The operation of pumping equipment in an autonomous water supply system is regulated by special automation. One of the main parts that controls network parameters is the pressure switch. This device has factory settings that determine the lowest and highest limits at which the pump turns on. If it is necessary to change the indicators, the pressure switch of the pumping station is adjusted. This operation does not require the involvement of specialists; knowing the setup rules, it can be carried out independently.

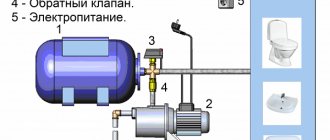

Water supply network with relay

Pumping station design

Factory-made pumping stations are fully equipped by the manufacturer and ready for use. Their main purpose is forced water supply. To understand how to set up a pumping station, you need to know its structure.

Such mechanisms operate according to a fairly simple scheme. Inside the accumulator there is an elastic container into which water is supplied using a pump. Filling the tank with water puts pressure on another part of the hydraulic tank filled with air or gas. When the pressure reaches the set values, the pump turns off. Taking water from the storage tank leads to a decrease in pressure in the system and when the minimum value is reached, the pump turns on again.

To turn the pump on and off, the equipment is equipped with a special pressure regulator for the pumping station. The owner can control the pressure level according to the readings of the pressure gauge, also installed on the equipment.

When does automation need to be reconfigured?

There are various reasons why a pump may not deliver the required value. Let's briefly list the most common ones:

- the equipment operates at a large suction depth and cannot achieve the required water supply;

- wear of the pump impeller, cannot drive water to the required force;

- increased wear of sealing seals, air leaks;

- the need to supply water with high pressure to a multi-story building or a highly located storage tank;

- mechanisms that consume water require more pressure.

In these and other similar cases, you will need to change the factory settings.

Main problems and causes

Various factors can damage a household pumping station, including damage to the integrity of the hydraulic tank or pipes, leakage of water or air, and the entry of various impurities into the system.

You can intervene in the operation of the pumping station in the event of problems with its operation in the following cases:

- Sand or other impurities have entered the system. This may cause corrosion and reduced performance. You can prevent clogging of the system by using various filter elements to purify water.

- Reduced air pressure in the system. This phenomenon leads to frequent operation of the pump and a decrease in its service life. Regular measurement of air pressure and setting up a pumping station if necessary helps to avoid such troubles.

- Violation of the tightness of joints in the suction pipeline. As a result, the engine is constantly running, but water is not pumped.

- Incorrect adjustment of the hydrophore causes a lot of inconvenience and can cause a malfunction of the pumping station.

Regular inspection and preventive maintenance ensure the service life of pumping equipment. It is important to remember that before adjusting the pressure at the pumping station, the pumping station must be disconnected from the power supply and the water drained.

Troubleshooting Methods

Troubleshooting jobs can be simple or complex. In the first case, it is enough to replace the cartridges in the filter and eliminate leaks. The second option involves taking further measures if simple measures do not produce results. In this case, it is important to know how to set up the hydrophore.

More complex troubleshooting steps for pumping equipment include adjusting the pressure in the hydraulic tank and adjusting the pressure switch. In this case, you need to know what pressure should be in the water supply station.

There are several problems with the operation of a household pumping station that you can try to fix yourself.

Is any setup necessary at all?

Of course, independently or with the help of a specialist, but anyone who has assembled their own pumping station from individual elements will need to set up a pressure switch.

There is an opinion that ready-made pumping stations, purchased assembled, are equipped with a pressure switch already configured and prepared for operation. In practice, this is not always the case.

Before connecting and setting the pressure switch, you should carefully study the technical documentation provided by the manufacturer to find out the maximum permissible pressure values

Each plumbing system has individual characteristics. And the needs of the residents of the house may be different.

A constant pressure system for a home with only a shower, kitchen sink and bathtub is significantly different from the needs of a spacious cottage with a Jacuzzi and hydromassage. Factory settings do not always correspond to the real state of affairs.

Pumping stations are usually already equipped with a pressure switch, but still, after connecting it, it will have to be configured for the needs of a specific water supply system

In addition to setting the pressure switch when installing a pumping station, you should also periodically check and adjust its operation.

The same operation will have to be repeated if any part of the pumping station fails, is repaired or replaced. The procedure for adjusting the equipment is practically no different from the procedure for setting it up.

Deviation from equipment operation requirements

Continuous operation of the equipment, without shutting down, is noted if the automation of the pumping station is configured incorrectly. In particular, we are talking about too high set pressure values. In addition, this occurs when the engine is idling, which is not accompanied by pumping water.

