When designing and installing sewer systems, great attention is paid to ensuring the safety of their use - removing unpleasant odors, explosive gases, and preventing sewage from entering the home. One of the effective means for protecting premises from the penetration of fecal waste is a 50 mm sewer check valve.

It is worth noting that sewer check valves are not mandatory elements in the system. But in some specific cases they can be useful, preventing the slightest possibility of dirty water appearing in the home.

Rice. 1 Check valve for sewerage 50 mm - appearance

Purpose of the locking device

The check valve is an important element of the “protective fittings” of any pipeline. Its main purpose in the overall technological system is to prevent a possible change in the direction of the flow of the working fluid. All valves of this type freely pass the working medium in the desired direction and prevent its movement in the opposite direction.

The purpose of check valves in sewer systems is similar - by releasing waste from the internal sewer system into the general house system, they prevent their reverse flow in the event of a plug, blockage or other problem on the subsequent section of the pipeline.

Additional functions of the products are to protect individual housing construction from wastewater that overflows the drain well; prevent rodents from accessing the sewer system (for this, a 50 mm sewer check valve is often used).

Controls and technical characteristics

The device can be controlled in two ways:

- mechanical;

- in an automatic way.

The main technical characteristics of check valves include:

- nominal diameter (DN) - cross-sectional size of the openings of the connecting pipes (from 50 mm to 300 mm);

- nominal pressure (PN) - the value of the highest excess pressure of the working medium at a temperature of 20ºС;

- throughput coefficient (Kvs) - water flow (m³/h) with a temperature of 20ºС;

- operating temperature range - depends on the materials used and is indicated in the technical specifications for specific samples;

- installation type - horizontal or vertical;

- type of connection to the pipeline.

Design and principle of operation of the product

Check valve in operation

Standard check valve components:

- Housing with pipes (inlet, outlet) and inspection cover.

- A working shut-off element - disk, valve, membrane, ball - to shut off the pipeline over the entire internal cross-sectional area.

- Seal to ensure a tight fit of the working element to the body during reverse flow of drainage masses.

- Return spring of the locking element.

- Lever mechanism for forced opening of the valve manually. It makes it easy to adjust the position of the damper. It can be fixed vertically or horizontally.

The check valve works as follows. Initially, the damper blocks the entrance to the housing chamber. The pressure of the flow of drainage masses lifts it without obstacles, and the water or the contents of the toilet rushes to the sewer without delay. If there is a blockage or blockage in the pipes located behind the valve, a reverse flow of liquid occurs. Its pressure presses the working element against the support ring of the housing and reliably closes the passage - liquid waste does not return to the apartment or house.

Check valve with electric motor

This modern analogue of a check valve runs on electricity; in case of frequent power outages, there are models with batteries. In this device, the locking membrane is always completely open, which prevents the formation of dirt build-ups on it, which prevent it from closing completely if necessary.

The device operates as follows:

- the liquid begins to move in the opposite direction and fills the pipes;

- when the pipe is filled to 70% of its volume, the probe installed inside sends a signal to the electrical unit;

- sound and light alarms are triggered, notifying you of trouble;

- the damper closes automatically.

Classification of products used

Based on the type of working locking element, the following design options for sewer pipe valves are distinguished:

- Lifting . The principle of their operation is described above. The passage through them is blocked by a damper or disk.

- Rotary (petal) . A distinctive feature is that the locking membrane resembles a petal. They work similarly with lifting type products.

- Ball . The locking element is a balloon filled with air. With the “correct” movement of waste liquids, it rises and rolls into the recess provided for by the design of the housing. The flow passes freely into the common drain system, and the ball then rolls back to its original place under its own weight. In an emergency, the reverse flow, with its pressure, presses the sphere harder, which reliably blocks the passage.

- Wafer . These check valves are suitable for sewer pipes with a pipe size of 50 mm. Products in the shape of a low cylinder with a rotary valve are placed inside the pipe. They are capable of passing only water without any solid particles or inclusions - therefore they are designed for discharging liquid from sinks and bathtubs.

check valve types

Benefits of using such a device

Now let's figure out what a sewer air valve does.

It is worth saying that this device has several functions:

- Neutralization of unpleasant odors. We have already talked about this, and we note once again that this is the main function of such a device.

