Pumping station: how it works

There is no equipment that never breaks down, and pumping stations - even if they are from the most famous manufacturers - are no exception. What is very pleasing is that the causes of malfunctions are often not in the pump itself, and problems can be eliminated quite easily. What are they expressed in, and for what reasons do they arise?

Our short instructions will tell you about this. And after watching the video in this article, you will find the answer to the question: “What to do if the water supply pumping station does not work?”

Reasons for jerking

Manifestations also vary. This is when the water from the tap comes out in jerks or when there is a surge in the pressure created by the pump when sucking liquid from a well or well.

Most often, this situation occurs because:

- An air lock has formed in the pipeline. As a result, the pumping station works to push it through, and periodically this succeeds, but as soon as the pressure breaks through, the pressure drops, and the pump is forced to pump up pressure in the system again.

- The pressure switch has failed. The pressure gauge shows correctly, but the pump does not turn on and off in a timely manner. This is due to an underestimated upper limit or an overestimated lower threshold.

- The system has depressurized. This could be a hole in the pipeline, an insufficiently tight connection, poor-quality shut-off valves, or damage to the working chamber of the pump, as well as failure of its mechanical components.

In each case, repairs must be made. A preliminary audit is carried out in order to identify the true cause. If there are no visible consequences, you have to go through the entire chain from the well to the consumer.

Water from the tap comes out in jerks (jumps) with air - why?

Water from the tap comes out in jerks (jumps) with air - why?

This happens after the water is turned off and water pipes (networks) are repaired.

Air has entered the system, the water flows in jerks, jerks, and the same air comes out with a hiss.

The simplest, but not the most correct option for a particular user, is to remove the aerator

When the pressure is working, the air will leave the system, the hissing and jerking will stop.

And this is not the right option, because the user “runs” through his water meters, through filters, and if he has fine filters installed, then after this “run” of rusty water, cartridges and filter fillers will have to be changed.

Do nothing, wait until the neighbors on the riser above and below drive the rusty water through their taps and mixers, meters, filters.

All you have to do is unscrew the coarse filter mesh, wash it, put it back in place and that’s it.

Well, or take the “blow” on yourself, drive all this dirt through your pipes, filters, taps.

If after the main valves (on the risers of hot water supply and hot water supply) “American” valves are installed,

If the American ones are immediately after the riser (this also happens), before the main taps, then of course this option is not working.

In fact, in your question you gave the answer. Water from the tap comes with air since the system is aired. Most likely, repair work was carried out on the pipeline, as a result of which air entered the system. When water is supplied to the system, the water pushes out this air and it turns out that the water from the tap seems to come in spurts.

This often happens after stopping the water supply to the system and completely or partially draining it. After the supply is resumed, the air does not immediately leave the system - it is blown away by water pressure.

When we open the tap, we release air, which comes out much faster than water. Its place in the pipes is filled with water and it partially comes out mixed with air. The air in the system is not distributed evenly, often leaving “plugs” in the upper levels. It’s these air “plugs” that start spitting out when you open the tap, either air or water. To prevent this from happening after the water stops, just open the tap slightly to bleed out the air. The water runs steadily - you can use it.

Why does a well pump not supply water evenly?

There are many reasons:

The water level in the well has decreased.

The pump takes water, supplies it to the system - then it is left without water.

How to treat:

turn off the pump, install

dry running protection

, since operation without water will lead to pump failure.

Dry well

2. Malfunction of the pressure switch or automation unit.

If

relay

or the automation unit is acting up - the pump will behave extremely strangely.

How to treat:

replace or repair the pressure switch (automation unit).

Pressure switch PM5

Voltage surges in the network.

The pump will run unevenly.

How to treat:

install

Voltage regulator

.

Voltage regulator

Very low pressure in the accumulator (or none at all).

In this case, the pump will constantly turn on and off - accordingly, the water will be supplied in jerks.

How to treat:

adjust the pressure in the air cavity

hydraulic tank

.

Hydraulic accumulator device

The membrane in the hydraulic tank is torn.

A torn membrane and lack of air pressure in the hydraulic tank give the same symptom: the pump constantly turns on and off. There are two ways to check whether the membrane is intact.

