Blockages in pipes under the sink happen in every home. And this is not always due to the accumulation of small household waste in the sump. Blockages often occur caused by fat settling on the walls of the pipes, narrowing their lumen to a minimum. As a result, some call plumbers, others buy chemicals that corrode the grease. Chemicals corrode the inner surface of iron pipes and aggravate environmental problems. However, a means has long been invented to protect sewers from corrosion, and the owner’s wallet from costs - grease traps. The mission of the device is to solve this problem at various scales.

Purpose of the device and its types

Fats and organic oils that fall into the sewer are practically insoluble in water.

To prevent fats from getting into the drain pipes and freezing there in the form of a solid deposit, plumbers advise installing a grease trap under the sink or other drain point. This device allows water to pass through itself, but the fat remains inside. As fat accumulates, it is removed and the device filters further.

For large food enterprises, large-capacity industrial grease traps are used, and for small workshops and bakeries, small household appliances have been developed that are suitable for private houses and apartments.

There must be a drain cleaner in the house, but if you have to use it constantly, it is easier to prevent blockages

Models, depending on the area of application, are made from different materials:

- inexpensive household containers are made from plastic;

- large containers for installation in basements and wells with positive temperatures are made of fiberglass;

- industrial boxes for restaurants and workshops are made of stainless steel or concrete, equipped with additional pumps, level sensors and filters, several partitions, as well as external control panels and automatic cleaning. The productivity of such structures reaches 100 liters per second.

The principle of action of the tablets is based on the decomposition of pollutants thanks to a complex of anaerobic microbial communities

Modern home models can also have several partitions for better water purification, retention of solid fractions, a compartment for the chemical decomposition of fats with drugs or the biological processing of oils by living bacteria. As a result of a process that is absolutely safe for human health, water is obtained with a low sediment content and without an unpleasant odor. This grease trap design can be cleaned much less frequently than a mechanical one.

EVO STOK 1.0-70 – from 10,577 rubles

A non-volatile device with a one-piece body and a working space divided into three sections by fixed partitions. The design includes a tightly closing lid and a removable tray on the inlet pipe. All elements that are required to seal the device at the input and output are present in the basic configuration of the device.

To remove debris from similar models used in catering units, it is necessary to completely drain the water. In EVO STOK 1.0-70, coarse sediment settles in a quick-release filter tray. One of the obvious inconveniences during operation is a specific smell (comes from the device if you do not clean it every day, but simply monitor the level of accumulated fat).

It is best to clean the container before starting work, before the fat has melted. If during operation it turns out that even though the device is relatively clean, the sewer pipe is clogged with grease, it is necessary to check whether the technical characteristics of the device correspond to the actual potential of the connected sanitary fixtures.

| Productivity, m³/h | 1 |

| Peak discharge, l/min | 70 |

| Weight, kg | 15 |

| Dimensions (LxWxH), mm | 620x470x420 |

| Height of the pipe (inlet/outlet), mm | 345/320 |

| Electrical equipment | Non-volatile |

| Manufacturer country | Russia |

The performance check of EVO STOK 1.0-70 is shown in the video:

Types of grease traps for sinks

There are quite a few types of grease traps, and they all have different performance and equipment. This equipment can be classified according to the body material and design features.

Grease traps can be plastic, fiberglass, metal.

Image gallery Photos from Plastic grease traps are sensitive to mechanical stress, so they are made mainly for domestic purposes

Fiberglass grease traps are manufactured primarily for industrial purposes, as they are much stronger than plastic ones.

Stainless steel grease traps will last for several decades and remain just as beautiful

It is not advisable to peel off the paint on painted metal grease traps, as this will speed up the corrosion process.

Plastic grease trap for sink

Industrial fiberglass grease trap

Stainless steel grease trap

Painted metal grease trap

Both industrial and the simplest household models of grease traps can be made from polypropylene and polyethylene. They are durable, cheap, lightweight and do not require special maintenance. Most grease traps under the sink are made of this material.