Such a deviation in performance may occur for the following reasons:

- The first start of the pump was carried out without filling with water. To solve the problem, you need to pour water into the pump using a special funnel and adjust the hydrophore.

- The pipeline is damaged or an air lock has formed in the suction valve. Such a problem can only be detected by checking the entire length of the pipeline for bends, narrowings or air pockets. Identified problems should be eliminated and damaged areas replaced.

- There is no access to water for operating equipment. The solution to the problem is to find the reasons for the lack of water and eliminate them.

- Blockage in the pipeline. Simply cleaning the pipeline and removing accumulated contaminants can help fix the problem.

If the station starts working and turns off after a short period of time, then the problem may be a damaged membrane. In this case, the membrane needs to be replaced. A similar situation can occur if there is no necessary pressure in the system. Here you need to take the appropriate measurements and check the hydraulic tank for cracks or other damage.

The situation with blocking the operation of the check valve occurs quite rarely. This occurs when debris or foreign objects enter the system. The situation can be corrected by disassembling the pipeline in the problem area and removing the blockage.

About idle speed protection

In some cases, water may not pass through the pump, but it will continue to work. This mode of operation of the device is extremely undesirable, as it significantly reduces the service life. However, this only applies to devices with a wet rotor, where water acts as a cooling and lubricating fluid.

Diagram of operation of a dry-running flow relay

To avoid equipment failure, it is necessary to install a relay that protects against dry operation. The contacts should open when there is no water and turn off the device. The engine of the device can only be started if there is a sufficient amount of water.

If water consumption from a well or well exceeds its supply, then idling cannot be avoided. In this regard, installing a water pressure switch for pumping stations will help cope with this situation.

Idle detection can be calculated using one of several values:

- pressure at the outlet pipe;

- water level;

- fluid flow through the device.

Helpful information! Protecting the device from idle operation in the water supply systems of country houses is necessary. Most often it is used in conjunction with other automation devices.

Engine malfunction

If during the inspection the engine stops and there is no characteristic noise, then we can talk about the following:

- There is no connection to the electrical network or the voltage is too low. The solution to the problem is to check the equipment connection diagram.

- Fuse blown. In this case, the element must be replaced.

- The impeller is jammed. Difficult turning of the impeller indicates that it is jammed, so first of all you need to find out what caused this situation.

- Damaged relay. The solution to such a malfunction will be to adjust the relay or completely replace it, for which you need to know the design of the pressure switch at the pumping station.

Don’t think that engine problems can always be fixed on your own. In most cases, only specialists from the service center can solve problems.

Some tips and tricks

For normal functioning of the pumping station, it is recommended to measure the air pressure in the hydraulic accumulator every three months. This measure will help maintain stable settings in the operation of the equipment. A sharp change in indicators may indicate some kind of breakdown that needs to be fixed.

In order to quickly monitor the condition of the system, it makes sense to simply record the readings of the water pressure gauge from time to time when turning the pump on and off. If they correspond to the numbers set when setting up the equipment, the system can be considered normal.

A noticeable difference indicates that you need to check the air pressure in the hydraulic tank and, possibly, reconfigure the pressure switch. Sometimes you just need to pump a little air into the accumulator, and the performance will return to normal.

The accuracy of the pressure gauge indicators has a certain error. This may be partly due to the friction of its moving parts during measurements. To improve the reading process, it is recommended to additionally lubricate the pressure gauge before starting measurements.

The pressure switch, like other mechanisms, tends to wear out over time. Initially, you should choose a durable product. An important factor in the long-term operation of the pressure switch is the correct settings. This device should not be used at the maximum permissible upper pressure values.

If problems and inaccuracies appear in the operation of the pressure switch, it may need to be disassembled and cleaned of contaminants.

You should leave a small margin, then the elements of the device will not wear out so quickly. If it is necessary to set the upper pressure in the system at a sufficiently high level, for example, five atmospheres, it is better to purchase a relay with a maximum permissible operating value of six atmospheres. Finding such a model is more difficult, but it is quite possible.

Serious damage to the pressure switch can be caused by contaminants in the water pipes. This is a typical situation for old water pipelines made of metal structures.

Before installing the pumping station, it is recommended to thoroughly clean the water supply system. It wouldn’t hurt to completely replace metal pipes with plastic structures, if possible.

When adjusting the relay, the adjusting springs should be treated with extreme care. If they are compressed too much, e.g. are twisted during the setup process, errors will very soon begin to be observed during operation of the device. Relay failure in the near future is almost guaranteed.