By knocking on the tank body (dull sound - the tank is filled with water,

membrane

torn. Voiced – the membrane is intact). Or by pressing the nipple of the pumping unit. If air comes out, everything is fine with the membrane. If water appears, the membrane is torn.

How to treat:

replace the membrane.

Membrane torn

The water in the well has disappeared. What to do, what to do

The most reliable source of water outside the city is a well. Of course, the process of drilling for water takes longer than digging a well. However, the well is more productive and has a longer service life. But what to do if the water in the well suddenly disappears? This situation is not uncommon. Based on the technology of welded joining of casing pipes, rust can lead to elementary silting of a water well.

Why might the water disappear? There are not many options - this happens, as a rule, in two cases - either after a long break in the use of the well, or during intensive water intake. If the aquifer is thin, then your neighbors’ new wells may simply be deprived of water.

In most cases, the easiest way is to drill a new water well. This, as a rule, pays off faster, and the probability of finding water is 100% (if you drill for limestone).

Is it still possible to restore the equipped well? Usually this is pumping with a stream of water (under pressure), this helps in small sand wells. A fire truck is a great alternative.

Here are a number of measures to restore silted water sources for a country house: directly cleaning the well, pumping under pressure, flushing with some special reagents.

I would like to stipulate in advance the high cost of well restoration work. Before starting, it is necessary to study the column (video filming of the wellbore). Next, the accumulated debris is removed. But whatever one may say, the silted water intake part of the well is the main reason for the lack of water.

A stream of water mixture is supplied from the machine through hoses. The pressure reaches 10-15 atmospheres, which makes it possible to quite effectively stimulate the flow of necessary water.

The “water hammer” method is extreme. An old water well can simply break in half.

One of the options for water loss in the autonomous water supply system of a country house is a pump breakage. Alas, saving on the quality of consumables (cable, fittings, adapter for HDPE pipe) leads to unexpected surprises and additional cash investments from the wallet of the owner of a country house.

The method of connecting casing pipes using welding is also common (used in the nineties of the last century). When ordering a new well, pay attention to the fastening methods; saving on this is extremely unjustified.

Possible problems with the source

The most common problems that can arise with a well and the presence of water in it are:

- Reducing the water level in the well (partial, periodic or permanent);

- Drying out of the well (meaning the complete drying of the well or a situation where water can quickly run out);

- The water supply to the water supply system is jerky.

It is important to remember: the occurrence of such problems can often be the result of improper drilling and source management. Therefore, it is always necessary to invite experienced professionals to carry out work.

Why does water come from a well with air and how to fix this problem

An autonomous water supply system from a well in a country house or on a summer cottage can solve many problems. Firstly, to make staying in nature comfortable, and secondly, to grow a rich harvest, since regular watering will no longer be a problem. Having many advantages, the pumping station requires not only proper installation and equipping with a filtration system, but also regular washing and preventive procedures. A common phenomenon: the supply of water from a source along with air.

Organizing the location of the pumping station

The selection of a hydraulic accumulator and pump is carried out in accordance with the user’s requirements and operating conditions. For each case and conditions, be it watering a garden, or supplying water to one- or two-story houses, you need to select a hydrophore of the appropriate type. The main differences between the types of this equipment are the pressure and pumping forces, and the terms of operation. If the house has a basement and it meets certain parameters, it is recommended to choose it for placing equipment. The main parameters of the room for installing the compressor:

- sufficient sound insulation;

- temperature from 5 to 25 degrees, all year round;

- floor slope, ventilation;

- area from 5 m, height from 2.2 m;

- the distance between the pumping station and the wall is from 0.6 m.

Schematic representation of options for placing pumping stations Source https://kanalizaciya1.ru

Some of these parameters can be adjusted: improve sound insulation, insulate the room, add heating, etc. But the easiest thing is to find a place that will require minimal correction. It is also possible to purchase a mini station and install it directly under the sink. The caveat is that mini versions of pumps may not have sufficient power. If it is impossible to properly organize the space to accommodate the station yourself, you will need the help of specialists.

Pump or pumping station

The main difference between a pump and a pumping station is the ability to automatically control water pressure in the water supply system. Full operation of the equipment is ensured by the presence of electrical power and a sufficient amount of water in the source used.