- Saving. The fact is that when laying a sewer system, it becomes necessary to install a return line. If you use the valve we describe, you can neglect such a costly procedure.

- Making work easier. It does not have to be installed on the roof. Sometimes this turns out to be a very problematic procedure.

Clearly illustrated operating principle

- Increasing the efficiency of the highway. If the house has a relatively large number of plumbing elements (at least 5), then the presence of such a device is simply necessary. Otherwise, the sewerage system will not cope with the task.

The valve installation method allows us to distinguish the following designs:

- Flanged . Suitable for connection to large cross-section pipes that have a similar fastening element. The valve with flanges is conveniently mounted on pipeline sections with a vertical or horizontal arrangement.

- Bell- shaped The valve with a conical socket and a rubber sealing ring easily mates with other pipeline elements.

- Couplings . The products are designed to mate with pipes (mostly metal) of small diameters - up to 2.5 inches.

Flanged and Union Check Valve

The material for the manufacture of check valves is:

- Stainless steel . Used for the production of interflange products. Other types of valves can also be manufactured for inclusion in a metal pipe system. In products made from other materials, stainless steel dampers can be used.

- Polyvinyl chloride (PVC) . The most common material for large cross-section sewer valve bodies.

- Polypropylene . The sewer check valve 110-315 mm polypropylene remains operational at +95°C without deformation. The housing material includes components that can partially suppress the operating noise of the product.

- ABS plastic . This thermoplastic resin produces durable and impact-resistant housings for check valves.

- Cast iron . Such designs are recommended for installation in loaded systems (usually external) made of large-section cast iron pipes.

Step-by-step installation instructions

Most air valves are produced by manufacturers to connect to DN110 pipes. If the connecting size of the device does not correspond to the size of the pipe, a special adapter is used. For pipes DN50 or DN75, aerators with the corresponding diameter of the connecting outlet or equipped with a reducing insert are used.

It must be remembered that a valve designed for pipes with a diameter less than 110 mm can be installed for a maximum of two plumbing points.

In areas of transition from a pipe of a larger diameter to a valve with a smaller diameter, reducer inserts and various adapters are used. To install the aerator on a cast iron pipe, there are also special adapters that ensure a reliable joint between the plastic and the metal.

At the beginning of the work, the installation location of the valve is determined, taking into account the installation rules and its accessibility for further maintenance.

Next, perform the following steps:

- The water supply in the house is turned off.

- If the installation is carried out on a previously installed pipeline, then a tie-in is made and a special adapter is installed.

Most aerator models have a bell-type connection.

The assembly of such connections is carried out in the following sequence:

- The outer surface of the smooth part and the surface inside the socket are cleaned of dust.

- Wipe the sealing ring from possible contamination and place it in the socket groove.

- The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin.

- Place the smooth end of the valve into the socket up to the mark. The quality of the connection is checked by rotating the parts relative to each other, followed by returning to their original position.

If necessary, the area with the connected vacuum valve is secured with a clamp. Upon completion of work, it is necessary to check the joints for leaks.

The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin

For hidden installation, special models of vacuum valves are used. If the riser is hidden in a fine or protective box, then measures must be taken to ensure the flow of air into the sewer valve. To do this, a ventilation hole is made according to the size of the aerator mesh.

The aerator body is buried in the wall, the fastening element is adjusted so that its outer edge is flush with the wall surface. The only visible element remains the decorative grille, which can be attached using self-tapping screws or inserted manually. For aesthetic reasons, it is available in the most popular color options - white, gray, black and chrome.

Some valve models can be used as drain cleaning holes. To do this, remove the decorative cover, take out the internal mechanism of the fan valve and insert the cable inside.

Valve Selection Tips

- To install the valve, before connecting the apartment sewer system to the common house sewer system, select a product for a non-pressure system.

- Any type of valve can be installed in front of the bathtub or sink. The main requirement for it is compliance with the fastening and diameter of suitable pipes.

- When installing the valve in a vertical riser, use a product with the appropriate mark on the packaging.

- Valve models designed only for vertical installation should not be used on horizontal sections of the pipeline, and vice versa.

- You cannot install a valve designed for pressure in a non-pressure system - it works with crushed waste materials and will quickly become clogged with waste from the toilet.

- To install a plastic valve on a pipeline made of cast iron or steel, special plastic adapters will be required.