Fiberglass. These models have increased strength and resistance to chemicals, so they can be installed outdoors and dug into the ground.

Metal. Stainless steel grease traps can be easily washed with hard brushes without fear of damaging the surface. They look aesthetically pleasing, but are not cheap. Models made of stainless steel and aluminum are almost eternal, unlike products made of galvanized and painted steel, which can rust over time.

Automatic grease traps are often equipped with a special sensor that starts the process of selecting fat mass when it reaches a certain level

Separators in private homes can be made independently, and there are not many design requirements for them, so there are countless options for the design of this equipment. However, they can still be divided into the following types:

- Grease traps under the sink. They will be discussed in detail below. Such equipment is manually serviced and installed in apartments, houses, and small cafes.

- Industrial (shop) models. They are used in catering units designed for hundreds of people, in boarding houses and sanatoriums, as well as in food industry enterprises. Often such models are equipped with fill sensors.

- Automatic. They have an electric mechanism for automatic grease collection, which facilitates maintenance and prevents clogging of the inlet and outlet pipes.

- Located below the sewer level. Such models are installed in the basement or in the ground. They have a built-in electric pump that pumps purified water to the level of the sewer drain.

- Wells. These are large industrial grease traps in the form of a cylinder that can be installed in special external wells. Their maintenance is carried out through the hatch.

For household needs, it is enough to purchase a regular grease trap for the sink, which you can service yourself once every few weeks. These small devices have a simple design and structure.

KS-Zh-2V – from 45,000 rubles

KS-Zh is a line of energy-independent well-type grease traps. Designed for the purification of industrial wastewater before discharge into the city sewer system. “2B” – vertical layout of the device. Installed in the ground, cleaned through the hatch.

The advantages of the “junior” model of the KS-Zh line are the productivity and working volume of the device. Thanks to which flows of up to 300 liters per minute are effectively processed. The minimum service interval for the device is six months.

Of the minuses, constant investments will be required: for calculations - to the designer, for preparation of the site and installation of the device - to specialized specialists, for cleaning - to a professional sewer specialist. To monitor your current fat level, it is best to use a custom sensor, which is offered as an option by the manufacturer.

| Productivity, m³/h | 7.2 |

| Peak discharge, l/min | 300 |

| Dimensions (height/diameter), mm | 1300/800 |

| Electrical equipment | Non-volatile, medium density sensors are optionally mounted. |

| Manufacturer country | Russia |

Industrial KS-Zh in a video from the manufacturer:

Sources

- https://KitchenGuide.su/remont/uxod/zhiroulovitel-pod-mojku.html

- https://sovet-ingenera.com/kanaliz/k-drugoe/zhiroulovitel-pod-mojku.html

- https://CdelayRemont.ru/obzor-zhiroulovitelej

Features of the grease separator

Operating principle and differences between models

So, as mentioned above, there are two types of grease traps:

- Industrial.

- Household.

The latter are a small septic tank, which is located under the sink. During the process of cooking and washing dishes, the device takes over primary wastewater, cleaning it from grease.

In the photo - an industrial grease trap

This septic tank works on the principle of a septic tank. As a rule, it is a rectangular container, inside of which there are partitions that divide the space into several chambers. Since fat particles are much lighter than water, they are retained in a special settling chamber, and the water freely flows into the sewer.

It should be noted that household grease traps come in two types:

| Autonomous | The device does not require an electrical connection to operate. |

| Electrical | In this case, the liquid is pumped out into the sewer system forcibly using an electric pump. Accordingly, for the device to operate, it must be connected to a power supply. |

In addition, the products differ in the principle of water intake:

| Salvo | They are distinguished by the ability to receive a large amount of wastewater during peak discharge. This model should be used if you wash dishes by pouring water into the sink, after which it is drained in one burst. |

| Sewage | Designed for cases where dishes are washed under running water. |

Household grease traps for sinks differ from industrial ones primarily in that they are designed to process a small amount of wastewater. As a rule, this figure fluctuates in the range of 0.5-1.5 cubic meters per hour.