The pumping station is installed in a caissonSource https://i2.wp.com

Causes of breakdowns

Even if the operating instructions for the pumping station (hydrophore) are strictly followed, no one is immune from equipment breakdowns

Even if the operating instructions for the pumping station (hydrophore) are strictly followed, no one is immune from equipment breakdowns. Thus, any malfunctions in the operation of the station, from improper operation to complete shutdown, are most often caused by one of the listed reasons or a combination of them:

- no power is supplied to the station;

- there is no water in the system;

- breakdown of pumping equipment;

- malfunction of the membrane tank;

- breakdown of the automation unit, etc.

Since all pumping stations for water supply to a private home have a fairly simple and uncomplicated design, you can eliminate minor faults and breakdowns on your own. In some cases, it is enough to disassemble the hydrophore and replace the worn part, in others, sealing a crack in the hydraulic tank will help, and sometimes the hydrophore does not turn on due to lack of power.

If the causes of the breakdown are not known to you, and you cannot fix the problem yourself, you will have to contact a specialist. Next we will look at frequent breakdowns of the hydrophore for water supply to a private home, their causes and methods of elimination.

If the water level in the well drops

Scheme of groundwater levels

Do you use your well all year round and have never noticed a lack of water in your home before? Are you faced with a situation where the water in the well quickly runs out or periodically there is no water at all to the bottom level? Why did this happen? Let's look at possible causes and solutions to the problem. The main prerequisite for such source behavior may be:

- Natural change in geological conditions at the location of your well. That is, there is a displacement of the bottom of the formation from which you draw water).

- Changes in aquifers by season (most often in the summer the reservoir can decrease, in the cold season it can increase).

- Defects. allowed during the construction of the well or during its operation (here we mean an insufficiently deep well, lack of sealing of the rings, the appearance of cracks, an incorrectly selected filter, etc.).

- Silting of filters (if the well has not been used for a long time).

Operating principle of a pump with an expansion tank

A compressor with an expansion tank is considered to be an outdated model. Today, more modern and practical modifications of this type of equipment are available. The reason for this opinion was the design of the tank. Impracticality and cumbersomeness are the main characteristics of this device. The water level is controlled mechanically, thanks to a float.

The main disadvantages of the pump-tank system:

- Large tank sizes;

- Uncontrolled water level when the float breaks;

- Difficulties during installation;

- Water flows by gravity - low pressure;

- The tank should be well above the level of the pumping system.

Scheme of operation of a pumping station with a hydraulic accumulatorSource https://strojdvor.ru

Next step

You have checked the device for contamination and the electrical system, so why is the pump still not pumping water? Now inspect and thoroughly check the device itself. The pump has a filter device that may become clogged. In this case, clean it or replace it. This clogging problem can also occur with the check valve of the pumping station.

If everything is in order, then a more unfavorable option comes next. If the pump suddenly worked while there was no liquid in the tank, then the sensor inside the device could simply burn out due to overheating. In this case, you can’t do anything with your own hands. It is not even recommended to go to a specialist, because the water pump will no longer show as reliable a result as in the old days.

If the water is completely gone

This phenomenon often happens if your well is no longer new and has been in operation for more than three years. Often such a well, dug to the level of the high water, produces either a small volume of water over time, or the water in it runs out (dries up) completely. The reason is the work of the aquifer at two or more points or its drying out. In this case, you need to either make (drill) a new well (or better yet, an artesian well), or deepen the old one to a depth of more than 10 meters. The decision is made based on financial capabilities and the available area of the site.

Troubleshooting

Having made sure that there are no gusts on the route, and all connections are sealed, we can conclude that water from the well comes in jerks due to the breakdown of one of the units:

- Pressure switch. The correctness of the pressure gauge readings is checked, which must be replaced if necessary. To do this, you need to use another instrument, for example, a car tire pressure gauge. Instructions on how to configure the relay.

- Hydraulic tank. Damage may be to both the body and the diaphragm or bulb, depending on the type of structure. If, after pressing the nipple to bleed air, splashes fly from the exhaust pipe, then this is exactly the problem. The bulb or diaphragm must be replaced with a new one.

- Pump. Damage to the housing and depressurization of the working chamber are visible to the naked eye. But if the reason is the wear of mechanical components (shaft, bearings, wheels, blades), then you will have to disassemble the device and carefully inspect every detail. Dirt, silt, sand, clay are removed.