If, while checking the operation of the pumping station, a gradual increase in shutdown pressure is observed, this may indicate that the device is clogged. You don't need to change it right away.

You need to unscrew the four mounting bolts on the pressure relay housing, remove the membrane assembly and thoroughly rinse the inside of the relay, where possible, as well as all small holes.

Sometimes it is enough to simply remove the relay and clean its holes on the outside without disassembling it. It also wouldn't hurt to clean the entire pumping station. If water suddenly begins to flow directly from the relay housing, it means that particles of contaminants have broken through the membrane. In this case, the device will have to be completely replaced.

Insufficient water pressure in the system

Problems with water pressure can arise due to incorrect adjustment of the automation of the pumping station, but most often this occurs in the following cases:

- When configuring the system operation, values were set below the recommended minimum parameters. The problem can be solved by simply adjusting the pressure regulator of the pumping station in accordance with the instructions).

- Blockage of the pipeline or pump impeller due to accumulated contaminants. The malfunction can be eliminated by cleaning the elements of the pumping equipment.

- Air penetration into the pipeline. After checking the tightness of connections and pipeline elements, the problem almost always becomes irrelevant. In rare cases, major intervention may be required.

Sometimes you may encounter a situation where poor sealing of water pipes causes air to be drawn in by the pump. A similar situation occurs when the water level is too low, which leads to air being pumped into the system when water is drawn in.

Need to know

When setting high pressure, the suction equipment is turned on much more often, which leads to accelerated wear of the main parts. However, this pressure allows you to use even a shower cabin with hydromassage without any difficulties.

A visual diagram of supplying a residential building with water from a well

At low pressure, the device supplying liquid from a well or borehole wears out less, but in this case you will have to be content with an ordinary bath. It is unlikely that you will be able to appreciate all the delights of a jacuzzi and other devices that require fairly strong pressure.

Thus, the choice must be made depending on the goals being pursued. Everyone decides for themselves what to prefer in a particular case.

Why is a hydraulic tank needed in the system?

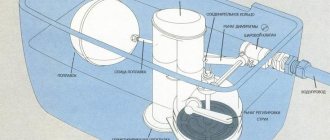

The membrane tank is a metal container, inside of which there is a rubber bulb for collecting water. During operation, the space between the rubber bulb and the walls of the storage tank is filled with air.

In some models of pumping equipment, the hydraulic tank consists of two compartments separated by a membrane. One compartment is filled with water, air is pumped into the other compartment.

An increase in the volume of water in the device leads to an increase in air pressure, which pushes water out of the storage tank. This operating system maintains constant water pressure even when the pump is stopped.

The hydraulic tank requires constant inspection and maintenance; in particular, it is recommended to regularly remove air from the bulb. The fact is that along with water, tiny air bubbles can get into it, which gradually accumulate inside the pear. As a result, the useful volume inside it begins to decrease. Air bubbles are removed through a special valve, which can be located in the upper part of a large hydraulic accumulator. If the container is small, then you need to disconnect the equipment from the power supply and drain the water several times and refill it again.

Air pressure control

At one of the stages of production of a pumping station, all its constituent elements are adjusted, including adjustment of the water pressure switch. However, after purchasing equipment in a store, it is necessary to recheck the pressure, since in most cases there is a decrease in air pressure in the interval between leaving the production line and direct sale. During operation, pressure indicators are monitored approximately twice a year. In such a situation, it is important to know how to set up automation at the pumping station.

You can measure pressure using a pressure gauge, but it is recommended to use the most accurate measuring instruments. The fact is that a deviation from the specified parameters even by 0.5 bar can negatively affect the operation of the equipment. The most reliable results can be obtained by using a car pressure gauge, which has a scale with the smallest graduation and a pressure sensor at the pumping station.

The air pressure in the membrane tank depends on the switch-on pressure values set using the relay and is 0.9 of it. In addition, in tanks with different volumes the air pressure can be 1-2 bar. The indicator is adjusted by means of a nipple through which air is pumped in or released.

A smaller amount of air in the system allows you to fill the container with water more, while the more water, the stronger the pressure. Accordingly, as water is withdrawn, the pressure will gradually decrease. If this factor is not significant for the consumer, then it is quite possible to set the lowest pressure value in the water supply station. However, the air pressure should not be less than 1 bar. Otherwise, the bulb filled with water will constantly rub against the walls of the tank, which may cause damage.

If water supply under high pressure is required, then the pressure value when adjusting the water pressure switch in the water supply system must be set within 1.5 bar. In this case, a more even and strong flow of water is ensured.

