Modern, familiar amenities in a country cottage will make your stay comfortable. It is especially important to have a pipe enter the house from a well in the absence of a centralized water supply. This task is fully achievable even for non-professionals; based on this, we will select the most suitable local delivery method for us in order to obtain natural benefits from our source.

The optimal solution is to install a squeegee, in other words, pipes with threads at 2 ends, and compress the ring wall with 2 flanges using gaskets. This is exactly how we make the connection and this will easily but reliably solve the problem of how to seal the pipe.

Wiring from the well to the house

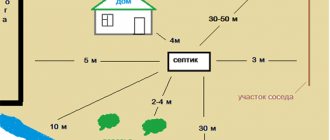

Before we begin work, we will clarify the possible freezing depth in our area in accordance with SNiP.

Pipes, their characteristics

To distribute water from a well to a house (initially supplying it to the home and introducing water into the building), we use a HDPE pipe.

- The optimal diameter for laying underground is 32 mm with a wall thickness of more than 2 mm.

- The length of the pipe under the foundation inside the house and into the well should be with a half-meter margin.

Metal-plastic water pipes made of aluminum with double-sided polyethylene coating are currently at the peak of popularity: they are durable, virtually eternal and do not affect the smell and taste of natural water. In addition, their smooth surface prevents clogging, protects against condensation and does not rust under any circumstances.

A competent choice of pipe diameter also contributes to our comfort:

- a very narrow pipe moves noisily through (turbulization of the flow occurs),

- lime deposits will soon appear inside it.

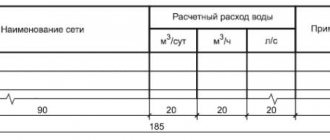

We will take the correct diameter when calculating the high flow speed (in most cases 2 m/s) and the length of our pipeline:

- at 30 m you need a diameter of 25 mm - that’s 1 inch;

- for a longer line - 32 mm - already 1.25 inches;

- for a system up to ten meters – only 20 mm.

- For such a line from the well, we dig a trench in the ground (ditch depth 1.5-2 m), we bring it under the foundation of the house.

Input device

Advice! The thickness of the insulation wall is more than 9 mm, and the internal diameter is 35 mm. Such a compensator insulation will protect our highway from soil deformations during the inevitable shrinkage of an already buried trench.

- We seal the joints with reinforced tape.

- We lay the pipe prepared in this way in a dug trench, and at the point of its entry into the well, we drill 2 holes in the rings with a hammer drill.

- Now let’s insert the pipe into the ring 30 cm.

- We pull the electric cable of the pump into the trench, already located in a HDPE pipe with a diameter of 20 mm. And we bring it inside the ring, but through a different hole.

Note! Experts recommend using waterproof PVA cable 4x1.5 mm for borehole pumps - its price is not much more, but its reliability is much higher.

- In the same pipe we run an electric PVS 3x1.5 mm socket cable for a pumping station, a second pump or lighting. To do this, we make a third hole, in other words, each pipe has its own hole.

Attention! Iron corrugation is not suitable for passing pipes through the ring, since it will not protect against water seepage from the ground.

- Later, we seal the inlet hole on both sides with a quick-hardening solution, probably with a hydraulic seal.

- Finally, we bury the trench, pouring it with water.

Technology of using ready-made compounds

Ready-made waterproofing seals are most often used to seal leaks when the water that leaks or leaks can cause serious damage.

When using ready-made hydraulic seals, it is necessary to strictly follow the work technology:

- Surface preparation . At this stage, using a perforator or hammer, it is necessary to clean the surface of the well from exfoliated concrete. However, first the surface must be cleaned of dust, dirt, and mold.

- Expansion of the repaired area . It is necessary to widen the hole by 20-30 mm and deepen the hole by 30-50 mm. This is done in order to “refresh” the edges of the hole. In this case, you should try to give the sealed crack the shape of a funnel. When sealing a seam, it is necessary to strip it and deepen it by 5-10 mm. To expand, it is best to use a wide spatula, working the damaged area from top to bottom. Small cracks and holes can be expanded in any direction as convenient for the repairman.

- Preparation of the solution. The solution is prepared no later than 2 minutes before use. Recommendations for preparation, proportions, optimal water temperature - all this must be studied before preparing the waterproofing mixture. To dilute the mixture, use a clean metal (not aluminum!) container.