Grease separator design

Design

Almost all household grease separators for sinks have the same design. As mentioned above, the body of the container has a rectangular shape.

The following elements are located inside it:

- Inlet pipe – designed to supply wastewater into the container.

- Flow damper - reduces the speed of incoming water.

- Partition – ensures retention of sedimented masses and thereby prevents the overflow of settled sludge.

- Air vent – designed to ventilate the container.

- Outlet pipe – ensures drainage of grease-free wastewater into the sewer system.

As we can see, the design is extremely simple.

The device takes up minimal space under the sink

Advantages

The main advantage of a grease trap is, of course, the protection of the sewer system from contamination.

But, besides this, this device has other positive qualities:

- It has compact dimensions and light weight, so connecting the device does not cause any difficulties.

- All parts are made from environmentally friendly materials.

- High efficiency - fatty and oily substances are captured by 95 - 100 percent.

- Cleaning the grease trap under the sink is quite simple and does not take much time.

- A wide range of models, so you can always choose the appropriate device model.

- Durability due to the simplicity of the design.

- Affordable price, especially for autonomous household models.

Thanks to all these points, grease traps have become widespread in everyday life.

Flaws

As for the shortcomings, there are few of them. The main one is that the grease trap under the sink needs to be cleaned periodically.

This can be done using any available means or a special spatula, which is included in the kit. With its help, the sludge is simply scooped out of the container, after which the grease trap is washed.

Cleaning the container

In addition, devices equipped with an electric pump increase energy consumption, and in the absence of it, do not work at all.

Methods for cleaning containers from deposits ↑

There will be no problems cleaning household grease traps under the sink. They are usually small in volume, so they are easy to disconnect from the sewer and clean out by hand. The productivity of such devices is 0.1-2 l/s. Models with higher productivity are considered industrial, and to service them you have to resort to either pumps or special equipment.

Industrial models are equipped with automation that monitors the level of contamination and signals the need for preventive maintenance. Household appliances most often do not have such devices; containers have to be checked regularly. Below we offer detailed video instructions for manual cleaning of the fat separator.

Cleaning an industrial grease trap

Step-by-step video instructions for maintenance ↑

When choosing and making a grease trap for your sink with your own hands, pay attention to the quality of the material from which the body is made. The service life of the device depends on this

Plastic and fiberglass models do not withstand strong impacts well, so care must be taken to ensure that the devices are installed correctly. If you are planning to buy an industrial device, give preference to manufacturers that provide a warranty. Otherwise, devices of different brands differ little from each other.

When choosing such an intuitive and simple piece of furniture, it is important to pay attention to details, because a kitchen sink cabinet can also become an additional …

How to choose or make a comfortable cabinet for a kitchen sink with your own hands

There is a common joke that lovers of travel often visit the capital of the apartment - the kitchen. This is truly the most visited place in the house. They gather here...

Operating rules

When using a grease trap for a home sink, you must follow several specific rules that will allow you to achieve maximum efficiency in the operation of the equipment, prevent flooding and the appearance of an unpleasant odor in the kitchen.

In particular we are talking about the following:

- Mineral and synthetic oils should not be present in water waste.

- It is not recommended to connect the equipment to the toilet.

- It is forbidden to install a pump in front of the grease trap to avoid the formation of an emulsion that does not settle well.

- The inlet pipe should be located at a minimum distance from the sink and at a slope of at least 2 degrees.

- Purified water must immediately go into the sewer system.

- It is recommended to connect the equipment in the ventilation system shaft (if there is a corresponding hole in the wall or ceiling).

Types of devices

Before moving on to the question of how to choose a grease trap, it is more logical to first learn about the range of such devices.

Main types

There are industrial and household appliances.

- Industrial grease traps are purchased for installation in large enterprises where the technology involves processing raw materials containing a large percentage of fats or oils.