- Filter. Clogging of the coarse filtration unit can also lead to unstable operation of the pumping station. The mesh needs to be cleaned and replaced if necessary. The electrical part of the system is checked separately.

Voltage surges, breakdown of the control unit and other electrical problems can cause jerks in the operation of the pumping station. It is not recommended to carry out repairs on your own without specialized skills. It is worth contacting the service center.

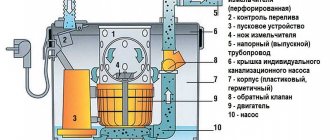

Construction of a surface pumping station

Surface stations are equipment for household water pumping, not of the submersible type, installed as close as possible to the well. As a rule, they operate from a regular electrical network. The main components of this type of pumping equipment:

- Surface (not submersible) pump;

- Water intake hose;

- Return block valve;

- mesh filter to protect the pump from contamination;

- pressure control relay to control the operation of the compressor;

- water sensor for insurance against dry running;

- pressure gauge

What to do when the warranty period has expired and the equipment has broken down? In this situation, two scenarios are possible. The first is calling a specialist. The second is self-repair. But, for him, you need to know the main faults and methods for eliminating them.

Surface pumping stationSource https://jeelex-pro.ru

How to protect the station from breakdowns

In order to never puzzle over why water flows unevenly through the pipes, it is enough to initially assemble the system correctly.

If the problem is already evident, then after the repair you need to check whether everything was done correctly at the stage of arranging the source. Thus, pipes and hoses should not be kinked or deformed, which leads to a decrease in throughput.

The system includes a check valve that prevents the reverse flow of liquid through the pipeline. Check whether the pump power is selected correctly. To do this, the calculation takes into account the depth of water in a well or well, the distance of the source from the house, and the number of consumers. The flow rate of the source cannot be less than the productivity specified in the technical passport for the pumping station.

Any leaky connection can cause air leaks, which causes interruptions in the water supply. And attempts to save money by excluding any of the nodes from the system always leads to the fact that it works inefficiently. But all this can be corrected if you select all the components correctly and install them in the right sequence. The procedure is simple if you approach the issue with due care.

Problems typical for centrifugal pumps

First of all, before the station is put into operation for the first time, the pump is filled with water. It is also necessary to bleed air through a plunger - a special device in the upper part of the body. When some of the air remains inside, there will either be no supply at all, or the pressure will be very weak.

In this case, the operation of the station is usually accompanied by unpleasant noise:

- A decrease in pressure below the nominal value also occurs due to clogging at any point in the suction system: pump wheel blades, filter mesh or supply pipeline. Usually installing a coarse filter on the suction hose helps to cope with this problem.

Preparing the station for operation: filling

- In general, if we think from the point of view of geometry, pressure can be considered the height of the rise of water, which is carried out due to the energy generated by the pump. And if this distance exceeds the capabilities of the unit, then even correct filling will not help it achieve rated performance.

- Simply put, if a station is designed to supply water from a depth of seven meters, then it makes no sense to install it on a ten-meter well. In addition, in such a situation, the phenomenon of cavitation (steam formation) may occur - and this has a detrimental effect on all working parts of the pump, especially on the impeller.

The temperature of the pumped liquid is also of great importance here. As it increases, the suction height, due to friction losses, decreases significantly.

How to protect the station from breakdown

The station's pressure indicators are monitored using pressure gauges installed on both the suction and supply pipelines. Deviations of their values in one direction or another indicate problems, the cause of which should be found out as quickly as possible.

- For the operation of the pump, it is very important that the shaft always maintains the specified direction of movement. To prevent it from unwinding in the opposite direction, a check valve is placed on the pressure pipe.

Check valve with strainer

- When installing the pipeline, it is necessary to make a slope towards the supply side. This will prevent air from entering the water flow. Also, to avoid this problem, the suction pipeline must be immersed in the liquid by at least 50-80 cm.

- The service life of a centrifugal pump largely depends on the smooth rotation of the shaft. If appropriate measures are not taken when runout occurs, all seals begin to wear out rapidly.

- The condition of bearings and seals depends mainly on the accuracy of alignment. But when it comes to a pumping station, you don’t have to worry about this, since its elements are centered by the manufacturer during the assembly process of the unit.

The main task of the station owner is to correctly calculate the diameter of the supply pipeline. Then excessive voltage will not be created in it, which as a result is transferred to the pump.