- Filling the crack. We fill no more than 50-70%. This is necessary so that the waterproofing solution, which expands during the hardening process, does not damage the walls of the well.

- Stabilization of the filling. Press the finished filling with your hands for 3-5 seconds to several minutes (indicated in the instructions for use).

- Care. Depending on the mixture used, it may be necessary to periodically wet the seal over a period of 12-24 hours. If the instructions do not provide for this, then there is no need to do this.

- Treating the seal with a waterproofing compound . At this stage, a penetrating waterproofing material is used, which will protect the concrete wall of the well and the installed hydraulic seal from further destruction. From ready-made waterproofing mixtures you can choose: “Osmosil”, “Hydrotex”. Waterproofing can be applied only after the filling has completely hardened, unless otherwise provided by the manufacturer.

When diluting the solution, strictly follow the proportions specified by the manufacturer. You should not skimp and try to dilute the mixture thinner or, in an effort to increase its effectiveness, make it too thick. In both cases, the waterproofing properties of the seal will be impaired.

Often, along with sealing cracks, more serious damage is revealed that requires major repairs of the well. We recommend reading information about their elimination methods.

Pipe insertion for winter water supply

The winter option is possible with any foundation - columnar or strip.

- First, we will make a warm insertion of the HDPE pipe into the well.

- Here we will lay a self-regulating electrical cable, insulate it with foil and insulate it with 50 mm Energoflex, and wrap it with reinforced tape.

- This end part of the pipe also protrudes 20 cm above the floor. As a result, we will take the factory final heating cable into the ground and 100 percent guarantee of its tightness without a terrible short circuit.

- Sections of the heating pipe must be sealed. We attach a heating cable to all examples of HDPE with foil; it is insulated with a porous filler and protected from damage by a reliable sheath. But the difficulty of sealing is upsetting.

- We make a warm connection into the house under the floor: we connect the heating pipe to the HDPE pipe from the well with a strong compression coupling right at the depth of its simple laying: 1.5-2 m (but only in a non-freezing area of the ground).

Note! There is no need to fill the inlet with expanded clay or sawdust, so that water does not accumulate in them, like in a sponge.

Connecting a water supply station to a pipe

The installation depth is the average between the high groundwater level in spring and the depth of probable freezing. This is how we found out the pipes exiting the well directly from the ground.

It’s easy to equip such a station in your home: we connect a pipe with a check valve at the other end to it and plug the plug into the socket. But how can you arrange it in a well with your own hands?

Construction of a water pipeline in summer

People live in dachas mainly only during the warm season, so the water supply system can be built according to a simplified scheme - without digging into deep trenches, insulation and cable heating devices.

There are two options for summer water supply:

- Temporary: the network is laid directly on the surface of the earth or in closed trays buried in the ground (in the latter case, the pipes will not interfere with walking and traffic). In the simplest version, the water supply is assembled from rubber or silicone hoses; a more durable option is a system of HDPE pipes. For the winter, the pipeline will need to be dismantled, so HDPE pipes are the most preferable: all pipeline connections are assembled and disassembled literally with bare hands.

- Permanent: the pipes are hidden in shallow trenches, so there is no need for annual dismantling - just drain the water from the system for the winter.

To avoid difficulties in finding hidden leaks, you can use polypropylene pipes, the installation of which by welding (a very simple operation) creates more reliable permanent connections.

Inserting a pipe into a sewer well

The independent insertion of a sewer pipe into the well is fully possible if we carry it out in the sequence specified by the experts.

This will save us money and work time.

- Let's start laying from the most remote place on a slope to the pipe that leads to the sewer well.

- Knee-shaped sinkholes - accumulations of clogging waste - are unacceptable.

- We lay the drain pipe above groundwater, but not within the boundaries of soil freezing - otherwise it must be insulated with foam plastic.

- Silicone plumbing sealant guarantees the strength of the joints, and we sharpen the cut edges of the pipes for better and easier assembly.

- At the connection to the houses we will install an exhaust riser, and in order to improve draft, we will arrange it higher than the roof.

- When connecting plumbing, we install a pipe hydraulic lock - an elbow invariably filled with water, so that sewer gases do not get inside the house.

Signs of a system seal failure

There are several signs that the waterproofing layer needs to be restored. An example would be:

- Cloudiness of drinking water. As previously noted, sewage leakage can have an impact on drinking water: the appearance of odors, cloudiness, and impurities. It is possible to accurately determine the cause of changes in the quality of drinking water only through special research.

