Industrial and domestic wastewater is a source of hazardous chemical compounds, heavy metals and microorganisms. Disposing of such waste without preliminary processing causes great harm to the environment. Physical and chemical methods of wastewater treatment make it safe for the environment.

In order not to cause harm to the environment and people, wastewater must be treated.

Difference between water purification and disinfection

Purification and disinfection are different stages of lowering the hazard class of waste water. Both methods are often used. During treatment, chemical and mechanical impurities are removed from wastewater. Disinfection is carried out to destroy microorganisms, including:

- bacteria;

- helminths, their eggs;

- viruses;

- fungi, etc.

Physical, chemical and complex disinfection methods are used. The first method includes exposure to ultrasound, ultraviolet radiation, etc. Chemical methods involve the use of reagents such as:

- ozone;

- chlorine dioxide;

- polymer antiseptics;

- sodium hypochlorite, etc.

Combined disinfection includes a number of physical and chemical cleaning methods. This technology provides the best results.

See also: Implemented water treatment projects at various industrial facilities, housing and communal services, energy, etc. from

Need for wastewater treatment

Comprehensive wastewater treatment is required to eliminate biological, mechanical, chemical and other pollutants. This set of measures is necessary to make water as safe as possible for people.

Discharge of wastewater without treatment leads to severe pollution of the soil, water and atmosphere. This often provokes the death of entire biotopes.

Due to the destruction of habitats, many species of living beings are now on the verge of extinction. Even if untreated sewage water enters a reservoir, this can lead to the death of fish, amphibians and mollusks in the reservoir.

Characteristics of pollutants

Effluents include large amounts of toxic substances. In the classification they are subdivided depending on the degree of danger. Impurities affect living organisms in different ways. Characteristics of the most dangerous wastewater:

Classification and composition of wastewater.

Household waste contains many organic compounds, residues of chemical detergents, etc. These substances are harmful to fish, but are also a breeding ground for green bacteria. An increase in the number of these microorganisms leads to greater heating of the water and a decrease in the oxygen content in it. In addition, the discharge of such waste without preliminary treatment contributes to an increase in the amount of harmful compounds in water bodies and soil.- Waste water from pulp and paper mills that has not undergone comprehensive treatment contains dyes, phenols, varnish residues, wood components, etc. When decomposing, these substances provoke the release of hydrogen sulfide, methane, carbon dioxide and other dangerous gases. At the same time, such waste causes an increase in the number of cyanobacteria in water bodies.

- Waste from the chemical and petroleum industries can increase the viscosity of water and reduce its oxygen content. In such wastewater, the presence of dangerous toxins is determined that can destroy all fish and amphibians living in the reservoir, and lead to the death of wild and domestic animals that come to quench their thirst. In addition, such waste can make the soil unsuitable for economic activity for many years.

- Waste from meat and dairy industry enterprises discharges effluents containing fragments of wool, fat, blood, cheese crumbs, etc. These substances make the aquatic environment more alkaline. In addition, such wastewater is a breeding ground for viruses, bacteria and fungi. Fish, wild land animals, waterfowl and aquatic plants become infected with pathogenic microflora and die, which leads to disruption of the natural balance.

- Waste from textile industry enterprises contains residues of synthetic and natural fibers, heavy metal molecules, etc. These contaminants clog the digestive systems of fish and shellfish. In addition, effluent changes the enzymatic reaction of water.

- Effluents from food processing plants contain a lot of nitrates and phosphates, which are a breeding ground for cyanobacteria. The proliferation of green algae leads to a decrease in oxygen content in the water and the death of fish.

Requirements and standards

Each enterprise must carry out waste water treatment in accordance with the federal law of 2011 “On water supply and sanitation.”

All types of contaminants must be removed from effluents before they are returned to natural or fishery facilities. This requirement is described in SanPiN 2.1.5.980-00 - “Hygienic requirements for the protection of surface waters.”

Water disposal through the central wastewater treatment plant: whoever purifies wastewater before discharge is responsible for its quality

Subscribers often discharge wastewater of non-standard quality into the centralized sewerage system (hereinafter referred to as the CWS). As a result, the organization of water supply and sewerage services (hereinafter referred to as WSS) is forced to discharge wastewater into water bodies in violation of the standards for permissible discharges. Who is responsible for the final pollution of a water body?

