- It is possible to purchase pipes with a geotextile coating;

- They should be laid on a site that must be prepared in advance.

Pipes for pumping may also be necessary, but their installation must be provided for in the design, since it is important to ensure that dense soil is not sucked in during the pumping process. To achieve this effect and do it as correctly as possible, it is important:

Drainage pipes for a septic tank in the image

- Punch a hole in the pipe intended for pumping, which should be several cm in diameter;

- Such a hole is made at a distance of at least 10-15 cm from the edge of the pipe;

- The diameter of the pumping pipe must comply with GOST.

Installation of sewer pipes to a septic tank

Installation work must begin by digging a trench, the size of which must necessarily correspond to the diameter of the selected pipes. You can dig:

- Manually;

- Use the help of special equipment.

Types of vacuum cleaners

It is important that the tank capacity of the machine matches the volume that needs to be pumped out. The smaller the car, the cheaper it is to pump out. The minimum volume of a GAS tank is 2 m³. The compact machine will fit into narrow passages and gates. Its light weight allows it to be driven onto paving slabs. Can pump out the volume of approximately 1 concrete ring with a radius of 1.5 m.

The most common car is GAZ with a tank volume of 4 m³. The septic tank hatch should be located at a maximum distance of 16 m from the tank.

Almost all brands of sewage disposal machines are equipped with hoses 10-15 m long. But often this is not enough. Therefore, owners equip their equipment with additional hoses; the average hose length is 20-25 m. The longer the hose, the greater the power loss. If the distance from the pumped-out container to the intended location of the machine is more than 25 m, a vehicle with a high-performance vacuum pump is required.

An important characteristic of a sewer pumping machine is fuel consumption. Japanese diesel models are practical because they do not consume fuel during pumping. They are equipped with convenient, automatically collapsing hoses. The tank of such a machine is durable because it is galvanized on the inside.

Types and uses

The sewer system removes large amounts of liquid, which may contain large particles. Therefore, tubular products with a cross-section from 50 to 110 mm are recommended for use here.

A smaller cross-section pipeline is suitable for creating an internal network. This includes outlets from household appliances and plumbing fixtures.

Pipelines for the general sewerage outlet are assembled from large-sized elements. Most often, installation is carried out through the toilet. This is due to several reasons:

- A large amount of water is drained from the toilet cistern at the same time.

- Large waste passes through the toilet, which can cause blockage in a narrow pipeline.

Which septic tank is best?

Cleaning a drain is quite a difficult process, and you need to try to simplify it in advance. Autonomous sewerage can be made of two types. The first is a drainage well. The bottom and walls should absorb liquid as much as possible, then the cesspool will last for many years without pumping, since everything will be absorbed into the ground, but after a few years you will still have to pump it out, only it will be much more difficult to do this. The sediment will lie in a dense layer on the ground and “hold on” to it so that the vacuum cleaner will not pull out a certain volume.

The second type is hermetic structures. They are metal, plastic, concrete structures that contain everything and do not even let water into the ground. Some make chambos with a hard bottom and aerated walls. Such a structure can be made in a few minutes by punching concrete rings in several places with a hammer drill. Thus, the thinner suspension goes into the ground, while the thicker one remains in the hole.

When ordering a sewer truck under a contract, the cost of services is usually reduced by 20%, so it will be more profitable to calculate how long it takes to fill the container and sign papers with any company providing sewage disposal services.