What characteristics should be changed?

A simple control unit has two variable characteristics:

- The first, pump start pressure (P), is the lower limit at which the pump starts.

- The second is the delta (ΔP) pressure between the start point and the upper cutoff at which the pump stops.

It is worth noting a feature of all mechanical relays. If you adjust the lower start limit, the upper limit will also adjust by the same amount. Here is an example, at 1.5 atmospheres of start and 3.0 stops, increasing the pump starting force to 2.0 atm, the upper cut-off will increase to 3.5 atm.

However, when adjusting the delta (ΔР), setting the pump shut-off pressure, the pump starting force will remain the same.

Example: at 1.5 atm. and 3.0 atm., ΔР equals 1.5 atm. By reducing ΔР to 1.0 atm, the upper cutoff will become 2.5 atm. The launch point will remain the same, 1.5 atm.

Knowing this feature of the relay, when rebuilding the upper cutoff of the pump, it is enough to adjust ΔР , that is, perform 1 alteration.

But when you adjust the lower start pressure limit, the upper stop cutoff will change. It may also need to be adjusted. That is, you need to perform 2 settings.

When changing the settings, you should know that the pump cutoff should be 0.3 - 0.5 bar lower than the maximum pressure level that the pump can create. This pressure level must be written in the manual (instructions) for the pump.

For example, with a maximum pressure of 55 meters that the pump can reach, the cutoff should be no higher than 5.0 - 5.2 bar . Otherwise, the pump will work for a long time without turning off, trying to reach the maximum set level. This will lead to premature wear and increased energy consumption.

The ΔP value affects another parameter - how often the pump will turn on. The higher the delta, the less frequently the pump will start and the longer it will last.

But you shouldn’t set too big a difference either, otherwise the pump will pump longer, after the water flow stops, until it can raise the pressure to the set level. In addition, using tap water at high pressure is not convenient.

Below is a table for possible situations that require adjusting the regulator and which springs should be readjusted:

| Situation | Adjustable points | Rework option |

| The pump runs for a long time without stopping | The upper pump stop cut-off should be changed. | 1st: lower ΔP (the starting point will remain the same), the pump will turn on more often 2nd: lower P, the cutoff will also decrease |

| Water flows weakly from the tap | The start pressure should be increased and the cut-out pressure should be maintained. | Compress spring P, weaken spring ΔP, returning to its previous value |

| Increase overall pressure | The cut-in pressure should be increased | Compress spring P, the cutoff will also become higher, you may need to reduce it |

| Reduce overall pressure | The starting pressure should be reduced | Loosen spring P, the upper cutoff will also decrease |

| The pump starts often, you need to do it less often | The cut-out pressure should be increased | Compress the spring ΔР, without exceeding the maximum pressure (95% of the pump pressure) |

Relay operating principle

The main element of the pressure switch can be called a group of contacts mounted on a metal base. It is this part that turns the device on and off. A large and small spring is located next to the contacts; they regulate the pressure inside the system and help in deciding how to increase the water pressure in the pumping station. A membrane cover is attached to the lower part of the metal base; under it you can directly see the membrane and the metal piston. The entire structure is covered by a plastic cap.

To understand how to properly set up a pumping station, you need to know that the pressure switch works according to the following scheme:

- When you open the tap, water from the storage tank flows to the collection point. In the process of emptying the container, the pressure begins to gradually decrease, and accordingly, the degree of pressure of the membrane on the piston decreases. The contacts close and the pump starts working.

- While the pump is operating, the taps at the dispensing points can be open, at which time water is supplied to the consumer. When the tap is closed, the hydraulic tank begins to fill with water.

- An increase in the water level in the tank leads to increased pressure in the system, which begins to put pressure on the membrane. It begins to put pressure on the piston, which opens the contacts and stops the pump.

A properly adjusted water pump pressure regulator ensures normal frequency of switching on and off of the pumping station, normal water pressure and equipment service life. Incorrectly set parameters cause continuous operation of the pump or its complete stop.

How to properly adjust the relay and calculate pressure

All devices leave the production line with certain settings, but additional testing must be performed after purchase. When purchasing, you need to find out from the seller what values the manufacturer recommends using when adjusting the depth pressure. In other words, the pressure at which contacts close and open.

If the station fails due to improper adjustment of the pressure switch of the jumbo pumping station, then it will be impossible to take advantage of the manufacturer's warranty.

When calculating the pressure parameters for turning the device on and off, the manufacturer takes into account the expected operating conditions. When developing the operating parameters of various pump models, operating conditions are also taken into account.