- Visual shift of rings. Established standards for installation work stipulate that when creating a structure, a flat surface without protrusions should be obtained. This is due to the fact that the protrusions become a place for sediment accumulation, and the inaccurate location of the rings causes a significant deterioration in the waterproofing properties of the structure.

- The appearance of a sharp unpleasant odor in the area if the well is sealed may indicate that sewage is entering the environment.

The shift of the well rings leads to a violation of the waterproofing properties of the structure.

Sewage, both organic and chemical, has a negative impact on the environment, as a result of which the vegetation on the site begins to die.

Conclusion

It is clear that plumbing is the most popular engineering system for healthy comfort. The instructions we received will help us independently, correctly and properly lay out this most important local system. This decentralized method involves connecting to an already drilled artesian well or directly supplying well water to the house.

Let's summarize the procedure.

- We will wrap the pipes with insulation or simple glass wool, securing it with wire and wrapping it with moisture-proof film.

- We lay pre-insulated pipes in the trench. It is necessary to insulate the pipes completely along their entire length, as well as at the points where they enter the well or house.

- After this, we fill the trench, sometimes compacting the earth.

The entrance of the system to the ring is the most important place due to the seepage of contaminated water. It is necessary to check the functionality of the new water supply system; the absence of leaks is the expected result of our work. The video in this article will show the correct insertion of the well pipe.

Modern, familiar amenities in a country cottage will make your stay comfortable. It is especially important to have a pipe entering the house from a well in the absence of a centralized water supply. This task is quite feasible even for non-professionals, so we will select the most suitable method for us to locally deliver such a natural benefit from our source.

The optimal solution is to install a squeegee, that is, pipes with threads at 2 ends, as well as compressing the ring wall with 2 flanges using gaskets. This is how we make the connection and with this we will simply but reliably solve the problem of how to seal the pipe.

We take water into the installed system from the house through the outlet pipe.

Ready-made waterproofing seals

Ready-made hydraulic seals for concrete wells are very convenient: to use such a seal, it is enough to dilute the solution with water according to the manufacturer’s instructions. Let's look at the most popular waterproofing sealing mixtures.

Option #1: water plug. This mixture contains fine-grained quartz sand, aluminum cement, and active chemical additives that give the composition plasticity and allow it to quickly harden. Using this type of seal, you can quickly eliminate a leak within 2 minutes.

The waterplug can be used at temperatures from +5 to +35 degrees. It is used in waterproofing swimming pools, underwater bridges and similar structures. Among the disadvantages of this hydroseal is the need for dilution with warm water +20-25 degrees, which in some cases is not entirely convenient.

Option #2: peneplug. Available in the form of a dry powder that must be diluted in water. This mixture is intended for waterproofing concrete wells, as well as wells paved with brick, natural or artificial stone. The hydroseal is based on high-quality cement, quartz sand and polymer additives.

This mixture is capable of stopping a leak with a pressure of more than 5 atmospheres. Hardening time 40 seconds.

Option #3: powder ex

A fast-acting waterproofing seal that sets within 10 seconds after application. This filling has excellent characteristics: frost resistance, resistance to aggressive environments, ease of use.

The disadvantages of this mixture include high cost and the inability to work at temperatures below +5 degrees.

After using any chemicals to perform repair operations, well water should be submitted for analysis to the SES or a laboratory accredited to conduct this type of research. Studying the composition of the water will help to find out whether there are any sources of pollution left in the mine, or whether the repair material has affected the quality characteristics.

Wiring from the well to the house

Diagram with pumping equipment in the house.

Before starting work, we will clarify the likely depth of freezing in our area according to SNiP.

Pipes, their characteristics

To distribute water from the well to the house (initially supplying it to the dwelling and introducing water into the building), we use HDPE pipe.

This is usually a black plastic pipe.

- The optimal diameter for laying underground is 32 mm with a wall thickness of more than 2 mm.

- The length of the pipe under the foundation inside the house and into the well should be with a half-meter margin.

Metal-plastic water pipes made of aluminum with double-sided polyethylene coating are now at the peak of popularity: they are durable, almost eternal and do not affect the taste and smell of natural water. In addition, their smooth surface prevents clogging, protects against condensation and never rusts.