- Domestic tanks are the “destiny” of houses, apartments, as well as numerous public catering establishments. As a rule, grease traps are installed in bars, restaurants, cafes and canteens.

The operating principle of both structures is the same. Grease traps differ only in size. Both types can be vertical or horizontal, intended for indoors or outdoors. There is one difference: industrial models cannot be cleaned manually due to their large dimensions. In this case, special equipment is used: the set of such devices includes a special pump and a fat level sensor. Vacuum trucks can easily handle large tanks.

Traps and materials for them

There are three suitable options: for the production of grease traps, plastic, fiberglass and stainless steel are used.

Plastic structures

This material is distinguished by its light weight, practicality, and the ability to create the most unusual shapes of structures. If we talk about household grease traps, then plastic models can be considered optimal. Their biggest advantage is the ability to quickly clean.

Advantages of plastic (polypropylene, polyethylene) traps:

- relatively low price of models;

- safety for owners and the environment;

- ease of cleaning: the container is easy to clean with any detergent;

- versatility of the material: it is the basis for many household devices;

- long service life: it is believed that plastic can last 25-30 years.

A wide range of polymer products joins the “army” of advantages: you can choose the volume, shape of the structure, and dimensions of the grease trap. It is possible to make an individual order. A question may arise about the temperature that the polymer material can withstand. The maximum value is 70°. Air temperature - from 5 to 40°.

Fiberglass grease traps

This material is ideal for use in industrial plants with large volumes of liquid to be treated. Fiberglass is able to withstand maximum pressure; it can be installed both indoors and outside buildings, on the street.

Advantages of fiberglass as a fat fighter:

- light weight, but enviable strength, ease of use;

- maximum resistance to chemicals and aggressive environments.

Separately, it is necessary to note the versatility and reliability of the products: after installing fiberglass grease traps anywhere, you will not have to worry about the tank becoming damaged.

Stainless steel traps

If we think about reliability, practicality, convenience and care, then it is difficult to find equal rivals for this material. “Living” evidence are sinks that are made of stainless steel. However, in this case, there is an obstacle for owners of apartments or houses: this is a higher price when compared with the cost of all plastic (composite) models.

For this reason, such steel structures are often purchased for catering establishments. Sometimes they are bought for large private houses. However, owners make decisions about the appropriateness of a particular device based on their own considerations.

Unit for prevention

A grease trap is an installation that, figuratively speaking, separates the wheat from the chaff. It is built into the sewerage system to prevent fatty deposits in pipes. And this technique is based on one simple principle - fat always rises to the surface of a certain volume of cool water. Most often, such devices are used in canteens and cookeries, where this is justified by sanitary standards. But you can also make a homemade grease trap at home. After all, its advantages are obvious:

- it prevents very unpleasant blockages in the sewer;

- the device of such a household installation is simple;

- Maintenance of such equipment is minimal.

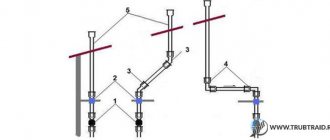

Let’s first consider what the simplest “filling” of a household grease trap is. The main elements that a simple separator includes are given below.

- Inlet pipe.

- Partition.

- The outlet pipe to the sewer, usually in the form of a tee.

- All this is located in a box-shaped plastic case, the inlet and drain pipes look out.

Diagram of a household grease trap

If all these elements are present, the operating principle is as follows: water with fat enters through the inlet pipe from the kitchen sink. Inside our unit, liquid fills the primary chamber, where it settles a little, and meanwhile the fat rises to the top. This chamber is separated from the rest of the device by a partition.

However, this wall does not stretch all the way to the top. Its height is approximately two-thirds of the height of the box. So there remains a gap. It is through this upper “vent” that fat-free water flows into the adjacent chamber and at the very bottom enters the outlet pipe, most often made in the form of a tee. After which, in fact, the liquid flows into the sewer.