The organization of water and wastewater services is not a source of generation of wastewater, which is received at the water treatment center, because:

1) contaminated wastewater is generated by CSV subscribers;

2) the water and wastewater services organization handles the wastewater entering the central wastewater treatment center, the quality of which, by and large, initially does not depend on the water and wastewater services organization itself;

3) The capacity of the wastewater treatment facilities of the central wastewater treatment plant is always limited, therefore, the quality of wastewater discharged into the centralized wastewater treatment plant directly affects the quality of wastewater discharged by the water and waste management organization into the water body.

By the way

If the situation were different and water and wastewater organizations could hypothetically provide the required wastewater treatment regardless of its initial quality, then there would be no: • wastewater disposal standards for wastewater composition/wastewater composition standards; • requirements for the composition and properties of wastewater, established in order to prevent negative impacts on the wastewater treatment plant; • subscriber fees for excess discharge; • subscriber fees for negative impact on the central bank.

Considering the limits of the capabilities of treatment facilities and the fact that subscribers often discharge wastewater of non-standard quality into water treatment centers, the following problem is very common: water and wastewater organizations discharge wastewater into water bodies in violation of the standards for permissible discharges .

If subscribers discharge wastewater into the central water supply center, the quality of which does not meet the established requirements (this may be an excess of wastewater disposal standards for the composition of wastewater/wastewater composition standards, or a violation of the requirements established by the rules of cold water supply and wastewater disposal), this affects and violates interests of the water and wastewater services organization.

What interests of the water and waste management organization may be violated? First of all, economic (although there is a high probability of negative administrative and legal consequences for the organization of water and wastewater services).

Within the topic under consideration, the economic interests of the water and waste management organization will be the interests associated with the lack of need:

• bear the costs of eliminating the consequences of the negative impact of wastewater on WSS facilities;

• pay a fee for negative environmental impact (hereinafter referred to as NVOS) in an “extra-limit” amount;

• compensate for damage caused to the environment (water bodies).

To protect the listed economic interests of water and wastewater services organizations, as well as to protect the environment from the negative impact of wastewater discharged into water bodies through water treatment centers, the legislator has come up with special mechanisms that are well known to business entities.

Protection Mechanisms

The first group of requirements that make up the mechanism for protecting the interests of the water and waste management organization are various requirements for wastewater quality .

Next come the requirements for the need to pay various types of fees for violating wastewater quality requirements.

The law also provides for a compensation mechanism that imposes obligations on subscribers to reimburse “extraordinary costs” of the water and utility services organization:

• actual damage caused - if the discharge of the subscriber's wastewater resulted in the destruction of structures, facilities and equipment of the central waste water treatment plant and disruption of the operation of treatment facilities that occurred as a result of violations committed by the subscriber;

• additional costs associated with an increase in fees for excess discharge of wastewater (fees for NVOS) - if the discharge of the subscriber's wastewater resulted in disruption of the operation of treatment facilities and excess discharge of wastewater into a water body;

• costs associated with compensation for damage caused to a water body - if the discharge of the subscriber's wastewater resulted in disruption of the treatment facilities and damage to the water body.

The list of protection mechanisms can be continued, but in this material we do not pursue the goal of covering this issue in detail.

We are only trying to demonstrate the following:

• water and wastewater services organizations have various tools to influence subscribers in terms of regulating the quality of wastewater discharged to the central wastewater treatment plant;

• the law stipulates that the costs of the water and wastewater services organization associated with the consequences of the discharge of wastewater of non-standard quality into the central wastewater treatment plant must be compensated.

Does this mean that the role of the water and waste management organization is reduced to a minimum?:

• accept wastewater into the central wastewater treatment plant;

• control their quality;

• clean as much as possible;

• discharge into a water body without bearing responsibility for something that the water and waste management organization seems unable to influence?

Both water and wastewater services organizations, and CSV subscribers, and especially the supervisory authorities, probably know that this is not so. Let us recall the definition of the concept of “water disposal”:

Dictionary

Wastewater disposal is the reception, transportation and treatment of wastewater using a wastewater treatment plant [1].

The water and wastewater services organization is a water user, the water quality assessment of which is standardized and limited by permitting documentation. This means that, first of all, the water and waste management organization is responsible for the quality of wastewater discharged into a water body .

All possible mechanisms of influence on CSV subscribers were invented not only to protect the interests of the water and wastewater services organization, but also for environmental purposes.