- Models of products with flanges must be placed on pipes with the same type of fastening.

- It is not advisable to install metal valves on plastic pipes.

- The cost of check valves can vary by an order of magnitude. However, expensive models do not guarantee great advantages during operation.

Before purchasing

Before purchasing a check valve for the sewer system, you need to decide on the exact location of its installation and know the type of sewer system - free-flow or pressure (with a pump in the pipe system).

When choosing the required model, they also take into account the dimensions of the product, the manufacturer’s warranty period, build quality, complexity of the upcoming installation, material, functionality, and recommendations of practitioners.

Why do you need a non-return valve for a sewer?

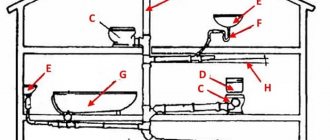

Connection diagram

Schemes for installing check valves are developed in accordance with the technical characteristics of the device and a description of the conditions for its further operation. In the photo you can see examples of the location of the device:

- to protect the washing machine;

- on an external sewer pipe.

The nuances of installing sewer valves

- Before installation, you must perform a visual inspection of the purchased product. For further work, leave the structure without visible defects, chips, cracks and deformations.

- After this, the functionality of the valve in the bath is checked using water, which is alternately supplied from different sides through the body pipes. If necessary, at this stage it is easy to eliminate minor faults or replace the product under warranty.

- There is always an arrow on the body of any model. It helps to correctly orient the product during installation - with an arrow towards the common collector or drain well.

- Before work, you must definitely agree with the residents of your riser (from apartments on the upper floors) about a temporary refusal to use water supply and sewerage. Such forethought helps to avoid unexpected troubles.

- If the materials of the product and pipes are different or have different diameters, you will need to install special transition elements that are purchased in advance.

- Each connecting joint must be sealed.

- After installing the valve, the functionality of the drain system and the tightness of the connections are checked. Deficiencies are immediately eliminated. If there are no problems, the sewerage system is suitable for use.

For self-installation

Every home craftsman can independently install a valve of any type. You don’t need a professional or any expensive tool for this. The non-return valve for sewerage is not yet a well-known and widespread device. Therefore, for those who first encountered the product and decided to install it, the following tips will be useful.

Installation of a check valve is simplified if it is sequentially assembled together with all elements of the future sewer system into a common chain. This happens when the entire drainage system of an apartment or house is completely replaced during a major renovation or during the construction of a new home.

When installing the device in an operating sewer system, the role of preliminary marking and careful removal of the pipe section for inserting the valve in this place is important. Installation on metal and cast iron pipes is more complicated than on plastic ones - it may require the involvement of specialists with practical experience in performing such work.

You may also like - Slope of sewer pipes according to SNiP

Work progress

If you plan to install a check valve in a residential high-rise building, you must:

- 24 hours before the start of installation, notify all residents about the upcoming work;

- perform a shutdown using valves installed in the inlet section of the cold and hot water supply to prevent unauthorized entry of water into the sewerage system circuit;

- notify all neighbors immediately about the very beginning of work to replace the device;

- After completing installation of the product, turn on the water in the entrance.

The work itself on installing a device with a threaded connection type is carried out in the following sequence:

- choose a location for installing the device and cut out a part of the pipe there that is equal in size to the length of the valve;

- cut threads at the ends of the pipes;

- clean the remaining chips;

- take a strand of flax fiber of such length as to ensure the number of windings is 1.5 - 2 times greater than the number of thread turns and lay it clockwise, wrapping the entire length of the threaded section;

- apply a layer of sealant over the wound flax;

- Screw on the valve and tighten the fastening using a wrench or torque wrench.

A useful video on the process of installing a locking device in a bathroom can be viewed in the video:

Valve Maintenance

Timely inspection and periodic maintenance of the check valve increases the service life of the device and ensures its reliable operation.

Important! At the stage of designing the drain system and installing the valve, it is necessary to provide for ease of access to the product for the necessary maintenance.

The sewer valve is serviced quarterly. To do this, remove or unscrew the top inspection cover. Then a visual inspection of the condition of the product is carried out, the debris accumulated in it is removed, and, if necessary, the edging and/or damper is replaced. The reason for unscheduled maintenance of the check valve may be the deterioration of the drain system, the presence of additional unnatural noise and vibrations in the valve when draining waste.