At the same time, all the collected fat remains on the surface of a constantly maintained volume of the working medium. Therefore, the described separator is serviceable. As the unpleasant suspension accumulates, the device must be completely disconnected from the line and then emptied of its contents. This operation must be done at least once every two weeks. It all depends on the amount of dirt and the intensity of use of the sink. Next, we will consider the process of creating such a home appliance that needs to be cleaned periodically.

Advantages of a septic tank without pumping

If you decide to make a biological septic tank with your own hands at the dacha, then the option of arranging a dacha sewage system will entail a lot of positive aspects.

- First of all, wastewater, which, according to SNiP, is 98% purified in such a septic tank, does not pose a threat to the environment and to humans.

- A country septic tank, built on the principle of biological treatment, does not require the constant use of sewage disposal equipment. This means that the family budget will be saved.

Care and maintenance of the device

If the grease trap is used heavily, grease removal operations may need to be performed every couple of weeks. The accumulation of contaminants is monitored by opening the top lid of the container. The fat clot that has accumulated in the upper part of the container must be removed. For this purpose, a special cage is suitable, which is included in the factory configuration of some devices. You can also use a suitable-sized ladle or an ordinary mug. Food fat mixed with dirt to form a clot is quite dense, so it easily collects like foam from the surface of a liquid and is thrown into the trash.

To ensure that the grease trap unit installed under the sink does not create emergency problems, and also works effectively for at least the period stated by the manufacturer, it requires simple annual maintenance. To do this, it is disconnected from the siphon supply and sewer lines and thoroughly washed to get rid of heavy bottom sediments.

Equipment installation technology

The installation process of a fat separator can be carried out in various ways. It is necessary to choose the optimal type of installation depending on the type and characteristics of the grease trap. Let's consider several options for installing separators.

Installation of an outdoor grease trap

The installation procedure for an industrial grease trap is complex and time-consuming. Therefore, most trap buyers prefer to entrust the installation of equipment to specialists.

In order to carry out the installation yourself, it is necessary to carry out a number of preparatory work:

We select a place for installation. When choosing, you should take into account the layout of the site, as well as the possibility of performing landscaping work in the future.

We determine the size of the pit for mounting the device - its depth should be such that the grease trap cover is approximately 4 cm higher than the surface of the ground.

We dig a hole. At the very bottom we will equip a solid formwork into which we will pour a mixture of sand and cement. For sandy soils and loams, a solution prepared in a ratio of 1:5 is optimal.

We wait until the solution hardens, at least 14 days.

When the preparation of the base for installation is completed, you can proceed directly to the installation of the equipment. To do this, we install the grease trap body on a concrete base and securely fasten the device to the hinges embedded in a homemade concrete slab during the pouring period. If you forgot to install the hinges, they can be secured with anchor bolts.

Now we are constructing unique plywood walls around the equipment installed in the pit. This process is necessary to prevent soil shedding. If you plan to operate the separator in a cold climate, then it must be covered with heat-insulating material. Mineral wool or polystyrene foam is suitable for this.

All that remains is to connect the grease trap to the communication networks. To do this, the outlet pipe of the equipment must be connected to the drainage system. The joints must be treated with sealant. And we connect the inlet pipe of the device to the sewer pipe. Coat the joints of the elements with sealant.

We fill all the free space created between around the grease trap body with soil. Usually backfilling is used, during which the soil dug out from this place during the hole digging stage must be filled into the opening.

We must not forget about the need to install a fan riser. It is required to remove excess gases accumulated in the sewer system. If there is a large load on the wastewater disposal system, it is better to install several risers at once. The fat accumulation sensor, which is installed inside the equipment, will warn you about the need for a cleaning procedure.

Outdoor grease traps are often cleaned by specialists from specialized companies using pumps or special equipment

It is recommended that the installation and installation of industrial grease traps be carried out with the assistance of professional installers. They must have permits to carry out the full range of work.