Today, Federal Law No. 416-FZ contains important instructions:

Extract from Federal Law No. 416-FZ

Article 30.2. Calculation of fees for the discharge of pollutants in excess of the established standards for the composition of wastewater and collection of the specified fee from subscribers […] 4. Funds received by the organization carrying out water disposal in the form of fees for the discharge of pollutants in excess of the established standards for the composition of wastewater are used to pay for negative impact on the environment, compensation for damage caused to water bodies, and also as a source of financing [2] for the investment program of an organization carrying out wastewater disposal, in terms of implementing measures to reduce the negative impact on the environment .

However, the cited norm came into force on 01/01/2019. Before this date, it was possible to derive the responsibility of the water and wastewater services organization for the construction, reconstruction, modernization, and technical re-equipment of treatment facilities only from the general requirements for the protection of water bodies, which must be observed by any water users.

It must be said that these requirements in practice sometimes revealed their inconsistency (despite their very imperative nature, such as, for example, the requirements related to the establishment of limits on discharges only if there are plans to reduce discharges).

When it comes to claims from supervisory authorities addressed to water and wastewater organizations on the issue of the quality of discharged wastewater, compensation for damage caused to a water body as a result of the discharge of wastewater of non-standard quality, often the key argument in the dispute between the water and wastewater services organization is the argument “the fault of the water utility in violating quality requirements there is no waste water or harm to the water body.”

To be more precise and formal: there is no cause-and-effect relationship between the actions of the water and waste management organization and the resulting consequences in the form of deterioration in the quality of water in a water body.

The logic is based, in particular, on the fact that the quality of wastewater is not entirely subject to the control of the organization carrying out wastewater disposal; The quality of wastewater is primarily the work of subscribers (collectively and individually). Consequently, the water and waste management organization should not be held liable for causing damage to a water body.

Many arbitration courts think differently, pointing out that organizations engaged in wastewater disposal must ensure wastewater treatment, and must also improve the systems of treatment facilities - that’s why they are water and wastewater services organizations.

Let's take one of the cases as an example.

Resolution of the Arbitration Court of the Far Eastern District dated November 28, 2019 in case No. A51-8049/2018

During an inspection carried out in relation to the water utility, the state environmental supervision authority discovered that the wastewater received from subscribers and discharged into the water body contained pollutants in concentrations exceeding the established requirements.

Discharge of wastewater into a water body leads to a violation of water quality standards in water bodies of fishery importance.

Vodokanal, among other things, insisted that there was no cause-and-effect relationship between its actions and the resulting consequences in the form of deterioration in the quality of water in the water body.

However, the arbitration courts of appeal and cassation instances ruled:

1) the fact that the water utility caused harm to the water body is proven by the very fact of the discharge of wastewater into the water body in excess of the maximum permissible concentration;

2) the actions of the water utility are illegal;

3) there is a cause-and-effect relationship between the illegal actions of the water utility and the damage caused to the water body.

It is interesting how the arbitration courts explained the existence of a cause-and-effect relationship, as well as the guilt of the water and waste management organization in causing harm to the water body:

The appellate court noted that the enterprise, knowing about the real consequences and the actual negative impact on the environment of its economic activities, negligently fails to act, without taking real actions to eliminate the violation of environmental legislation.

The basis for this conclusion, in our opinion, was one of the arguments of the supervisory authority:

[Enterprise - approx. author] for 9 years, charging subscribers for the provision of wastewater services, does not treat the received wastewater, does not carry out measures aimed at neutralizing the negative impact on the environment. Knowing about the real consequences and the actual negative impact of its economic activities on the environment, it negligently remains inactive, without taking real steps and actions to eliminate violations of environmental legislation.

Thus, both the supervisory authority and the arbitration courts actually found the water and wastewater services organization guilty of improperly performing the functions assigned to it for water disposal : receiving, transporting and, of course, treating wastewater .

[1] Clause 2 of Art. 2 of the Federal Law of December 7, 2011 No. 416-FZ “On Water Supply and Sanitation” (as amended on December 25, 2018; hereinafter referred to as Federal Law No. 416-FZ).

[2] Here and below it is emphasized by the author.

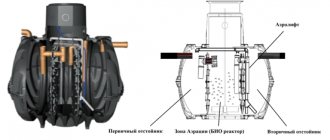

Technological diagram of the operation of water treatment facilities

The waste liquid must go a long way to get rid of all harmful chemical, organic, mechanical, biological and other impurities. The technological scheme of the wastewater treatment system is quite complex. First, preparatory activities are carried out, including:

- An averaging process that takes 18-24 hours, mixing waters containing different amounts of pollutants.