A competent choice of pipe diameter also contributes to our comfort:

- a pipe that is too narrow moves noisily (turbulence of the flow occurs),

- lime deposits will soon appear inside it.

We obtain the correct diameter by calculating the maximum flow speed (usually 2 m/s) and the length of our pipeline:

- at 30 m you need a diameter of 25 mm - that’s 1 inch;

- for a longer line - 32 mm - already 1.25 inches;

- for a system up to 10 m – only 20 mm.

- For such a highway from the well, we dig a trench in the ground (trench depth 1.5-2 m), we bring it directly under the foundation of the house.

Possible problems with concrete rings

To begin with, let’s pay attention to the fact that wells made from concrete rings are more susceptible to leakage. Plastic structures are often seamless; waterproofing has to be carried out only at the connection points of pipes or other elements. The most common problems with concrete rings include the following:

- Moisture can seep through seams or in places where pipes connect to wells if waterproofing work is performed poorly. In this case, the situation of wear of waterproofing under the influence of the environment quite often occurs.

- Sewage can penetrate into the environment not only through the joints of the rings, but also through the bottom part. In this case, the well creation technology was most often violated.

- The reinforced concrete rings themselves can become damaged due to exposure to low temperatures, errors made during installation work, and for many other reasons. Moisture can slowly penetrate into the environment through cracks.

- Over several years of operation, concrete walls may lose their thickness due to the slow destruction of the structure under the influence of the environment. As the wall thickness of the rings decreases, the waterproofing qualities are significantly reduced, and moisture also begins to seep into the environment.

During operation, reinforced concrete wells can wear out, the integrity of the concrete is destroyed, and therefore leaks and unpleasant odors around the well are possible.

- There are no such problems with plastic wells, but you can encounter a situation where cracks appear under the influence of low temperature and pressure from the environment. In some cases, the problem can be solved by using special insulating materials; in others, the destruction of the plastic becomes critical and the well has to be replaced.

Pipe insertion for winter water supply

The winter option is possible with any foundation - columnar or strip.

- First, we will make a warm insertion of the HDPE pipe into the well.

- Here we will lay a self-regulating electrical cable, insulate it with foil and insulate it with 50 mm Energoflex, and wrap it with reinforced tape.

- This end part of the pipe also protrudes 20 cm above the floor. As a result, we will receive the factory final heating cable in the ground and a 100% guarantee of its tightness without a dangerous short circuit.

- Sections of the heating pipe must be sealed. We attach a heating cable to all HDPE samples with foil; it is insulated with a porous filler and protected from damage by a reliable sheath. However, the difficulty of sealing is upsetting.

- We make a warm connection into the house under the floor: we connect the heating pipe to the HDPE pipe from the well with a strong compression coupling right at the depth of its usual placement: 1.5-2 m (but only in a non-freezing area of the ground).

Note! You should not fill the inlet with expanded clay or sawdust so that water does not accumulate in them, like in a sponge.

Connecting a water supply station to a pipe

It is the pumping station that is the most cost-effective comprehensive solution to the problem of water supply.

The installation depth is the average between the maximum groundwater level in spring and the depth of possible freezing. This is how we determined the pipes exiting the well directly from the ground.

We install it in a house or in a basement where the groundwater level is high.

It is simple to equip such a station in the house: we connect a pipe with a check valve at the other end to it and plug the plug into the socket. But how can you arrange it in a well with your own hands?

Knowledge of certain subtleties will help here.

If groundwater is low, we will install a station in a deck.

- We attach the bracket to the ring inside. We fix the horizontal parts of the bracket with bolts on the edges of the cross member.

- Next, we lower the pumping station down onto the bracket.

- We screw a 1″ squeegee onto the outlet directly from the pump, a 1″ tee onto it, and a drain valve with a rotating rod on top onto the outlet of the tee.

- Then we install a 1″ tap on the passage section of the tee, then a compression adapter on a 32 mm pipe (for supplying water to the main line).

- We screw a 1″ elbow (90 degrees down) onto the suction section of the pump, onto it with a compression coupling to connect it to the pipe, onto the coupling and screw the pipe down to the beginning of the second ring from the bottom.

- Now we install a check valve at its end, as well as a filter for the well - the now popular factory-made tip with a coarse filter will do.