Also, professional specialists have the necessary construction equipment for installation, so they can perform the necessary procedures for stable and long-term operation of the equipment.

Installing a grease trap indoors

Installing a household separator under a sink is a simpler process than installing equipment outside. To do this, you first need to choose the optimal location for installing the equipment.

It should be located on an easily accessible, hard and as level surface as possible, close to plumbing equipment.

It remains to perform a number of sequential actions:

We bring the outlet pipe of the equipment into the sewerage system. At the connection point you need to install a rubber gasket, which comes with the device. We connect the inlet pipe of the trap to the outlet pipe of the sanitary equipment or to the pipeline (at the junction of the sink and washing equipment), not forgetting to install a special gasket. We fill the grease trap with the required amount of water to check the device for leaks.

If the test is successful, you can install the lid on the grease trap. Once the cover is installed, the installation of the equipment can be considered complete.

For more information on how to choose and install a grease trap under a sink, read this material.

How to install?

Installing a grease trap is not difficult; this work can be done independently. When performing installation, you must adhere to certain rules:

- First decide on the installation location and check whether there is enough space for installation. So, placement under the sink may be hampered by plumbing. Keep in mind that the grease trap will need to be cleaned periodically, so it must be easily accessible;

- prepare the horizontal surface where the grease trap will be installed;

- check the completeness; all pipes and fastening elements necessary for assembly must be present;

- Now you can install and connect the grease trap, following the instructions;

- during the installation process, it is necessary to seal all joints using plumbing sealant or sealing tape;

- carry out tests to ensure the installation is leak-tight.

Separator maintenance and monitoring

Servicing a grease trap is not the most pleasant procedure, but it is much more unpleasant to clean out clogged sewer pipes.

The frequency of cleaning a household separator depends on several parameters:

- volume of the grease trap tank;

- family diet, which determines the composition of wastewater;

- temperature of the water used.

Due to these factors, the frequency of separator cleaning may vary from several weeks to several months.

Before cleaning the grease trap, it is necessary to open the windows for cross ventilation and wear protective gloves, because harmful bacteria multiply during the breakdown of fats

Close attention to the level of wastewater must be paid in the first weeks of operation. It is necessary to periodically open the grease trap lid and check the solid waste level

If the bottom layer of fat reaches the level of the outlet, it may become clogged, causing the tank to overflow and flood the room.

It is advisable to remove the fat mass when it reaches a level 4-5 cm above the lower edge of the water drainage pipe. To remove fat, you need to open the tank lid and pull out the top viscous layer using gloves, a ladle or other available device.

After inspecting the grease trap, you can rinse it with hot water for several minutes.

When the approximate period of safe operation of a grease trap has already been established experimentally, you can look into it much less often.

Tips for choosing

Correct operation of the device and reliable protection of sewer pipes and from grease deposits and blockages depends on the correct choice of a grease trap.

How the device works

For domestic use, it is enough to purchase a device whose productivity ranges from 0.1 to 2 l/sec. Large restaurants and enterprises producing fat-containing food products are equipped with large grease traps. Here they focus on the specifics of production. Thus, at enterprises producing dairy products, grease traps are equipped with tank filling sensors and pumps that pump wastewater into the tank.

Cleaning the tank

You can get rid of a specific unpleasant odor in a catering area by installing an automatic, compact grease trap. Place it directly under the sink. Modification of many models provides for the output of wastewater to a separate receiver. Maintenance of such devices does not require much time - it is enough to periodically clean the pipes from large particles, and use any detergent to remove sediment.

Compact device for a small dining room

To prevent the formation of blockages, sewer pipes are periodically washed with hot water.

Varieties

Conventionally, grease traps can be divided into several categories depending on the manufacturer, parameters for using the equipment, the method of its installation and materials of manufacture.

For the manufacture of grease traps, stainless steel, plastic and fiberglass are used. The advantages of plastic products are as follows:

- Tanks can be manufactured to order that meet certain criteria - with a certain throughput, dimensions and shape;

- the PVC product is easy to use and maintain - it is enough to periodically clean the tank;

- The material is environmentally friendly and has a long service life.