When servicing the valve in use, you should also follow the manufacturer's recommendations specified in the product instructions.

Conclusion

Now you will certainly be able to choose a suitable air valve for sewerage 110. However, if you could not understand all the details, then do not be discouraged (see also the article “Why do you need cable ducting and how is it laid”).

In the video presented in this article you will find additional information on this topic, which will help you understand everything.

Did you like the article? Subscribe to our Yandex.Zen channel

Causes and consequences of sewer blockages

Possible destruction or mechanical damage to pipeline elements creates an emergency situation. But most often, emergency situations in sanitary systems for the removal of products from human household activities are associated with the occurrence of internal blockages, which necessarily provoke a stop and reverse movement of the discharged wastewater.

A simple malfunction leads to serious problems, which usually affect the lower floor apartments of apartment buildings or the sanitary premises of the lower level of private buildings. The location of the blockage in these cases is in the horizontal sewer pipes passing through the basement. Residents of the upper floors can also suffer, which happens less frequently. To do this, it is enough to have a plug in the vertical riser between floors. Installing a sewer check valve eliminates the possibility of such domestic accidents in apartments. This device will also protect private homeowners.

Causes of plugs and blockages in drain pipes:

- Blockage of the drain pipe due to violation of the rules for using the sewer system. In this case, the traffic jam is created by large food waste, diapers, plastic bags, cotton wool, pieces of thick cardboard, rags and other bulky items that are not sent to a special garbage container.

- Long-term operation of pipes is accompanied by the gradual formation of sediment on their inner walls and a decrease in the working clearance (section). Subsequently, the rough inner surface of the pipes more easily retains solid particles, which settle and gradually form an impenetrable plug in the overall system.

- Incorrect pipeline slope allows solid particles to settle on its walls. To avoid this, the flow of discharged liquids must have a certain speed. To change the slope of the pipes, you will have to completely redo the problematic system.

- The formation of plugs is also facilitated by bends located perpendicular to the main pipeline. The flow of liquid in these areas slows down sharply, delaying large inclusions - the reason for the formation of plugs.

The consequence of an internal blockage of a sewer pipe that occurs for any of the reasons listed is the accumulation of liquid and its reverse flow. Immediately, the toilet bowl (closest to the plug site) accumulates with the contents of the waste system, with possible overflow of the liquid mass over the edge. In this situation, the unpleasant smell ceases to be a problem, in comparison with the upcoming cleaning, repairs and expenses for purchasing new things to replace the damaged ones.

Is it really necessary?

Installation of a sewer check valve 50 or 110 is not always required; there are certain situations when installing this device does not make much sense. For example, residents of apartments on the 6th floor of an apartment building do not have to worry about possible sewer flooding through the central blockage, because... the pressure of waste fluids will not maintain a high level when rising to the 6th floor.

In general, there are situations when it is strongly recommended to install the device:

- location of the apartment on the first/second floor of a multi-storey building;

- location of office space on the first two floors;

- private 1-storey house;

- cottage-type country house with 2-3 floors.

In the above situations, it is financially more profitable and easier to install a valve on plumbing fixtures in advance than to later repair the premises and deal with the negative consequences of a clogged and broken sewer. It is especially important to install the mechanism in houses with old pipelines. Pipes in such buildings usually have a layer of sediment on the inner walls, resulting in a smaller working area and an increased likelihood of clogging.

Determining the installation location

It is important to know! The air valve for sewerage is usually mounted 20-30 cm above the main pipe. During installation work, do not allow dust, dirt or liquid to penetrate the membrane. For optimal performance, a systematic supply of oxygen is necessary.

For installation in an apartment, the device is mounted on a pipeline in a vertical position. This method will not provide ventilation to the riser, but will eliminate odors in a specific area.

It is recommended to install a sewer air valve in a private house. In this case, it is possible not to carry the fan structure through the roof. But some experts argue that it should be mounted only as an auxiliary part to the riser.

In private houses and apartments, plastic sewers are installed. Air elements are also made from polypropylene or PVC.

The valve must be installed:

- In high-rise buildings that are connected to wastewater treatment plants.

- In waste disposal areas.

- When connecting sewerage to sanitary facilities.

- In systems that can be connected horizontally.