Application of bitumen-gasoline solution

To seal the joints, a bitumen-gasoline solution can be used, which also has quite attractive water-repellent properties. To perform sealing work you will need the following materials and tools:

- A cement gun that delivers the substance under pressure. In order to clog all the cracks with greater efficiency, you should use equipment that is capable of supplying waterproofing material under high pressure.

- A wooden spatula will be needed to adjust the location of the waterproofing layer.

- Bitumen and gasoline act as the main components. In some cases, mastic is added.

When using the mixture in question, the well is sealed in three layers. The main recommendations for performing the work include the following points:

- The first layer is prepared by mixing bitumen and gasoline in a ratio of 1 to 4. The other two layers are prepared by mixing bitumen and gasoline in a ratio of 1 to 1.

- When making a sealing mixture, use bitumen grade of at least 3.

- The application of the solution is carried out using a compressor, which creates pressure and sprays the composition.

- Before starting work, you need to prepare the surface. To do this, it is cleaned of debris and dirt.

- Each layer is applied only after the previous one has completely dried.

- The last layer is represented by mastic, onto which a sealing sheet is glued. The overlap should be at least 10 centimeters.

- All seams are protected from external influences by applying a large layer of mastic.

Bitumen-gasoline solution is a material for waterproofing concrete structures.

Painting with a bitumen-gasoline solution is carried out in three layers; do not forget, the solution is very flammable and can easily ignite. Experts recommend creating a mastic layer of at least 2 millimeters. Compact it using a wooden spatula.

Inserting a pipe into a sewer well

Independent installation of a sewer pipe into a well is quite possible if we carry it out in the sequence specified by experts.

This will save us money and work time.

We maintain a slope from the house to the drainage pit - this will ensure normal drainage.

- Let's start laying from the most remote place on a slope to the pipe that leads to the sewer well.

At bends we will set up an inspection area for cleaning.

- Knee-shaped sinkholes - accumulations of clogging waste - are unacceptable.

- We lay the drain pipe above groundwater, but not within the boundaries of soil freezing - otherwise it must be insulated with foam plastic.

Features of materials for the manufacture of wells ↑

Filtering or storage tanks are made of concrete, reinforced concrete, metal, and plastic. All these materials have their advantages, and the features of inserting sewer pipes into wells largely depend on their strength and thickness:

- Concrete and reinforced concrete. The most reliable and practical materials for the construction of storage tanks. They are characterized by high mechanical strength. If properly waterproofed, the tanks will be completely sealed. At the same time, the greatest number of difficulties arise when installing sewerage into a concrete well. The material is thick, durable and difficult to process with tools.

- Metal. Not the best choice for an autonomous sewer system for a private house. Even the highest quality metal tanks last no more than 10-15 years. They quickly collapse under the influence of moisture and chemicals. But it is much easier to arrange the entry into a metal sewer well than into a concrete one. You can always make a hole for the pipe, which will not be much larger than its diameter. This makes it easier to seal the insertion site.

- Plastic. In recent years, industrially produced plastic containers have been increasingly used. They are impermeable to water, do not require additional waterproofing, and tolerate aggressive chemicals well. Problems rarely arise with inserting a pipe into a sewer well, because... ready-made structures are often supplied with all the necessary components. The main thing is not to make a mistake with the diameter.

Welded plastic construction

Conclusion

It is clear that water supply is the most popular engineering system for creating healthy comfort. The instructions we received will help us independently, correctly and efficiently install this important local system. This decentralized method means connecting to an already drilled artesian well or directly supplying well water to the house.

Let's summarize the procedure.

- We wrap the pipes with insulation or simple glass wool, securing it with wire and wrapping it with moisture-proof film.

- We lay pre-insulated pipes in the trench. It is advisable to insulate pipes along their entire length, as well as at the points where they enter the well or house.

- Then we fill the trench, periodically compacting the earth.

The entrance of the system to the ring is the most critical place due to the seepage of contaminated water. It is mandatory to check the functionality of the new water supply system; the absence of leaks is the expected result of our work. The video in this article will demonstrate the correct insertion of a well pipe.

a wide range of services for water supply, heating, gasification, repair work

One of the most important technological operations performed during the construction of water supply and sewerage networks is the insertion of a pipe into a well. If it is potable, then high-quality sealing of the walls, including at the points where they connect to the pipes, will prevent dirty surface water from entering it.

Types of seals for hydraulic structures

Previously, before the invention of hydraulic seals, wooden boards, hemp and jute materials were used as plugs for wells. A significant drawback of outdated types was rapid delamination and decay, which led to a deterioration in the quality composition and taste of well water.