Plastic product

Fiberglass products are often used for industrial purposes, since the material is particularly resistant to chemically active environments. The equipment assumes both internal and external types of installation - the body is durable, not afraid of environmental influences, easy to clean and lightweight.

Fiberglass tanks

Large enterprises use grease traps with a steel casing. Such equipment has a high cost, but it is justified by the performance properties of the material. It is characterized by high anti-corrosion properties, universal installation - inside and outside, and a long service life.

Stainless steel product

What does the market offer?

Today on the market of plumbing fixtures in the Russian Federation there are quite a lot of products from companies that produce grease separators for kitchen sinks. Among them are the leaders:

- Products

It can be found in four layout modifications: “standard”, “pro”, “auto-assembled”, “steel”. In each of these configurations, you can select a grease trap that matches the tasks assigned to it. The choice may be influenced by the following parameters: productivity - 0.5-1.5 m3/h, peak water discharge - 25-175 l, number of connected sinks - 1-3, material of the working container - polypropylene or steel. However, ease of maintenance is also important, which is provided by removable plates or canisters for fat, as well as garbage trays in certain modifications. The most compact device has dimensions of 420*320*370 mm (L*W*H). - Evostok OIL separators are also presented in models - from the smallest, designed for installation under sinks in standard apartments, to large-sized ones, capable of cleaning the drains of large cottages, canteens, restaurants, etc. They are distinguished by the simplicity of their internal structure, assembled in a polypropylene case using a two-chamber design. Dimensions of the smallest model – 420*320*370 mm.

- The Termit brand offers only four standard sizes of its separators, covering the most popular segment, installed under grease trap sinks. The containers of the devices are made of high-density polyethylene in a three-chamber design. An additional option in their configuration may be a tray for garbage and large waste. This is a removable plastic container that can be easily removed and washed when filled. The smallest installation is 450x350x395 mm.

- Triton-PM cleaners are reliable units of the Russian brand. Available in two-chamber cast polymer housings. Their models occupy the entire functional range in terms of operating capacity and peak discharge for use in everyday life, as well as in mini-industry (cafes, canteens, restaurants). Although the dimensions of the smallest standard product are 420*320*370 mm, the manufacturer is ready to manufacture a separation plumbing installation to suit the customer’s individual requests.

As a contrasting example, consider the Hydrig automatic grease removal equipment. These are quite complex and expensive stainless steel products intended for use primarily in catering facilities.

Grease trap "Hydrig"

In them, the technological separation process occurs due to electrical heating of wastewater, followed by separation and collection of fat mechanically. The equipment is energy-dependent, but provides the highest degree of purification compared to the above-described gravitational installations. The dimensions of the main unit of the smallest model are 590*500*335 mm.

Grease trap under the sink: creating and installing it yourself

Grease traps: design and principle of operation

The installation of grease traps at industrial and food facilities is subject to the availability of appropriate sanitary standards and regulations, but as for use in domestic conditions, is this device really necessary in the home? To do this, you need to understand what effect fatty substances have on the sewer system:

- When cooled, fatty acids turn into a flocculent mass, which settles on the walls of the pipes and over time leads to their clogging, reducing the flow of water. Over time, the system becomes completely impassable and must be cleaned (in the worst case, repaired).

- Fats lead to the gradual formation of caustic substances that have a persistent foul odor.

- Over time, fatty deposits oxidize and corrode the sewer system from the inside, rendering it completely unusable.

As you can see, using a grease trap is quite justified even at home. Let us briefly consider the device of a household installation. A grease trap is a completely sealed container with a removable lid, made of food-grade plastic and divided into several sections. The outermost ones are connected to pipes that cut into the waste pipeline. Installed under the sink.