- Neutralization - adding sulfate acid, milk of lime, carbon dioxide and other reagents to wastewater to eliminate dissolved acids and alkalis.

- Cooling of hot waste water to remove explosive gases.

Technological diagram of the operation of treatment facilities.

The next stage is the mechanical removal of impurities. Main cleaning stages:

- placement in settling tanks;

- centrifuge processing;

- removal of petroleum products, fat and oils;

- filtration;

- wastewater coagulation;

- aeration;

- membrane filtration.

Then destructive cleaning is performed, which involves the oxidation of organic substances by aerobic and anaerobic microorganisms, as well as chemical reagents or heat treatment. Next, deep water purification is carried out. It includes the following methods:

- lightening;

- filtration;

- disinfection.

After such purification, the wastewater can be returned to a natural reservoir or reused in the production cycle.

What is it and why is it needed?

Wastewater treatment is an activity by which pollutants are removed from industrial and domestic wastewater. The complex is carried out before the liquid is discharged into reservoirs .

Each enterprise is obliged to carry out wastewater treatment; this is stipulated in the Water Code of the Russian Federation and the Federal Law of 2011 “On Water Supply and Wastewater Disposal”.

If measures are neglected, pollution will enter the natural reservoir and soil, and poison the local ecosystem. The number of plants and animals will decrease. Hazardous substances accumulate in biota and enter the human body through the food chain.

Industrial and domestic wastewater

can be sent to the same treatment plant .

Mixing them optimizes the ratio of carbon and sodium, carbon and phosphorus, which increases the efficiency of biological treatment.

The process takes place at industrial or municipal wastewater treatment plants.

Reference. If residential buildings are not connected to the central sewer system, domestic local facilities (LOFs) are used to treat wastewater.

Industrial VOCs are required if the effluent contains aggressive or biotoxic contaminants. The bulk of impurities are removed, then the water is supplied to general production facilities.

Mechanical methods of wastewater treatment

There are many mechanical methods of wastewater treatment that help remove debris of different fractions. This is the primary stage of removing contaminants.

Lattices

Grates are fairly simple equipment that receives wastewater during drainage. Depending on the design features, such devices are radial, vertical and horizontal. The device captures large solid elements.

Motorized screens are necessary to eliminate large particles in wastewater.

Such installations move waste to a special collection. Often the gratings are equipped with special settling tanks that retain suspended particles falling under the influence of gravity. This provides deeper primary wastewater treatment.

Advocacy

Most treatment plants have special settling tanks. During the processing process, stratification of waste water is observed. Heavy impurities sink down, a film of light compounds appears on the surface, and in the middle of the reservoir a layer of relatively clean aqueous medium containing suspended pollutants is formed. After settling, it is possible to remove solid debris and film. Subsequently, the wastewater is moved for deeper treatment.

Hydrocyclone

The removal of contaminants in this installation is based on the physical properties of centrifugal force. Water enters the apparatus and begins to move in a spiral. As a result of this, mechanical particles are separated from the main flow and settle in the sludge storage tank. Clean liquid is discharged through the pipe. Solid waste accumulates at the bottom of the hydrocyclone and must be removed periodically.

Scheme of wastewater treatment using a hydrocyclone.

Sand traps

Such devices are used to eliminate small pollutants, suspended matter and mineral compounds. More often, treatment plants use tangential sand traps equipped with a tangential water supply. In the peripheral part, the drains move downwards, and in the center - upwards. The rotation is slow, so the sand is deposited in a cone-shaped structure. The device is cleaned periodically. The filtered sand is taken to a special site or disposed of.

Centrifugation

This method of removing impurities is based on the action of centrifugal force. The drain is placed in a special apparatus that ensures rotation of the liquid. After processing, water flows out of one pipe, pre-cleaned from solid particles, and garbage is removed from the other. This method provides a high degree of elimination of mechanical pollutants.

Filtration

To carry out filtration, a system of perforated partitions is installed in a separate container, on which material is placed that traps solid particles. Depending on the design, such devices can be with downward or upward flow. The former are more reliable and provide maximum removal of solid impurities.

Scheme of purification using filtration.

Microfiltration

This method of removing impurities involves the use of special membranes made of ceramics, polymer, glass, etc. When passing through such a filter, particles up to 0.1-1 microns are retained. This processing method gives good results, but it is more often used for final purification when there are few undissolved impurities in the water. This is due to the fact that the pores of the filter can quickly become clogged when trying to pass heavily contaminated wastewater through it.