With the invention of the hydraulic seal, it became much easier to eliminate leaks and operate wells. Modern manufacturers of building materials offer ready-made waterproofing compositions based on polymer materials.

However, many well owners and professional repair teams prefer to use self-made seals, rightly believing that this will lead to cheaper repair work without loss of quality.

Hydroseals are divided into two types:

- Pressure, quick-hardening mixtures . It takes 10 to 60 seconds for them to harden. A special repair compound that has waterproofing properties is applied over such a seal.

- Non-pressure, hardening within 5-7 minutes . Such mixtures are used not for emergency work, but for preventive work, for example, planned insulation of seams.

We'll look at each option in more detail below.

Waterproofing grouting materials (water seals) are often used in emergency cases, when the time of hardening determines how much water will run out or seep in, thus the amount and severity of damage that can be prevented depends on the quality and correct use of the water seal.

High-quality hydraulic seals can eliminate leaks in 30 seconds, stopping the flow up to 7 atmospheres!

Waterproofing seals are used in the following cases:

- to protect drinking water in a well from groundwater penetration

- plugging water breakthroughs in basements, adits, wells

- isolation of a breakthrough in places of contact of the floor, walls, between foundation blocks

- hermetic sealing of seams and cracks in wells

- express pipeline repair.

Inserting a pipe into a well

Let's start with the fact that the hole in the wall should be larger than the diameter of the pipe, but not by much. The smaller the gap, the easier it is to seal it.

When it comes to plumbing, pipes made of steel and metal-plastic are most often used for its construction:

- To insert them into the well, use a brass elongated drive, which is inserted into the hole. But first, the entrance circumference is treated with silicone, liquid glass or fiber rubber. Bitumen mastic, in this case, cannot be used.

- From a piece of rubber you need to cut out two patches with your own hands with a radius that covers the entrance circle. The easiest way to do this is to use an old car camera. Make small holes in the center of the patches so that they can be pulled onto the squeegee with force. You will get an excellent rubber seal, which is put on both sides on the squeegee installed in the hole.

- Then, washers are put on top of the rubber bands and the nuts are tightened. The edges of the seals can be coated with “Moment-montage” glue and pressed to the surface of the walls. The connection unit is ready, all that remains is to screw the fittings onto the fittings and make a threaded connection of the pipes. This type of connection is called a crimp connection, and this is the only correct method that should be used when installing an autonomous water supply system.

- Many people mistakenly believe that the entrance hole can be sealed with foam. This is a completely wrong opinion! The foam is not intended for use in water. Over time, the structure of the foam is destroyed, and its particles end up in well water. So, the price of the material does not matter here, the main thing is to get a high-quality connection.

- If the pipeline is installed from low-pressure plastic pipes (LDPE), then corrugation is used instead of a conduit. Its connection with the walls of the well can be sealed in the same way as in the case of metal pipes. HDPE passes inside the corrugated pipe. You can see such a connection in the photo at the beginning of the article.

Sewer passage through the well wall: foundation

At one of the stages of building a private house, a sewerage passage through the well wall is installed. In other words, you need to cut the pipe into the sewer well. The insertion pattern and procedure depend on the material from which the pipes and the well are made.

Material for making wells

In order to properly arrange the sewer passage through the well wall, you need to know the characteristics of the material that was used to construct the well.

Plastic containers do not allow water to pass through, so additional waterproofing is not required. The materials are resistant to aggressive chemicals. The insertion of a pipe into a well made of plastic or other polymers is facilitated by ready-made holes and components.

Metal wells are poorly resistant to moisture and aggressive chemicals, so their service life is short. However, making a hole for the pipe entrance in a metal container is easier and faster. There are no problems with sealing the joint.

Concrete and reinforced concrete structures have high strength and reliability. With proper waterproofing of the sewerage entry point, complete tightness of the structure is achieved. However, insertion becomes more complicated due to the strength of the material and the intractability of the material to be processed with different tools.

The rules listed above also apply in cases where it is necessary to arrange a drainage sewer passage through a brick wall.

Material for making pipes

Correct entry into the well depends on the material used to make the pipes. Great demand is noted for ceramic, cast iron, asbestos-cement and plastic pipe products.