A grease trap is classified as a septic tank. All used water passes through it. The basic operating principle of the installation is the difference in the densities of water and fat. First, the wastewater flows through the inlet pipe into the container. Since fat is less dense, its particles float on the water surface and, thanks to the partitions installed across it, are removed from there into a special storage tank. You can only remove accumulated grease in a household grease trap manually.

Making a grease trap with your own hands

Most often, materials such as steel, food grade plastic, fiberglass and polypropylene are used to manufacture this unit. We will consider the simplest option - making a plastic device.

Advice. If you have unnecessary products made from harmless plastic in your household, then you can safely use them to create a container for the unit.

Before proceeding directly to creating the design, it is important to make basic calculations that will help calculate the optimal installation volume for a particular water supply system. First, let’s calculate the productivity of the unit being created

So, we use the following formula: P=nPs, where

- P - septic tank productivity, l/s;

- n is the number of sinks in the room;

- Рs — water supply speed (usually equal to 0.1 l/s).

After we know the productivity of the unit being constructed, we determine the required volume of the structure using the formula: V=60Pt, where

- t – average duration of fatty acid sedimentation (about 6 minutes);

- P is the unit’s performance, which we already know.

We make an installation drawing according to the received dimensions. Now you can start preparing tools and materials:

- material for the installation body (in our case - food grade plastic);

- sanitary silicone;

- construction adhesive;

- a piece of thermoplastic pipe with a diameter of 5 cm;

- thermoplastic elbow with a diameter of 5 cm;

- thermoplastic tee with a diameter of 5 cm.

The first step is to cut the parts for the body. For this we use a hacksaw / jigsaw. First we glue the sides (body) of our structure, only after that we fix the bottom. Then we install the internal partitions (their height should be 2/3 of the height of the side walls). We make the joints airtight using silicone.

We install an elbow into the assembled structure (it will act as an inlet pipe). We make an outlet pipe from a piece of pipe and a tee. There's only one small thing left to do - the top cover for the structure. We fix the rubber seal at the points of contact with the body. You can proceed to installing the unit in the work area.

Features of installation of the structure

Installing a grease trap is a fairly simple process, but it requires compliance with certain rules:

- First of all, we determine the location for installing the unit.

- We check and prepare the surface on which we will install the structure (it must be absolutely horizontal).

- We prepare all fastening elements for fixing the installation to the pipeline (clamps, fittings, etc.).

- We connect the inlet pipe to the sewer drain, and the outlet pipe to the drainage system.

- We test the installation after waiting for the first cleaning. If the unit has passed the test, the installation can be closed.

That's all, actually. In fact, as you can see, building and installing a grease trap for home use is quite simple. The main thing is to be careful, attentive and accurate. Good luck!

Self-assembly

If a home craftsman knows how to work with plastic, making connections by welding or using special glue, then you can assemble the grease trap with your own hands. Required:

- sheet plastic;

- glue for plastic;

- a piece of pipe made of polymer material with a diameter of 50 mm;

- tees and elbows (both parts with a diameter of 50 mm);

- Silicone sealant is used to seal the connections.

You can cut plastic yourself using a hacksaw, but it is better to take the material for cutting to a specialized workshop, where plastic cutting is carried out on machines with a laser cutter. The following is the assembly:

- First, a plastic body is glued together, consisting of walls, a bottom and a removable lid. A rubber seal is glued around the perimeter of the lid;

- then a partition is installed, its height should be less than the height of the body by about a third;

- the inlet and outlet pipes are made of plastic pipe, they are inserted using rubber seals. A tee is connected to the inlet pipe, and an elbow is connected to the outlet pipe;

- all joints must be carefully sealed using silicone plumbing sealant;

- now you need to test the tightness of the model by pouring water into it;

- If no problems are found, then you can install a homemade grease trap.

Advice! It should be understood that effective removal of fat from wastewater is only possible at an ambient temperature of less than 40 degrees. If the drains are hot, the fat will melt, which will significantly reduce the efficiency of the grease trap.