Types of structures

The table describes the equipment that is used at different stages of wastewater treatment.

For the mechanical stage:

| Installation | What is | Principle of operation |

| Sand traps | Horizontal or vertical installations of oblong shape. | Water moves through the equipment at a speed of 0.15-0.3 m/s. At this rate, mineral impurities with a diameter of 0.25 mm or more settle to the bottom, and small particles of organic matter remain in the water. |

| Septic tanks | Reservoirs where water stands still or moves very slowly. | Mechanical impurities settle to the bottom under the force of gravity. |

| Lattices | A filter cloth made of metal rods, which are located at a distance of 2-8 mm from each other. | Water passes through the rods and large debris is retained. |

| Oil traps and oil sand traps | 3-4 separate chambers connected to each other. | In the chambers, the wastewater settles, passes through a grate and a coalescence filter, and sorption materials. |

For the physico-chemical stage:

| Installation | What is | Principle of operation |

| Flotators | Reservoirs in which gas bubbles form. They are generated by an electric pump / electrolysis process / rotating turbines. | Gas bubbles rise and take with them fine particles. |

| Flocculators | A system of pipes in which the coagulant is mixed with wastewater and a chemical reaction occurs. | Coagulants combine with contaminants, form large flakes and precipitate. |

For the biological stage:

| Installation | What is | Principle of operation |

| Aero tanks | A rectangular tank through which wastewater mixed with activated sludge flows. | Aerobic bacteria break down organic matter in the presence of oxygen. O2 is supplied by mechanical or pneumatic aerators. |

| Membrane bioreactors | An aeration tank with a membrane that retains activated sludge after processing organic matter. | Aerobic bacteria break down organic matter in the presence of oxygen. O2 is supplied by mechanical or pneumatic aerators. |

| Biofilters | A reservoir with loading material on the surface of which a film of microorganisms forms. | The water passes through a porous filter media. The biological film on the granules breaks down contaminants. |

Filtration systems:

| Installation | What is | Principle of operation |

| Fixed partitions | Installations with filter fabric of different porosity. | The water passes through the filters and the contaminants remain behind the separating sheet. |

| Grain filters | Granular porous materials that are poured into pipes, tanks, flasks. | Water passes through the absorbent material granules and contaminants accumulate on their surface. |

| Ultrafiltration systems | Filters equipped with membranes - materials with a pore size of up to 0.2 microns. | The membranes allow water to pass through, but retain high-molecular contaminants (99.9% of impurities). |

Disinfection equipment:

| Installation | What is | Principle of operation |

| Ozonizers | Electrical installations with long hoses. The devices generate ozone, which penetrates into the water through tubes. | Ozone oxidizes lipids and lipoproteins of the bacterial cell wall. This leads to structural changes that are incompatible with cell life. |

| UV disinfectants | Devices equipped with several lamps. They are immersed in water and there they emit UV rays. | The lamps generate waves with a length of 200-280 nm. They destroy the genetic apparatus of harmful bacteria and viruses, which prevents them from reproducing. |

Physical filtration

Physical filtration methods help remove most types of chemical pollutants and pathogens from wastewater.

Magnetic processing

Magnetic influence activates the processes of crystallization of salts that form scale. With this treatment, the level of magnesium and calcium ions in the wastewater is reduced. These substances precipitate. In wastewater that has undergone such treatment, the content of organic compounds is reduced, incl. paraffins.

Scheme of wastewater treatment using magnetic influence.

Electromagnetic processing

With simple magnetic treatment, impurities from the water settle out in about a day. Then this process stops. With electromagnetic filtration, cleaning lasts up to 3-5 days.

Ultrasonic and ultraviolet treatment

These methods help eliminate bacteria, fungi and other harmful microorganisms.

Under the influence of ultrasound, many small bubbles containing heated gas are formed in the drains. When these elements burst, a strong pressure drop occurs, destroying the cell membrane of the microbes.

Exposure to ultraviolet light disinfects water well. Intense rays penetrate into the shell of microorganisms, destroying DNA. After such exposure, the pathogenic microflora stops multiplying and quickly dies.

Method for treating wastewater using ultrasound and ultraviolet light.

Ionizing radiation

Exposure of wastewater to ions neutralizes most types of toxins and poisons. In addition, this method helps to suppress the activity of pathogenic microorganisms. With this treatment, it is possible to eliminate up to 99% of toxic impurities.

Stages of contaminant extraction

There are 3 degrees of extraction of contaminants from wastewater:

- Primary – removal of debris, coarse impurities, surface contaminants and suspended solids.