Terms used when adjusting pressure switches

In the process of setting the pressure switch and adjusting the water pump, specific type names may be used that are understandable to a qualified technician. As for the average consumer, he may encounter some difficulties. For this reason, you should familiarize yourself with certain concepts to ensure the setup process goes smoothly.

In particular, we are talking about the following terms:

- Switch-on pressure

. This term is denoted by the index Rvkl, sometimes it can be called upper pressure. Already by the name you can determine that it indicates the pressure at which the pump resumes or begins to function, and water is supplied to the hydraulic tank. By default, the manufacturer specifies a value of 1.5 bar. - Shutdown pressure

. The index Poff is used for designation and is called lower pressure. The relay from the manufacturer indicates a value of about 3 bar. - Pressure drop

. This term is used to indicate the difference between the lower and upper pressure readings. In standard models with factory settings, this indicator is approximately 1.5 bar. - Maximum cut-out pressure

. The name of this term already indicates the maximum permissible pressure value in the pumping system and water supply. Deviation to a large extent can cause damage to the plumbing system and pumping equipment. By default, the manufacturer indicates a value of no more than 5 bar.

How to set recommended settings

Before setting up a water supply station, you need to measure and record the current values, for which you need to use a pressure gauge. Turn on the pump and record the pressure readings when it is turned on and off. Based on the results, they determine whether to increase or decrease the values when deciding how to adjust the deep-well pump.

The pressure setting of the pumping station is carried out as follows:

- Disconnect the pump from the power supply, drain the water and use a wrench to remove the relay cover.

- To adjust the activation pressure, you need to rotate the nut holding the large spring. When twisting it clockwise, the spring begins to compress and the required switching pressure is established. Various models can have an operating pressure of the pumping station in the range of 1.1-2.2 bar.

- By rotating the small spring nut clockwise, you can increase the difference between the cut-in and cut-out pressures. In most cases, this gap is equivalent to 1 bar. You need to know this before increasing the pressure in the pumping station. As a result, the shutdown pressure is fixed at a value in the range of 2.2-3.3 bar.

It is very important to understand that you cannot set the shutdown threshold by adjusting the small spring. Although many home craftsmen insist on this version. Using a small spring, the difference between the switch-on pressure value and the station switch-off pressure value is established. With the spring completely relaxed, the difference will be zero and the on and off values will be equal. As the spring is tightened, the delta between values gradually increases.

To check whether the water pressure switch has been adjusted correctly with your own hands, you need to measure the pressure using a pressure gauge. If after checking the recommended values are not obtained, then adjustment should be continued.

Prices for some models

In fact, you can buy a water pressure switch for a pump for a relatively small amount of money. The table shows prices for popular models from well-known manufacturers.

Relay Caliber RD-5 presented

| Image | Manufacturer and model | Price in rubles |

| Belamos PS-02 | 540 | |

| Caliber RD-5 | 490 | |

| Danfoss KP1 | 1 570 | |

| Gilex RDM-5 | 900 |

The Gilex RDM-5 model is on display.

As for the prices for electronic water pressure switches for pumps, they are approximately 2-3 times higher than for mechanical analogues. Such devices make it possible to more accurately adjust the operating range. In addition, they protect shut-off valves from possible water hammer.

Appearance of an electronic product with idle protection

Setting non-standard parameters

The pressure in the devices may differ from the manufacturer's recommendations. This situation arises when it is necessary to configure the equipment to the individual characteristics of the system, depending on the pressure in the water supply station.

If you increase the difference between the on and off pressure values, the relay will operate much less frequently. This allows you to extend the life of the pumping station, but the water pressure will be inconsistent.

If water supply under high pressure is required, then the delta pressure values must be reduced.

This will cause the pump to turn on more often. When independently deciding how to adjust the pumping station, you must remember that deviations from the values recommended by the manufacturer can negatively affect the operation of the water supply system. The fact is that all components of the pumping station operate at certain pressure values, violation of which can cause equipment failure. Therefore, before you set up the automation on the pump yourself, you need to get advice from an experienced specialist.

Consequences of not making the necessary adjustments

If the pump operates within the range of modes recommended by the instructions, then there will be no serious consequences for it . Users may only experience some inconvenience due to too high or low pressure.

If the station operates outside the established recommendations, for example, does not turn off for a long time or is turned on very often, in this case the station experiences increased loads, which will lead to premature wear of the impeller and the electrical part of the installation. The pump will not last long and will break prematurely.