Are you used to spending weekends in a country house? Or maybe you live in a private house within the city? Then you are familiar with the sewage problem from personal experience. Connecting to a central system is expensive and not always possible, and a regular sewage pit is a simple solution, but far from the best. Firstly, you will have to do something about the smell, and secondly, calling the car when it is full will also cost a decent amount. In general, it is better to think about sewerage in a house already at the construction stage.

Free consultation

Ecogrand

The manufacturer is positioning it as a treatment facility best suited for a country house - low energy consumption, stable operation and high autonomy.

If you need an independent sewer system for your home, contact us. In the shortest possible time, we will assess the area, offer a suitable option for you to locate a treatment plant, carry out preparatory work, deliver and install.

To solve your problem, you can call a specialist. Fill out the form, briefly describe your problem and we will call you back for a consultation.

Free consultation

Stages of installation work for the installation of treatment facilities

The principle by which the installation of storm sewer treatment facilities or equipment such as a wastewater treatment plant is carried out involves several stages, these include:

- pouring the foundation

- placement of equipment on the foundation

- welding work

- electric installation work

- clean water tests

- checking individual elements

- launch

In order to understand what the installation of local treatment facilities involves, let’s take a closer look at each stage of the work.

Stage 1. Arrangement of the foundation

Before a biological wastewater treatment plant is brought to the site, it is necessary to pour the foundation for it. This must be done in accordance with construction design documentation developed by a special institute. This documentation is developed taking into account the level and type of groundwater and many other important factors. Basically, the foundation is poured with a solid slab, however, in some cases it is also possible to construct a strip foundation.

Stage 2. Installing the module on the foundation

After the erected foundation has settled, a biological wastewater treatment plant is transferred to it. This is done using any special loading equipment or crane. The production of equipment such as a wastewater treatment plant includes the development of special fasteners for easy movement of the structure, which make it easy to move the module to the required location.

Stage 3. Welding work

In order for the deep biological treatment station to be convenient for human service, it is necessary to carry out welding work related to the installation of platforms for operating personnel, ladders, support handles and fences. These module elements are responsible for the comfort and safety of people who monitor how the installation of wastewater treatment plants works at enterprises.

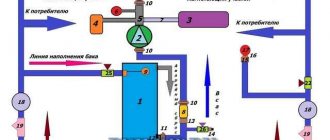

Stage 4. Electrical installation work

This stage is extremely important for the safe and proper operation of domestic or storm water treatment plants. After all, everything related to water and electricity should have special attention due to known physical properties. Electrical installation work includes activities such as: installation of a control panel (cabinet), laying cables and connecting electrical consumers.

Stage 5. Test run

At this stage, the installation of sewage treatment facilities involves a trial run of the installation for testing on clean water. During the test run, the biological wastewater treatment plant is checked for the possibility of leakage of certain module components. If a leak is detected, restoration measures are taken.

Stage 6. Equipment check

The penultimate stage involves checking the functionality of each piece of equipment. If damage, incorrect operation, or non-working equipment is detected, it is repaired, if possible, or completely replaced with another new one. These problems occur extremely rarely, and when they do occur, they are mainly associated with damage to pumping stations during transportation.

Stage 7. Launch

At the final stage, a test run is carried out, during which the biological wastewater treatment plant is checked for functionality after installation work has been completed. At this point, a release point must be agreed upon. Despite the fact that this is the final stage, the installation of treatment facilities at enterprises is not yet ready for full operation, since commissioning work is first required.

What factors are taken into account when designing?

The most important parameter that cannot be ignored is the required performance.

It is always determined with some reserve to avoid unpleasant surprises. Statistical analyzes of laboratory data are also required. This allows you to select the optimal number of purification stages, the best technological schemes and specific equipment parameters. Additionally you will have to study:

- urban development plan or its equivalent for the territory of the enterprise;

- conditions for approaching wastewater;

- necessary conditions for discharge after cleaning;

- engineering and geological survey data ;

- forecast for the growth of wastewater volumes as the territory is developed and economic capacity grows.

Characteristics

Gravity flow has several advantages over pressure-type septic tanks:

- The gravity sewer system is quite simple, so installation work does not require special knowledge and skills.

- There is no need to install additional pressure units.

- Plastic, which is characterized by a low price, is used as the starting material for the manufacture of a septic tank.

- Cleaning is performed without connecting to the power supply.

- When installed correctly, the internal walls of the pipeline self-clean.

- No special maintenance is required during operation.

Among the disadvantages of a gravity system, the need to create a slope is important, which requires deep deepening of the storage well. In addition, the system uses large diameter pipes, which can complicate the installation of pipe products.

Overview of species

When selecting VOCs for a private house, country house or cottage, you should understand how rational the use of the installation of a particular design will be. Most often, the dimensions, as well as its technical characteristics, are calculated based on the fact that on average one person consumes 200 liters of water per day. If you install small containers for a large number of people, then the wastewater simply will not have time to be processed, and the water after purification will still remain cloudy. At the same time, if the container is too large compared to the volume of wastewater, then the owner will waste a large amount of money on maintaining such a structure.