Malfunctions of pump protection systems

Typically, a properly assembled water supply system and high-quality pumps have devices that prevent them from operating in idle mode.

In the event of a malfunction of such protective devices: the well dry running relay and the float switches of the drains, well or sewage pump, the devices can operate in the absence of water.

Sometimes the float switch of well or drainage pumps, due to improper installation, does not fall along with a drop in the water level (it gets on a hillock or clings to a protruding object) - this leads to the electric pump operating in idling mode and its further failure.

Vibration pumps, which usually do not have external protective devices connected to the system, operating for a long time without water after its level drops, can fail in the absence of built-in thermal protection.

Case depressurization

Can a well completely run out of water, and what to do

? Connection diagram for a well pump.

The malfunction may be that the housing has become depressurized

When using the pump, it is important to ensure that the housing does not touch the walls of the well. During operation, the equipment vibrates, as a result, such touches can actually turn into serious impacts, the case will simply crack

This does not happen immediately; small cracks may appear at first, but gradually they grow. The impacts are usually not very strong, but there are about 100 of them per minute. This is enough to damage even a steel case.

It is possible to avoid depressurization, but to do this it is necessary to initially select the correct diameter of the equipment and install it in the well so that the body does not touch the walls of the barrel. You can help prevent severe crack expansion by performing regular preventive inspections. Failures can also occur if the equipment operates in dry mode, when the dynamic level drops.

Such a breakdown requires replacement of the winding.

Among the problems with the equipment, there may also be a malfunction such as exceeding productivity. Typically, a well is designed for a certain load, which cannot be exceeded. If this value changes, the well drains quickly, the pump begins to pump more and more sand, and gradually becomes clogged. In this case, there is more than one problem. The pump itself fails due to a large amount of sand that clogs the mechanism. And a well, if its productivity is exceeded, i.e. of the amount of water it can provide, it quickly dries out. The costs include not only repairing the pump, but also organizing a new well and deepening an existing one.

Submersible pumps have a reliable and durable design, but even they fail over time. Manufacturers today offer the most reliable deep-well pumps of various types, but their operating conditions suggest that individual components may gradually wear out and fail. This will require a stop and then replacement of parts. The causes of breakdowns may also relate to problems with the power supply; here everything is solved much easier, since the cause is most likely in insufficient voltage.

The equipment does not start

Most often, the unit does not turn on and does not draw water due to a break in the electrical network. To determine the location of the break in the circuit, you will have to use a tester

Most often, the unit does not turn on and does not draw water due to a break in the electrical network. To determine the location of the break in the circuit, you will have to use a tester. First of all, it is necessary to check the communications through which the pump pumps water, as well as the pressure switch, on the contacts of which oxide can accumulate and cause their malfunction. To clean the contacts, you can use fine-grained sandpaper or a needle file.

If the pump does not pump water and does not turn on, and no network breaks are found in the section from it to the source, then it is necessary to check each component of the pumping equipment, namely the winding and contacts.

Important: if the motor burns out, it can be restored by rewinding. However, in most cases you will have to buy new equipment, for example, a Marina unit.

Sometimes the pump does not draw water and does not start due to a broken starting capacitor. In this case, you will have to replace it yourself.

If, after starting the unit, a characteristic noise appears, but the impeller and other rotating parts do not begin to move, then there may be several reasons:

- If the device has been preserved for a long time and has not been used, then most likely the impeller is stuck to the body. To fix the problem, just rotate the impeller by hand several times.

- Sometimes the cause of this problem can be a broken capacitor. In this case, it will have to be replaced.

- If the parameters of the electrical network have changed, that is, the voltage is below the nominal voltage, then the unit will not work.

Video instructions for repairing pumping equipment for water supply to a country house:

Main types of faults and ways to eliminate them

Malfunctions of the pumping station and their elimination will not become a serious problem if the system is accurately diagnosed before starting work. In most cases, this does not require special equipment. The type of breakdown can be determined by external signs and with the help of elementary measurements, for which the devices installed in the system are used.

Pump rotation without pumping water

If the pump seems to be working properly at first glance, but there is no water in the tap at the same time, the way to correct the situation is determined by the cause of the problem. To detect it, you will have to check some parameters and operating conditions.