- Secondary – decomposition of organic waste.

- Tertiary (additional treatment) – extraction of suspended and colloidal particles, pesticides, fungicides, precipitation of phosphorus and nitrogen residues, reduction of COD. Indicators are brought to the standards of ODU or MPC.

At these stages, the following methods are used:

- Mechanical - the use of stationary or mobile filter units: coarse filters, sedimentation tanks, surface contaminant traps. After mechanical cleaning, the amount of contaminants in wastewater is reduced by 30-60%.

- Biological – cleaning using living microorganisms: bacteria, fungi, protozoa. Microorganisms use organic matter as food and convert it into safe biogas, methane and water. Biological methods eliminate 92-96% of contaminants.

- Physico-chemical – purification of wastewater from dissolved impurities and suspended solids using the laws of physics and chemical reagents. 96-98% of fine particles are removed from water.

- Disinfection – destruction of pathogenic bacteria and viruses. According to regulations, wastewater must not contain pathogens, so the efficiency of disinfection reaches 99.9%.

To clean gasoline, fuel oil, kerosene, and petroleum oils, oil traps and porous sorbents are most actively used:

- Activated carbon;

- Clays;

- Coke;

- Peat;

- Ash;

- Silica gels.

Reference. The maximum permissible concentration of petroleum products in wastewater does not exceed 0.01-0.3 mg/l. Such small values are due to the toxicity of the compounds to living organisms.

Chemical cleaning methods

Reagents are used to bind and remove dissolved chemicals from wastewater, which can negatively affect the overall environmental background.

Oxidation and reduction

The use of oxidizing reagents is indicated for removing zinc, copper, cyanide, hydrogen sulfide and sulfide ions from liquids. The most commonly used are fluorine, chlorine, potassium permanganate, hydrogen peroxide, etc. This cleaning option is not used at all stations, because it is expensive.

Ozonation

Ozonation is used to remove dangerous impurities such as arsenic, chromium, mercury, etc. The water in a special installation is saturated with ozone molecules that bind to dangerous compounds, causing them to precipitate. This is an extremely effective method of removing impurities.

Wastewater treatment by ozonation.

Neutralization

This method is used to remove alkalis and acids from water. Often special reagents are used to remove impurities, incl. soda, dolomite, lime milk, etc.

Precipitation

During sedimentation, special reagents are introduced into the wastewater, which, settling to the bottom, capture pollutants in their crystalline structure. The method is used less and less, because As a result of its use, a lot of sludge is generated. In addition, the content of salts and toxins in the water increases.

TREATMENT PLANT FOR THE CITY

The consumption of wastewater entering treatment directly depends on the number of residents, i.e. The water disposal rate is equal to the water consumption rate. Large volumes of liquid require appropriate containers and reservoirs. This fact generates interest in the design and operation of treatment facilities such as BIOTOK M and BIOTOK R.

When designing sewer networks of a populated area, the load on the pipelines is taken into account, which are selected based on the throughput capacity of the required amount of flow. In order to avoid the complex and expensive installation of very large diameter collectors, several treatment stations are being built in large cities.

Thus, the metropolis is divided into several “cities” (districts), and for each of them its own treatment station is designed and built.

A clear example is the treatment plants in the capital of Russia, among which there are Lyubertsy with a capacity of 3 million m3/day (the largest in Europe) and many others. The main block of WWTP data is the old modernized OS, providing half of the station's capacity, the other two blocks are 1 million m3/day and 500 thousand. m3/day

The design features of such wastewater treatment plants are the increased size of the structures compared to wastewater treatment plants in other cities: settling tanks with a diameter of 54 meters, and canals comparable to small rivers.

From a technology point of view, everything is standard: mechanical cleaning, sedimentation, biological treatment, secondary sedimentation, disinfection.

The only main feature is the type of structures for these stages of processing. For example, Moscow, as you know, was not built right away, but it has always been a great source for treatment facilities. Reinforced concrete structures were built, which today have undergone several reconstructions and modernizations. Due to a decrease in the amount of diluted clean water, some of the previously built structures are mothballed or used for other purposes. This is also a feature of the OS design: the old sand trap channels become an intermediate reservoir, the aeration tank corridor is transformed and works a little differently.

And if previously the wastewater treatment plant was significantly removed from the city, now it is located near new residential complexes.

For the same reason, sprayers are installed on such wastewater treatment plants, which release special substances that neutralize waste odors.