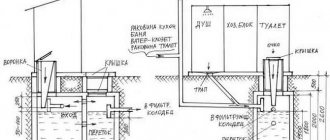

As for the types, the first one should be called the septic tank. This design purifies wastewater mechanically. Usually it has 2-4 chambers, where water is transported in turn, which must be purified. The design of a septic tank is usually gravity-fed. In the first chamber, water settles, and large particles go to the bottom. The decomposition process here is carried out slowly, because wastewater is processed using anaerobic methods. Reaching the opening of the pipe for liquid overflow, the waste flows into the next compartment. Here, with the help of aerobic bacteria, substances are broken down more quickly, and after filling the tank, the wastewater flows into the next compartment, from where the water flows through a special pipe into the filtration fields or into the drainage well. Aftertreatment systems are usually filled with crushed stone or sand.

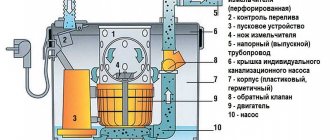

Another option is a biorefinery station as the VOC. The operating principle here is based on the use of aerobic bacteria. To do this, there must be oxygen in the structure. Its supply is provided by a compressor, that is, it is a system with forced aeration. The wastewater tank in such stations is usually made in the form of a rectangle, divided into 4 zones. In the first, wastewater settles. The second chamber is usually called an aeration tank. This is where cleaning begins with the help of beneficial bacteria, and this is where oxygen is pumped in by the compressor. Finally, organic matter is broken down and the so-called activated sludge is formed. All this mass is transferred to the third compartment, which is called a secondary settling tank. Here the sludge falls to the bottom and returns to the aeration tank, and the inactive sludge is pumped into a special settling tank. There the silt goes to the bottom, and the water flows into the receiving chamber.

This cleaning scheme gives almost 100% results. This design is a good solution for a country house, and a hole in the ground for it can be dug even with a shovel. Process water is used to water plants, and sludge is used as fertilizer. The disadvantage of this option will be energy dependence and energy consumption.

The third type of VOC is the simplest drain pit. This solution will be in demand if you are only in the house for a certain season. In this case, there is no point in installing VOCs, and you can use a pit where waste will simply accumulate. You can even buy some kind of ready-made container made of plastic. Installation and selection of the tank will be based on the characteristics of the site, as well as the soil. The water from such a pit does not need to be purified or discharged into the ground. It only needs to be cleaned from time to time - periodic pumping of wastewater can be done yourself, or you can use the services of a vacuum cleaner.

How to order a sewage treatment plant installation service

If you are a specialist in the field of water purification or at least know the basic concepts and indicators, then to receive a preliminary calculation of the cost of our services, you can fill out a questionnaire on our website, which will allow us to receive input data for creating a commercial proposal. And if you have been tasked with finding a supplier of water purification equipment, but all you know about it is that bad-smelling water is flowing down the drain, we recommend contacting our specialists at the phone number listed on our official website. We will ask the questions that interest us and help you formulate a request to calculate the cost of certain types of work. Our company is one of the market leaders in this area, so you can be sure that you are entrusting such an important issue to an experienced and competent company. Moreover, we have the lowest prices among our competitors. Even if you suddenly received a better price offer, just call us and we will make an even better offer. You can see examples of our work in a special section on the website, where you will find objects from Moscow, Yekaterinburg, Krasnoyarsk, Anapa and others. We work throughout Russia. We provide quality guarantees for all types of work and products, so you can be sure that if any problems or malfunctions arise during the warranty period, we will come and fix them free of charge and in a short time.

We work according to the contract, we meet deadlines

In the modern world, it is extremely important to work under a contract so as not to find yourself in a disadvantageous situation. Our company operates exclusively on this principle. Before starting any work, we sign an agreement that specifies all the necessary nuances, prices and deadlines for the contract. We rightfully consider punctuality to be one of our key advantages. After all, we always adhere to the deadlines initially agreed with the customer. In our practice, there have been a few cases where deadlines were not met, and this was either due to the fault of the customer or due to difficulties associated with transporting the cargo. We also draw your attention to the fact that we sell certified products that have high quality standards and are suitable for work even in the harshest conditions. By the way, if your facility is located in a place with difficult climatic conditions, then this fact also plays an important role in the process of equipment installation. Our specialists know about all the features of operating equipment in hot and cold climates, which ordinary construction companies may not know. Order a product or service from us and see for yourself that we are a serious company that works honestly and conscientiously!

Installation of a plastic septic tank

- Work begins with digging trenches and a pit, taking into account the dimensions of the existing container and taking into account the reserve, which is 30-40 cm.

- A concrete slab is placed on the bottom, leveled using a building level, on which the tank is installed, strengthening it with bandage cables, which avoids pushing a light plastic container to the surface under the influence of seasonal heaving of the soil.

- The free space of the pit is backfilled with a cement-sand mixture, which is prepared from five parts of sand mixed with one part of cement. The layer is compacted every 20cm of backfill.

Some do not trust plastic structures, preferring septic tanks made of concrete rings. This time-tested technology will also ensure the efficient operation of external sewage systems.