- Determine the condition and performance of the check valve , which is located inside the well or well. Debris or sand trapped in it can prevent it from opening, and a closed valve prevents fluid from rising to the pump.

- Check whether the section of pipeline between the pumping unit and the source is filled with water . Sometimes, due to equipment failure, power outages or other disturbances, this gap remains empty, which prevents the pump from pumping liquid. The discovered void can be filled through a special hole.

Pumping station in a house with a pipeline connected to it from a water source

- The most difficult situation is the presence of a large amount of insoluble impurities in water with an abrasive effect. Often, there is a large amount of wear between the housing and the impeller of the unit. “Out-of-work” water supply pumping stations for a private home require expensive repairs. In this case, it will be necessary to replace the equipment (casing and impeller, if you can find components identical to the existing ones on sale, or the entire pump).

- The lack of water in the well can also cause water to not enter the system when the pump is running. One of the simplest solutions is to immerse the supply hose or pipeline deeper (but within the limits specified in the operating instructions).

- jamming of the impeller due to its “sticking” to the body during long-term storage of the pumping unit without use (the situation can be corrected by moving the impeller from its place manually and turning it several times),

- capacitor failure (replace),

- change in the parameters of the supply network (voltage is significantly lower than the nominal voltage).

Jerk mode of pump operation

The jerk mode is the frequent switching on and off of the pumping unit in automatic mode.

In this case, you should start checking the system by determining the pressure in the air chamber of the accumulator. You can determine the pressure using a car pressure gauge. If it is low, try pumping air into the chamber. Wait a while and measure again. If the pressure drops again, look for and eliminate the place of depressurization . The easiest way is to eliminate depressurization of connections. If a hole has formed in the body (for example, due to corrosion), you can use “cold welding”.

If the pumping station operates jerkily, the reason may lie in damage to the diaphragm . To eliminate the defect, it must be replaced.

Frequent switching on and off may be the result of a malfunction of the pressure switch .

Pressure instability

If, when the pump is working properly, water comes out of the tap in pulsating jerks, it means that air is leaking . All communications between the well (well) and the pump should be checked for leaks. Particular attention must be paid to the water level in the source and the correspondence of the pipe diameter to the suction height. The smaller the diameter, the smaller the height should be. For example, a pipe diameter of 25 mm (or 1 inch) corresponds to a suction height of about 9 meters.

The pump runs without stopping

If the automatic shutdown of the pump does not work, such a water supply system cannot be operated. Emergency operation can lead to premature wear or destruction of equipment.

The reason for the non-stop operation of the pump is the incorrect operation of the pressure switch or its failure. In most cases, repairing a pumping station pressure switch comes down to adjusting the device and setting the on and off parameters using nuts on the springs under the device cover.

Pressure switch device - nut P is responsible for setting the lower pressure level in the accumulator, nut Δ P is responsible for setting the difference between the upper and lower pressure levels

Another possible violation is blocking of the relay by salt deposits when the quality of the water in the source is low. In this case, it is necessary to remove the relay and clean the hole that comes into contact with water.

The pump does not turn on

In most cases, failure to turn on the pump is associated with a break in the electrical circuit . A tester will be required to thoroughly check and detect the break. First of all, you should check the supply lines and pressure switches. In the latter case, pay attention to the condition of the contacts - a layer of oxide may form on them, which can be removed by cleaning using a needle file or fine-grained sandpaper.

If no breaks are found in the section from the source to the entrance to the pump, you will have to conduct a thorough check of all components of the pumping unit:

A burnt-out engine can be restored by rewinding, but in some cases it will be necessary to purchase a new unit.

To repair a pumping station with your own hands with such “symptoms”, you may also need to replace a failed starting capacitor .

If the rotating parts of the pump do not move when turned on, and a characteristic hum appears, then the reasons for this phenomenon may be:

Find out more about how to set up a pumping station pressure switch in our separate material.

On our website we have information about the technical characteristics of the Rucheek pump, which has long established itself as an inexpensive but effective unit.

Tips for choosing pumps for garden waterfalls and fountains can be found here. Types and main parameters.