Other cleaning methods

Nowadays, aerobic and anaerobic microbes are actively used to eliminate pollutants from wastewater. In addition, hyperfiltration and electrochemical purification are increasingly used.

Anaerobic

This treatment uses anaerobic bacteria that do not require oxygen to function. The method is the least expensive, because no need to pump air into the container. This reduces the cost of removing pollutants from wastewater. The use of such microorganisms helps remove up to 85% of impurities.

Cleaning method using anaerobic microorganisms.

Aerobic

This cleaning method uses special bacteria that feed on pollutants. Often 2-stage systems are installed. In the first phase, the sludge mixture is recycled in a cylindrical container and the biocenosis increases. Mixers and air injection devices are installed here. In the next phase, sediment accumulates in the cone-shaped bottom. Here organic compounds are further oxidized.

The use of aerobic bacteria helps eliminate up to 99% of impurities.

Hyperfiltration

Hyperfiltration is also called reverse osmosis. This is a highly effective cleaning method. In this case, high-pressure wastewater is passed through a membrane containing micropores. Only water molecules pass through the filter. The resulting liquid has similar properties to the distillate.

Water purification technology using hyperfiltration.

Electrochemical cleaning

This method involves passing an electric current through waste water. Both insoluble and soluble electrodes can be used. Under the influence of current, crystallization of many types of impurities occurs. Then they precipitate. By electrolysis, residues of petroleum products, fats, etc. can be eliminated.

Read more about cleaning different types of wastewater

There are recommendations regarding the purification of domestic, surface and industrial wastewater. These types of waste water have different compositions of chemical pollutants. You can view completed water purification projects at enterprises from the KVANTA+ company here.

Industrial

Industrial wastewater must be treated separately, because their discharge into the general system will lead to overloading of city structures. The technological scheme for removing contaminants from waste water depends on the characteristics of the impurities. Some effluents may contain high levels of organic compounds, while others may contain heavy metals. The technology for purifying liquids to recommended values is selected taking into account the composition of contaminants.

The technology for industrial wastewater treatment differs depending on the composition of the wastewater.

Household

Domestic wastewater contains a high presence of mineral and organic compounds.

More often, biological cleaning methods, as well as special reagents, are used to eliminate pollutants.

Superficial

Surface water refers to liquid that enters storm drains. Such wastewater is considered to be precipitation, melted snow, etc. Water must flow into the sump. Solid particles washed away by precipitation will precipitate. After this, the effluent must be treated in a flotator to remove traces of petroleum products. Lastly, final cleaning is carried out using sorption filters. Only after this can the wastewater be returned to the natural reservoir.

1. Industrial wastewater can be accepted into the sewerage system, which does not cause disruption to the operation of sewer networks and structures, ensures the safety of their operation and can be purified together with city wastewater to the requirements and standards that satisfy the “Rules for the protection of surface waters from wastewater pollution.” waters"2. It is prohibited to discharge industrial wastewater containing:

- substances that can clog pipes, wells, gratings or deposit on the walls of pipes, wells, gratings (scale, lime, sand, gypsum, metal shavings, hide, cane, etc.);

— substances that have a destructive effect on the material of pipes and elements of sewerage structures;

— substances that impair wastewater treatment; — dangerous bacterial contaminants;

— radioactive substances;

— insoluble oils, resins, fuel oil;

— biological difficult-to-oxidize organic substances;

— biological “hard” surfactants;

— only mineral substances (including water from water treatment plants at thermal power plants and boiler houses);

- substances for which maximum limits have not been established

— permissible concentrations (MPC) in water of economic water bodies

— drinking, cultural, domestic and fishery water use. 3. It is strictly prohibited to discharge into the sewerage system:

- acids;

- flammable mixtures;

- toxic and soluble gaseous substances (in particular, solvents, gasoline, diethyl ether, dichloromethane, benzene, etc.) capable of forming toxic gases (hydrogen sulfide, carbon monoxide, hydrocyanic acids, vapors of highly volatile aromatic hydrocarbons, etc.) in sewer networks and structures .);

— explosive and toxic mixtures.

4. Industrial wastewater that has:

— COD is more than 2.5 times higher than BOD5 or total BOD. more than 1.5 times;

— concentrated mother and still solutions;

— volley discharges of industrial wastewater. A salvo discharge is considered to be the discharge of harmful substances into the sewer system of one or more substances regulated by these Rules in concentrations exceeding the MPC by 100 times or more;

— sediments from local treatment facilities, soil, construction and household waste, industrial waste;

— drainage and regulatory

— clean industrial wastewater;

— surface runoff from the territories of industrial sites (rain, melt, irrigation water, etc.).