The ceramic sewer passage through the well wall has a long service life and is resistant to external negative factors. No special knowledge is required to perform installation work. However, ceramic pipes do not withstand mechanical stress well.

Cast iron pipes are used less frequently, although they have high strength and excellent corrosion resistance. Low demand is due to high weight and rough inner surface.

Plastic is lightweight, resistant to aggressive environments, and inexpensive. The process of inserting into a sewer well is quite simple.

Also read: Foundation made from sewer pipes: features

Sidebar rules

The standard series sewer passage through the foundation is arranged in compliance with the basic rules:

- The sewer pipe is laid at a slope. When calculating, special formulas are used. A simplified version - for each linear meter of pipe a slope of 2 cm is made.

- After laying the pipes, determine the insertion location and make the appropriate marks.

- Polymer materials must be placed in the sleeve.

- The entry point is subject to mandatory sealing.

- The gap between the sleeve and the main structure is sealed with insulation and moisture-resistant material.

Concrete well entry point

Cutting into concrete is not a difficult job if you have various tools at hand. When setting up a sewer passage through the foundation, they use a hammer drill, metal punches, a drill, and a grinder. In difficult situations, a special diamond installation comes to the rescue.

When diamond drilling concrete there is virtually no damage to the surface, but such equipment is very expensive.

The hammer drill performs percussion drilling, which causes the formation of microcracks in the foundation, wall or concrete rings.

Hammerless drilling involves drilling a large number of holes with a drill. After this, the required hole is hollowed out with a sledgehammer, and the reinforcing bars are cut off with a grinder. This option is considered the safest, but takes a lot of time.

The insertion into the well of concrete rings is carried out using a hammer drill and an angle grinder. Using a hammer drill, a hole is made in the concrete ring. Its size is determined by the diameter of the incoming pipeline. If the structure contains metal reinforcement bars, they are cut off with a grinder. The edges of the hole are treated with liquid glass or a deep penetration primer.

The end of the pipe is cut flush with the wall of the well. If the sewerage system is made of ceramic or asbestos-cement pipes, then the joint area is concreted.

You can prepare the composition yourself by mixing 1 part cement, 3 parts clean sand and a liquid plasticizer. The resulting plug should be completely hardened. After this, a layer of a similar composition is applied to the joint.

The sewerage passage through the foundation can be sealed in the same way.

Special fittings are used to insert low-density polyethylene pipes into the well. They can be purchased in specialized stores. The work is performed in the following order:

- The edges of the hole in the concrete ring are coated with silicone or special liquid rubber.

- Insert the brass pipe.

- Patches are cut out of an old car tire; their size should be slightly larger than the diameter of the hole in the well ring.

- Slots are made in the center of the patches, and they are put on the pipe on both sides of the well.

- Place washers on top of the rubber bands and tighten with nuts.

- Then a fitting element is put on the pipe and the sewer pipe is brought in.

review:

Everything useful about sewerage - gidkanal.ru

GidKanal | Yandex Zen

Set for a device for introducing pipes into a well

- There are also ready-made units on sale, complete with sealant, designed for insertion into the wall of a concrete well. Such units are used in housing construction, and not only for connecting pipes to the walls of wells.

There are various options for introducing water into a house from a well, through foundations and walls of various designs. For example, to insert a pipe through an insulated basement wall with brick cladding, a fiber cement sleeve may be included in the kit.

Bottom filter diagram

Dornit or moisture-permeable geotextiles are placed at the bottom of the well . You cannot use black geotextiles similar to Izospan; they do not allow water to pass through well.

The edges of the material are wrapped onto the walls. Geotextiles are fixed to the bottom with a grid of larch or aspen beams. Several stones are placed on a wooden crate and covered with crushed stone, a layer of 15-25 cm. To further improve the quality and purification of water, you can lay another layer of geotextile on top of the crushed stone and fill it with silicon or small shungite crushed stone. With this scheme, the free edges of the material are fixed in a circle from the inside of the well ring with galvanized metal mounting tape using self-tapping screws and dowels.

Sealing the pipe passage through the well wall

The passage of the pipe through the ring wall is also considered a weak point . As a rule, during the construction of wells, the pipe is simply sealed in the hole with construction foam. But the foam does not have an airtight seal and is destroyed in the open air.