Tips for trouble-free operation

For reliable operation, the pumping station requires proper installation. To guarantee long, trouble-free operation, you need to:

- install the pump on a flat, rigid platform or support that does not allow vibration;

- operate the station only at positive temperatures;

- avoid overheating in the area where the pump is located (temperatures above 40 degrees), for which purpose it is rational to provide a blowing or ventilation system;

- use only pipes of the diameter recommended in the documentation for supplying and discharging water, so that the pump can show its declared characteristics;

- do not allow pipes to bend;

- provide a drainage system for emergency drainage, as well as pipes for pouring water into the supply circuit.

If water is drawn from a shallow well by a surface pump, measures must be taken to ensure that the turbine impeller is always in the water. To do this, the end of the hose or pipe is immersed in water, making sure that as much of its length as possible is in the liquid. The best way to ensure safety is to equip the fence line with a float. Its task is to raise and lower the end of the hose, constantly keeping it submerged in water.

The periodic maintenance list of the system includes monitoring pressure parameters. The air in the pumping station is checked through a spool or nipple outlet on the accumulator body. By attaching a pressure gauge to it, it is easy to see the indicators. Nominal pressure - from 1.5 to 1.8 atm. If there is a shortage of it, air is pumped through the outlet using a compressor or bicycle pump.

The pumping station operates jerkily: what is the cause of the malfunction?

Pumping station: how it works

There is no equipment that never breaks down, and pumping stations - even if they are from the most famous manufacturers - are no exception. What is very pleasing is that the causes of malfunctions are often not in the pump itself, and problems can be eliminated quite easily. What are they expressed in, and for what reasons do they arise?

Our short instructions will tell you about this. And after watching the video in this article, you will find the answer to the question: “What to do if the water supply pumping station does not work?”

What to do if water comes out of the well in spurts?

If you are the owner of a private well, then your site has an individual water supply and thus you do not depend on anyone. But as soon as you encounter a problem called “no water in the well,” all worries fall on your shoulders. Because you are the only person making a decision regarding your water intake source and identifying the reason why this happens.

What to do if the water in the well comes in jerks, if there is little water in the well or there is none at all, we will discuss below.

Causes of problems: the pumping station is leaking or not working

The most common errors that lead to breakdowns are:

- Initial purchase of low-quality equipment. For example, it is worth paying attention to the width of the metal gasket of the hydraulic tank near the inlet valve. And also on welds and membrane quality, on pump power.

- Equipment incompatibility. You can avoid this if you buy complete units at once.

- Incorrect installation. If installation does not require special skills, then it is better to entrust commissioning work to a specialist.

- Poor filtration. The entire system should be provided with a good mechanical coarse filter so that the equipment is not damaged by soil particles. You can order filtration equipment on the “Water of the Fatherland” website.

- Mechanical damage.

- Poor insulation from cold and moisture, direct sunlight, and other climatic factors. It is best to install the equipment in a special pavilion.

In fact, the main reason is the lack of regular inspection. Most problems can be eliminated at the onset of development, when the first symptoms are visible. Then it is more efficient, cheaper, and faster.

How to repair a water pumping station with your own hands

The first thing you need to do is find the fault. Visually inspect all components for mechanical damage. Once you have seen the source of the problem, disassemble the system, freeing the part. First, of course, you should disconnect the electric pump from the power supply so that there is no situation where it runs “dry”, because this can cause it to burn out.

Then there are two ways to proceed:

- Replacing a spare part. The components are not very expensive. The most expensive is the hydraulic tank, and it does not break down very often if a high-quality model was initially purchased. When purchasing spare parts, pay attention to the compliance with the technical specifications and the original brand. Replacement is carried out according to a simple scheme: dismantling, checking and cleaning connections, installing a new spare part.

- Repair. Sometimes this is worthwhile, but other times it is a waste of time. Based on your capabilities and the complexity of the breakdown.

Floor-standing dispenser AquaPro 6207CH (cooling/heating/room temp.)

Wall-mounted dispenser AquaPro 3207CH (cooling/heating)

Aeration column AS-0844 VO-90

Briefly about the main thing

Equipment that does not break does not exist. Repair is something that all owners, sooner or later, face. Therefore, knowledge about the basic nuances of the operation of the equipment is necessary for every user. Having them in your arsenal, you will minimize problems when repairing a particular working unit of the system, and save money.

Do you think timely diagnostics and troubleshooting will really help you save on pump system repairs? Or maybe it’s worth “finishing off” it and then repairing it at once?