5. In the water disposal systems of subscribers, it is not allowed to combine industrial wastewater, the interaction of which can lead to the formation of emulsions, toxic or explosive gases, as well as large amounts of insoluble substances (for example, wastewater containing calcium or magnesium salts, or alkaline solutions; soda and acidic waters; sulfates and waters with excessive acid content; sodium sulfide and waters with excessive alkali content; chlorine and phenol, etc.

6. Discharge of industrial wastewater into the sewer system must be carried out through independent outlets with a control well installed outside the territory of the enterprise. Sampling is carried out by employees of the Municipal Unitary Enterprise "UVKH" together with the subscriber's representative.

7. Industrial wastewater can be accepted into the sewer system if the content of harmful substances in it does not exceed the values specified in Appendix No. 1. The MPC of substances not listed in Appendix No. 1 when discharged into the sewer system should be taken as the corresponding MPC in the water of fishery reservoirs water use.

8. Maximum permissible concentrations of harmful substances for industrial wastewater specified in Appendix No. 1 are determined taking into account:

— MPC of pollutants in the water of water bodies used for fishing purposes, according to clause 19 of the “Rules for the Protection of Surface Waters,” 1991;

— conditions for the discharge of treated wastewater into the river. Ryazanka after sewage treatment plants;

— efficiency of removal of pollutants from industrial wastewater at sewage treatment plants;

— the ratio of the volumes of urban and industrial wastewater entering sewerage treatment plants;

— the possibility of using sludge from sewage treatment plants as fertilizer.

According to the requirement of Art. 27 of the Federal Law of December 7, 2011 No. 416-FZ “On Water Supply and Wastewater Disposal” in order to prevent negative impacts on the environment for the facilities of subscribers of the organization engaged in wastewater disposal, the categories of which are determined by Decree of the Government of the Russian Federation of March 18, 2013 No. 230, standards for permissible discharges of pollutants, other substances and microorganisms are established (hereinafter referred to as standards for permissible discharges of subscribers), as well as limits for discharges of pollutants, other substances and microorganisms.

Calculation of standards for permissible discharges of pollutants is carried out in accordance with the Methodology for developing standards for permissible discharges of substances and microorganisms into water bodies for water users, approved by Order of the Ministry of Natural Resources of Russia dated December 17, 2007 No. 333.

Information necessary for calculating VAT for subscribers, provided by the organization providing wastewater disposal:

Standards for permissible discharges of substances and microorganisms into the river. Ryazanka (VAT) for the municipal unitary enterprise "UVKH" were approved by the Water Resources Department of the Upper Volga Water Resources Management Institution in the Nizhny Novgorod Region dated July 2, 2014 No. 12-10/1370 for a period of 5 years.

According to the classification, the sewer networks of the municipal unitary enterprise "UVKH" belong to centralized household wastewater systems. Permissible concentrations of pollutants and other substances (Срс) in wastewater entering the wastewater systems of the organization carrying out wastewater disposal are given in Appendix 1. Concentrations of pollutants in wastewater from housing facilities (Szh) are presented in Appendix 2.

The annual consumption of wastewater (Q) entering the treatment facilities of the municipal unitary enterprise "UVKH", necessary for calculating VAT, is 2,355.3 thousand cubic meters. m, of which:

— annual wastewater consumption of subscribers not related to the housing stock (Qpr) — 1,436.7 thousand cubic meters. m.; - annual wastewater consumption from housing facilities, (Ql) - 918.6 thousand cubic meters. m.

What problems may arise

Most often, after passing through all stages of filtration, water remains quite heavily contaminated. This problem is especially acute in Russia. This is due to wear and tear and obsolescence of equipment designed to remove impurities.

In addition, professional cleaning devices are extremely expensive, so most regions cannot purchase them. Thus, ultraviolet disinfectants are installed only in a few large cities of Russia. Some wastewater treatment plants are underfunded, so in order to save energy and reagents, they do not carry out all the necessary stages of waste treatment.

Many enterprises are equipped with outdated treatment equipment, so they discharge rather polluted wastewater into rivers and lakes. Often producers do not want to invest money in installing the necessary equipment or pay for disposal at special enterprises, so they dump their waste into rivers. Fines for damage to the environment are relatively low, so they do not deter violators.