The most advanced option for sealing a pipe through a concrete wall is considered to be crimping mechanical sealing. This is done this way:

- A brass inch rod of the required length is installed into the hole in the well wall. In the central part, the squeegee is treated with Kilto Fiber Pool fiber rubber. The gap between the squeegee and the body of the ring is also treated with fibroesin. A rubber seal is placed on the squeegee and pressed with plates or washers. The squeegee is clamped from the inside and outside of the wall with nuts. Afterwards, 32 mm fittings are screwed onto the pipe, and the pipe is attached directly.

- All other schemes for passing rings without tightening create leaks.

Plumbing using a submersible pump in a well

This water supply scheme has a number of advantages over the scheme using a surface pumping station:

- a submersible pump needs less power to lift water than a pumping station;

- it is cheaper;

- can supply water from a depth of more than 9 m;

- cools down faster;

- does not make noise in the house, unlike a pumping station.

Disadvantages of a submersible pump: it is necessary to lay wires to power the pump, you need to cover the well from thieves. It is not advisable to install vibration pumps either in wells or boreholes. In addition to sound, vibrations compact the soil and can reduce water flow into the home. In the case of sand wells, the use of vibration pumps creates shedding of the sand lens, which leads to “sanding” of the bottom.

The well uses a submersible screw pump . Among submersible models of various types, these pumps have high efficiency. The screw circuit is not as sensitive to contamination, unlike centrifugal pumps. According to the manufacturer's instructions, the pump must be suspended vertically at a distance of at least 0.5 from the bottom of the well. But sometimes you can deviate from this scheme. For example, when the water in the well is only one ring from the bottom. In this case, when installing a well pump without a sensor, you can use a horizontal pump suspension scheme 20 cm from the bottom, thereby increasing the volume of water. Also, with this pump installation scheme, it is less likely to freeze in winter.

The plumbing that supplies water to the house is made from 32 mm HDPE pipe. The submersible pump is connected to the check valve on the pipe using clamps and a reinforced flexible hose. At the top, at the entrance of the pipe to the well, a tee with a tap is attached, which makes it possible to drain water from the pipe if it is necessary to move away from the house in winter.

Water supply with installation of a pumping station

This water supply system differs in that a check valve and a strainer are installed on the water intake head in the well part of the water supply system. The pump itself with automatic switching and often with a damper tank is located in the house in one block. There are pumping stations with soft start; they do not require a damper tank.

Preparatory stage and necessary tools

Before making the insert, it is necessary to perform a number of preparatory work. In apartment buildings, sewer pipes run in technological shafts. To get to them, it is necessary to dismantle part of the wall masonry and prepare the place for work. The better this stage is completed, the easier it will be to work. To arrange the insert, you will need the following tools and materials:

- grinder with cutting wheel for metal;

- a set of metalwork tools;

- hammer drill or drill;

- fittings, tees, bends, adapters;

- sealing mastics, clamps.

Before starting work, it is necessary to prepare a drawing (diagram) of the area to be mounted indicating the exact dimensions. Any inaccuracies during installation may result in an increase in the volume of operations performed. In multi-storey buildings, it would be useful to notify neighbors about the work being carried out and ask them not to use the sewer during this period.

What experts say

When installing a sewer well, it is quite important to pay attention to sealing all seams. Using the most modern sealing methods will eliminate the possibility of future problems.

On the suburban plot, even before its purchase, a concrete well was created. Some time after I started living on the property, I noticed that the water was cloudy and had a taste. It turned out that the problem was in the wastewater that got into the ground. Over the course of several decades, concrete began to leak. I waterproofed it using special tapes, and the problem was solved.

How to dig deep

There are no holes in a well made of reinforced concrete or brick; they are drilled after laying the pipe at the required level. The depth of the distribution system should be no higher than the level of seasonal soil freezing, the value of which can be found in the reference book.

The trench for laying the outlet must be deeper than the reference value:

- it is necessary to equip a sand and gravel cushion;

- organize insulation of pipes by electric heating or wrapping in mineral wool or polystyrene in case of a frostier winter.

How to use it correctly

In order for the sewage system to work properly, you must follow the operating rules. They do not require special resources, but do imply some requirements:

1. It is forbidden to flush solid things of large dimensions down the drain so as not to form a blockage, these include paper and hair.

2. Siphons should be cleaned periodically, and plumbing fixtures should also be cleaned with a plunger or a wire brush.

3.do not use chemicals to clean plumbing fixtures; it is better to replace them with cleaning using the hydrodynamic method.